Exhaust noise reduction system of separated exhaust type turbofan engine

A technology of turbofan engine and noise reduction system, which is applied to machines/engines, jet propulsion devices, etc., can solve the problems of poor mixing effect, reduce exhaust noise, attenuate engine exhaust speed, etc., and achieve low manufacturing and installation costs. , The effect of good noise reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

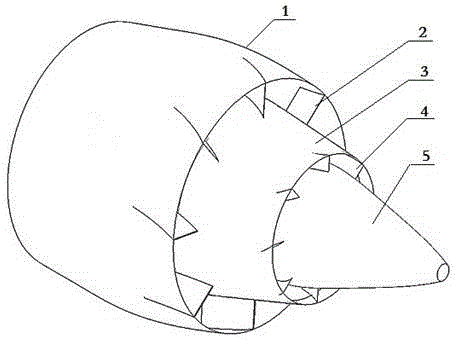

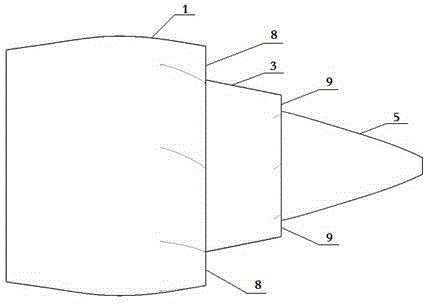

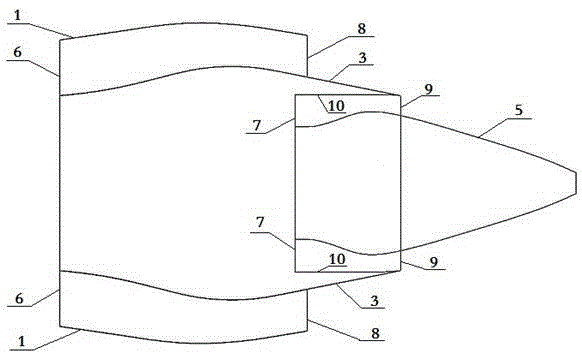

[0023] figure 1 , figure 2 with image 3 It is an integral structure for reducing exhaust noise of a separate exhaust turbofan engine proposed by the present invention. The connotation outer wall surface 10 and the wall surface of the exhaust rectifying inner cone 5 form a connotation exhaust channel, and the connotation exhaust inlet 7 is connected with the engine turbine outlet, and at the end of the connotation exhaust channel, that is, the inner side of the connotation exhaust outlet 9, a design Connotation cyclone4. Figure 4 , Figure 5 with Image 6 It shows the structure of the exhaust rectification inner cone 5 and the inner swirler 4, and the inner swirler (4) at the end of the inner channel has a certain angle with the central axis of the engine θ , under the action of the internal swirler 4, the connotation exhaust rotates clockwise or counterclockwise relative to the central axis of the engine (clockwise and counterclockwise here are related to the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com