Method for deicing aerial power line with load

A power line and ice melting technology, which is applied in the field of switching switches, can solve the problems of icing of overhead high-voltage transmission lines and a great threat to the safe and reliable operation of power systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

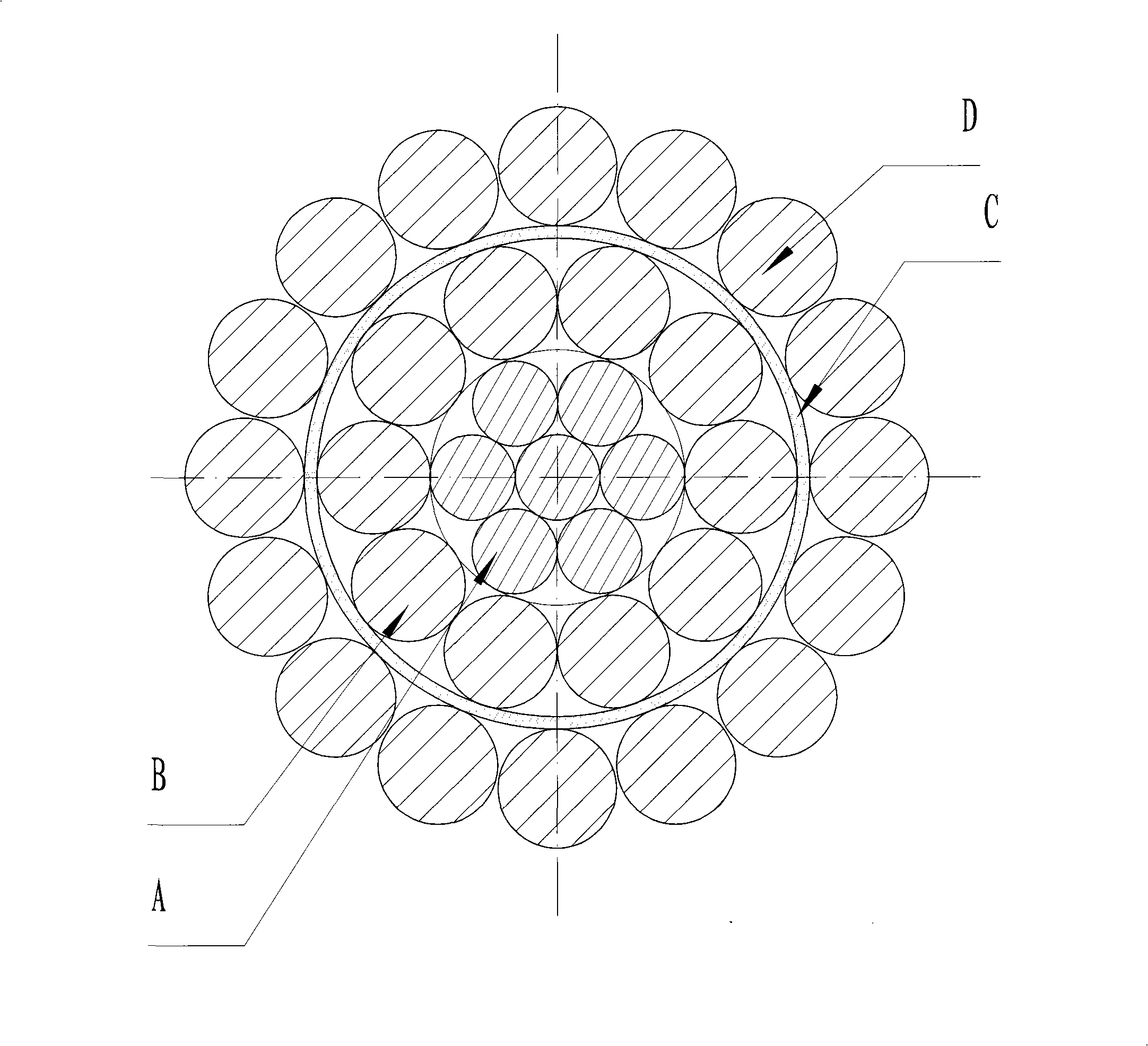

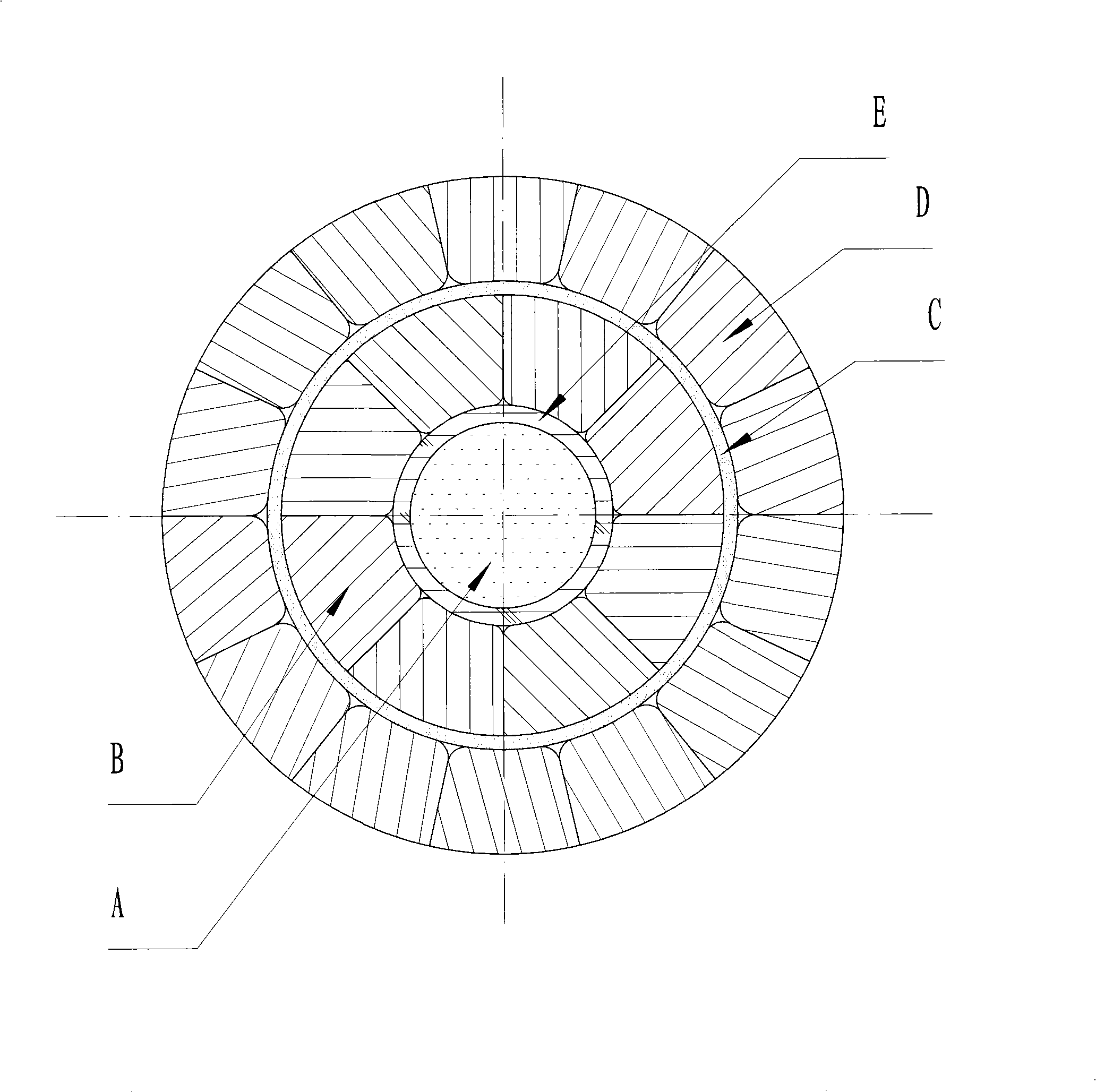

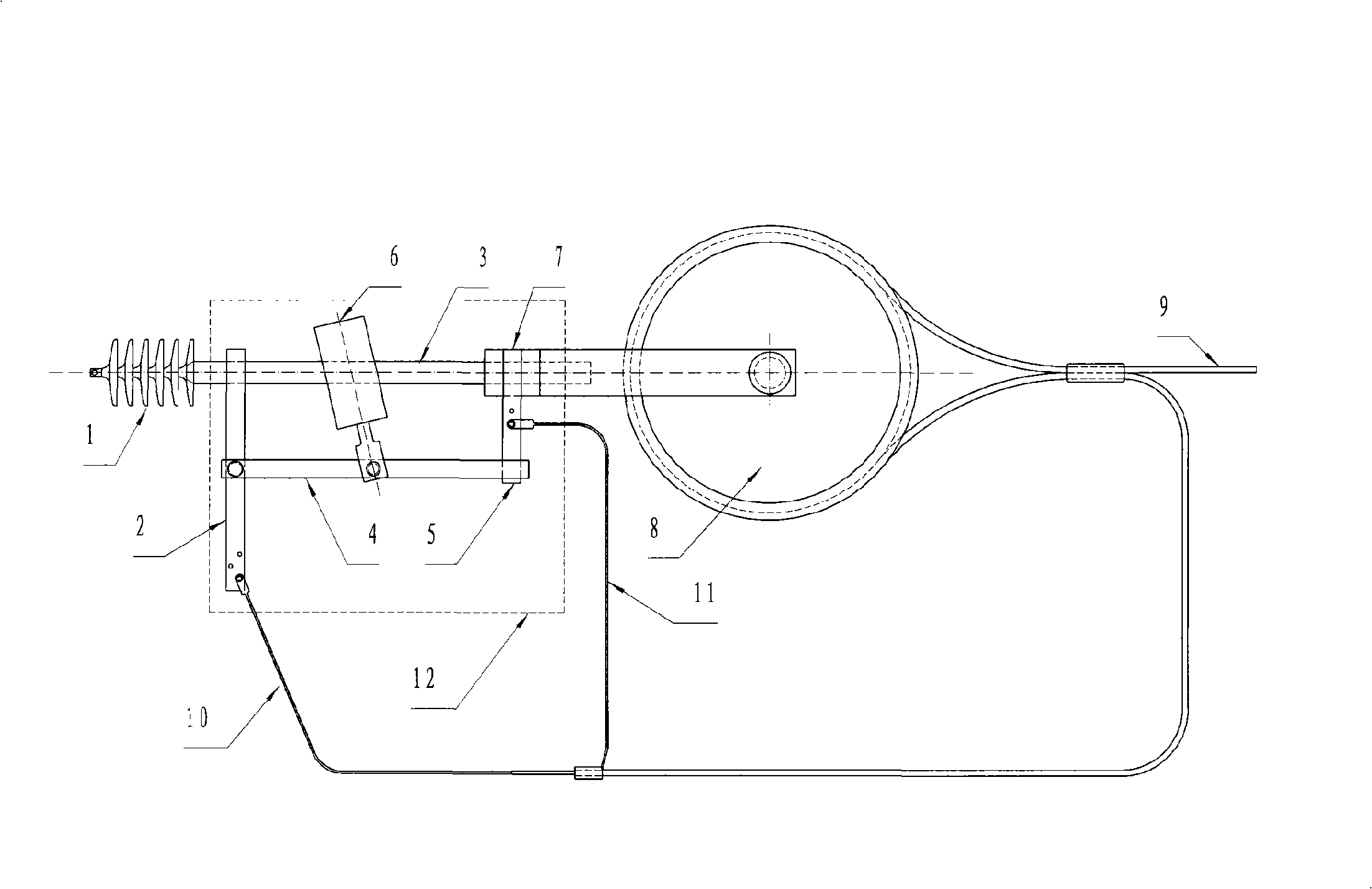

[0008] Refer to Figure 1 of the instruction manual. For power lines of this specification, the DC resistance at -5 degrees after A and B are connected in parallel is 0.1480Ω / KM, and the resistance after A, B, and D is connected in parallel is 0.0567Ω / KM. When D passes through 200A current in parallel, the line loss is 2268W / KM. When A and B are connected in parallel, they pass through 200A current. The surface temperature of the wire is higher than zero. If the ice-melting effect is not good, the current passing through the wire can be appropriately increased. When the current is 200A, the voltage drop at both ends of the wire is 30V / KM, so that the ice-melting switch can be installed every 75KM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com