Diamond coating cutter and manufacturing method thereof

A cutting tool and diamond coating technology, which is applied to drilling tool accessories, tools for lathes, tools for milling machines, etc., can solve the problems of polluting the vacuum chamber, being unavailable, and destroying the quality and purity of the diamond film. The effect of reducing manufacturing costs and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is a detailed description according to the embodiment shown in the drawings:

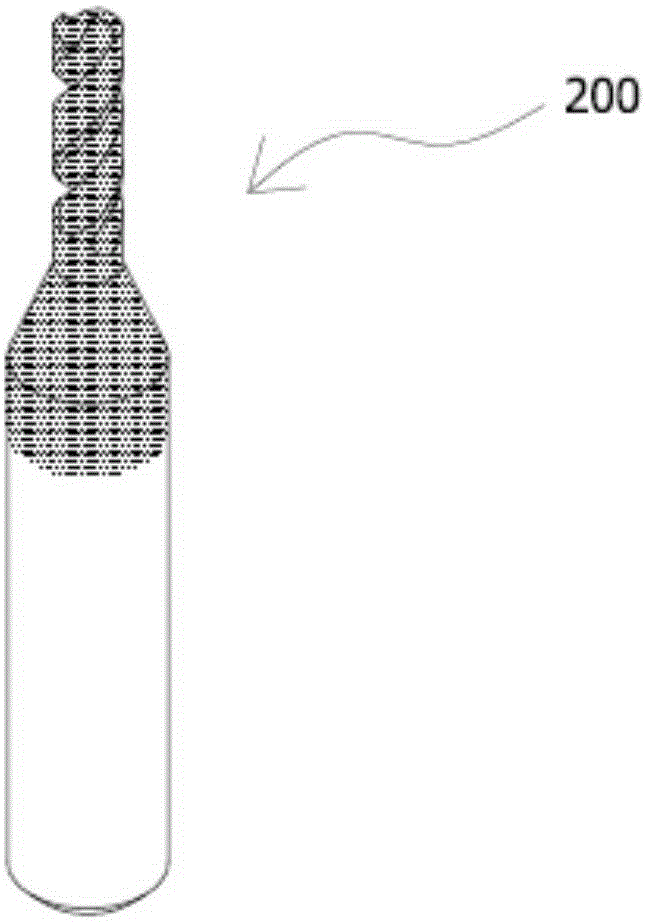

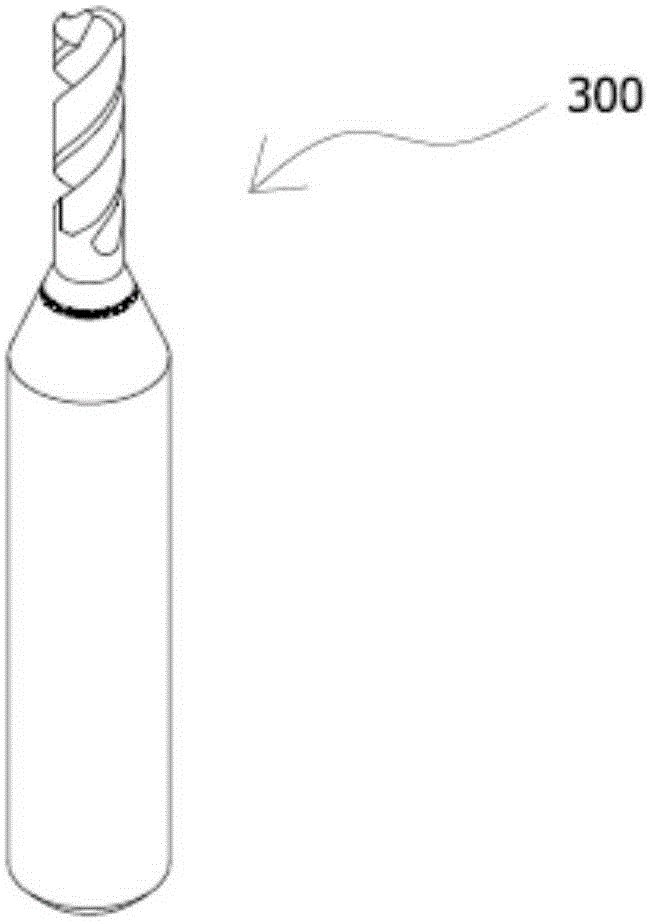

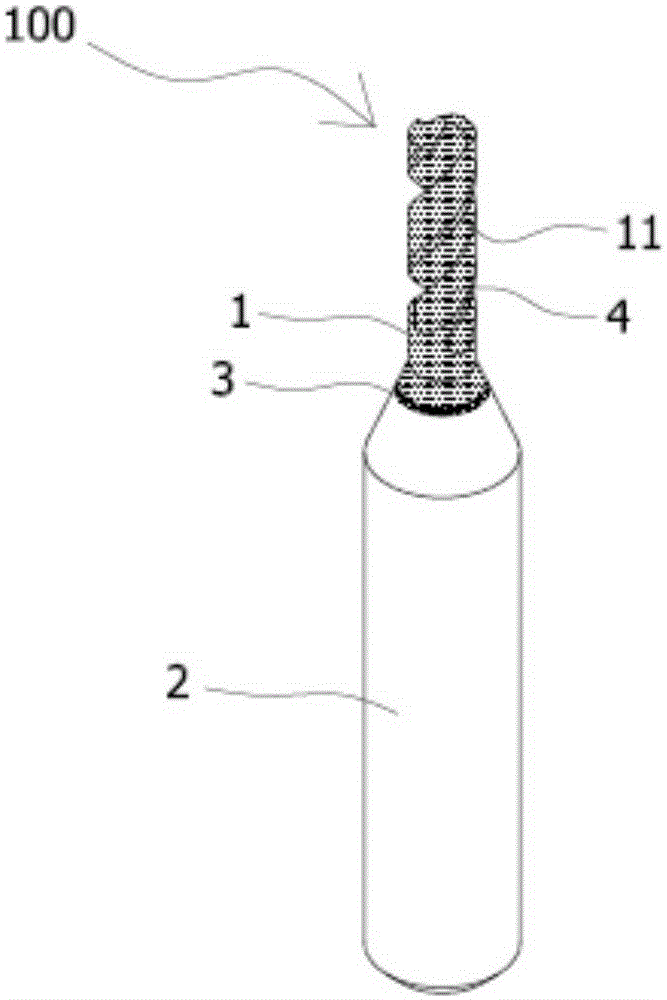

[0051] Such as image 3 , Figure 5 to Figure 7 As shown in the figure, a diamond-coated cutting tool is disclosed, which is characterized in that: the diamond-coated cutting tool 100 includes a first section of rod 1, which is cylindrical and made of sintered tungsten carbide material, and The outer surface is provided with at least one blade portion 11, which can be used for cutting; a second segment bar 2 is cylindrical and made of metal material, and the top is connected with the bottom end of the first segment bar 1, which can It is used for clamping the machine tool; a welding part 3, for the application of high-temperature solder S, is arranged between the bottom end of the first section bar 1 and the top end of the second section bar 2, and is used to join the first section bar 1 The second section of the rod 2 ; and a diamond film 4 are coated on the entire surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com