High temperature chamotte cooler for concrete

A cooling machine and clinker technology, which is applied in clinker production, cement production, etc., can solve the problems of high energy consumption and complex structure, and achieve the effects of reducing the difficulty and cost of manufacturing and installation, simple structure, and reduced manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

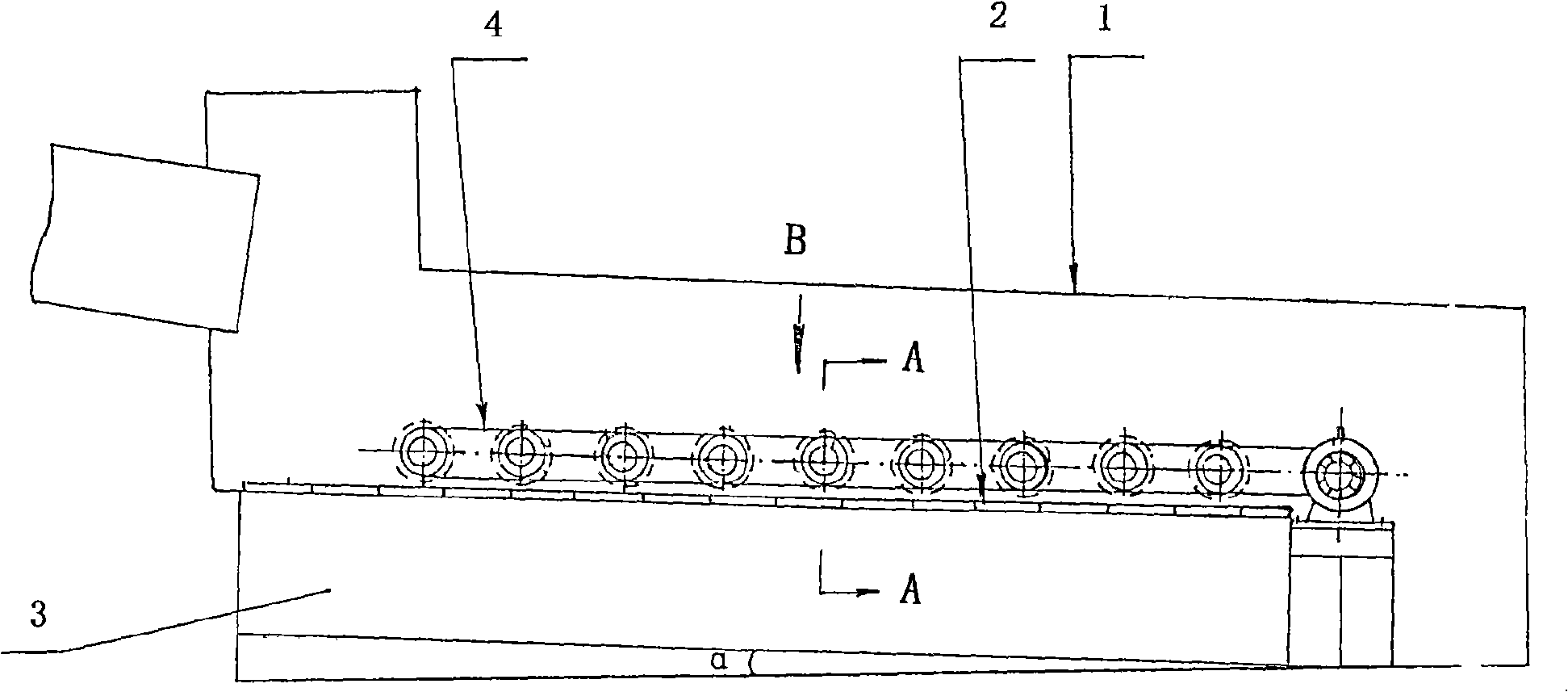

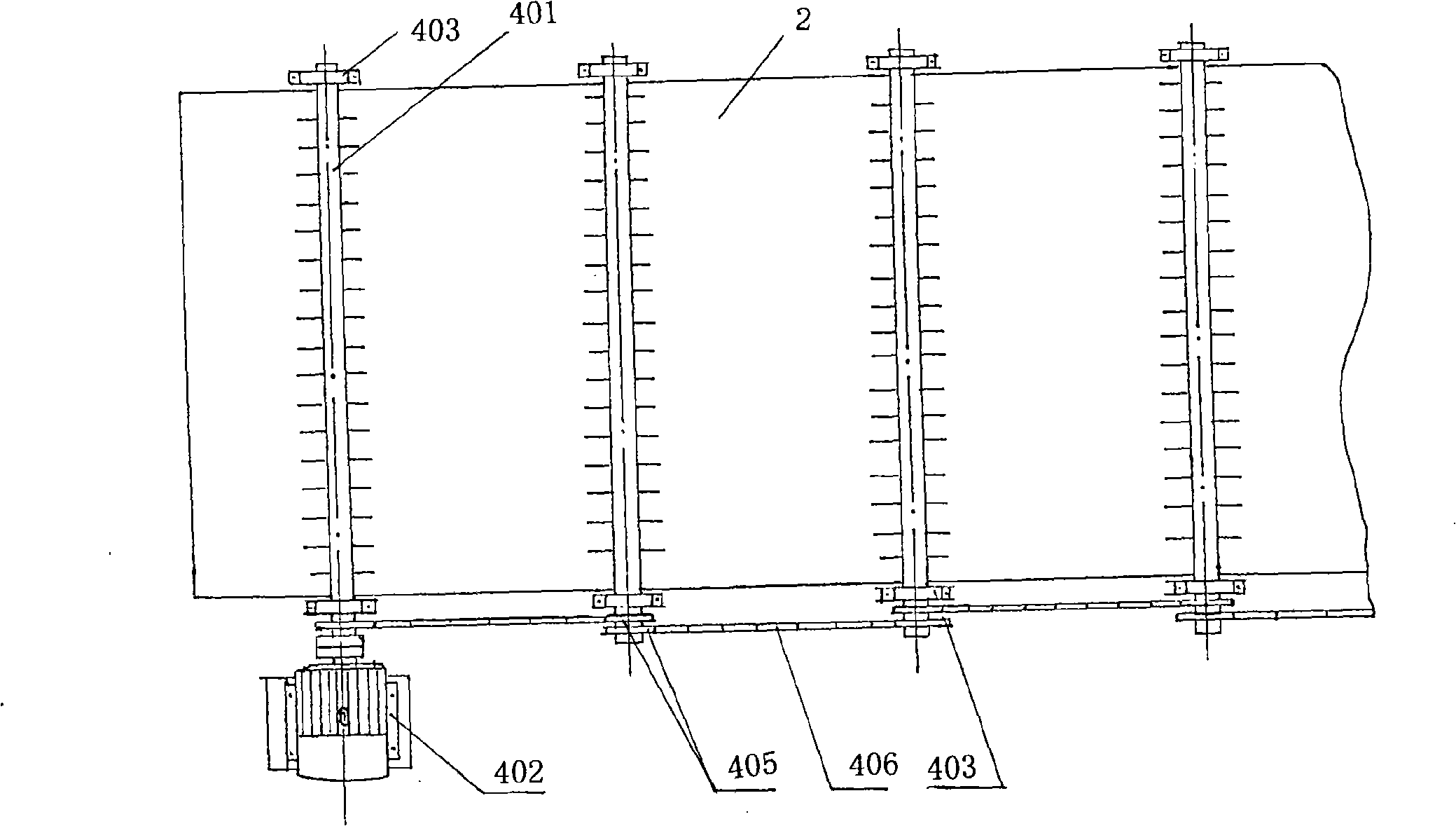

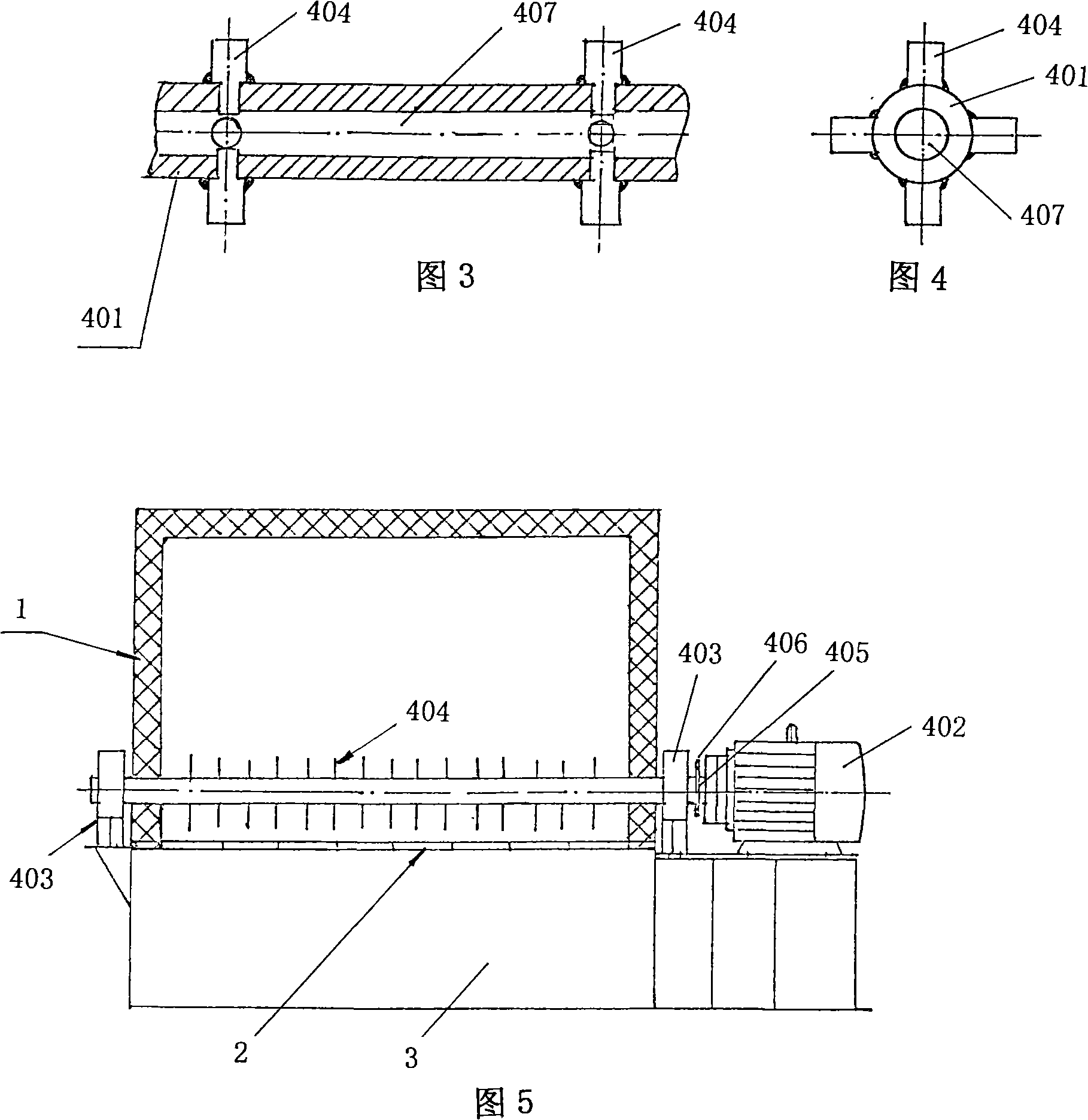

[0020] Such as figure 1 -5 shown.

[0021] A high-temperature cement clinker cooler, comprising a shell 1 and a clinker bed 2. The shell 1 is mounted on the clinker bed 2. One end is provided with a feed inlet and the other end is provided with a discharge outlet, the clinker bed 2 Supported on the bed 3, the clinker bed 2 can be designed to be inclined, that is, the feed end is high and the discharge end is low. The inclination angle α can be between 1 and 10 degrees, such as figure 1 As shown, the clinker bed 2 can be tilted during specific manufacturing, and the clinker bed 2 can also be tilted by tilting the bed 3, and the clinker bed 2 and the bed 3 can also be tilted at the same time to finally achieve the The method of tilting the material bed to the desired value tilts the clinker bed 2. On the clinker bed 2 can be installed one or several rolling rake clinker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com