A profile control agent/water blocking agent polymerization curing device and its working method

A curing device and polymerization curing technology, which are applied in chemical instruments and methods, drilling compositions, chemical liquid solidification, etc., can solve the problems of generating a large amount of heat and failing to meet product specifications, improving production efficiency and achieving qualified product specifications. , the effect of reducing the occupation of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

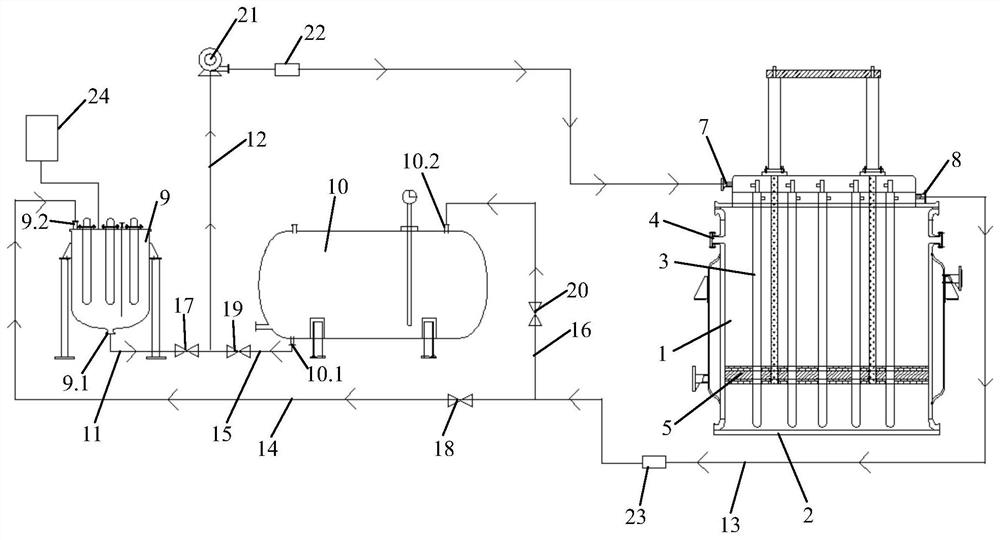

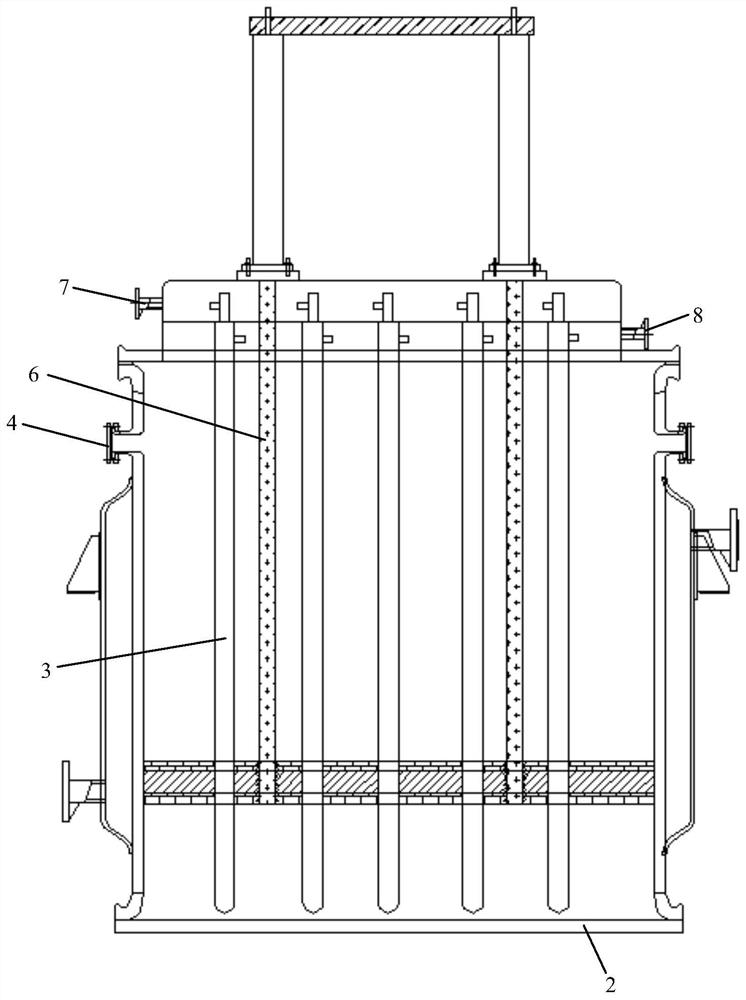

[0065] A profile control agent / water blocking agent polymerization curing device, such as Figure 1-2 As shown, the main body 1 of the curing device is included, and the main body 1 of the curing device is a cylindrical structure without a bottom plate. The bottom of the curing device is provided with a detachable blocking plate 2. The main body 1 of the curing device is provided with an extrusion device and several heat exchange tubes 3. , one side of the main body 1 of the curing device is provided with a feed port 4;

[0066] The extruding device includes an extruding plate 5 and a power unit that drives the extruding plate to move up and down. The edge of the extruding plate 5 is in contact with the interior of the main body 1 of the curing device, and the extruding plate 5 is fixed to the driving rod 6 of the power unit on its upper part. connected, the driving rod 6 moves up and down to drive the extruding plate 5 to move up and down in the main body 1 of the curing devi...

Embodiment 2

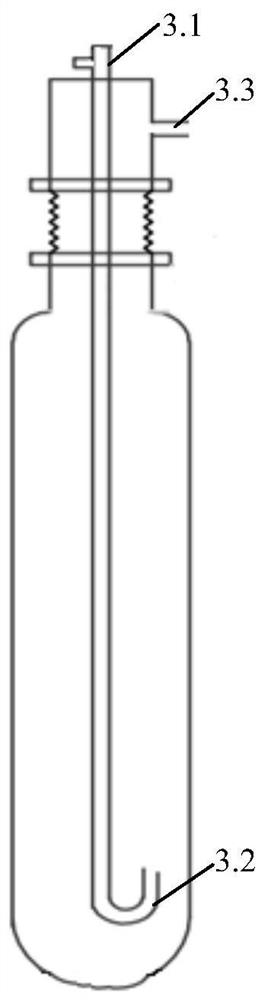

[0072] A profile control agent / water shutoff agent polymerization curing device, the structure is as shown in Example 1, the difference is, as image 3 As shown, the heat exchange tube 3 is a closed hollow structure, and a water inlet pipe 3.1 is inserted into the upper part of the heat exchange tube 3, and the water inlet pipe 3.1 extends vertically to the bottom of the heat exchange tube and a barb 3.2 is provided at the bottom;

[0073] A water outlet B 3.3 is provided on the upper side of the heat exchange tube 3 .

[0074] When the hot water enters through the upper water inlet pipe 3.1 of the heat exchange tube, it enters the bottom of the heat exchange tube 3 directly along the water inlet pipe 3.1, and flows out from the barb 3.2 at the bottom. The hot water fills the entire heat exchange tube and passes through the water outlet B 3.3 flows out, this design can ensure that hot water can enter the bottom of the heat exchange tube 3, and avoid hot water flowing out direc...

Embodiment 3

[0076] A profile control agent / water shutoff agent polymerization curing device, the structure is as shown in Example 2, the difference is that the upper part of the curing device main body 1 is provided with a water divider, which divides the water in the water inlet 7 to each into each heat exchange tube 3, and enters from the water inlet pipe 3.1 of the heat exchange tube, flows out from the water outlet B 3.3 of the heat exchange tube, and the water flowing out of multiple heat exchange tubes enters the water circulation system through the water outlet A8 of the curing device main body.

[0077] The heat exchange tube 3 is made of stainless steel, and its outer surface should be polished to reduce product retention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com