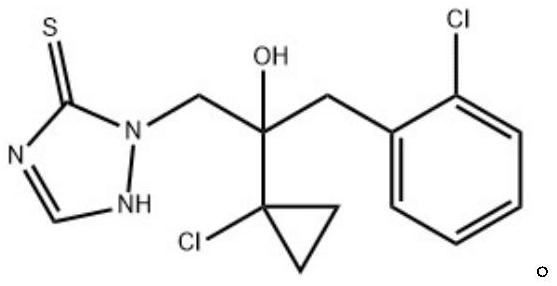

Prothioconazole microcapsule suspending agent as well as preparation method and application thereof

A microcapsule suspension, prothioconazole technology, applied in the direction of botany equipment and methods, applications, fungicides, etc., can solve the problems of harming non-target crops, increasing drug costs, resistance development, etc., to reduce pesticide application number of times, good storage stability, and the effect of reducing control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

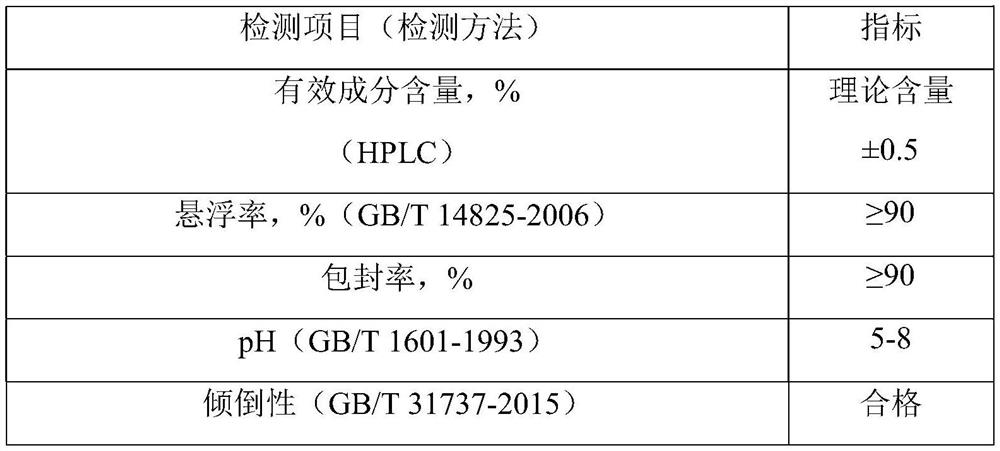

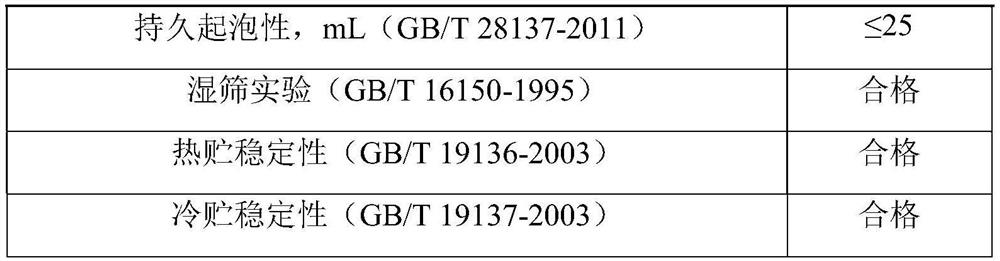

[0081] Embodiment 1: 1% prothioconazole microcapsule suspension

[0082] The preparation method of 1% prothioconazole microcapsule suspension is as follows:

[0083] Step 1: Dissolve 1.03g of 98% prothioconazole in 5g of Genagen 4296, add 4g of Nongyu 1602 and 1g of PAPI, mix and stir to form an oil phase;

[0084] Step 2: Add 0.1g of silicone antifoaming agent to 81.02g of deionized water and mix evenly, as water phase;

[0085] Step 3: mixing the oil phase and the water phase, and emulsification at a high speed of 8000rpm for 5min to obtain an oil-in-water emulsion;

[0086] Step 4: 0.3g of diethylenetriamine is prepared into 3g of 10% diethylenetriamine aqueous solution with deionized water and added to the oil-in-water emulsion, kept at 45°C, stirred at 300rpm for 3h, cooled to room temperature after the polymerization reaction is completed, and obtained intermediate reaction solution;

[0087] Step 5: add 2g YUS-FS3000, 2.5g ethylene glycol, 0.1g xanthan gum and 0.25g ...

Embodiment 2

[0088] Embodiment 2: 5% prothioconazole microcapsule suspension

[0089] The preparation method of 5% prothioconazole microcapsule suspension is as follows:

[0090] Step 1: Dissolve 5.11g 98% prothioconazole in 10g ADMA810 and add 4g 992 and 1.2g HDI, mix and stir well as oil phase;

[0091] Step 2: Add 0.1g of silicone antifoaming agent to 65.14g of deionized water and mix evenly, as the water phase;

[0092] Step 3: mixing the oil phase and the water phase, and emulsification at a high speed of 10000rpm for 5min to obtain an oil-in-water emulsion;

[0093] Step 4: 0.4g of tetraethylenepentamine was prepared into 8g of 5% tetraethylenepentamine aqueous solution with deionized water and added to the oil-in-water emulsion, kept at 45°C, stirred at 300rpm for 4h, cooled to room temperature after the polymerization reaction was completed, and obtained intermediate reaction solution;

[0094] Step 5: Put 3g 2500, 3 g of propylene glycol, 0.15 g of xanthan gum, and 0.3 g of...

Embodiment 3

[0095] Embodiment 3: 10% prothioconazole microcapsule suspension

[0096] The preparation method of 10% prothioconazole microcapsule suspension is as follows:

[0097] Step 1: Dissolve 10.21g of 98% prothioconazole in a mixed solvent composed of 20g of Genagen 4296 and 5g of No. 200 solvent oil, add 4g of YUS-5050PB and 1.8g of HDI, mix and stir evenly as an oil phase;

[0098] Step 2: Add 0.3g of organosilicon defoamer to 43.09g of deionized water and mix well to serve as the water phase;

[0099] Step 3: mixing the oil phase and the water phase, and emulsification at a high speed of 10000rpm for 5min to obtain an oil-in-water emulsion;

[0100] Step 4: Use deionized water to prepare 0.2 g of diethylene triamine into 8 g of a 2.5% diethylene triamine aqueous solution and add it to the oil-in-water emulsion, keep at 50° C., stir at 300 rpm for 4 hours, and cool down to room temperature after the polymerization reaction is completed to obtain intermediate reaction solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com