Gas distribution device for rotary atomization and evaporation

A gas distribution device and rotary atomization technology, applied in the direction of evaporation, evaporator accessories, separation methods, etc., can solve the problems of irregular shape of the volute structure, large installation space, poor rigidity of the volute structure, etc., to reduce drying Evaporation time, large air intake speed span, and the effect of improving the integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

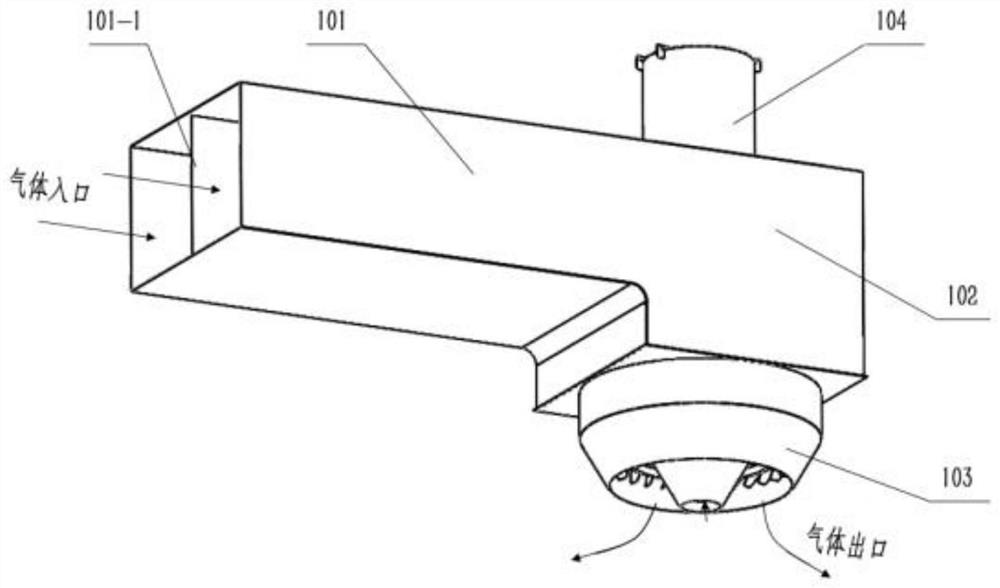

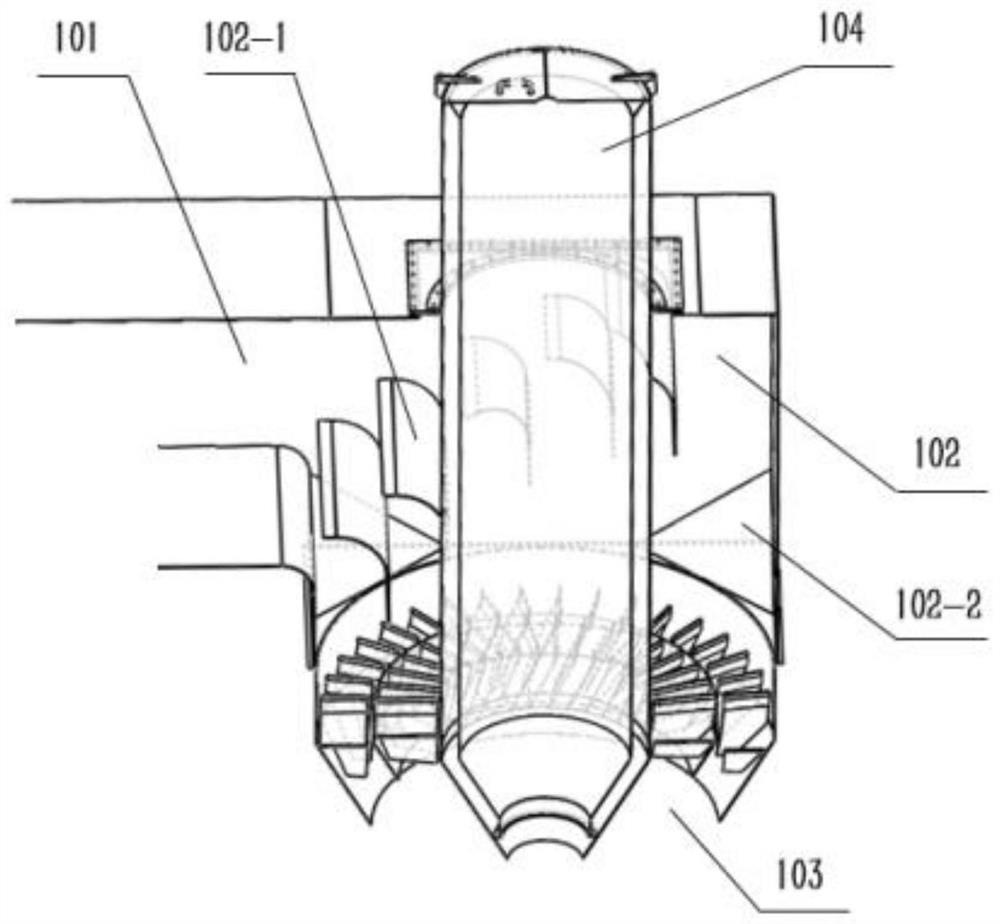

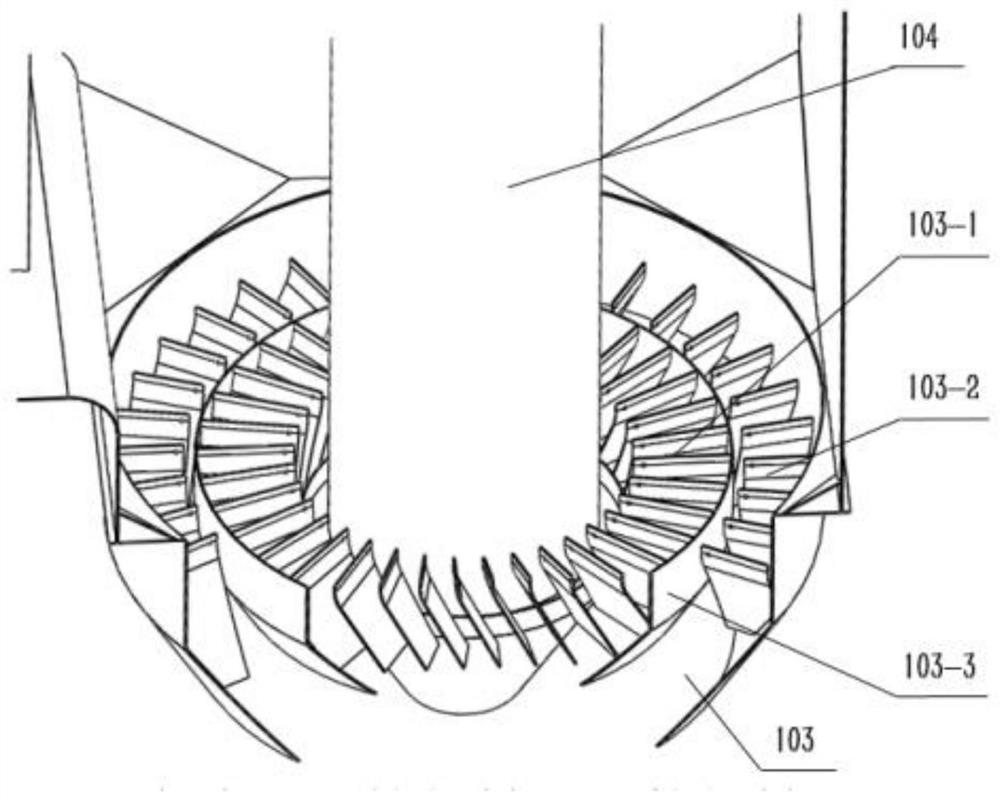

[0027] like figure 1 As shown, a gas distribution device for rotary atomization evaporation includes a gas distribution device body, and the gas distribution device body includes an inlet flow channel 101, a distribution flow channel 102, an outlet flow channel 103, a central cylinder 104, an inlet flow channel The channel is provided with a gas inlet, and the outlet channel is provided with a gas outlet. The air intake channel is a horizontally arranged rectangular straight tube channel, and a partition plate 101-1 is arranged in the air intake channel to divide the air intake channel into left and right side channels, and a partition plate is arranged inside the air intake channel to effectively improve the The integration effect of the gas flow field is improved, and the required length of the air inlet channel is shortened, so that the designed length of the air inlet air channel ensures the effective integration of the air inlet flow field and minimizes the overall size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com