Novel foamed plastic volume reduction machine

A technology of foam plastics and volume reducer, which is applied in grain processing, etc., can solve the problems of large volume, inconvenient treatment of waste materials, volume reduction, etc., and achieve the effect of low energy loss and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

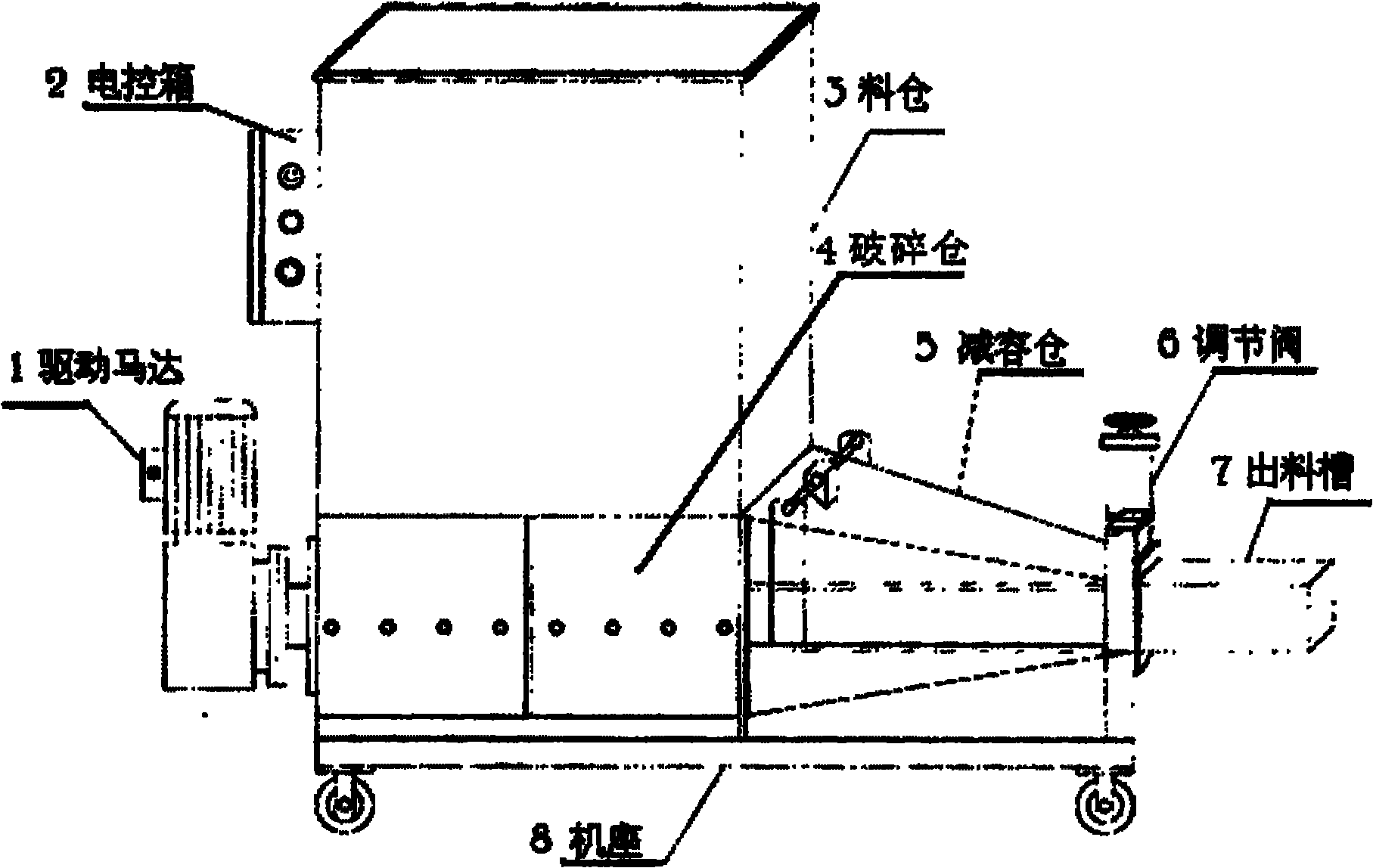

[0011] exist figure 1 Among them, the driving motor 1 drives the screw shaft of the main mechanism, and the material enters the machine from the material bin 3, and is screwed to the volume reduction bin 5 after being broken by the crushing bin, where the material is defoamed by the shear force of the spiral surface in the volume reduction bin At the same time, the volume under pressure is reduced, and the regulating valve 6 can adjust the pressure inside the volume reduction chamber 5, and the material after volume reduction is discharged through the discharge chute 7.

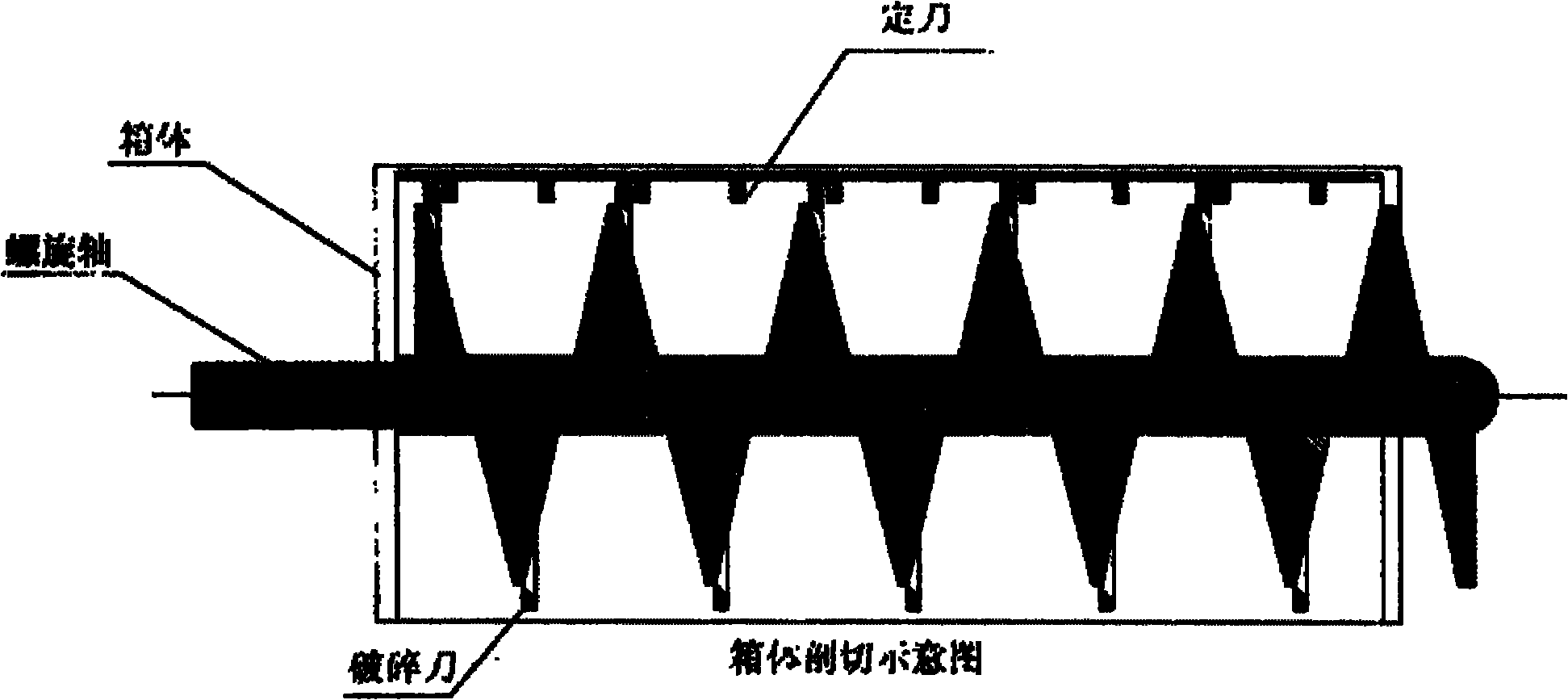

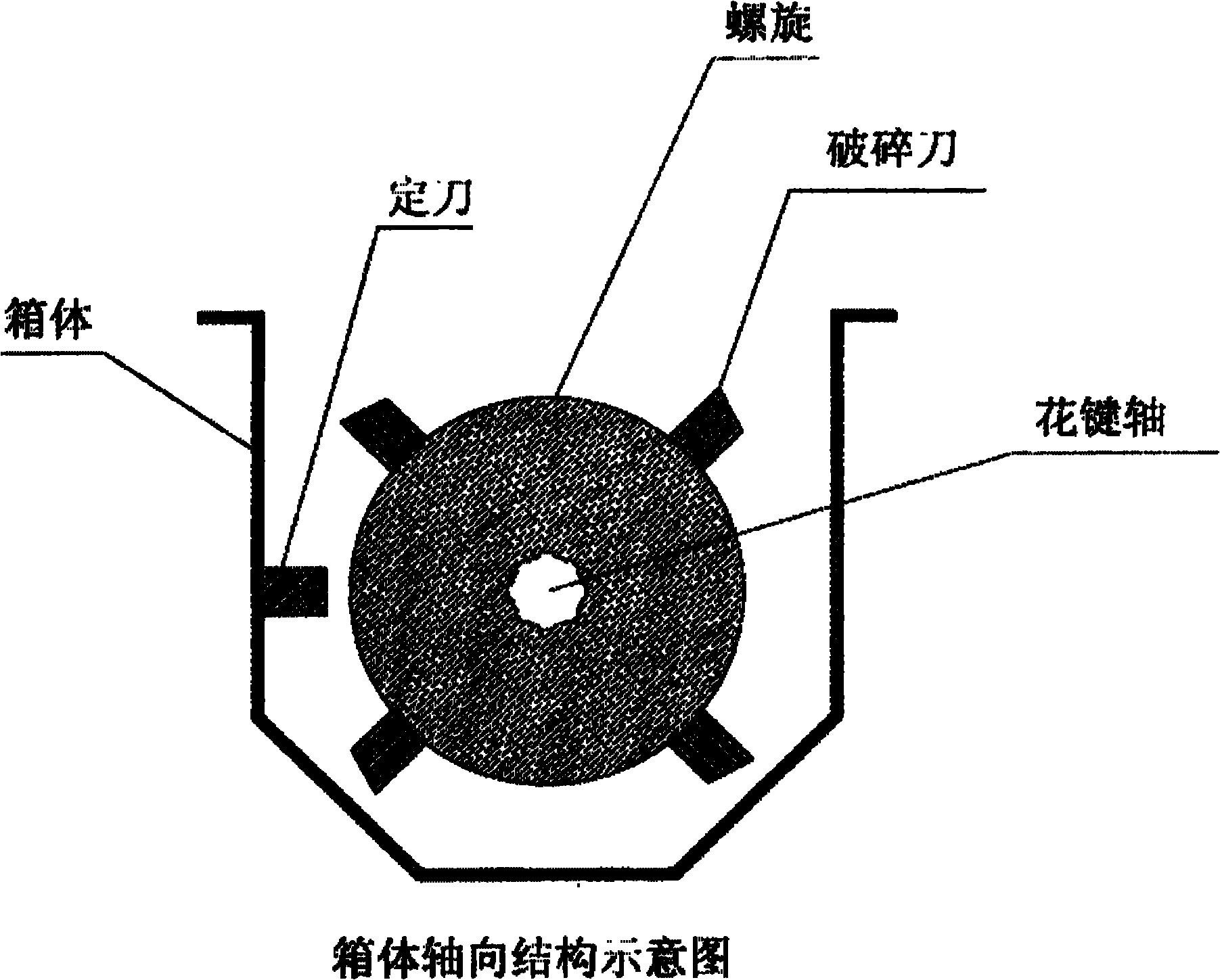

[0012] exist figure 2 with image 3 In the process, the crushing knife is installed on the screw, and the fixed knife is fixed on the wall of the box body. The crushing knife and the fixed knife make relative movements to break and cut the solid material. The crushed material is sent to the volume reduction bin by the screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com