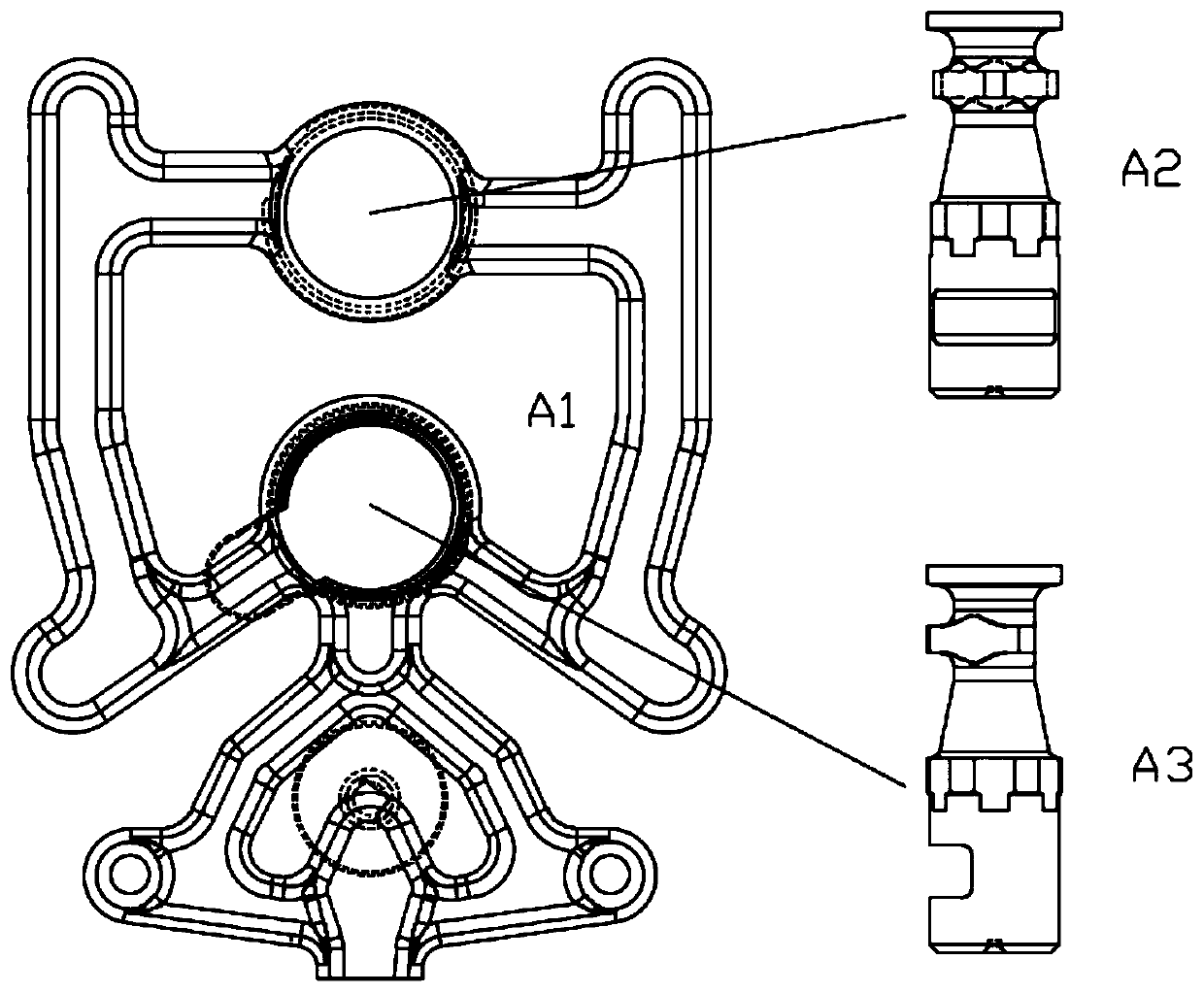

High-vacuum pressure casting die hydraulic vacuum valve

A technology of vacuum valve and die-casting mold, which is applied in the field of die-casting, can solve the problems of high cost of vacuum valve, waste of production components, and short time, and achieve the effects of unaffected concentricity, high suction efficiency, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

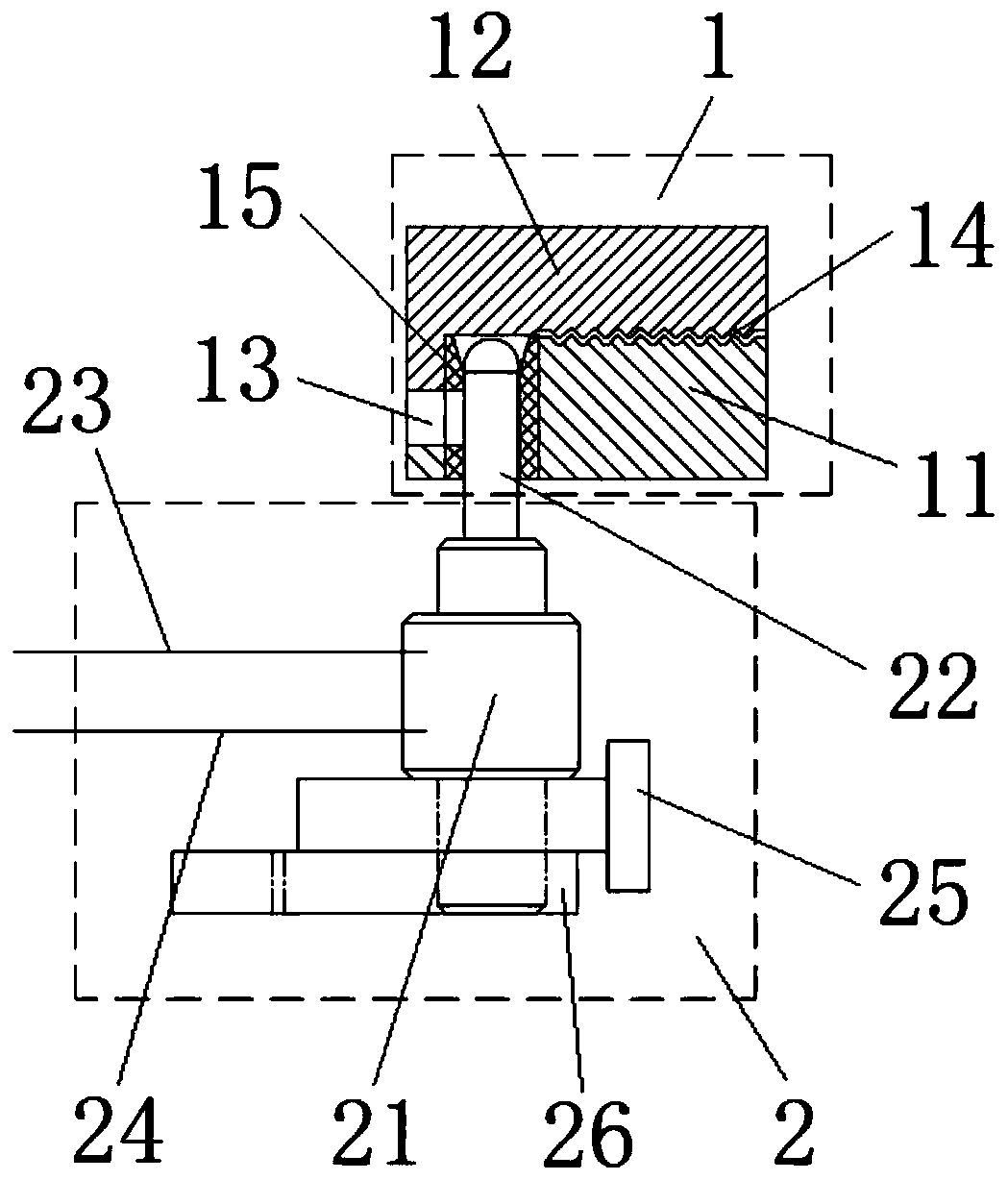

[0023] Such as figure 2 As shown, a hydraulic vacuum valve for a high vacuum die-casting mold of the present invention includes a mold 1 and a hydraulic driver 2; the mold 1 includes a movable template 11 and a fixed template 12, and a mold cavity is left in the middle after the movable template 11 and the fixed template 12 are joined together 13 and the vacuum suction port 14 that can communicate with the mold cavity 13, the vacuum valve seat 15 that can be shut off by the vacuum valve core 21 is provided between the vacuum suction port 14 and the mold cavity 13; And close the hydraulic cylinder 22 of the oil circuit 24, the vacuum valve core 21 telescopically moves in the hydraulic cylinder 22; the vacuum valve seat 15 has a through hole (not marked) connected with the mold cavity 13 above, and the top of the vacuum valve core 21 passes through the through hole , the vacuum suction port 14 is located in a direction perpendicular to the through hole. Because when the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com