Gas distribution device with spiral structure

A gas distribution device and spiral structure technology, applied in separation methods, evaporator accessories, evaporation, etc., can solve the problems of erosion and wear of the distribution device, polluted crystalline particles, and structural damage of the distribution device, and achieve the elimination of the dead angle of the gas flow field. The effect of reducing drying and evaporation time and increasing load elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

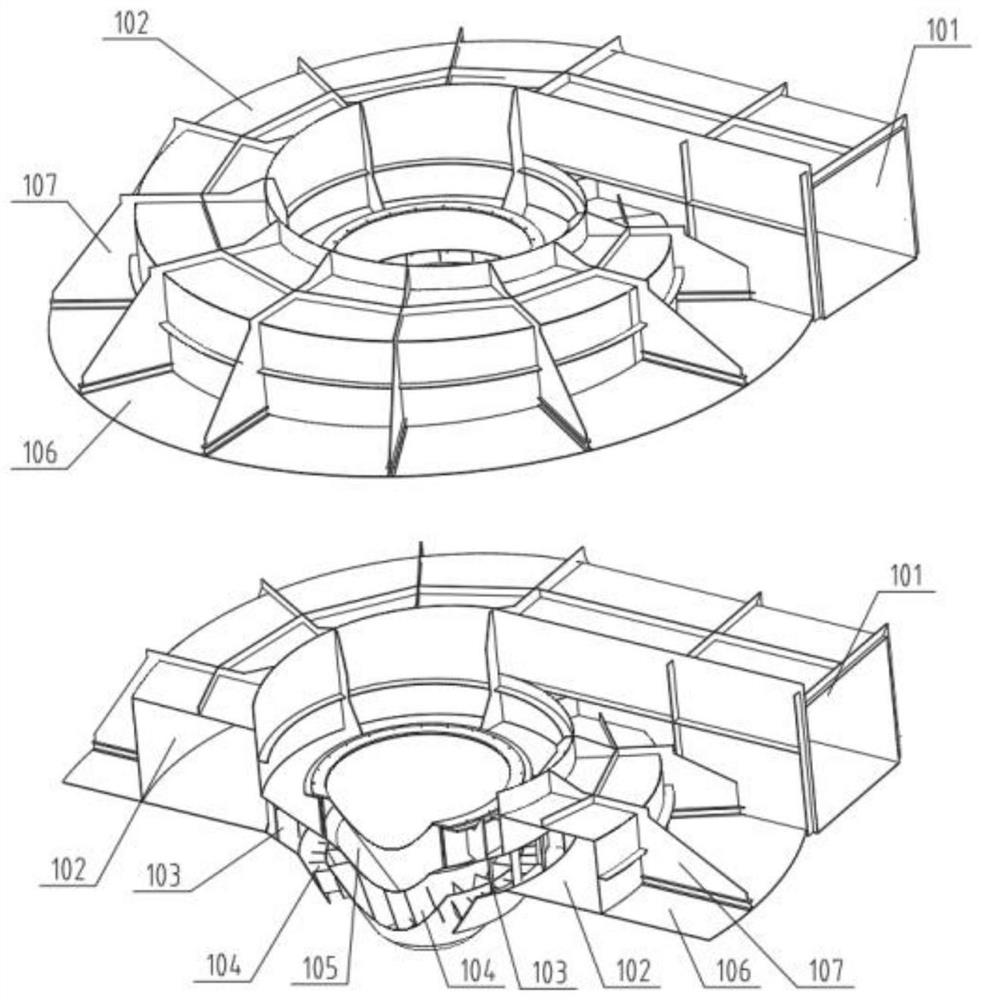

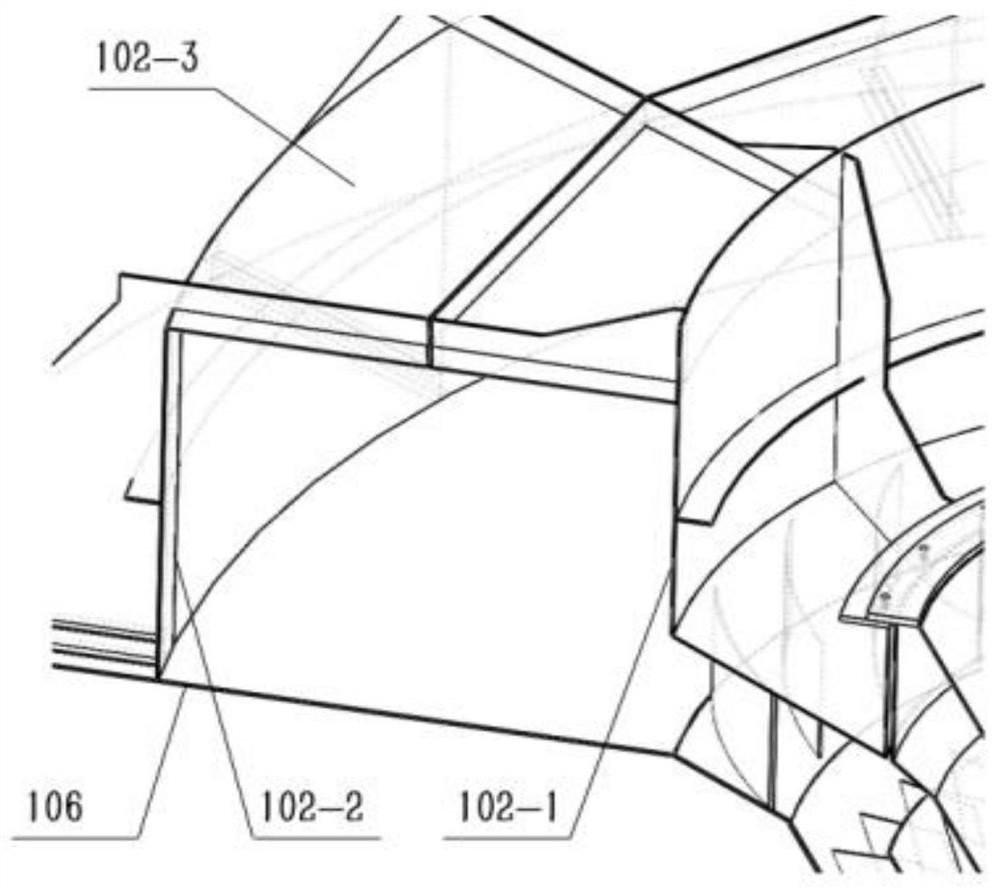

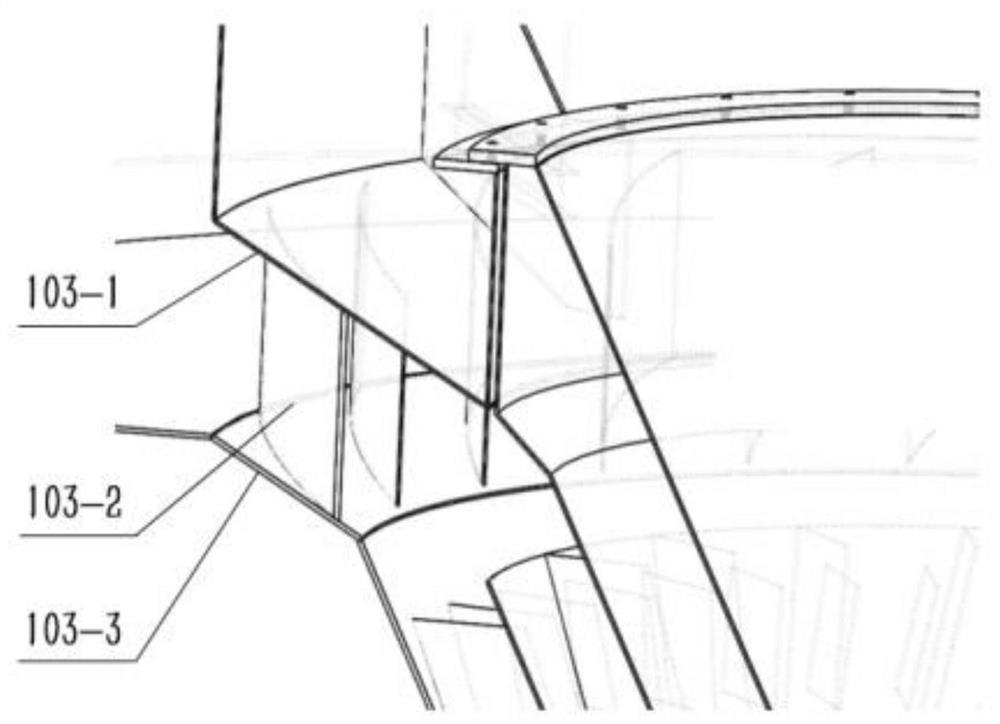

[0028] Such as figure 1 with Figure 4As shown, a gas distribution device with a spiral structure includes a device body and a reinforcement structure 107 detachably connected to the device body. The device body includes a bottom plate 106, and an air inlet 101 is arranged on the bottom plate. The straight tube structure is used at the inlet, and the length of the straight tube at the inlet is just enough to ensure the effective integration of the flow field at the inlet, while minimizing the overall size of the device; when the length of the straight tube at the inlet is lower than the design value, it will It leads to disorder of the intake air flow field, and when it is higher than the design value, it will lead to an increase in the overall size of the gas distribution device. The air inlet design has a large intake velocity span, which increases the load elasticity that the gas distribution device can handle. When dealing with different gas flows , the gas distribution e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com