Liquid material accurate weighing device, liquid supply system and concrete stirring station

A technology of precision weighing and liquid material, applied in the direction of liquid batching supply device, etc., can solve the problems of high manufacturing cost, low precision weighing device, complex structure, etc., to reduce manufacturing and installation costs, simple and reliable structure, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

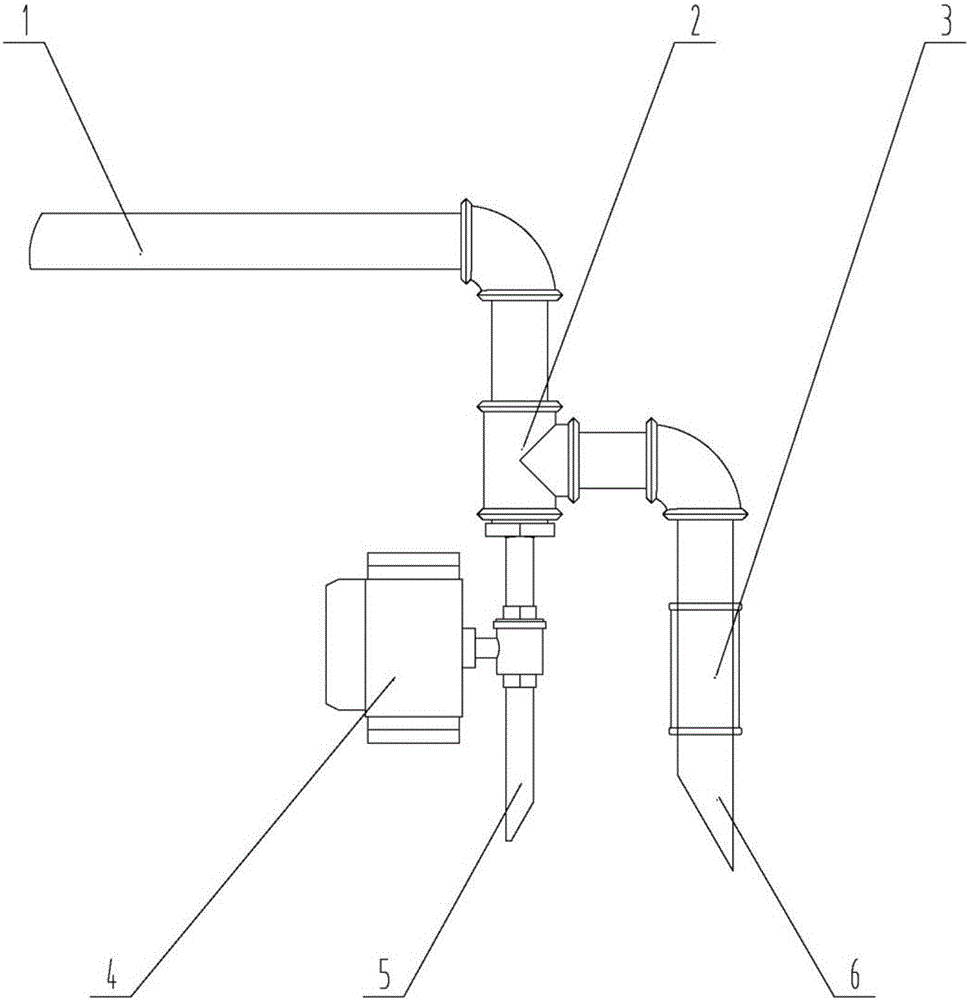

[0032] Such as figure 1 As shown, the first embodiment of the present invention is shown, a liquid material precision weighing device, comprising: a liquid inlet pipe 1, a three-way pipe fitting 2, a first liquid outlet pipe 6, a second liquid outlet pipe 5, arranged at the second The first switch 3 on a liquid outlet pipe 6 and the second switch 4 arranged on the second liquid outlet pipe 5, the outlet of the liquid inlet pipe 1 is connected with the first port of the three-way pipe fitting 2, the first liquid outlet pipe 6 The inlet of the inlet is connected with the second port of the three-way pipe fitting 2, the inlet of the second liquid outlet pipe 5 is connected with the third port of the three-way pipe fitting 2, and the inner diameter of the first liquid outlet pipe 6 is larger than the inner diameter of the second liquid outlet pipe 5 , the liquid inlet pipe 1 is located above the first liquid outlet pipe 6 and the second liquid outlet pipe 5 .

[0033] When the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com