Semi-dry ammonia desulphurization process for coke oven flue gas

An ammonia desulfurization and semi-dry technology, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of not reaching ultra-low emissions, general desulfurization efficiency, and increasing investment costs and burdens of enterprises. Achieve the effect of saving manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

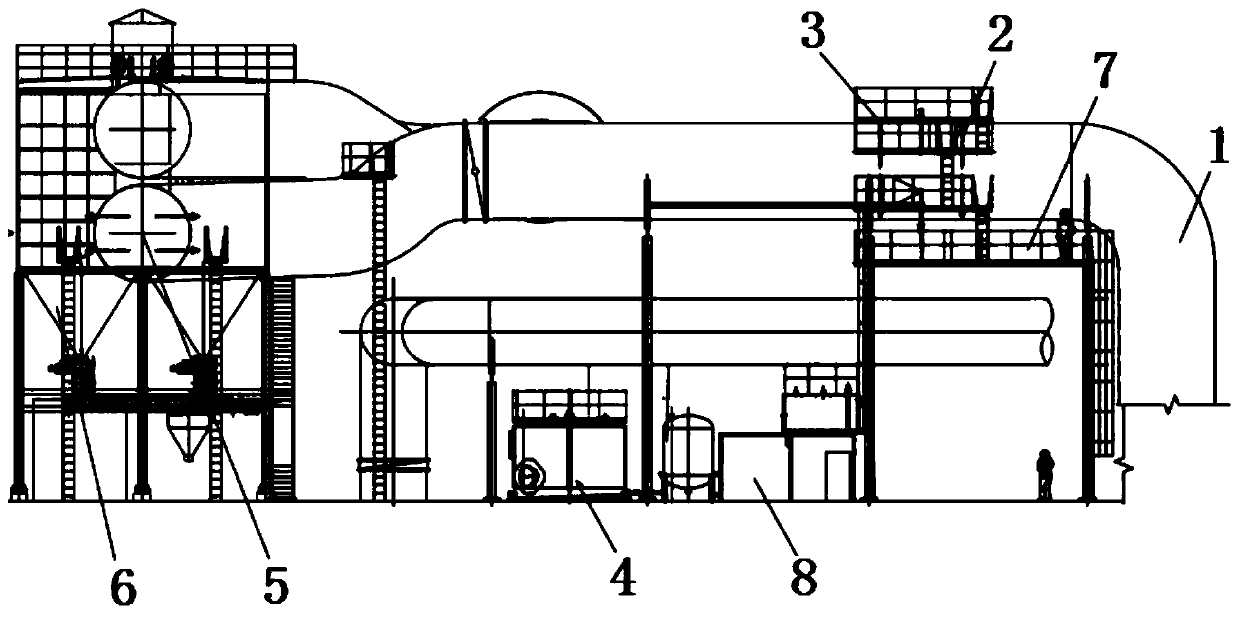

[0052] There are 2 groups of 4 coke ovens with an annual output of 1.04 million tons, a total of 160 holes, including 38 holes in No. 1 coke oven, 38 holes in No. 2 coke oven, 38 holes in No. 3 coke oven, 46 holes in No. No. 2 coke oven is a group, two flues have one chimney, which is No. 1 chimney, No. 3 and No. 4 coke ovens are a group, two flues have one chimney, which is No. No. chimney for Example 1 description.

[0053] The flue gas volume of No. 1 chimney is 110000Nm3 / h, the highest temperature of coke oven flue gas is 300°C, the lowest is 240°C, the average is 280°C, the inlet concentration of sulfur dioxide is 150mg / m3, and the inlet concentration of nitrogen oxides is 700mg / m3. Include the following steps:

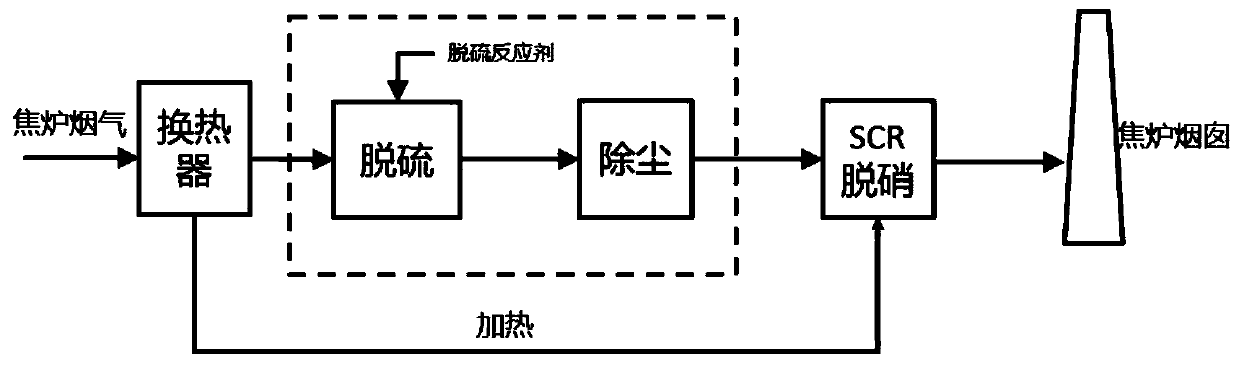

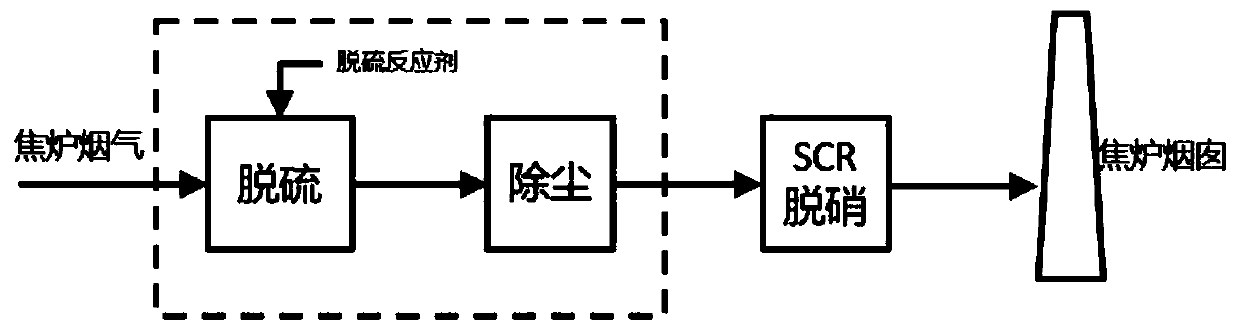

[0054] (1) First, the high-temperature coke oven flue gas enters the heat recovery device for heat exchange, and then enters the flue gas pipeline 1, so that the flue gas temperature is controlled at about 200°C;

[0055] (2) Then, send the coke oven flue gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com