Threading machine

A tapping machine and screw rod technology, which is applied in the field of tapping machines, can solve the problems of small moving space, difficult to use forklifts, cumbersome moving methods, etc., and achieve the effects of improving work efficiency, increasing service life, and low manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] For desktop tapping machines and other types of tapping machines, the position may need to be moved during use. The existing technology uses equipment such as forklifts for transfer. Inside, there is very little room to move and it is difficult to use a forklift.

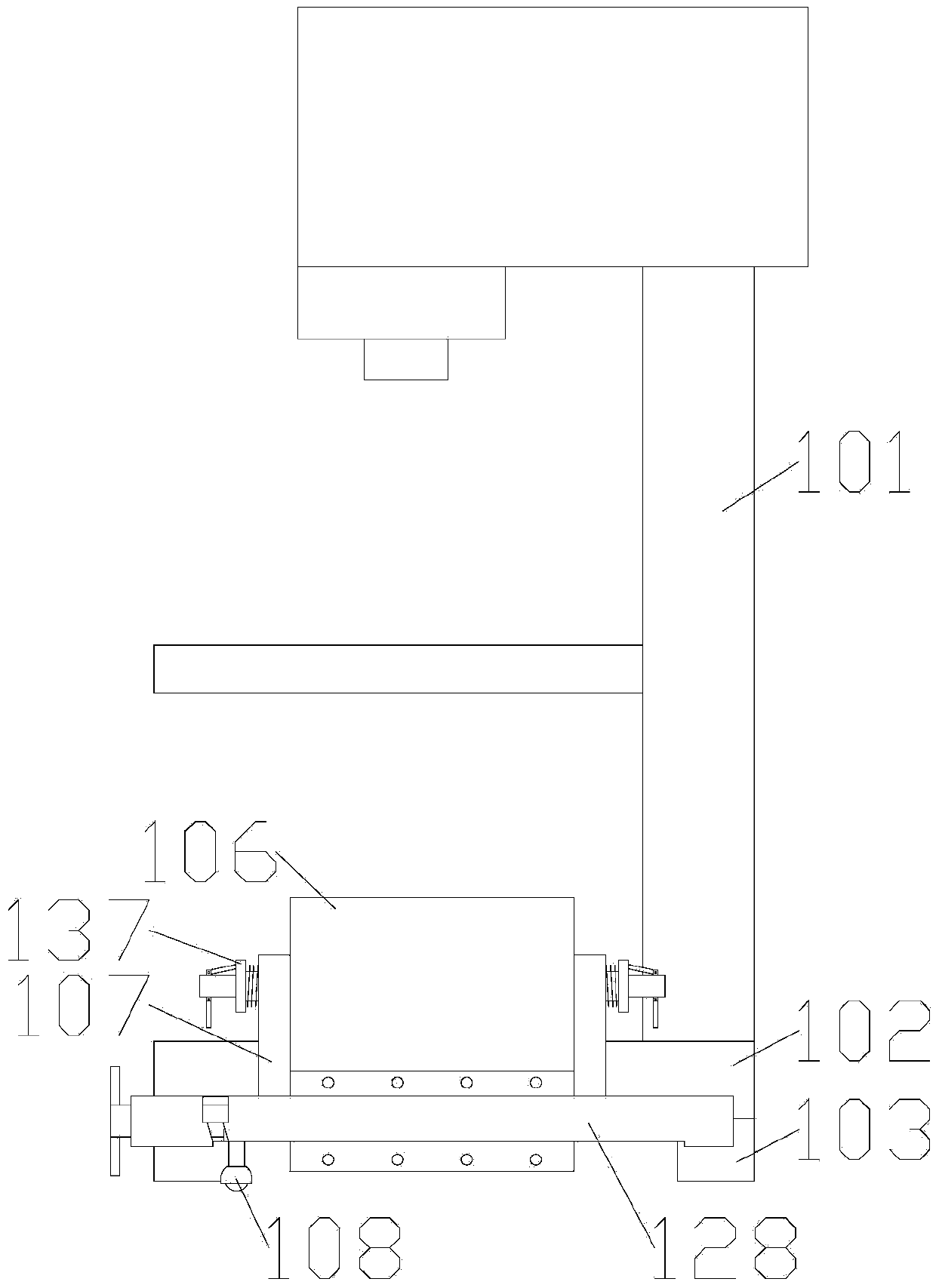

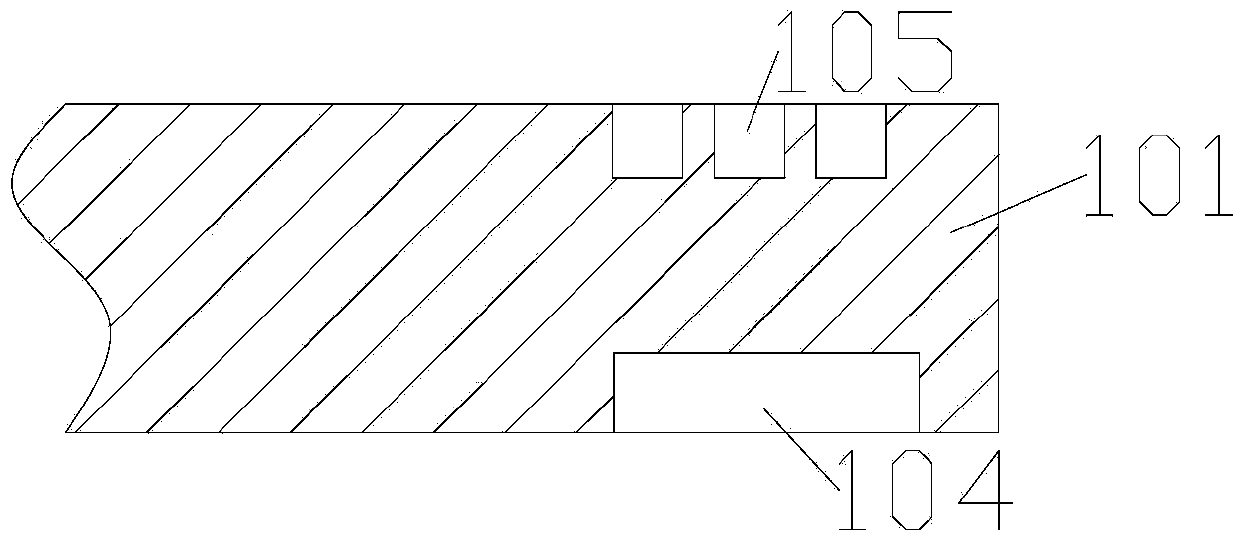

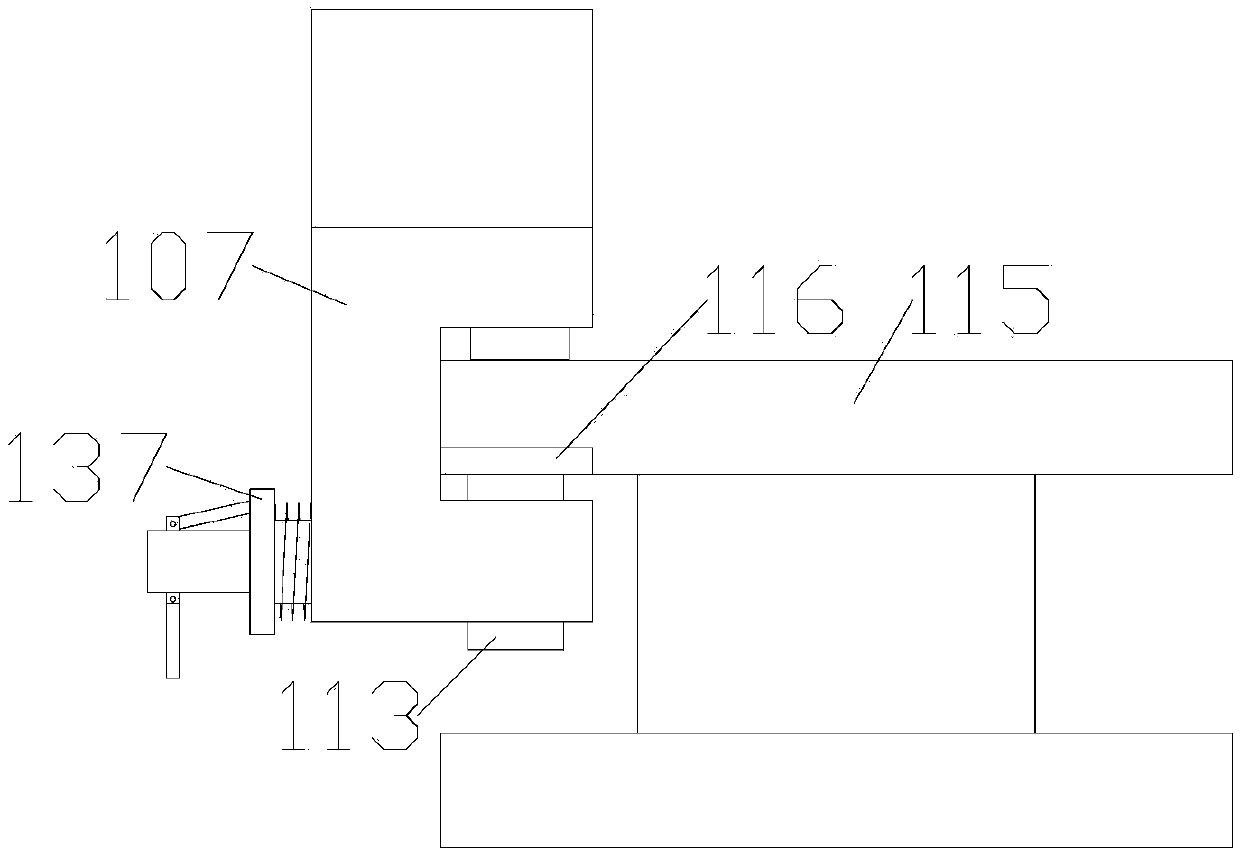

[0052] In order to improve the above problems, the present invention provides a tapping machine, which includes a tapping machine body and at least two transfer mechanisms. The bottom of the tapping machine body is a base, and grooves are arranged on both sides of the bottom of the base. The top of the top is provided with a first blind hole corresponding to the groove; each transfer mechanism includes a lifting piece, two fixing pieces and at least two walking pieces, the inside of the fixing piece is a “U”-shaped embedded through groove, and the fixing piece One of the side walls is provided with a bump inside, the other side wall is provided with a through hole, and a rod is pierced in the through hole, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com