An optimization method for the production process of hot-rolled smooth round steel bar

A technology of production process and optimization method, applied in the field of steel bar rolling, can solve the problems of high cost, near limit, low component ratio of machine components, etc., and achieve the effects of improving strength and toughness, reducing failure rate and high product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Taking the φ18mm smooth round steel bar as an example, the method for optimizing the production process of a hot-rolled smooth round steel bar according to the present invention is described. The rough rolling adopts 10 stands, and the finish rolling adopts 6 stands, which include the following steps in turn: billet heating, rough rolling, intermediate rolling, finish rolling, heat treatment, descaling, straightening, flying shear segmentation, sizing, bundling, Inspection and warehousing; the chemical composition of the material of the billet by weight percentage is: C: 0.23-0.25%, Si: 0.25-0.32%, Mn: 1.33%-1.41%, Nb: 0.025%-0.035%, V: 0.05% -0.06%, P≤0.045%, S≤0.045%, the balance is Fe and unavoidable impurities; the reduction load distribution control is carried out during rough rolling, and the specific control methods include:

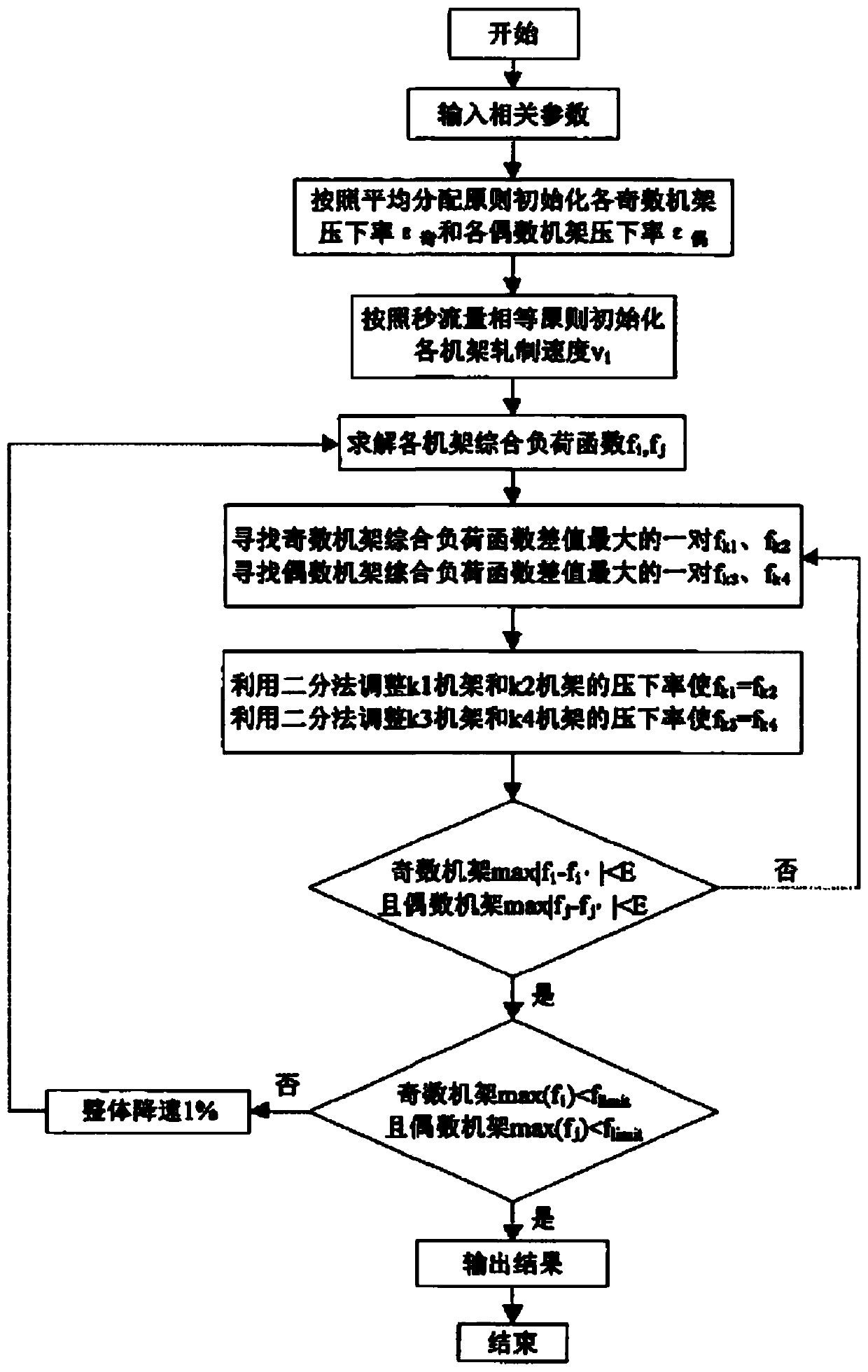

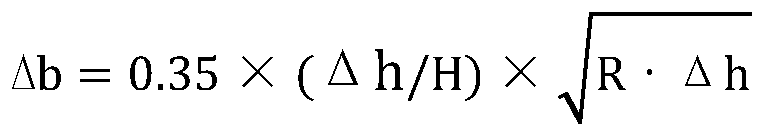

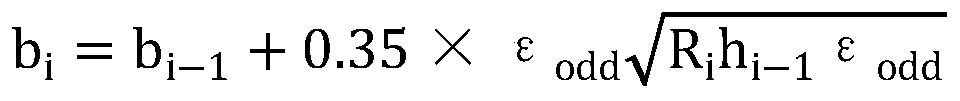

[0033] Step 1) From the billet size and rough rolling target size, initialize the reduction rate ε of odd groups of racks according to the ...

Embodiment 2

[0049] The optimized process as described in Example 1 includes the following for the weight ratio of materials: C: 0.23-0.25%, Si: 0.25-0.32%, Mn: 1.35%-1.41%, Nb: 0.025%-0.035%, V: 0.05%-0.06%, P≤0.035%, S≤0.035%, Cr0.0004%-0.0008%, the balance is Fe and unavoidable impurities.

[0050] GB / T1499.1-2017 national standard stipulates the relevant technical requirements of hot-rolled steel bar, the present invention sets embodiment and comparative example to measure yield strength and tensile strength index, embodiment and comparative example are set as follows (content is weight percentage):

[0051] Example C Si mn Nb V Cr P S Example 3 0.25 0.31 1.40 0.026 0.06 - 0.022 0.019 Example 4 0.23 0.27 1.37 0.028 0.05 0.00067 0.018 0.021 Example 5 0.23 0.27 1.37 0.028 0.05 0.00054 0.025 0.019 Comparative example 1 0.24 0.31 1.46 0.014 - - 0.020 0.025 Comparative example 2 0.27 0.61 1.49 0.017 0.11 0.12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com