Backward inclining prevention device of stay-rope-type cantilever crane

An anti-backward, cable-type technology used in cranes and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

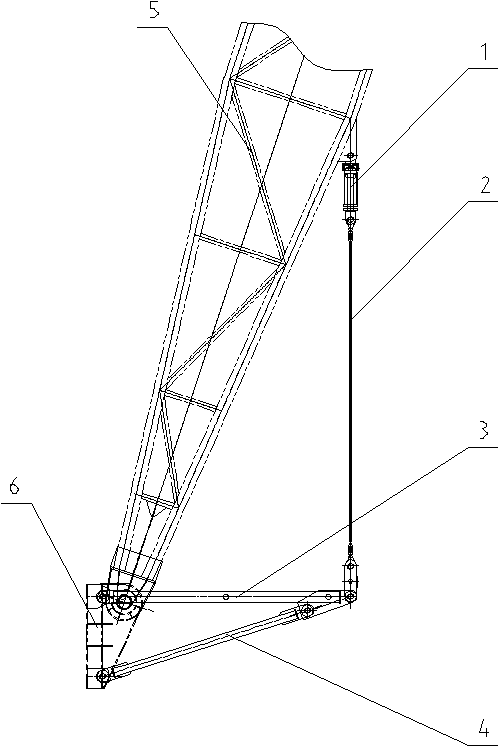

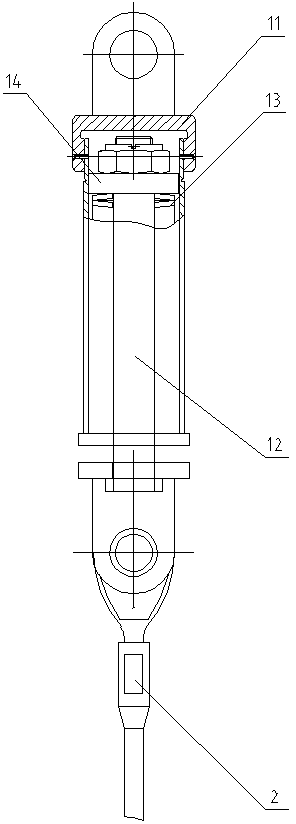

[0013] Such as figure 1 As shown, a cable-type boom anti-tilt device includes a disc spring device 1, a cable 2, a horizontal bar 3 and an oblique bar 4, and the top of the disc spring device 1 is hinged below the boom 5; One end of the horizontal bar 3 and the oblique bar 4 is respectively hinged up and down on the front end of the machine platform 6, and the other ends of the horizontal bar 3 and the oblique bar 4 are hinged to each other to form a stable tripod structure; The bottom of the cable is hinged, and the lower end of the stay cable 2 is hinged at the hinge point of the horizontal bar 3 and the oblique bar 4. The present invention adopts articulated connection, and there is no disengagement between the device and the arm frame 5 during the whole luffing process. When the luffing reaches a certain small range, the cable 2 tensions and compresses the disc spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com