Four-column suspending and rocking hydraulic support

A hydraulic support and floating technology, which is applied in the direction of pillars/supports, mine roof supports, mining equipment, etc., can solve the problems of high labor intensity, inconvenient maintenance, and small working space, so as to improve safety and stability, reduce Intermediate production links, the effect of reducing intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

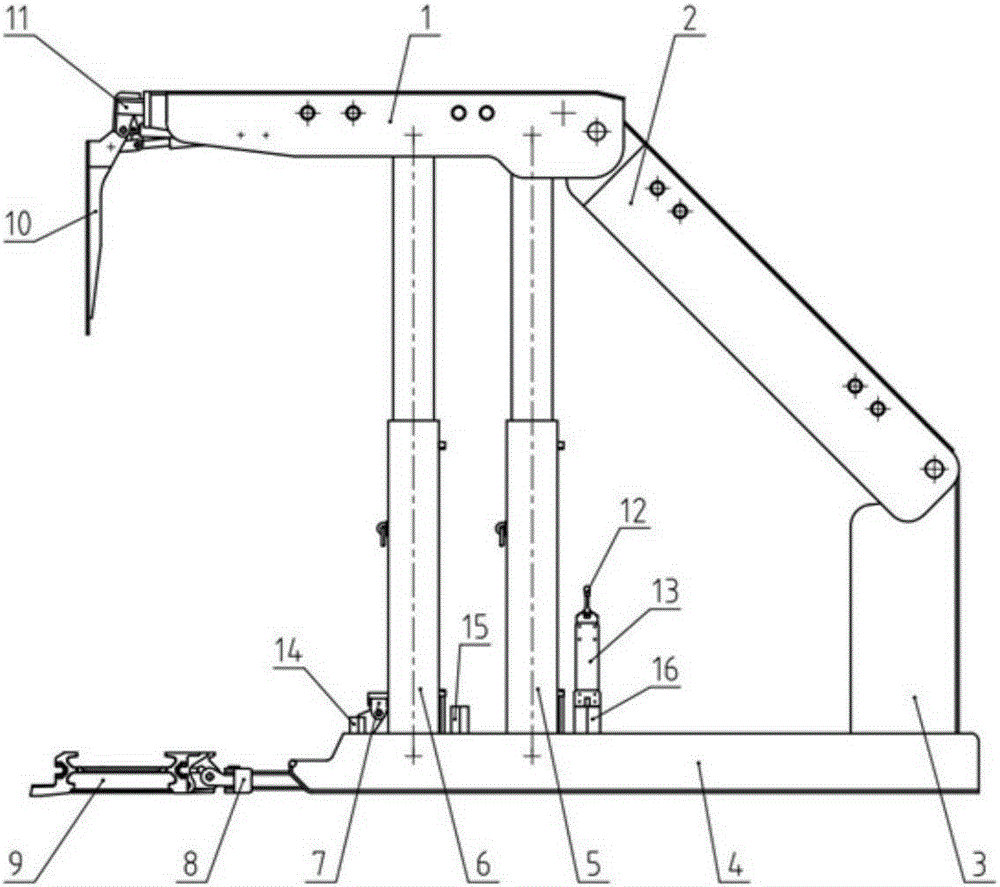

[0021] Embodiment 1: as figure 1 As shown, the four-column floating hydraulic support of the present invention is mainly composed of a top beam 1, a shield beam 2, an elevated frame 3, a base 4, a front suspension hydraulic column 6, a rear suspension hydraulic column 5, a bottom lifting device 7, and a push Device 8, scraper conveyor 9, side protection device 10, telescopic beam device 11, hydraulic control valve group 12, valve group bracket 13, front bridge 14, middle bridge 15 and rear bridge 16. The top beam 1, the shield beam 2, the elevated frame 3, and the base 4 are welded by steel plates or section steel. The front, middle and rear bridges 14, 15, 16 are welded by thick steel plates, and are welded with the base 4 as a whole. The hydraulic control valve group 12 adopts a manual operation valve group or an electro-hydraulic remote control valve group. The hydraulic control valve group 12 is the control center of each action of the support, and can be manually operate...

Embodiment 2

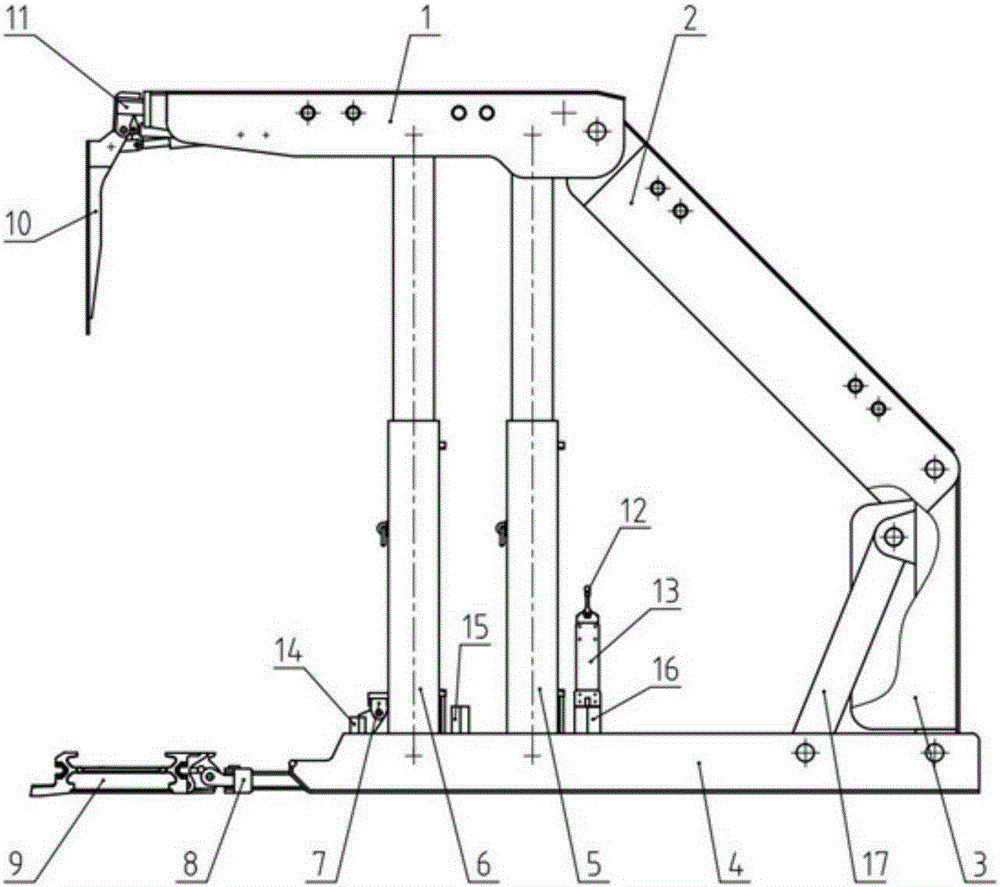

[0023] Embodiment 2: as figure 2 As shown, it is basically the same as Embodiment 1, and the same part is omitted. The difference is that the lower end of the elevating frame 3 at the rear of the support is hinged with the base 4, and a diagonal brace 17 that is used alone or arranged side by side is provided, the upper end is hinged with the elevating frame 3, and the lower end is hinged with the base 4.

Embodiment 3

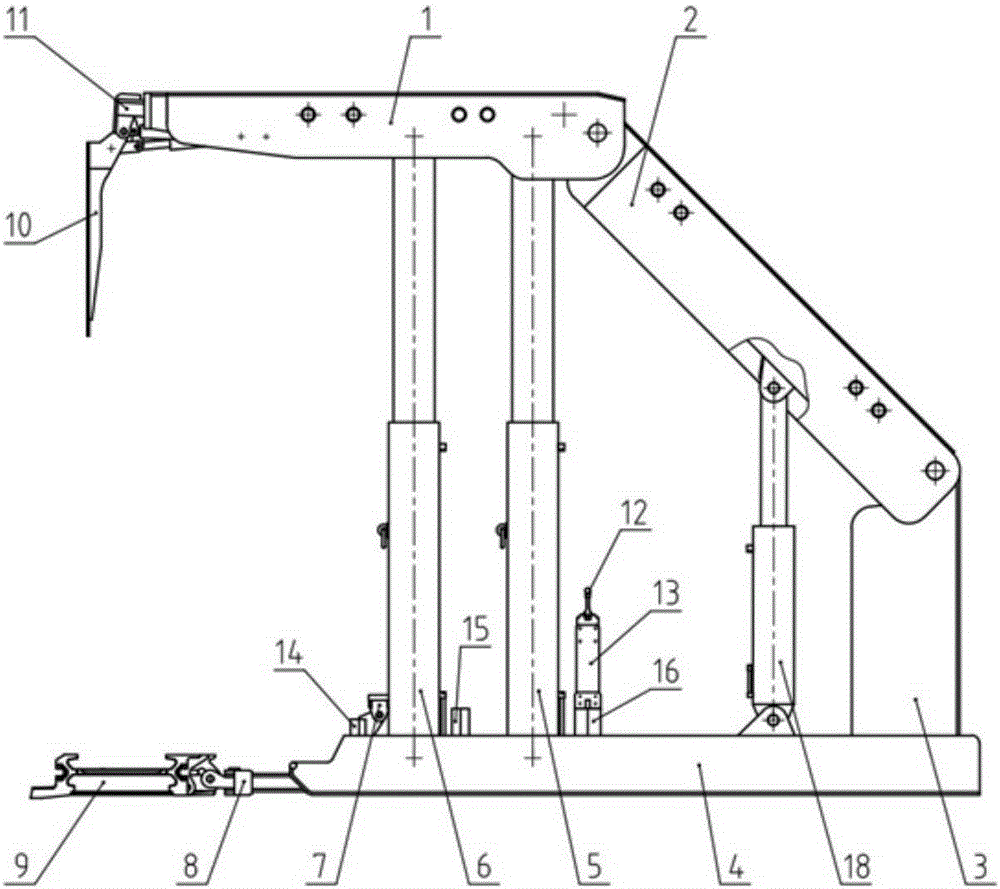

[0024] Embodiment 3: as image 3 As shown, it is basically the same as Embodiment 1, and the same part is omitted. The difference is that between the shield beam 2 and the base 4 there is an adjusting jack 18 that is used alone or in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com