Cold water recycling pipeline device and method for slice ice machine

A technology for cold water circulation and pipeline installation, which is applied in cooling fluid circulation installations, household refrigeration installations, ice making, etc., can solve the problems of large waste of electric energy and water resources, high manual operation and maintenance costs, complicated pipeline layout, etc., and achieve energy saving. energy consumption, reduce manual operation and maintenance costs, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

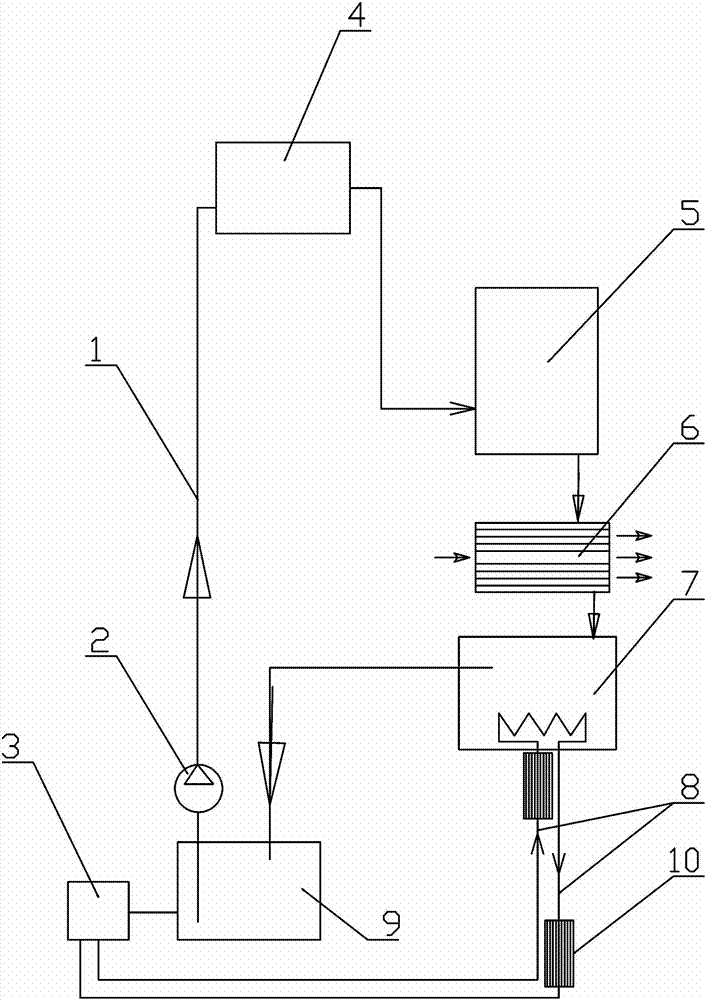

[0022] Such as figure 1 Among them, a piping device for circulating cold water in a flake ice machine, including a spiral tube evaporator 9 and a flake ice machine 5, the spiral tube evaporator 9 is connected to a water tank 4 through a pipeline 1 and a water pump 2, and the water tank 4 is connected to the flake ice through a pipeline The machine 5 is connected, the flake ice machine 5 is connected with the evaporator 6 through the pipeline, the evaporator 6 is connected with the evaporative condenser 7 through the pipeline, and the evaporative condenser 7 is connected with the spiral tube evaporator 9 through the pipeline.

[0023] The water tank 4 is located at the highest level, and the others from high to low are flake ice machine 5, evaporator 6, evaporative condenser 7 and spiral tube evaporator 9. This structure facilitates the installation of pipelines.

[0024] The evaporator 6 is an evaporator 6 used for cooling the air temperature of the flake ice conveyed by air....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com