Patents

Literature

41results about How to "Extended melting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

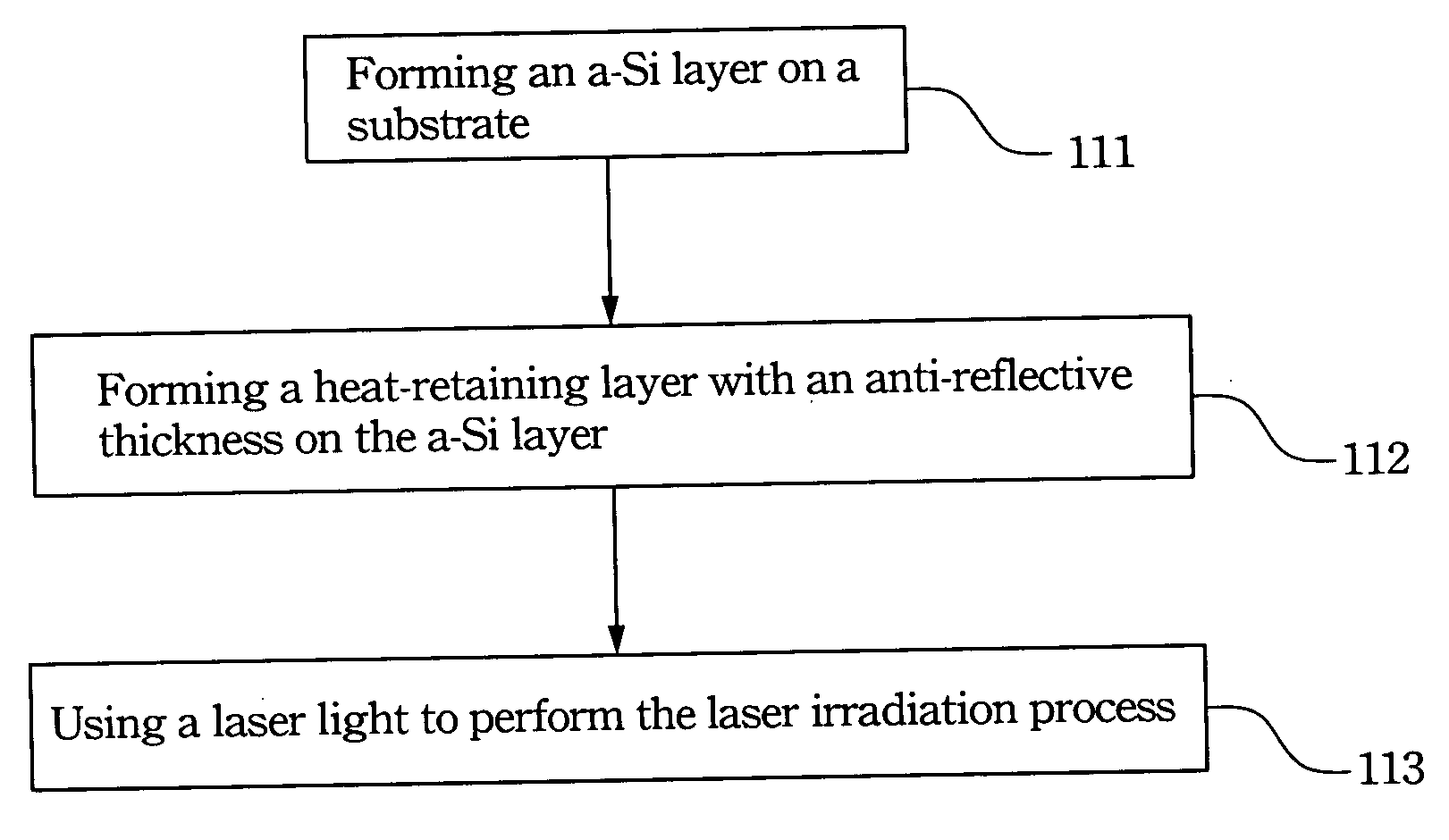

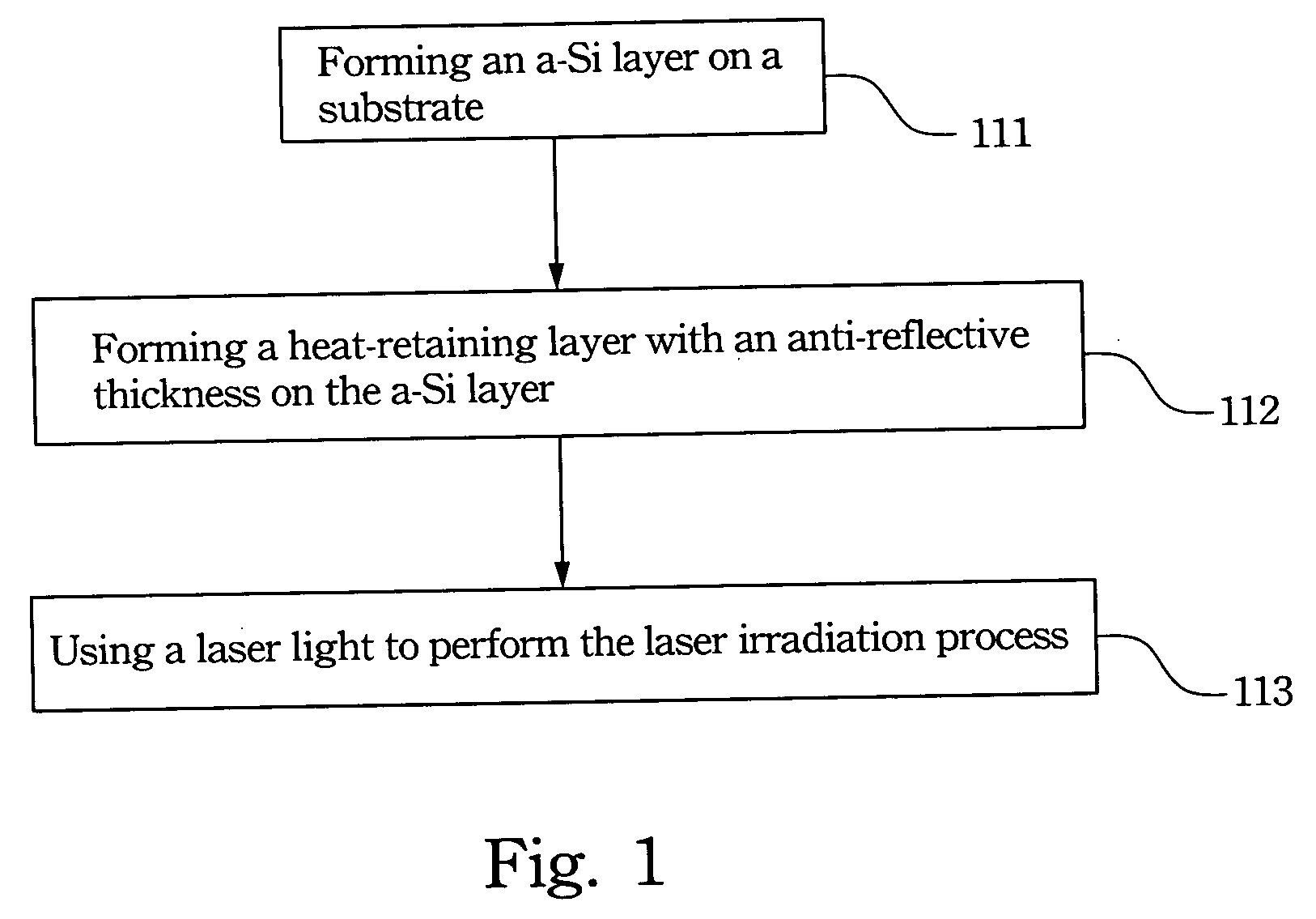

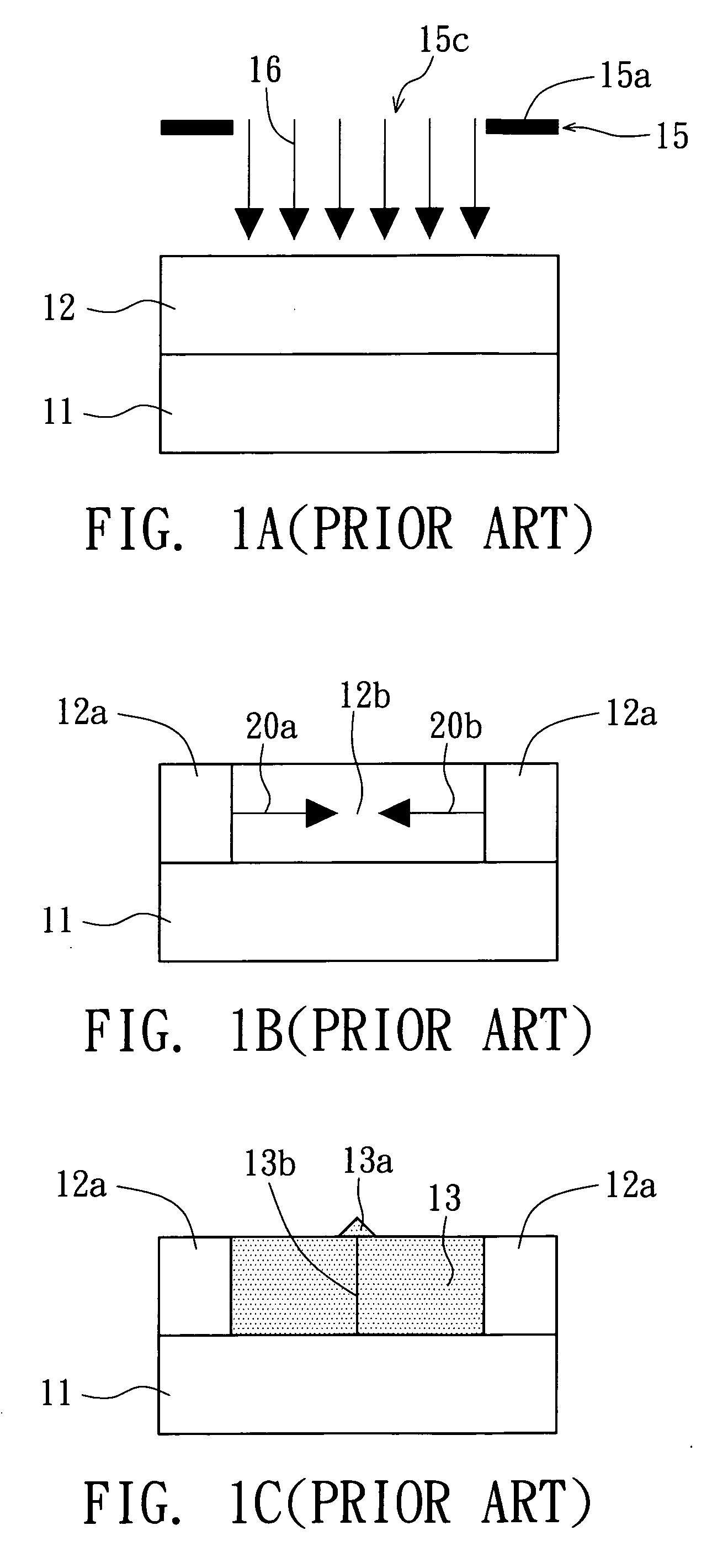

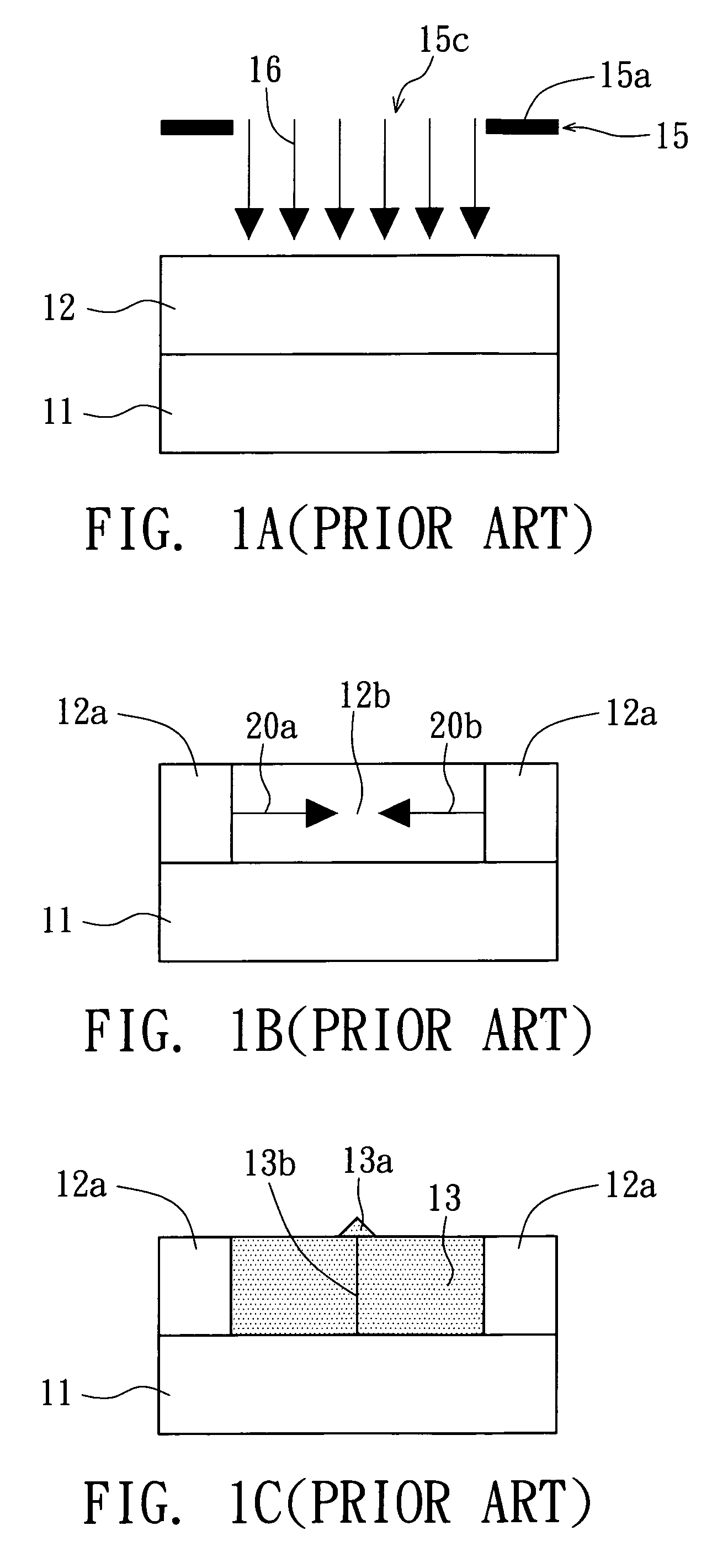

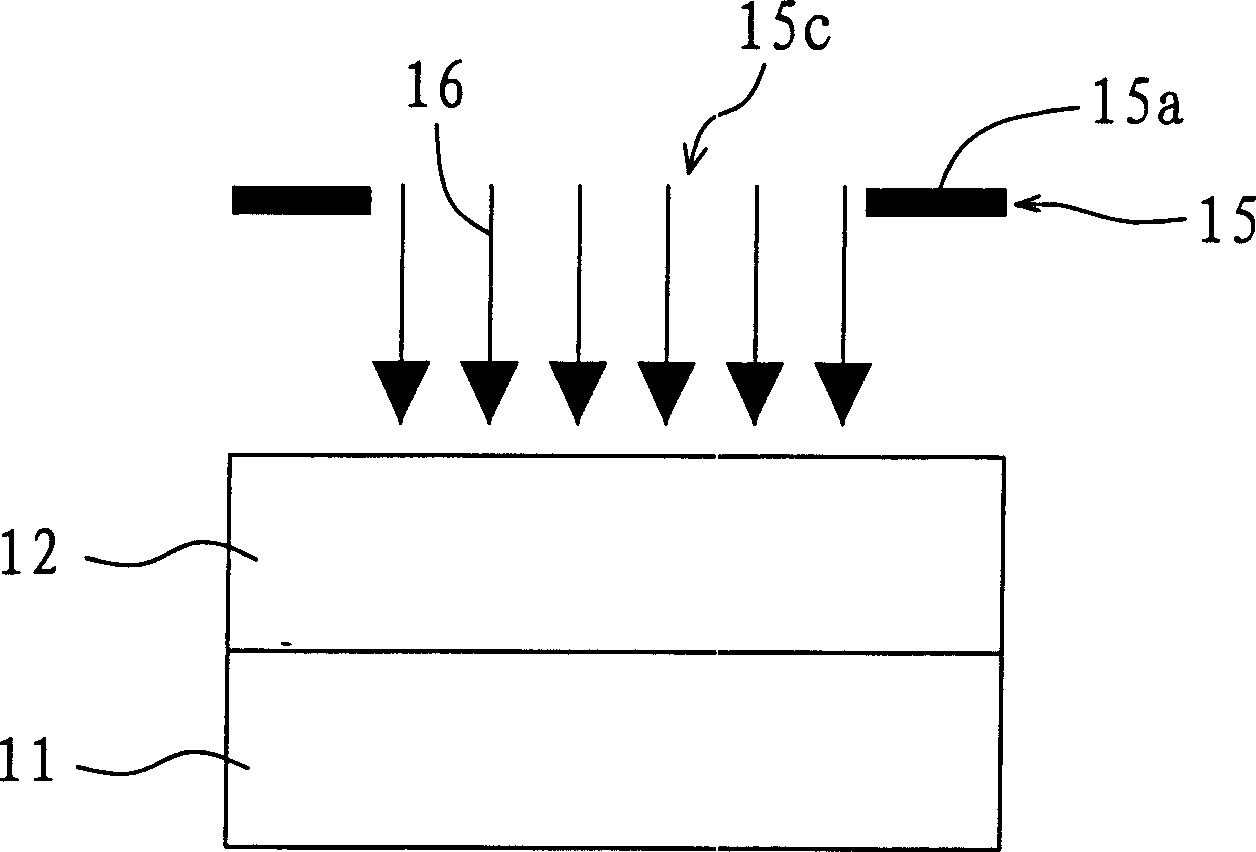

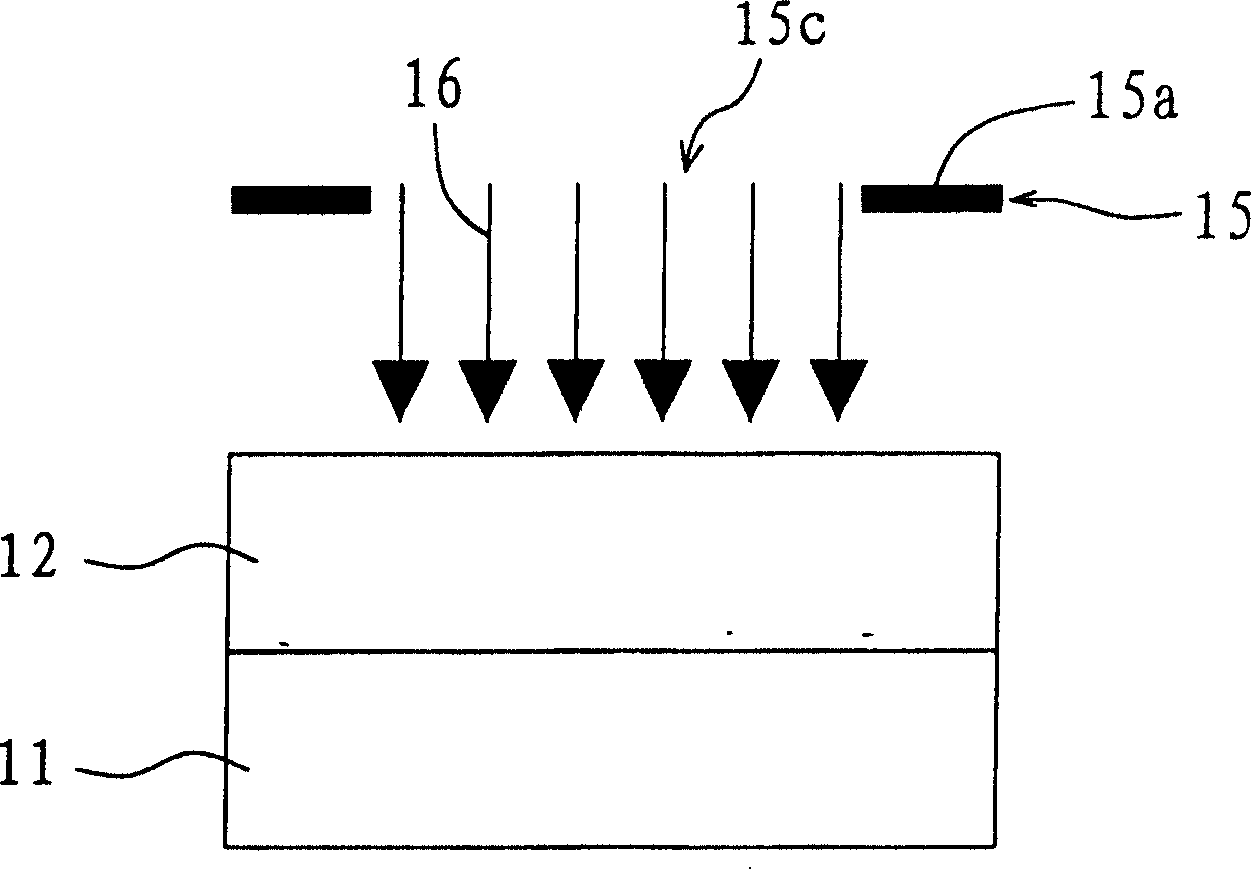

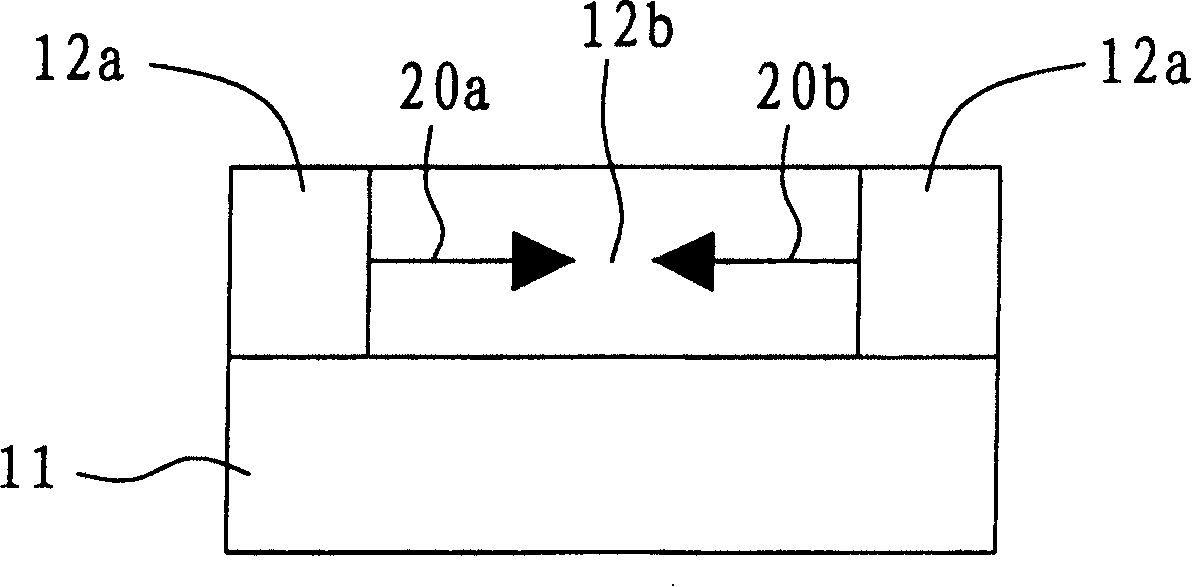

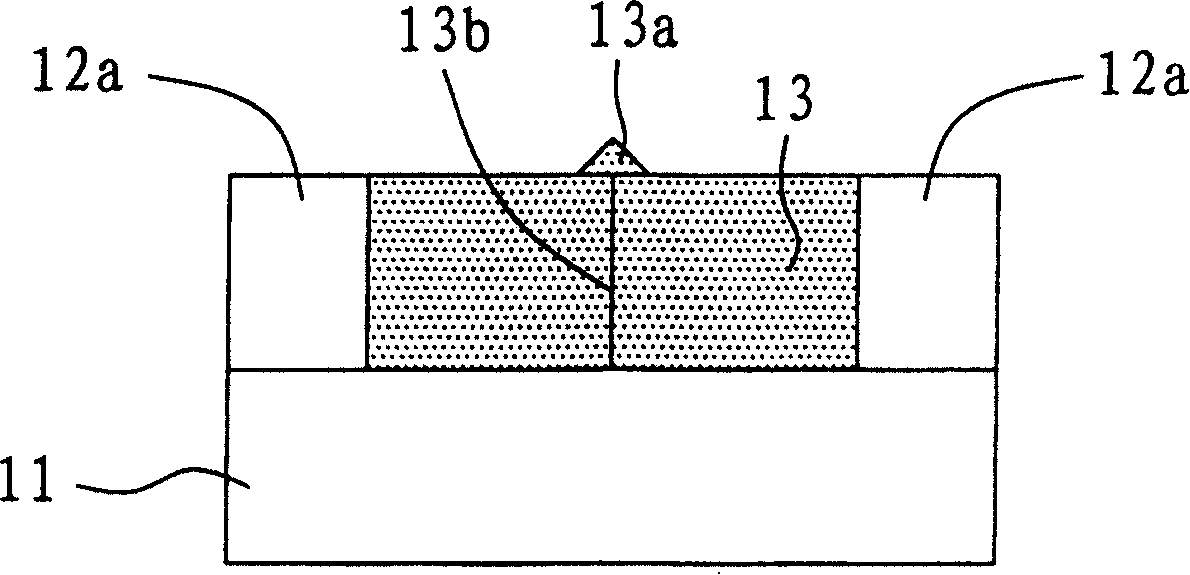

Method of enhancing laser crystallization for polycrystalline silicon fabrication

InactiveUS20060088986A1High crystallinityFine grainSolid-state devicesSemiconductor/solid-state device manufacturingLaser crystallizationOptoelectronics

An amorphous silicon layer and at least a heat-retaining layer are formed on a substrate in turn. Wherein, the heat-retaining layer is controlled to have an anti-reflective thickness for reducing the threshold laser energy to effect the melting of the amorphous silicon layer. Then, a laser irradiation process is performed to transform the amorphous silicon layer into a polycrystalline silicon layer. During the laser irratiation process, a portion of the laser energy transmits the heat-retaining layer to effect the melting of the amorphous silicon layer, and another portion of the laser energy is absorbed by the heat-retaining layer.

Owner:IND TECH RES INST

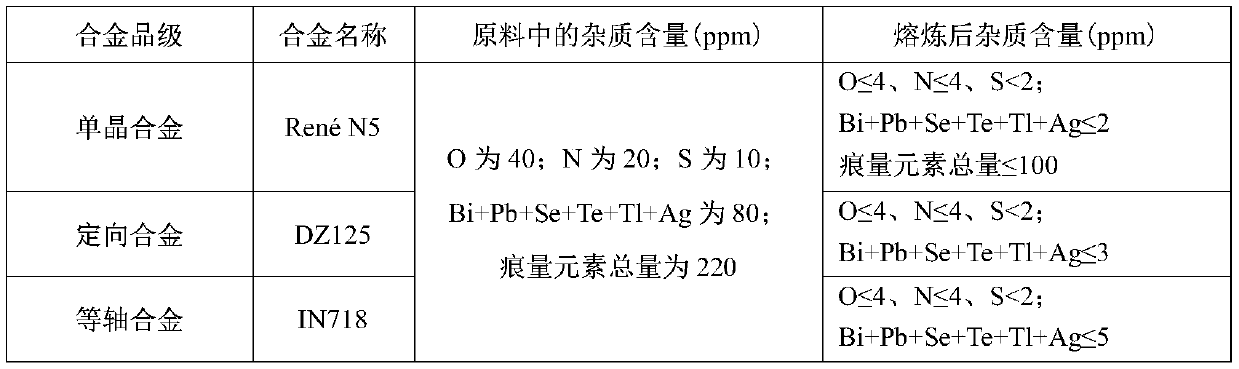

Pure purification smelting method used for nickel-based high-temperature alloy master alloy

The invention relates to a pure purification smelting method of an alloy, in particular to a pure purification smelting method for a nickel-based high-temperature alloy master alloy, and belongs to the technical field of metal smelting. According to the method, pure purification smelting of a master alloy is completed through material distributing and alloy melting, primary refining, alloying andsecondary refining, microalloying controlling and casting. The method has the advantages that the purity of vacuum melting can be effectively improved, the element segregation can be improved, and a nickel-based high-temperature alloy prepared by the method has the advantages that the purity is high, the segregation is low, the quality is remarkably higher than that of an alloy prepared through the existing technology and method, the quality of the nickel-based high-temperature alloy is improved, and the application field is expanded; nickel-based high-temperature alloys with different gradesand marks smelted by adopting the method has good effects; vacuum induction furnaces with the furnace types of 250 kg-grade and 1.5 ton-grade are adopted; and compared with an alloy before smelting and prepared through other technologies and methods, the alloy is remarkably improved in purity and uniformity.

Owner:METALINK SPECIAL ALLOYS CORP

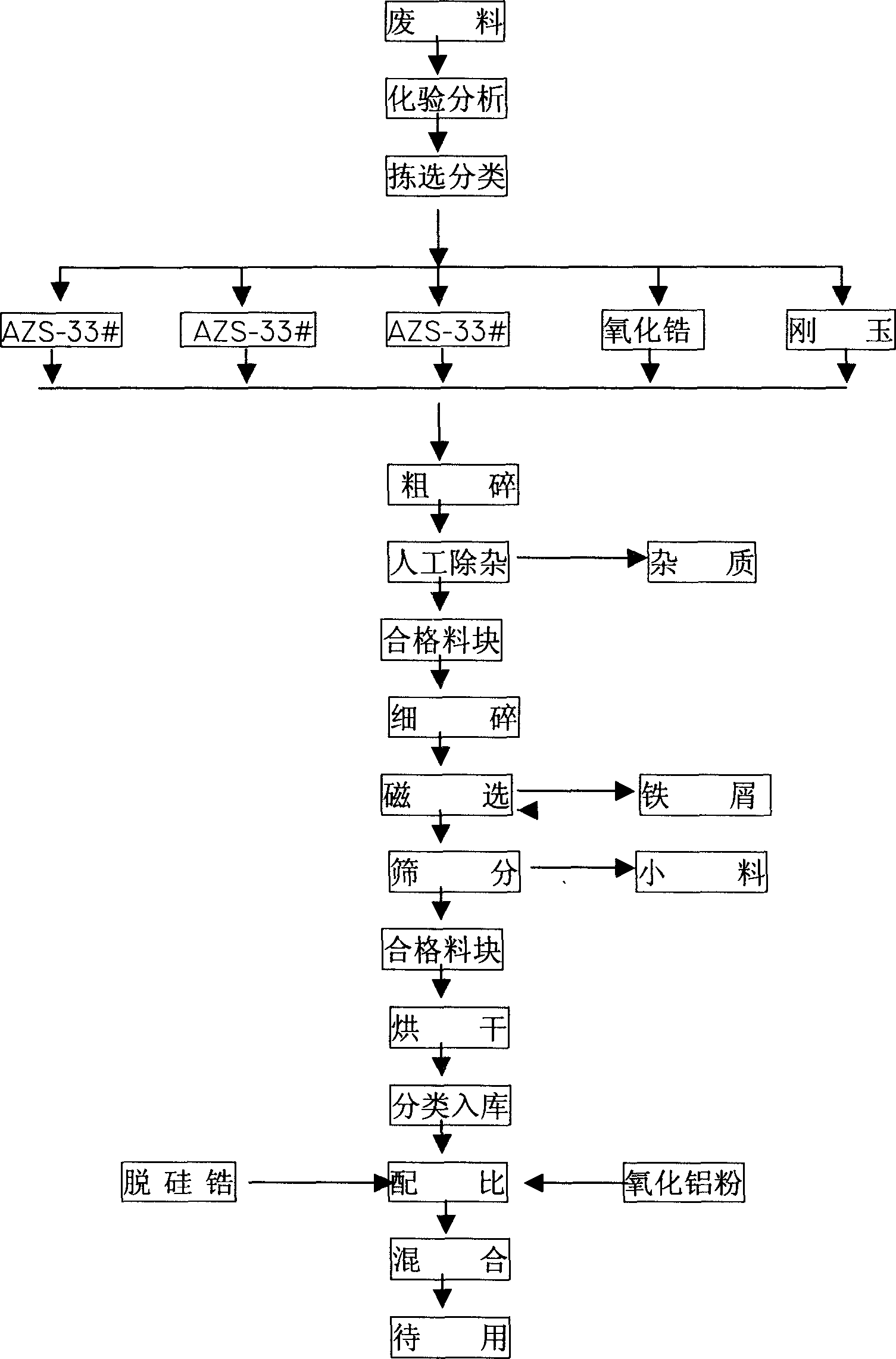

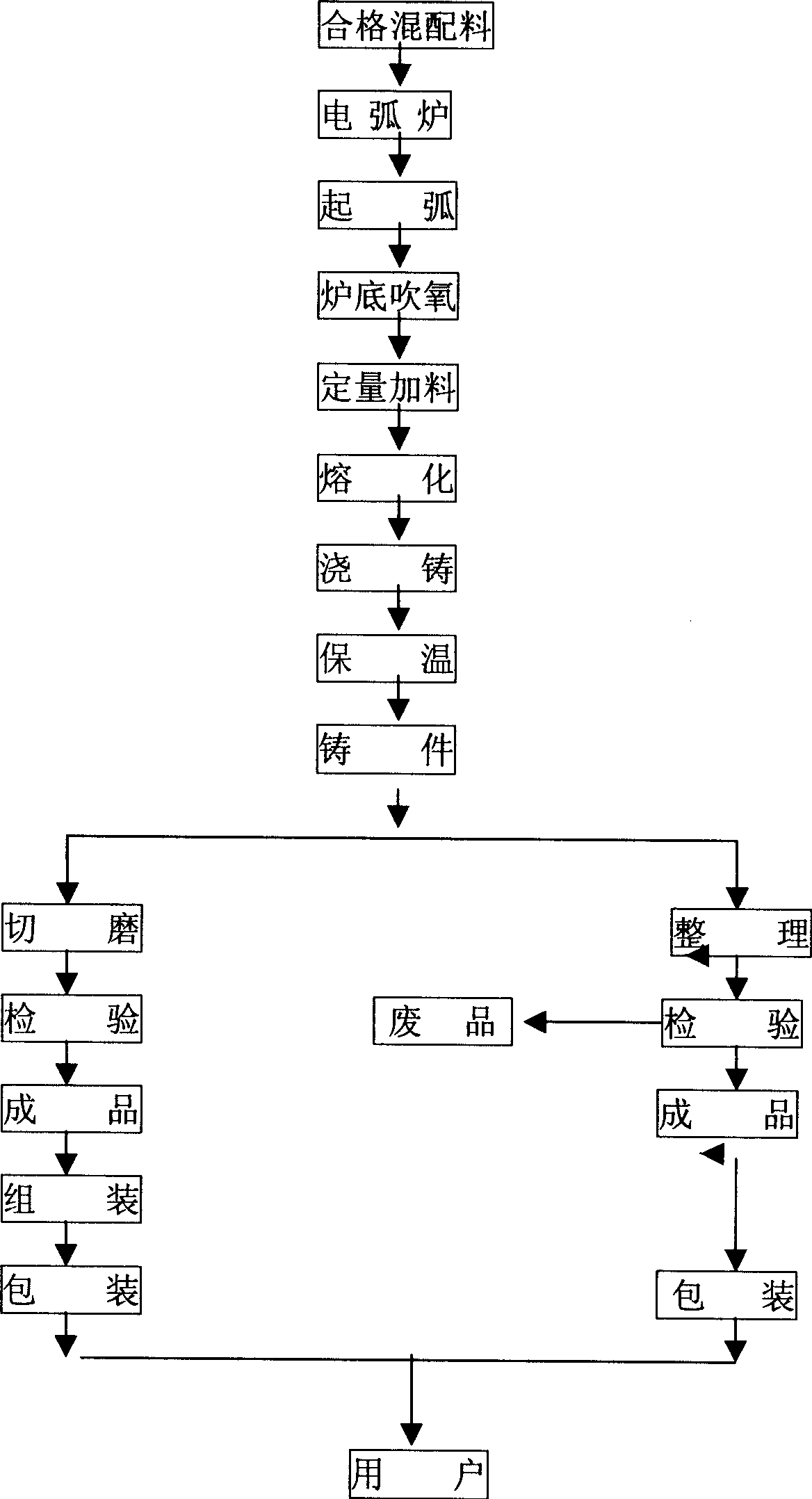

Process for producing electric smelting zirconium corundum 33#, 36#, 41# products by secondary casting

A process for preparing the electrocast zirconium corundum No.33, 36 and 41 includes such steps as pretreating the leftover of cast zirconium corundum, zirconium oxide and corundum, proportional mixing, smelting by blowing oxygen from furnace bottom for removing impurities, casting and holding the temp for a certain time.

Owner:侯松发

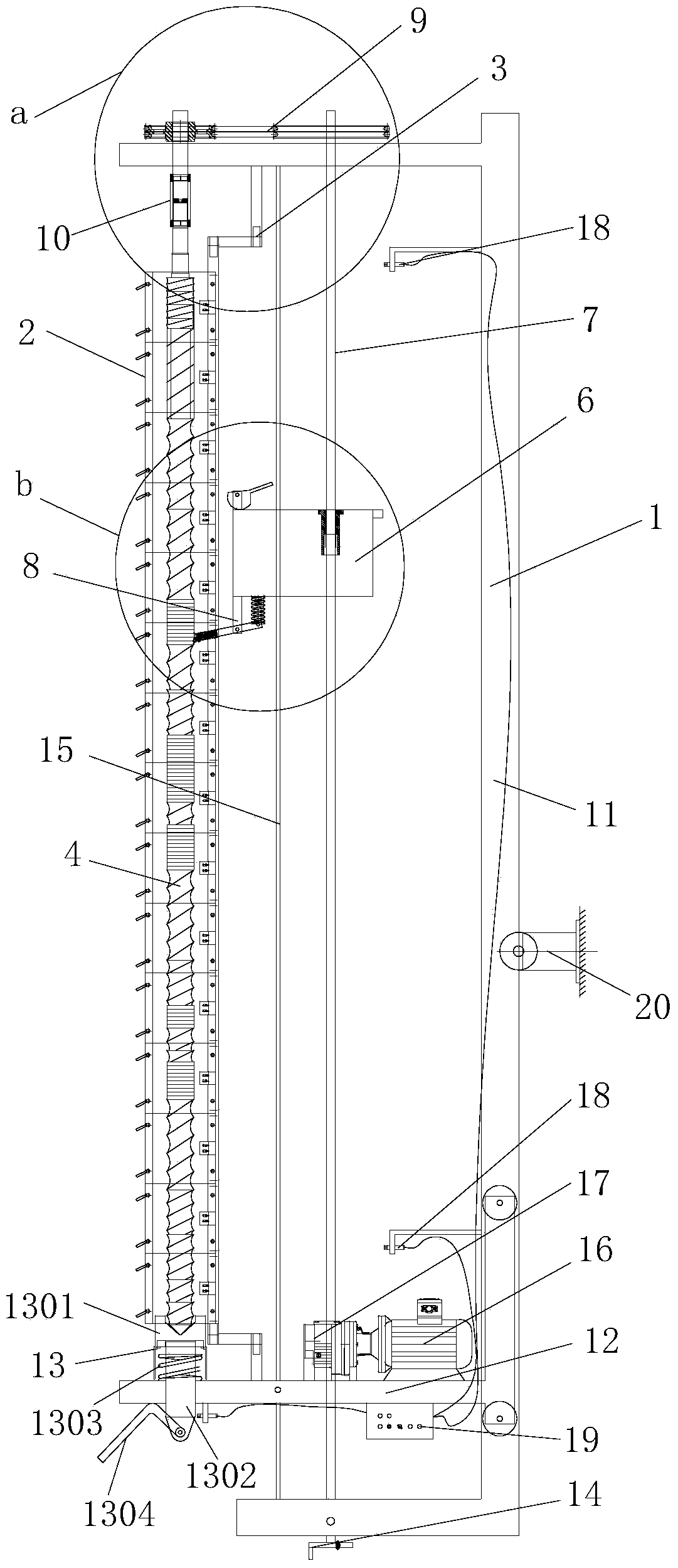

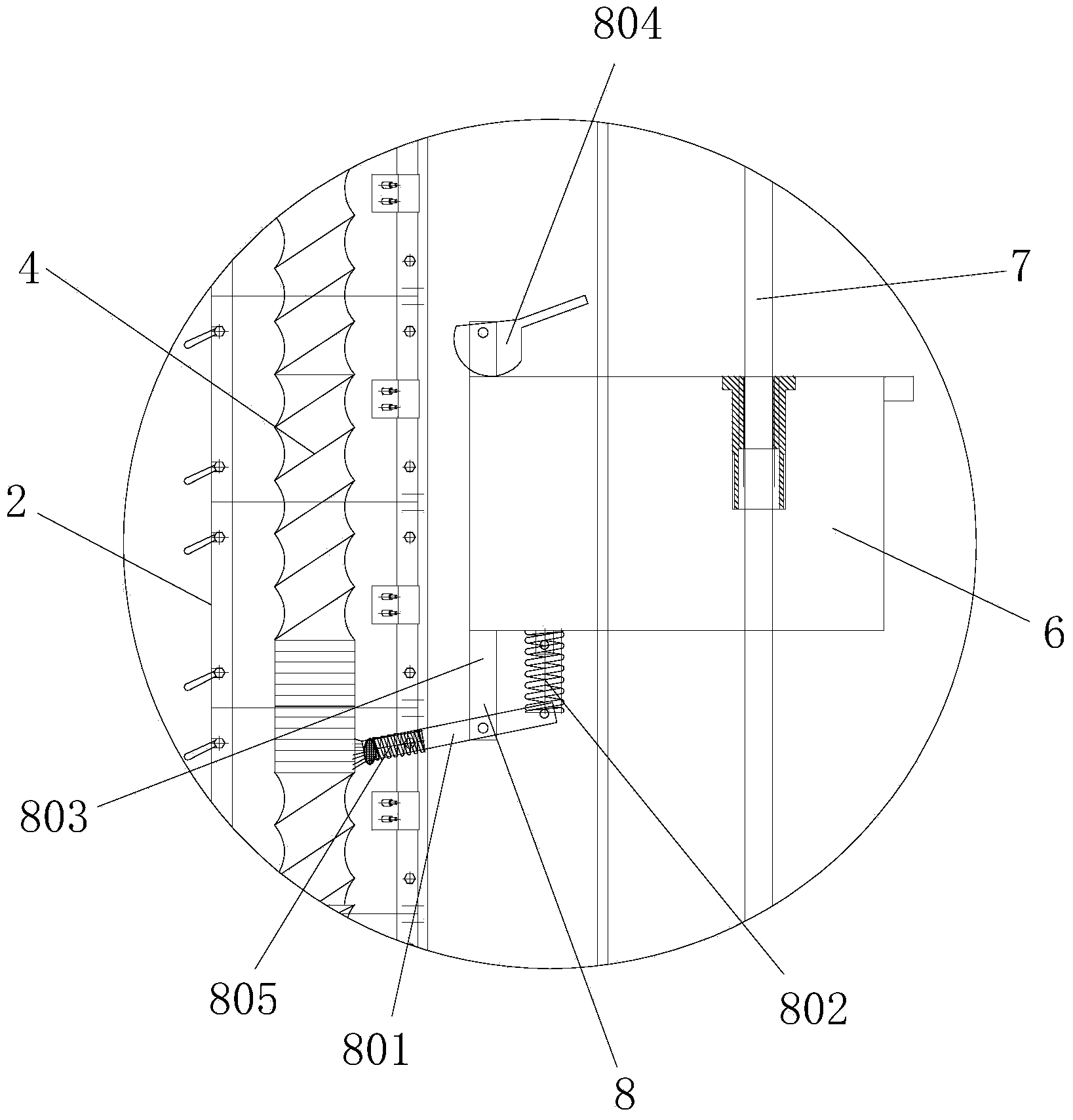

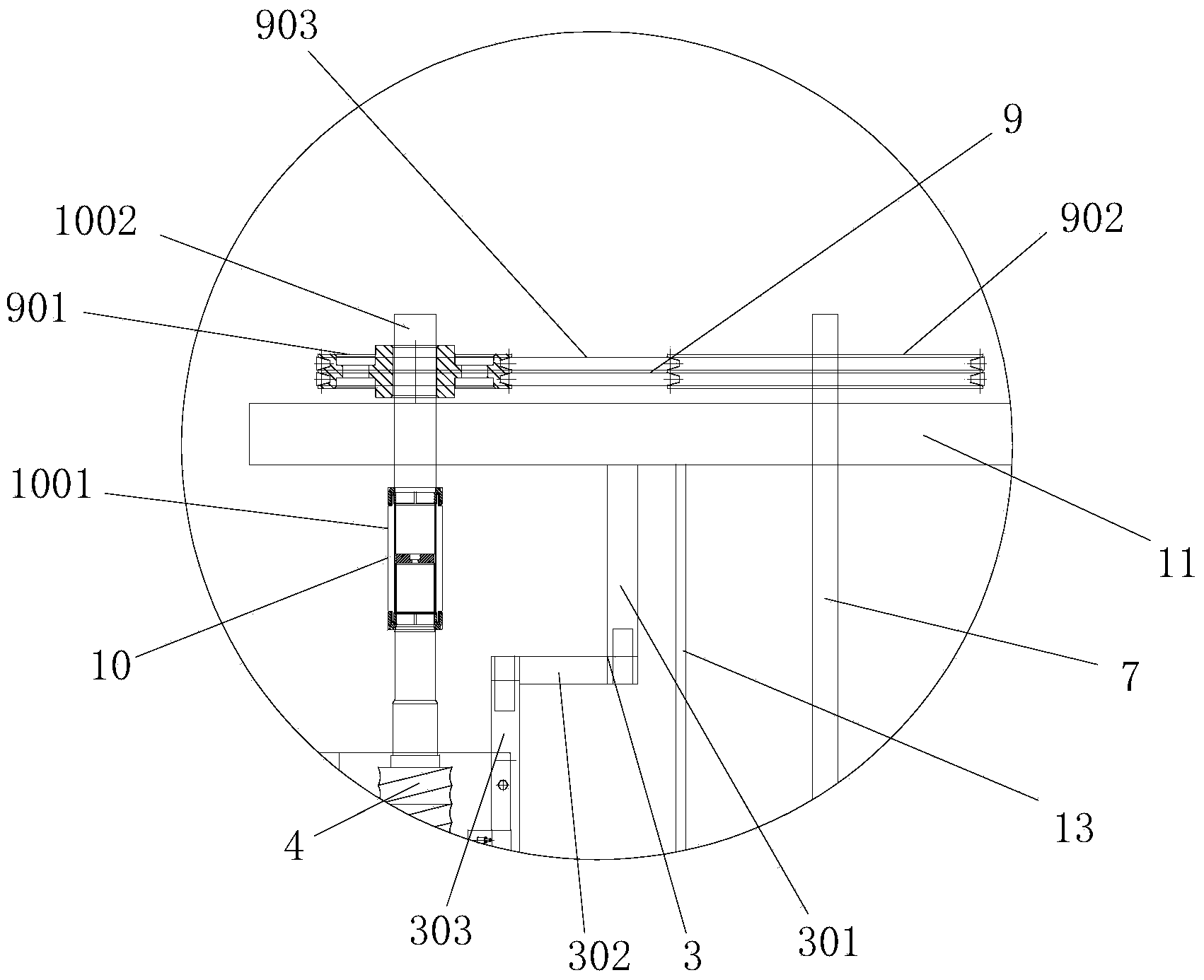

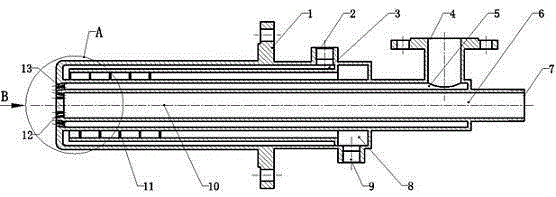

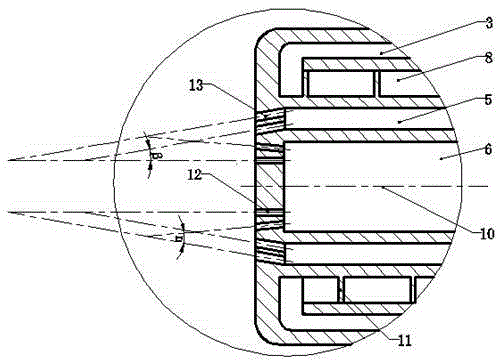

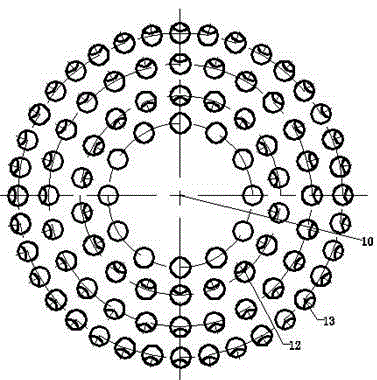

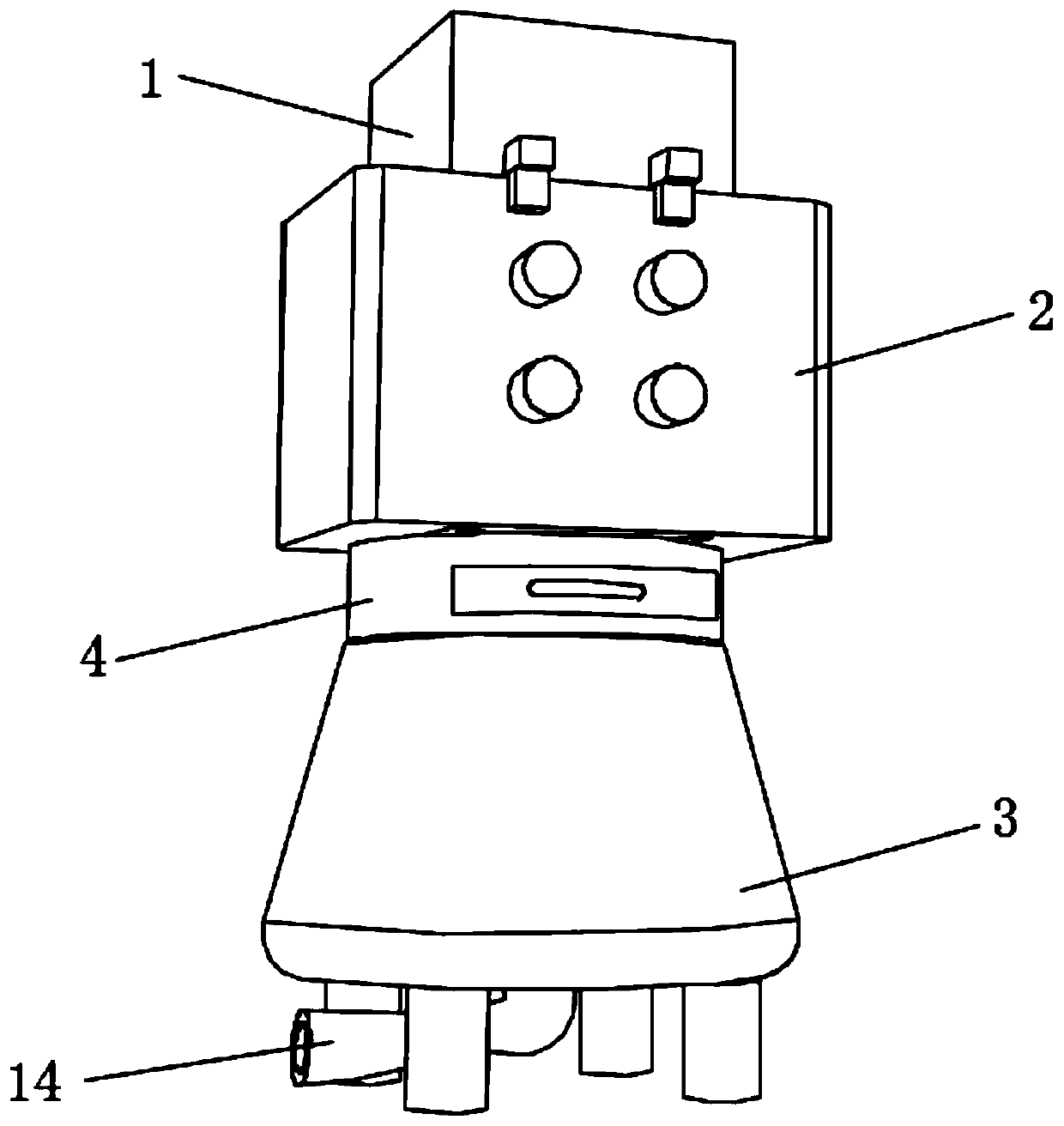

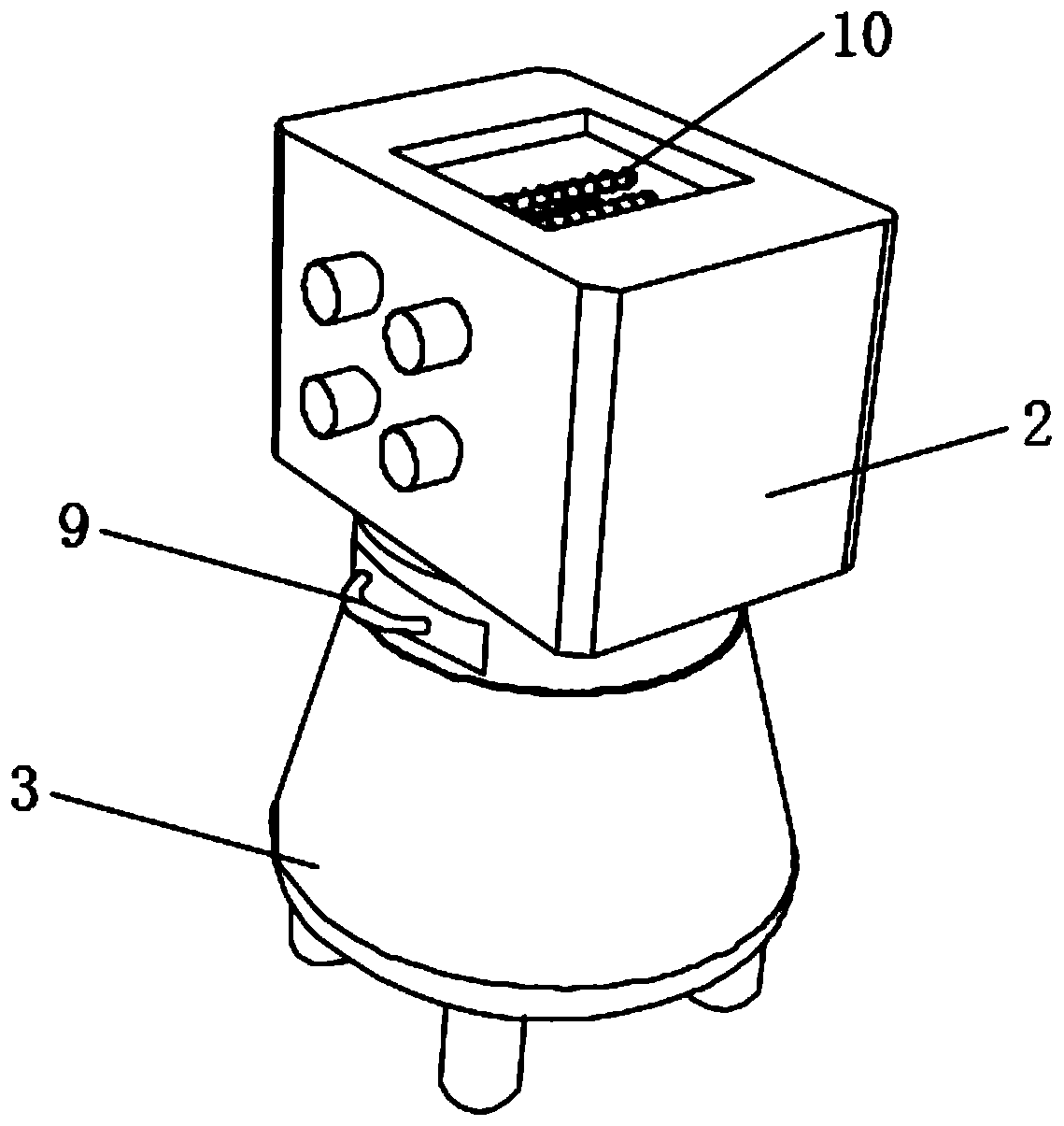

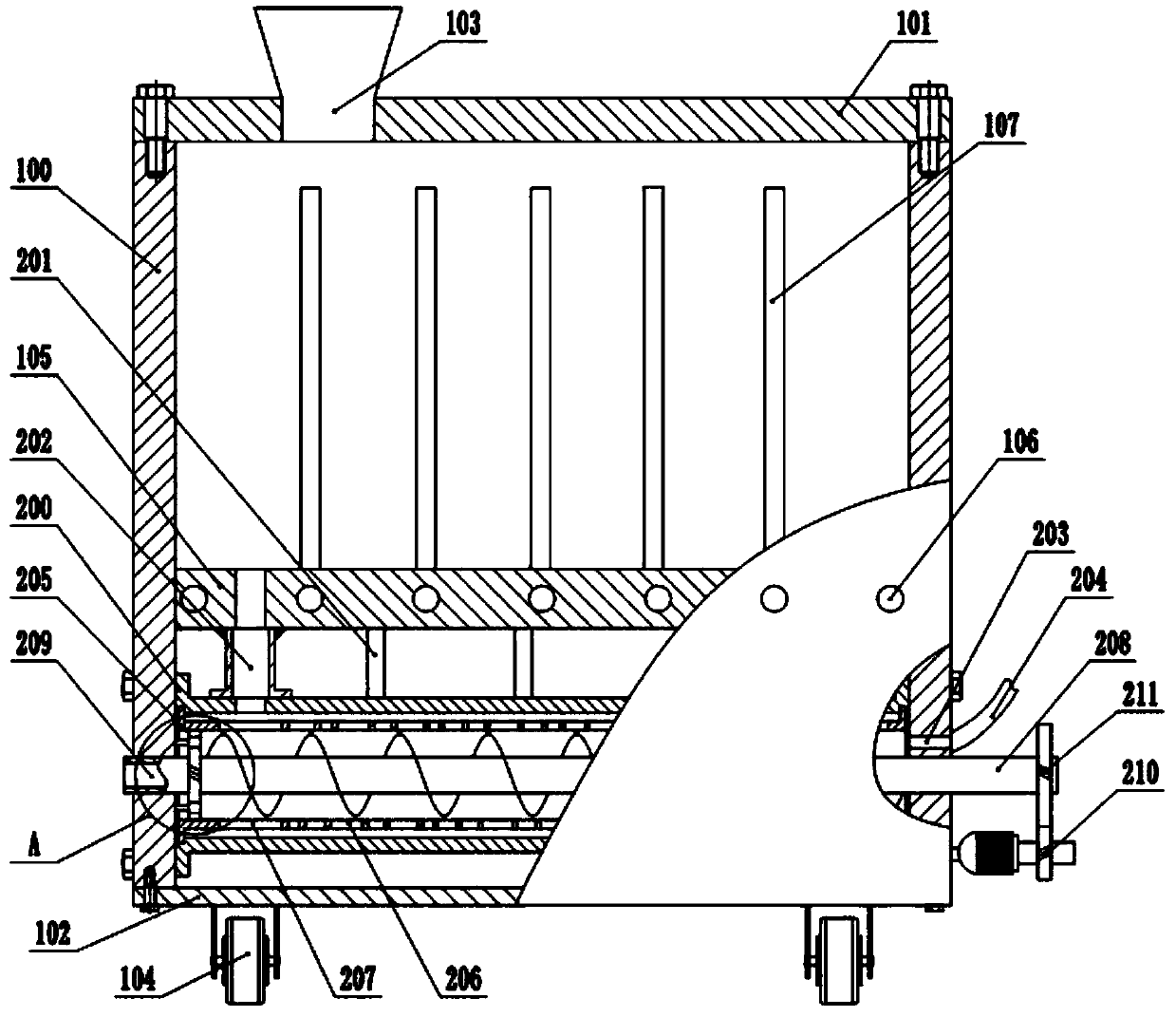

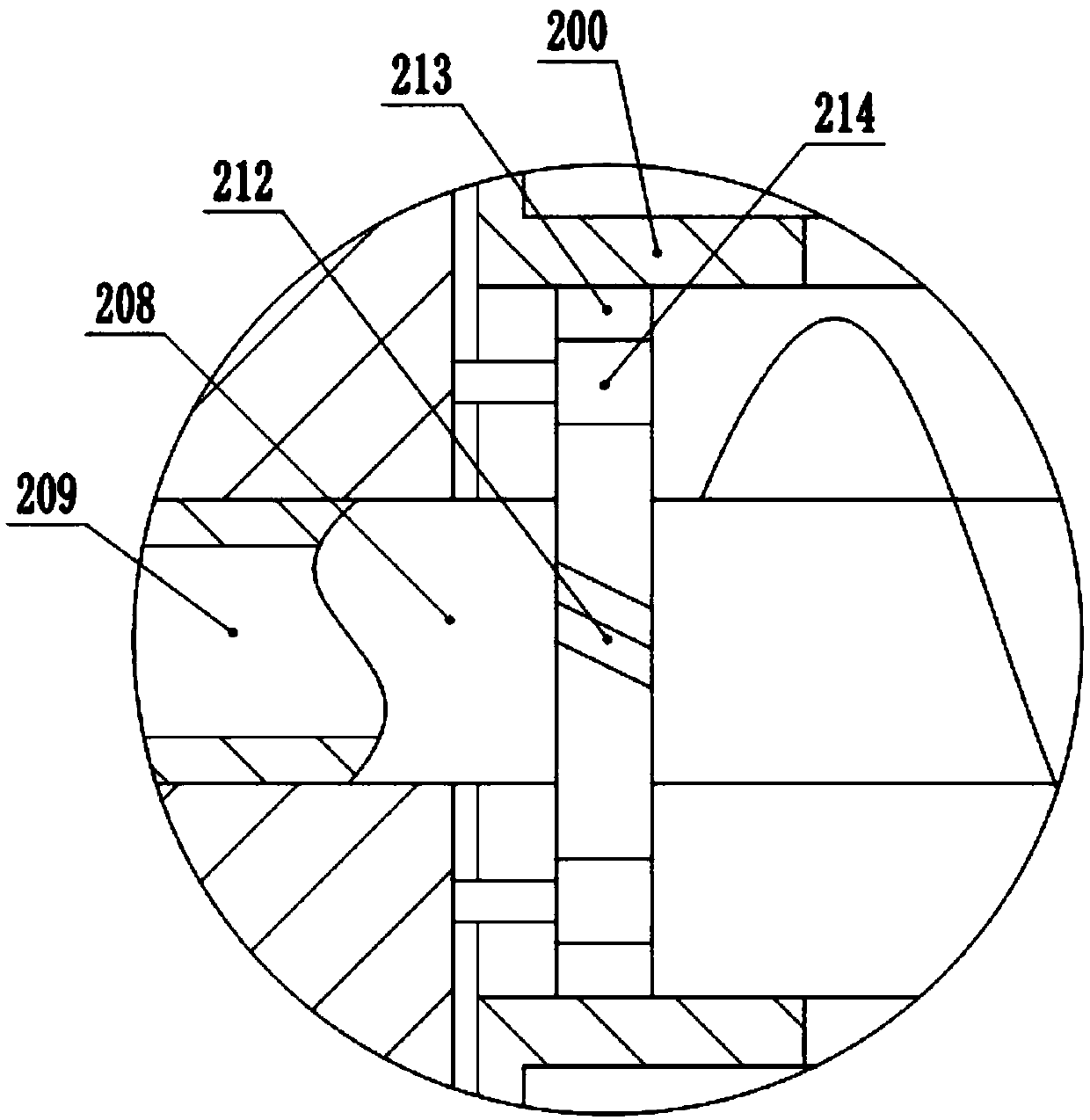

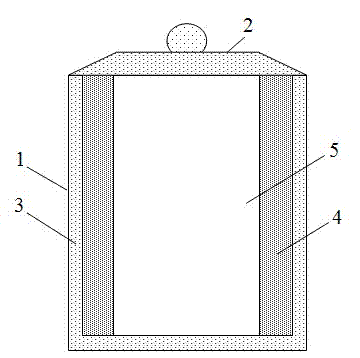

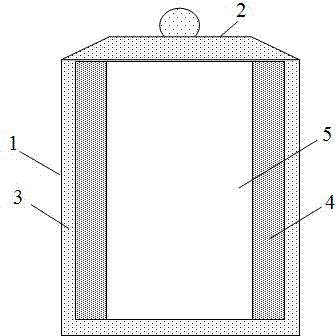

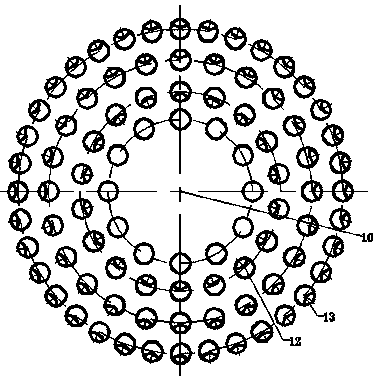

Automatic screw rod cleaning device

The invention discloses an automatic screw rod cleaning device, which comprises a cleaning frame, a heating ring and a rotating support frame, wherein the cleaning frame is used for installing and clamping a screw rod, and the heating ring is arranged on the cleaning frame through a rotating mechanism, when the screw rod is clamped and installed onto the cleaning frame, the heating ring is penetrated by the screw rod, and in addition, the heating ring covers the screw thread part of the whole screw rod. The heating ring in the automatic screw rod cleaning device covers the screw thread part of the whole screw rod, the circumference surface of the whole screw rod can be heated, the occurrence of a hardness reduction condition caused by local heating of the screw rod can be avoided, meanwhile, the surface of the screw rod can be fast heated, the melting time of attachment is shortened, and the work efficiency is greatly improved.

Owner:TIANJIN KINGFA NEW MATERIAL +1

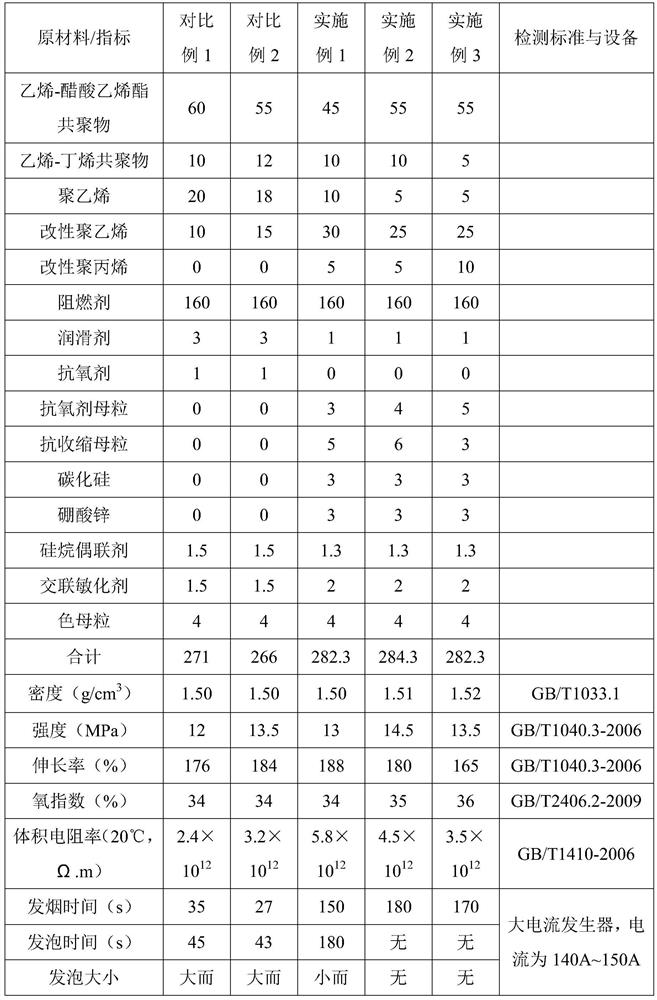

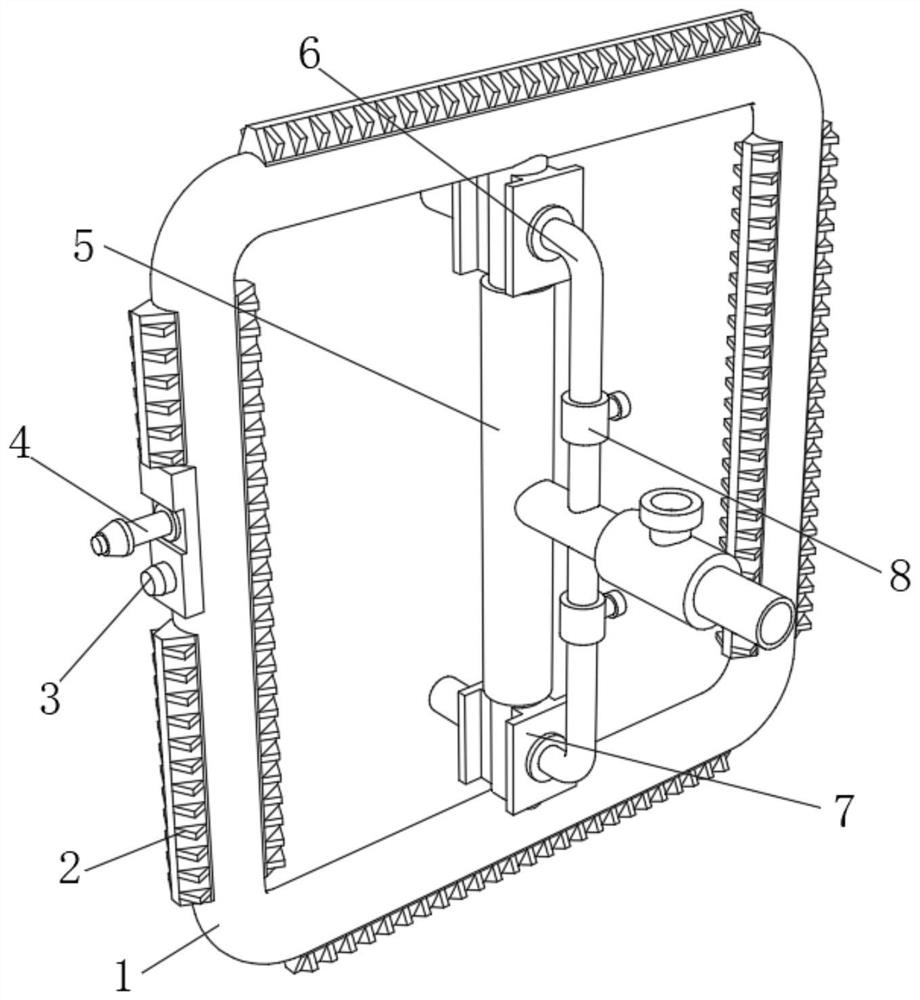

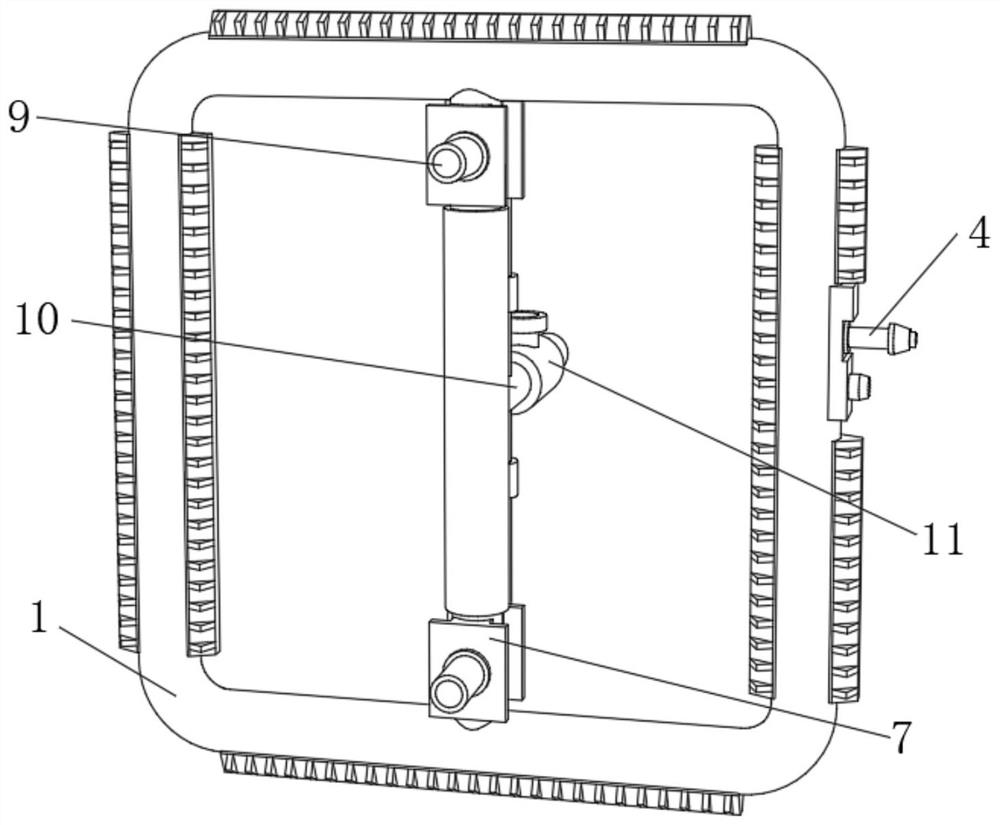

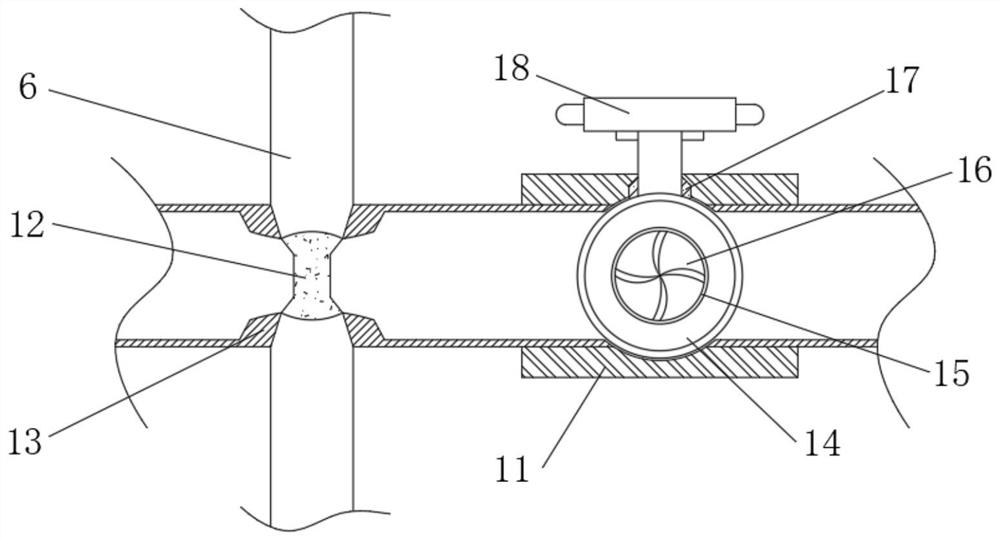

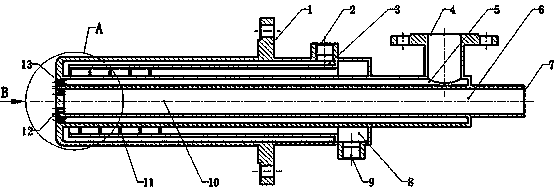

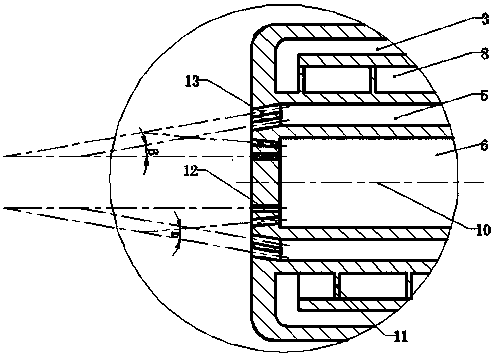

Water-cooled external mixing type pure oxygen gas burner for rotary iron-melting furnace

InactiveCN105240850AImprove cooling effectAvoid heat damageCombustion technology mitigationGaseous fuel burnerWater flowConvection heat

The invention belongs to the field of casting, and relates to pure oxygen gas burners, in particular to a pure oxygen gas burner for a rotary iron-melting furnace. The front end of the burner is provided with a plurality of gas spray orifices and oxygen spray orifices which are small in equivalent diameter. Meanwhile, line clusters formed by the center lines of the gas spray orifices and line clusters formed by the center lines of the oxygen spray orifices are made to intersect in space in front of the burner. By reducing the flame length, the power density of the pure oxygen gas rotary iron-melting furnace is increased, the melting efficiency of the rotary iron-melting furnace is improved, the melting time of the rotary iron-melting furnace is shortened, fuel is saved, and the production cost is reduced. A water inlet spiral flow channel blade is arranged in a water inlet cavity and a spiral flow channel is formed in a cooling water flow channel of the burner, so that the flow speed of cooling water is greatly increased, the convection heat exchange efficiency between the cooling water and the burner is improved, cooling of the cooling water to the burner is enhanced, and thermal damage to the burner caused by high-temperature flames after the flames of the burner are shortened is prevented.

Owner:殷黎丽 +1

Pug of firewood-fired Nixing pottery and process for manufacturing Nixing pottery from pug

InactiveCN106116511AExpanded firing temperature rangeAvoid burnsCeramic materials productionClaywaresFirewoodWoody plant

The invention provides pug of firewood-fired Nixing pottery and a process for manufacturing the Nixing pottery from the pug. The pug is prepared from, by weight, 5.5-6.8 parts of eastern mud, 1.3-2.0 parts of western mud, 1-1.5 parts of wood ash and 2-2.5 parts of kaolin. The process of for manufacturing the Nixing pottery from the pug comprises the steps of blank preparation, blank body forming, blank body drying and blank body firing; according to blank preparation, the eastern mud, the western mud, the wood ash and the kaolin with the formula amount are prepared into a blank through a conventional process; according to blank body burning, the blank body is fed into a wood-fired kiln, woody plants are adopted as fuel, the firing temperature ranges from 1,160 DEG C tot 1,180 DEG C, and after firing is completed, cooling and drawing are carried out. The kaolin and the wood ash are added into conventional Nixing pottery pug, so that the firing temperature range of the Nixing pottery is greatly widened; the melting temperature of ash of fuel wood can be reduced, the melting time of the ash can be shortened, and the fuel wood cost is greatly reduced.

Owner:钦州市壮冠坭兴陶材料开发有限公司

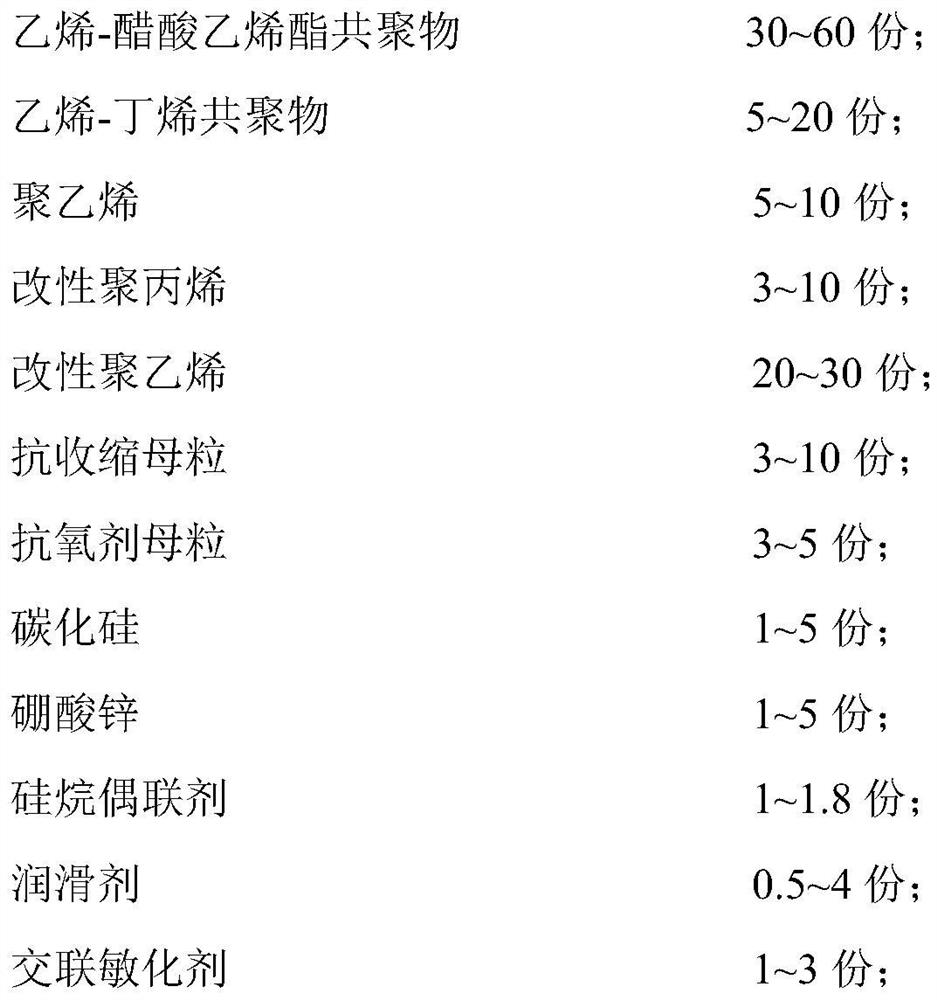

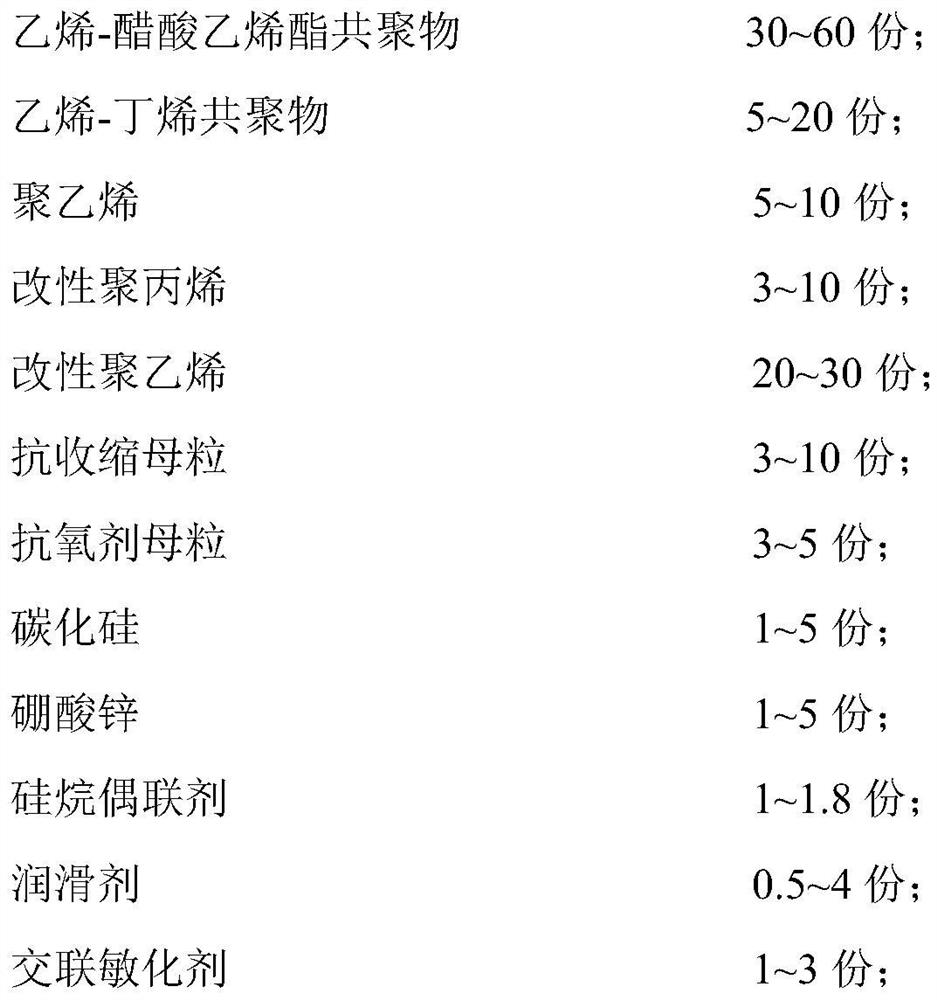

High-current-irradiation-resistant cross-linked low-smoke halogen-free flame-retardant polyolefin insulating material for cotton covered wire

InactiveCN111961278AExtended melting timeImprove flame retardant performancePlastic/resin/waxes insulatorsCarbide siliconPolymer science

The invention relates to a high-current-irradiation-resistant cross-linked low-smoke halogen-free flame-retardant polyolefin insulating material for cotton covered wires. The insulating material comprises the following components in parts by weight: 30-60 parts of an ethylene-vinyl acetate copolymer, 5 to 20 parts of an ethylene-butylene copolymer; 5-10 parts of polyethylene; 3-10 parts of modified polypropylene; 20 to 30 parts of modified polyethylene; 3 to 10 parts of anti-shrinkage master batch; 3-5 parts of antioxidant master batch; 1-5 parts of silicon carbide; 1-5 parts of zinc borate; 1to 1.8 parts of a silane coupling agent; 0.5 to 4 parts of a lubricant; and 1-3 parts of a cross-linking sensitizer. The irradiation cross-linked polyolefin insulating material is resistant to smoking, foaming and yellowing under the action of overload large current and is resistant to cracking, open fire combustion does not occur under the current condition of 100A-300A, the service life of an electric wire can be effectively prolonged when a short circuit occurs, and the risk of circuit fire is reduced.

Owner:中广核高新核材科技(苏州)有限公司 +1

Royal jelly and beeswax lozenge and preparation method thereof

InactiveCN106343463AImprove sour tasteExtended melting timeFood shapingFood ingredient as mouthfeel improving agentFreeze dryAdditive ingredient

Owner:SHANXI ACAD OF AGRI SCI GARDENING RES INST

Lemon 18K gold and manufacturing method thereof

The invention discloses lemon 18K gold and a manufacturing method thereof. The lemon 18K gold contains 75% of gold in mass percentage and 25% of repaired mouth in mass percentage; the repaired mouth comprises silver, copper, zinc and iridium powder; the ratio of the silver and the zinc to the copper in mass percentage is 1.2-1.3; the mass percentage of the zinc is 2.5-3.5%; and the mass percentage of the iridium powder is 0.004-0.012%. The manufacturing method comprises the steps of burdening, melting, refining and casting; in the refining process, mechanical disturbance is added; and a mouldis cast after being heated to 400-600DEG C. Through the invention, the problem that the traditional lemon 18K gold is bad in comprehensive mechanical property is solved.

Owner:新宝珠宝(深圳)有限公司

Asphalt melting device for highway engineering

The invention discloses an asphalt melting device for highway engineering, and belongs to the field of highway engineering. The asphalt melting device for highway engineering includes a crushing mechanism, a melting mechanism, a filtering mechanism and an insulation mechanism, a fixing clamping piece is fixedly connected to the side end of the crushing mechanism, and the crushing mechanism is connected to the upper end of the melting mechanism through the fixing clamping piece in a clamped mode; and the outer end of the melting mechanism is fixedly connected with an auxiliary motor unit, the auxiliary motor unit includes two pairs of auxiliary motors, a through hole matched with the auxiliary motor unit is formed in the side end of the melting mechanism, the power output ends of the auxiliary motors penetrate through the through hole and are fixedly connected with rotary heating spike assemblies, the two pairs of rotary heating spike assemblies are arranged in the melting area, and opposite rotation of the two adjacent pairs of rotary heating spike assemblies is used for making asphalt blocks mix evenly. On the one hand, the multiple crushing effect is further achieved, on the other hand, the melting time of the asphalt blocks in melting mechanism can be prolonged, and compared with original melting devices, the melting rate can be increased.

Owner:刘文伟 +6

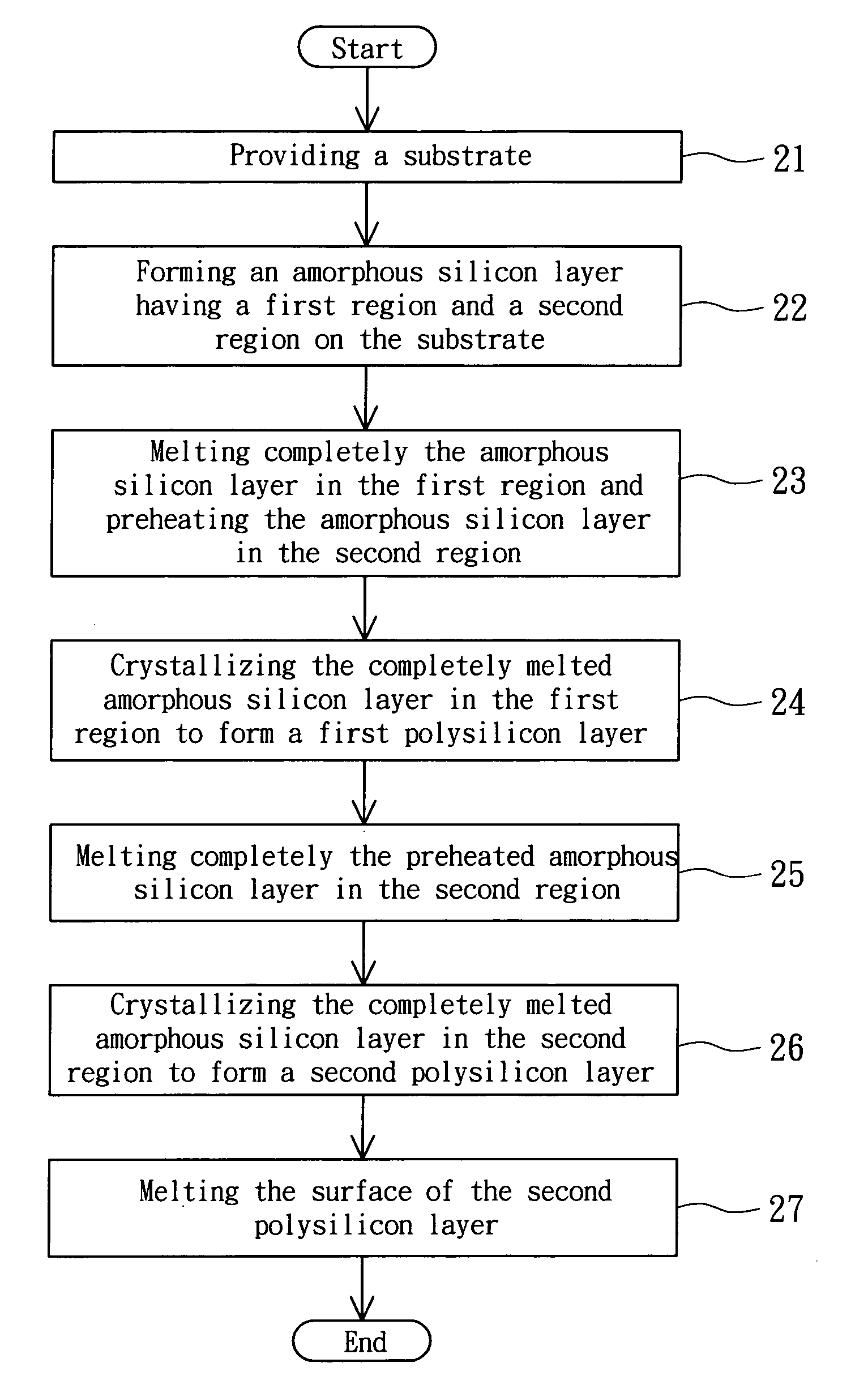

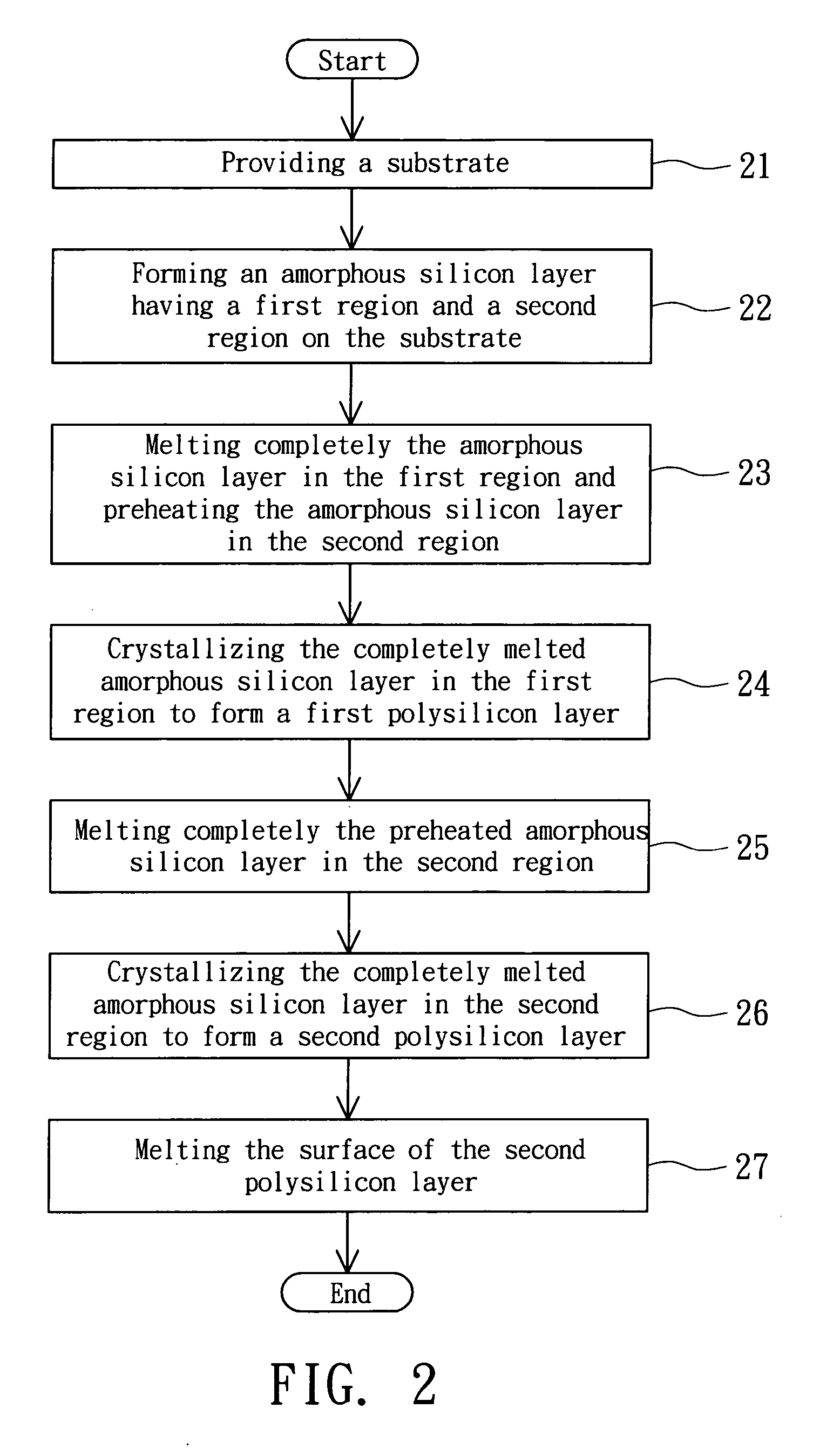

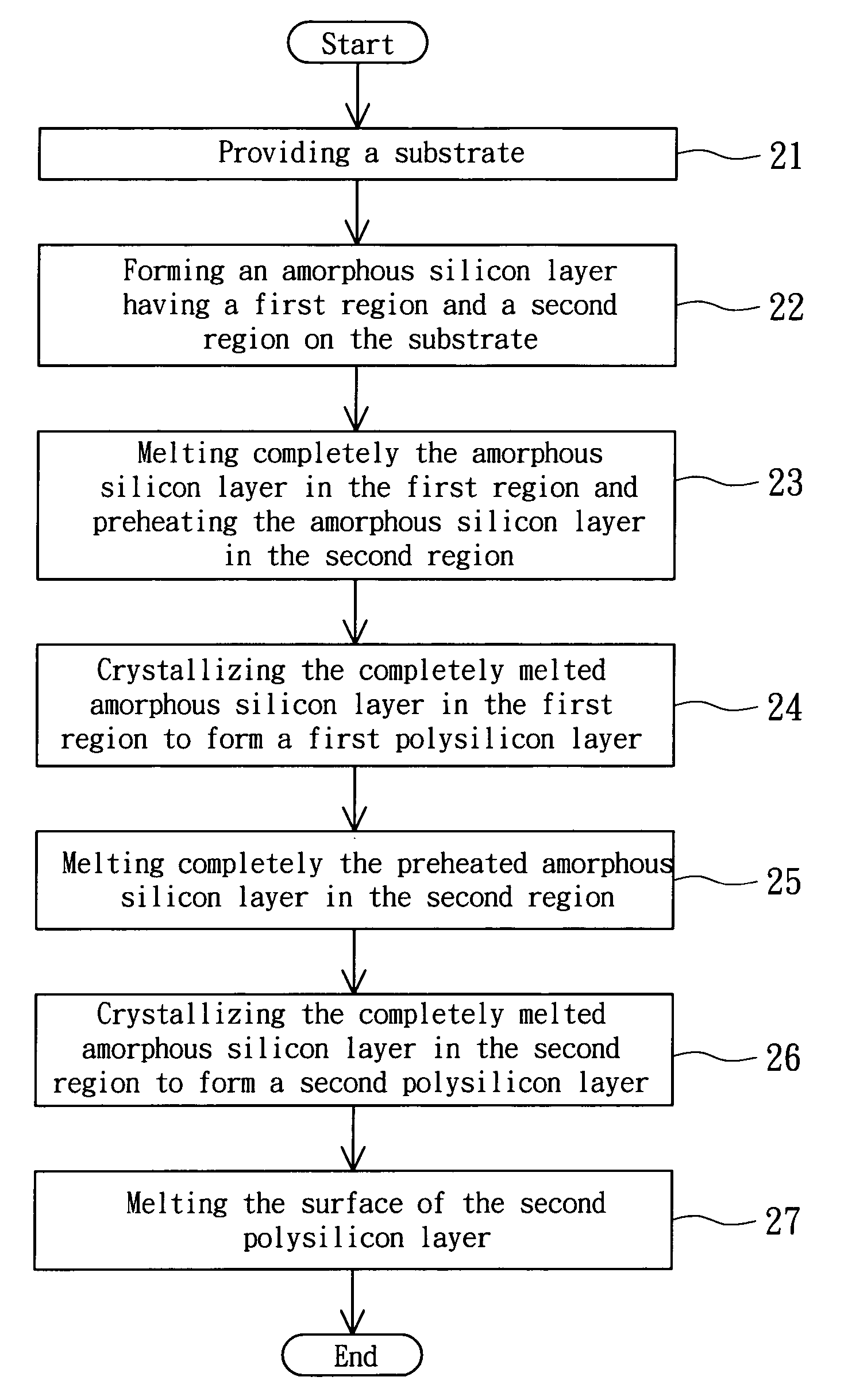

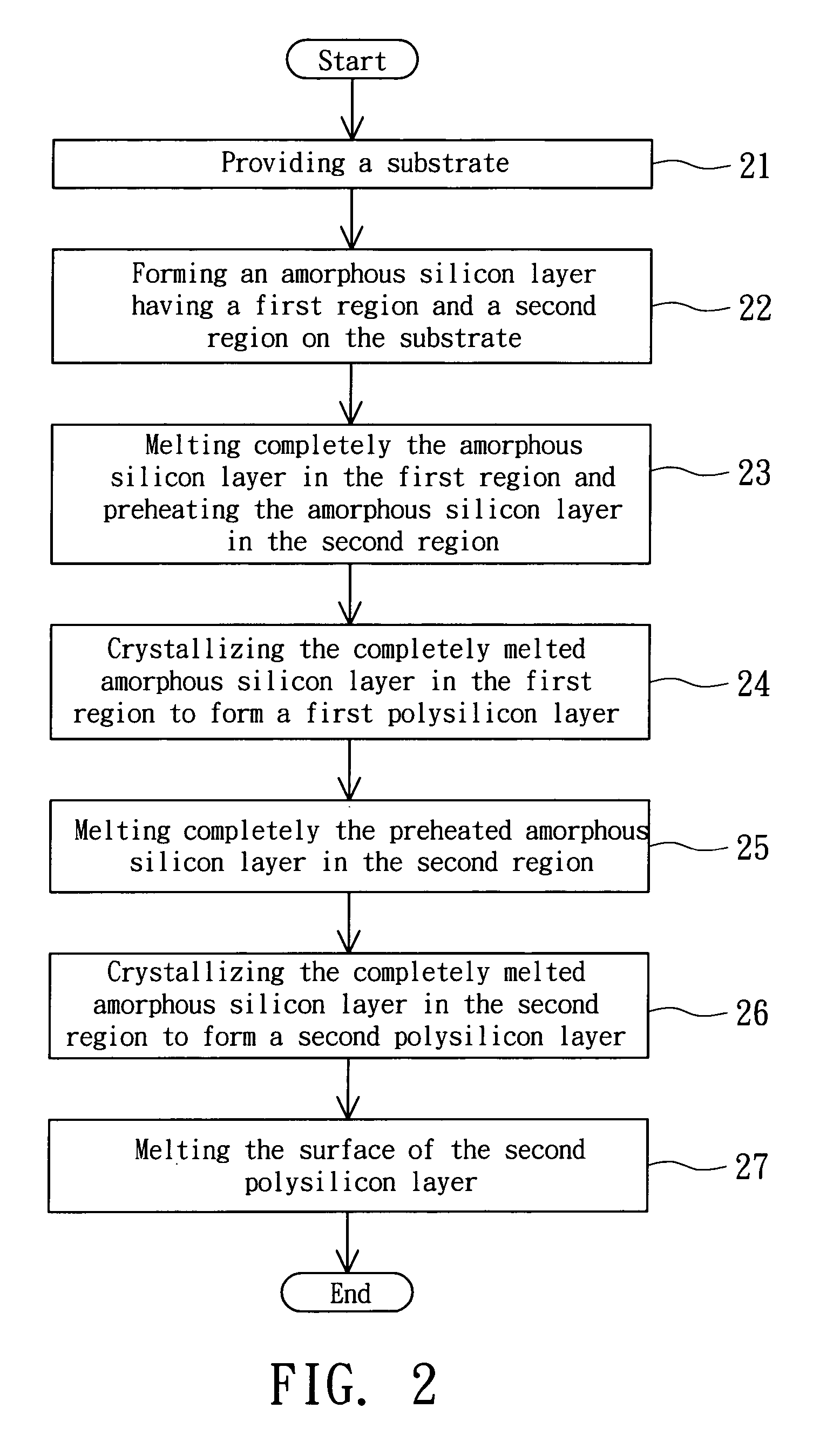

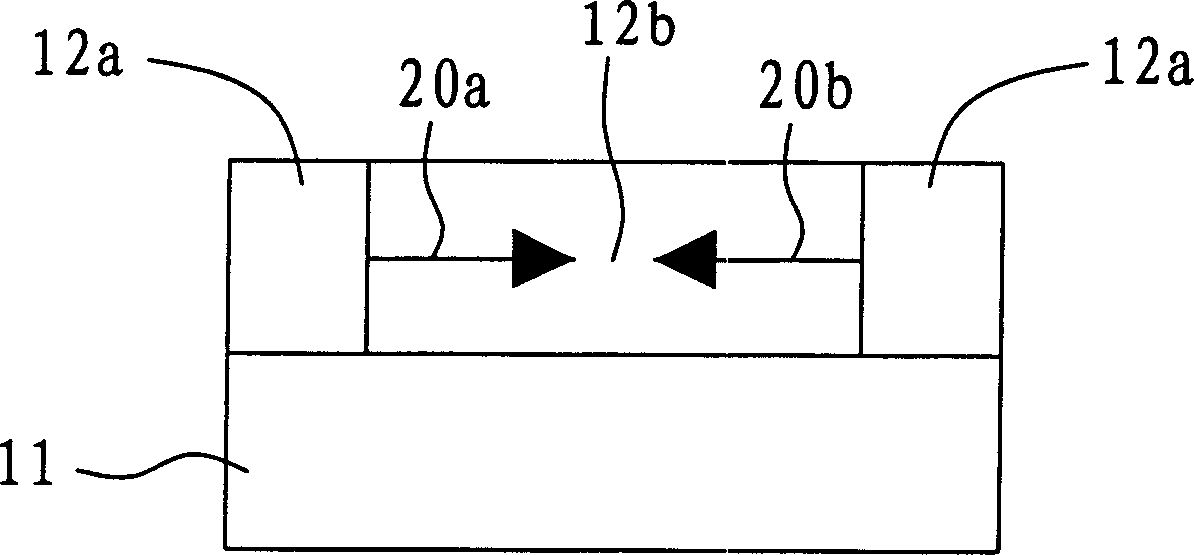

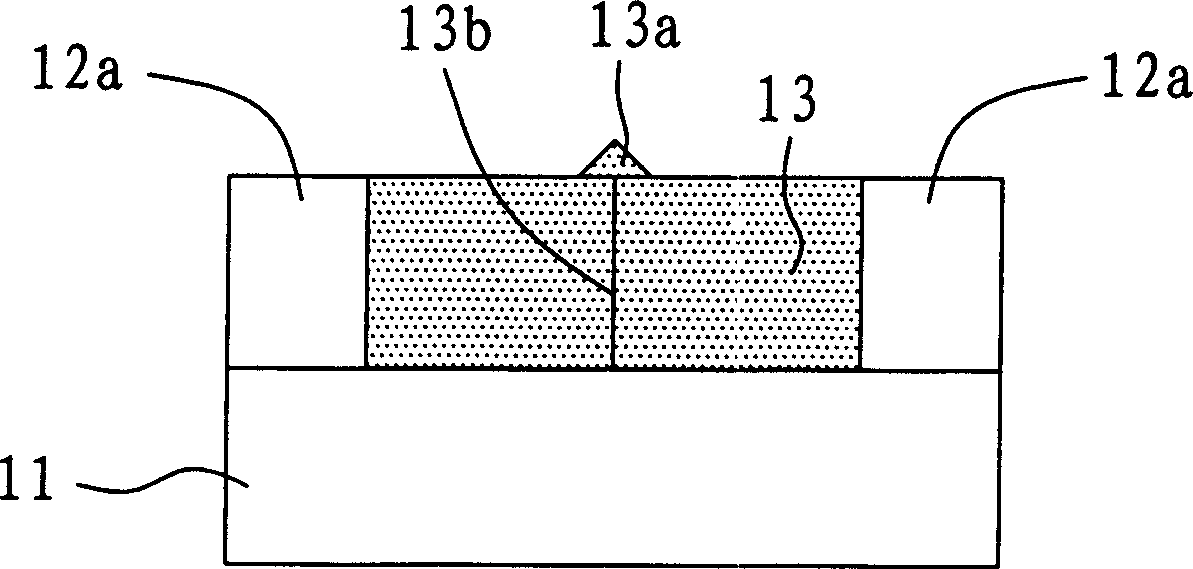

Method of manufacturing a polysilicon layer and a mask used therein

ActiveUS20060105551A1Reduce useIncrease utilization ratePolycrystalline material growthBy zone-melting liquidsOptoelectronicsPolycrystalline silicon

A method of manufacturing a polysilicon layer is provided. Firstly, a substrate is provided. Next, an amorphous silicon having a first region and a second region is formed on the substrate. After that, the amorphous silicon layer in the first region is completely melted and the amorphous silicon layer in the second region is preheated. The completely melted amorphous silicon layer in the first region is crystallized to form a first polysilicon layer. Next, the preheated amorphous silicon layer in the second region is completely melted. The completely melted amorphous silicon layer in the second region is crystallized to form a second polysilicon layer.

Owner:AU OPTRONICS CORP

Method of manufacturing a polysilicon layer and a mask used therein

ActiveUS7241650B2Reduce usageExtend the lifespanPolycrystalline material growthBy zone-melting liquidsAmorphous siliconOptoelectronics

A method of manufacturing a polysilicon layer is provided. Firstly, a substrate is provided. Next, an amorphous silicon having a first region and a second region is formed on the substrate. After that, the amorphous silicon layer in the first region is completely melted and the amorphous silicon layer in the second region is preheated. The completely melted amorphous silicon layer in the first region is crystallized to form a first polysilicon layer. Next, the preheated amorphous silicon layer in the second region is completely melted. The completely melted amorphous silicon layer in the second region is crystallized to form a second polysilicon layer.

Owner:AU OPTRONICS CORP

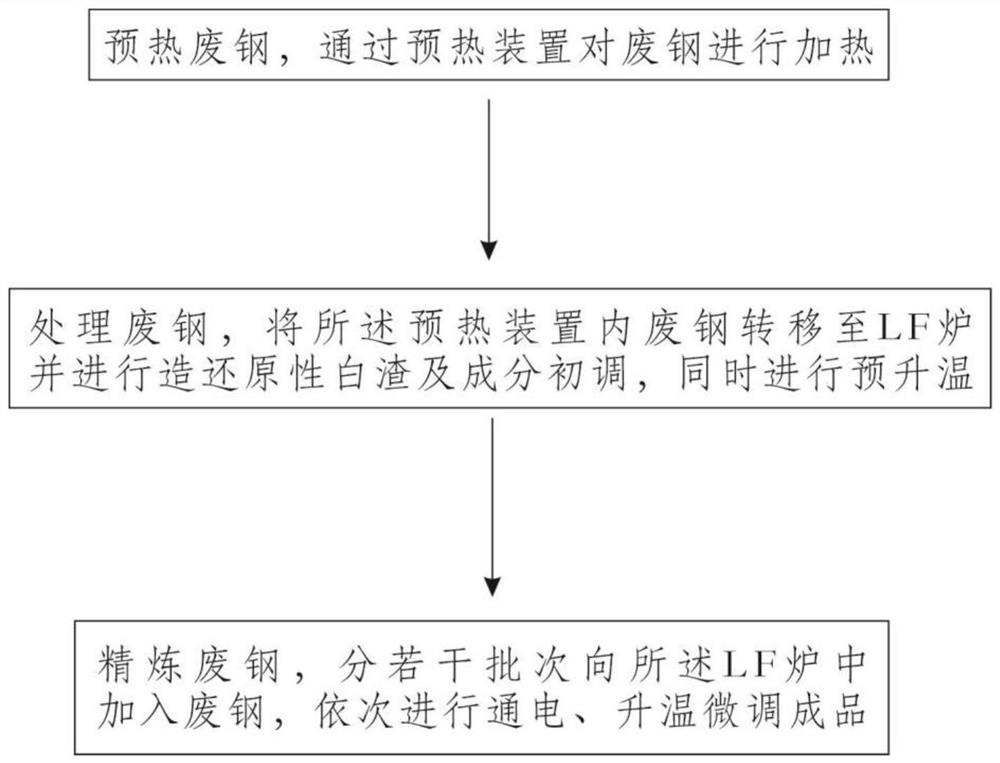

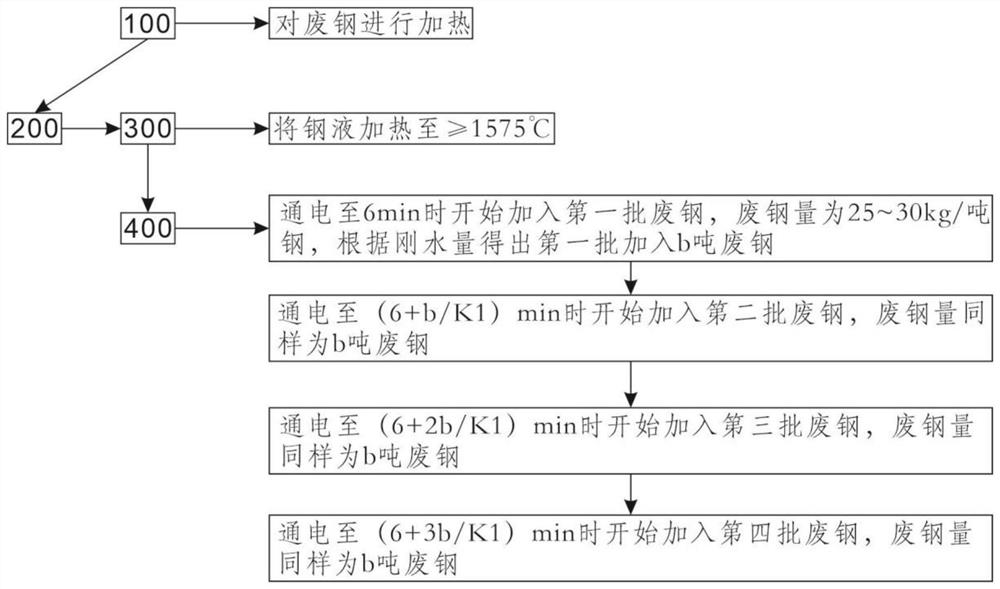

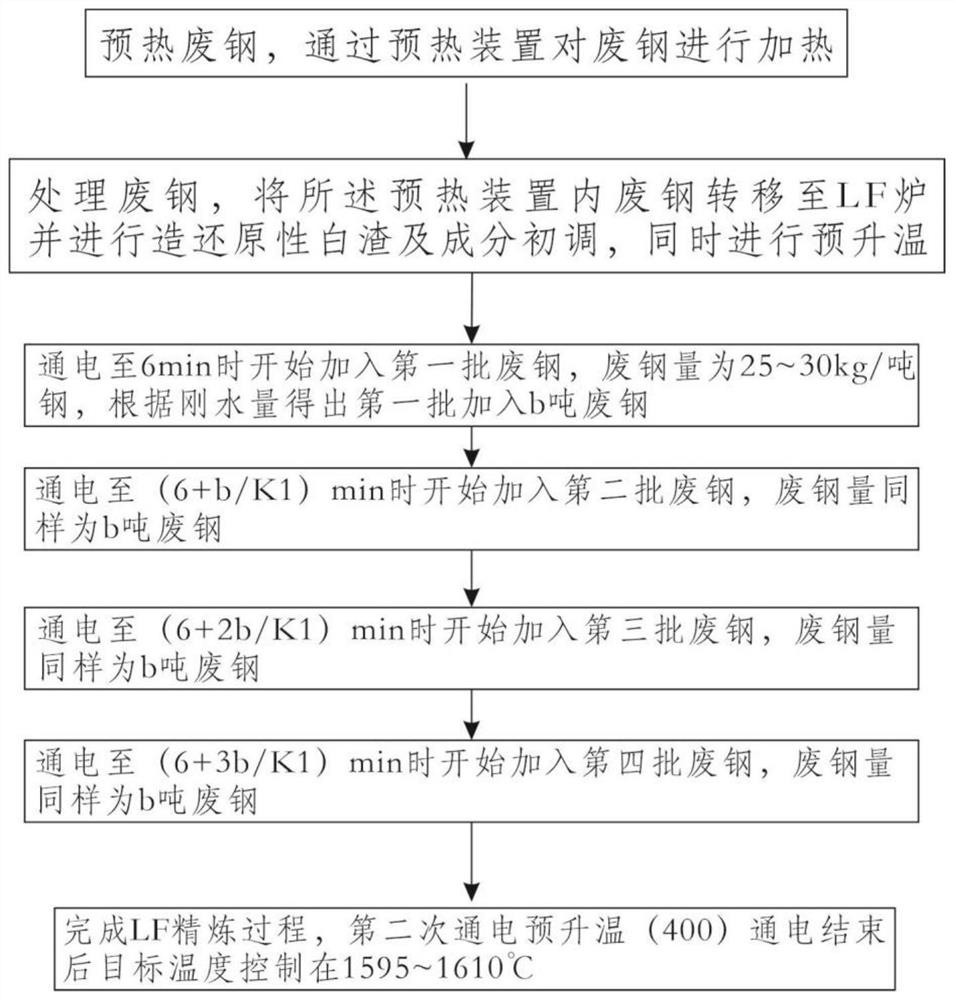

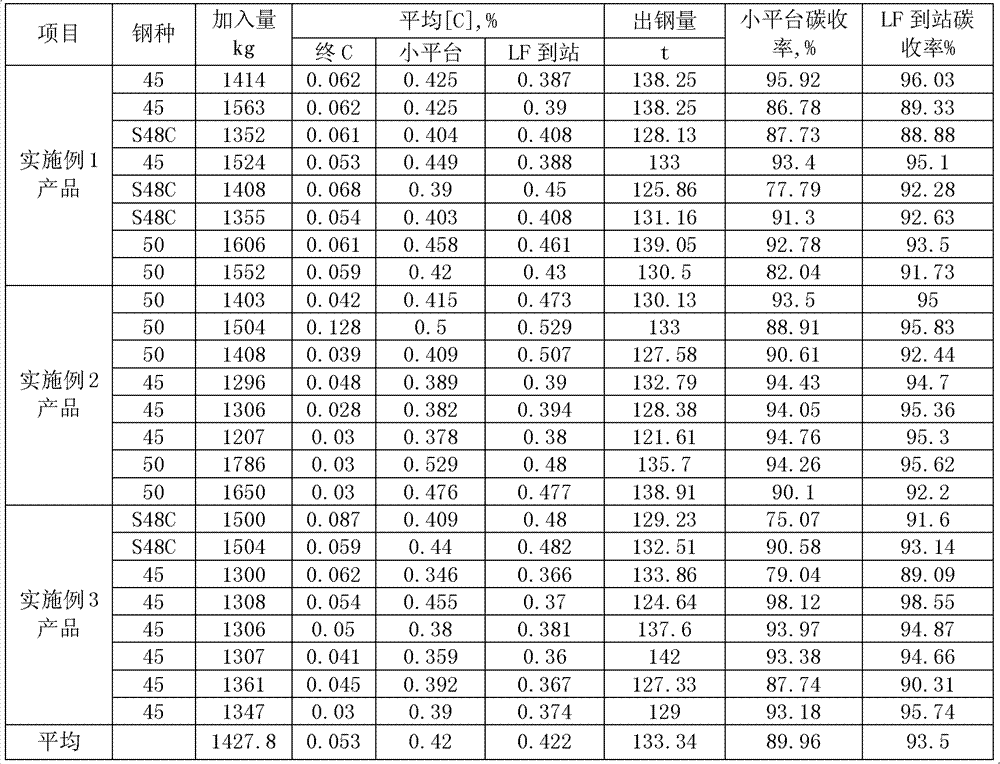

LF furnace refining method with high scrap ratio

The invention discloses an LF furnace refining method with a high scrap ratio, which comprises the following steps that scrap steel is preheated, and the scrap steel is heated through a preheating device; the scrap steel is treated, specifically, the scrap steel in the preheating device is transferred into an LF furnace, reducing white slag is manufactured, components are initially adjusted, and meanwhile preheating is conducted; and the scrap steel is refined, specifically, the scrap steel is added into the LF furnace in multiple batches, and electrifying, heating and fine adjustment of a finished product are conducted in sequence. According to the method, the adding amount of the LF refining scrap steel can reach 100-120 kg per ton of steel; only scrap steel melting and heating time is increased in the refining period, the refining period is increased by about 2 min when 1 ton of scrap steel is used, the scrap steel is added in the electrifying process, and extra stirring and melting time is not needed; top slag is made before the scrap steel is added, and the temperature of the molten steel is kept within the range of 1575-1610 DEG C in the scrap steel adding process, so that high-efficiency deep desulfurization can be realized, and the influence of high scrap steel ratio on the sulfur increasing amount of the molten steel is reduced; and the scrap steel is reasonably added in batches, so that the scrap steel can be quickly melted and uniformly mixed.

Owner:LIUZHOU IRON & STEEL

Method for preparing polycrystalline silicon layer and light shield

ActiveCN1614745AShorten the timeReduce energy useBy zone-melting liquidsSemiconductor/solid-state device manufacturingOptoelectronicsPolycrystalline silicon

The method includes following steps: firstly in base board, amorphous silicon has first amorphous silicon area and second amorphous silicon area; next a photomask is provided, the photomask consists of partly photo zone and photo zone; the partly photo zone and photo zone each relates to second amorphous silicon area and first amorphous silicon area. Laser is used to illuminate the photomask so that the first amorphous silicon area is entirely melted and the second amorphous is preheated; the melted first amorphous silicon area and the second preheated amorphous silicon are crystallized to form first polycrystalline silicon layer; the photomask and base board are moved to make the photo zone to correspond to the preheated second amorphous silicon area; laser is used to illuminate the photomask for making the preheated second amorphous silicon area to entirely melt so that the melted second amorphous silicon area will crystallize second polycrystalline silicon layer.

Owner:AU OPTRONICS CORP

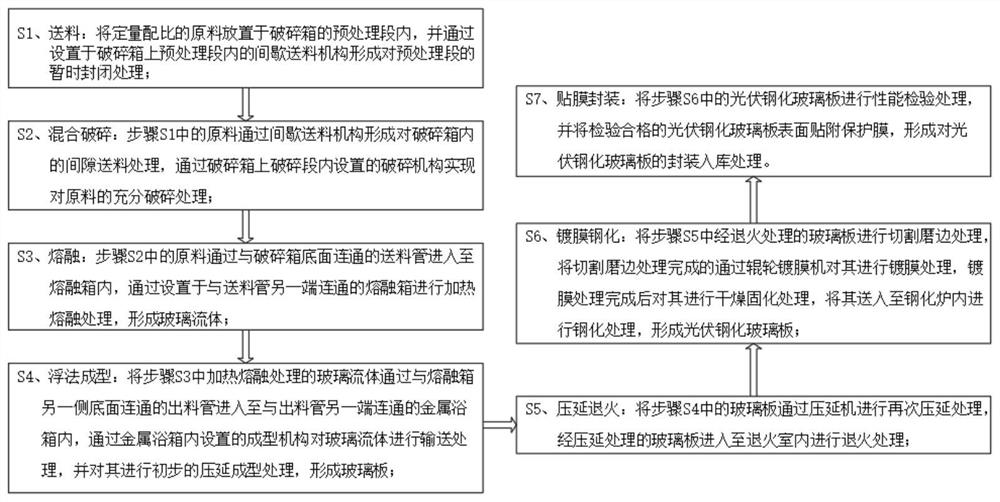

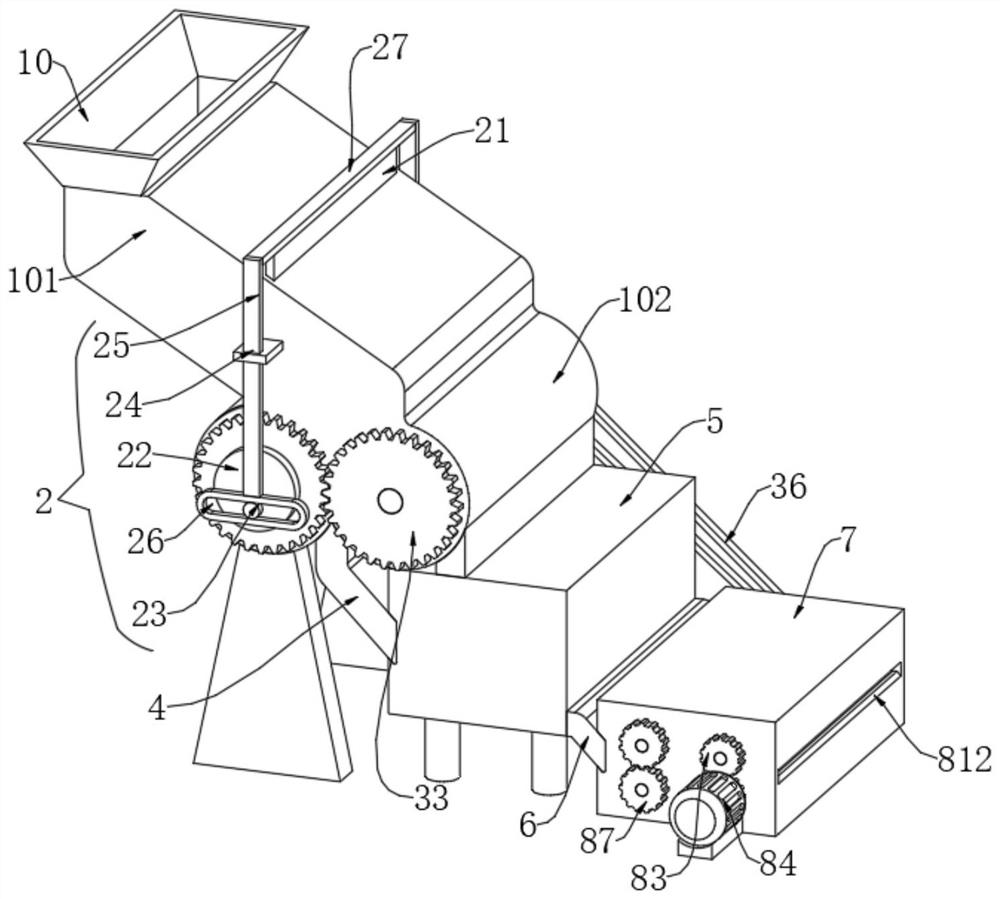

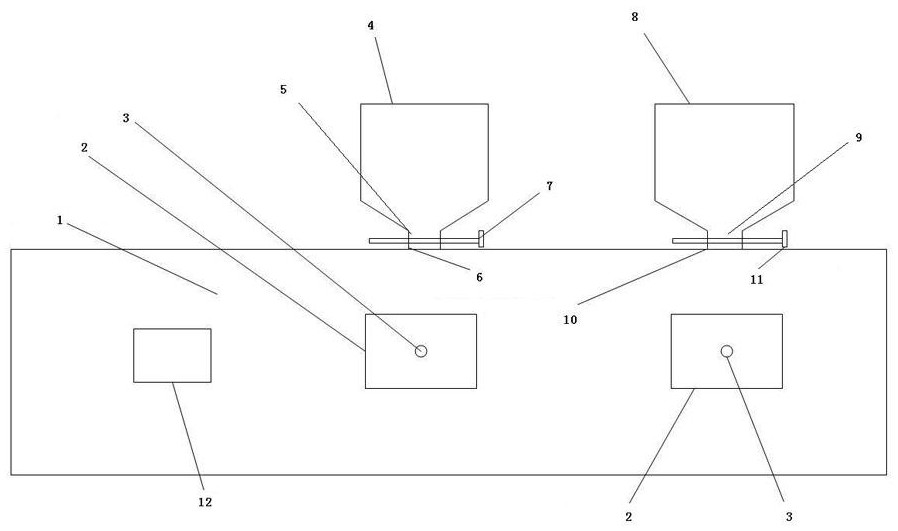

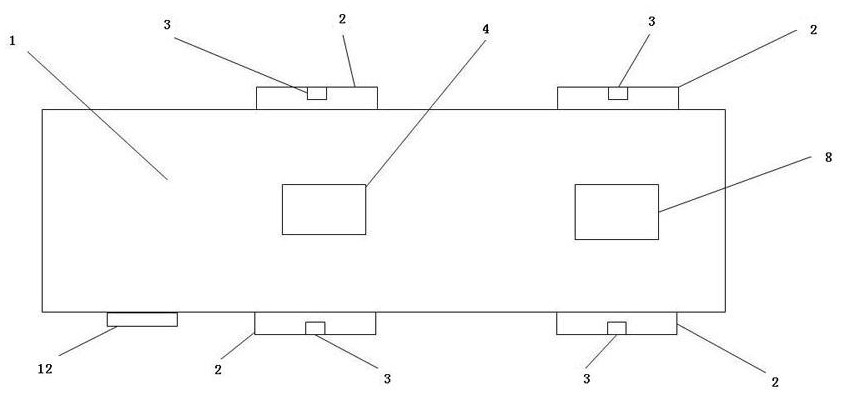

Photovoltaic glass production process

PendingCN114538755AImprove crushing effectIncrease melting timeEdge grinding machinesGlass rolling apparatusGlass productionCoating

The invention belongs to the technical field of photovoltaic glass processing, particularly relates to a photovoltaic glass production process, and aims to solve the problems of poor continuity during mixing, melting and calendaring treatment of photovoltaic glass during processing and poor thickness uniformity during calendaring treatment of an original sheet, and the following scheme is provided: the photovoltaic glass production process comprises the following steps: S1, feeding; s2, mixing and crushing; s3, melting is conducted; s4, float forming; s5, calendaring and annealing; s6, coating and tempering; s7, film pasting and packaging; according to the invention, intermittent feeding of raw materials is formed through the intermittent feeding mechanism, crushing treatment is carried out on the raw materials in cooperation with the crushing roller, and a melt subjected to melting treatment is carried out by the carrying plate, conveyed by the conveying roller, guided and calendered by the guide plate and calendered and conveyed by the calendering roller, so that the forming effect of the melt in the metal bath box is effectively improved; and the thickness of the melt during forming is greatly reduced, so that the calender can conveniently carry out uniform calendering treatment on the formed melt, and the calendering uniformity of the melt is greatly improved.

Owner:泰州索拉特特种玻璃有限公司

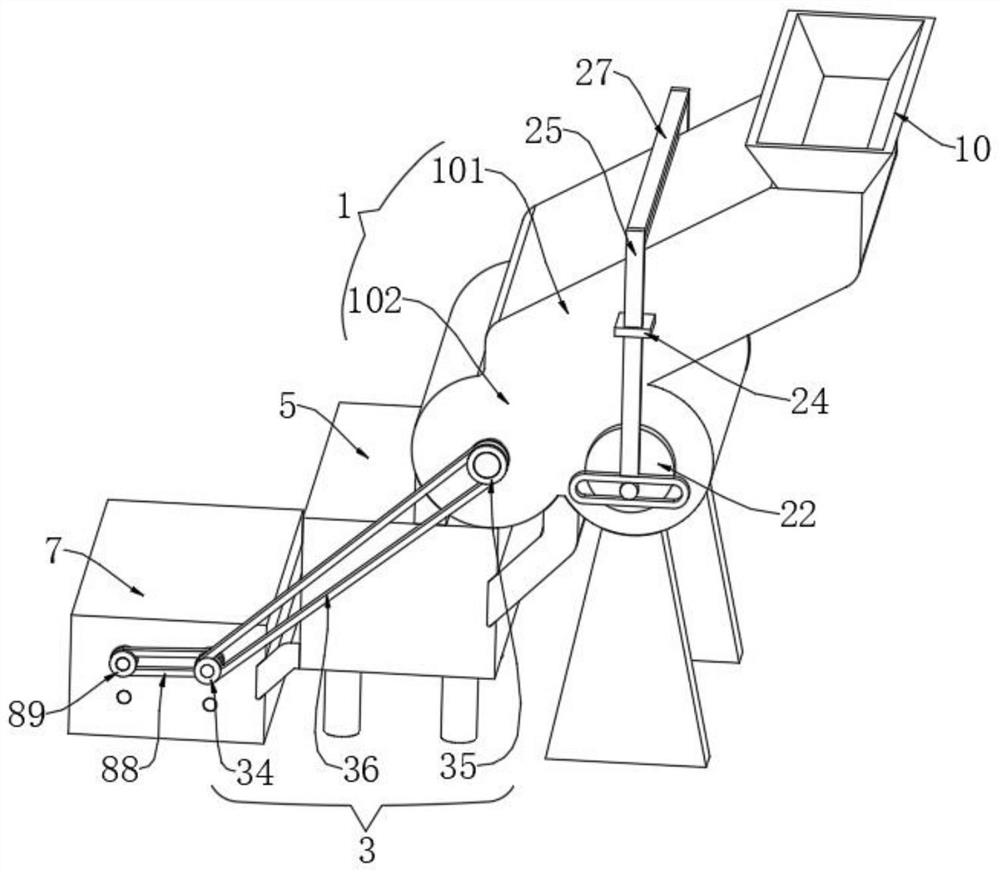

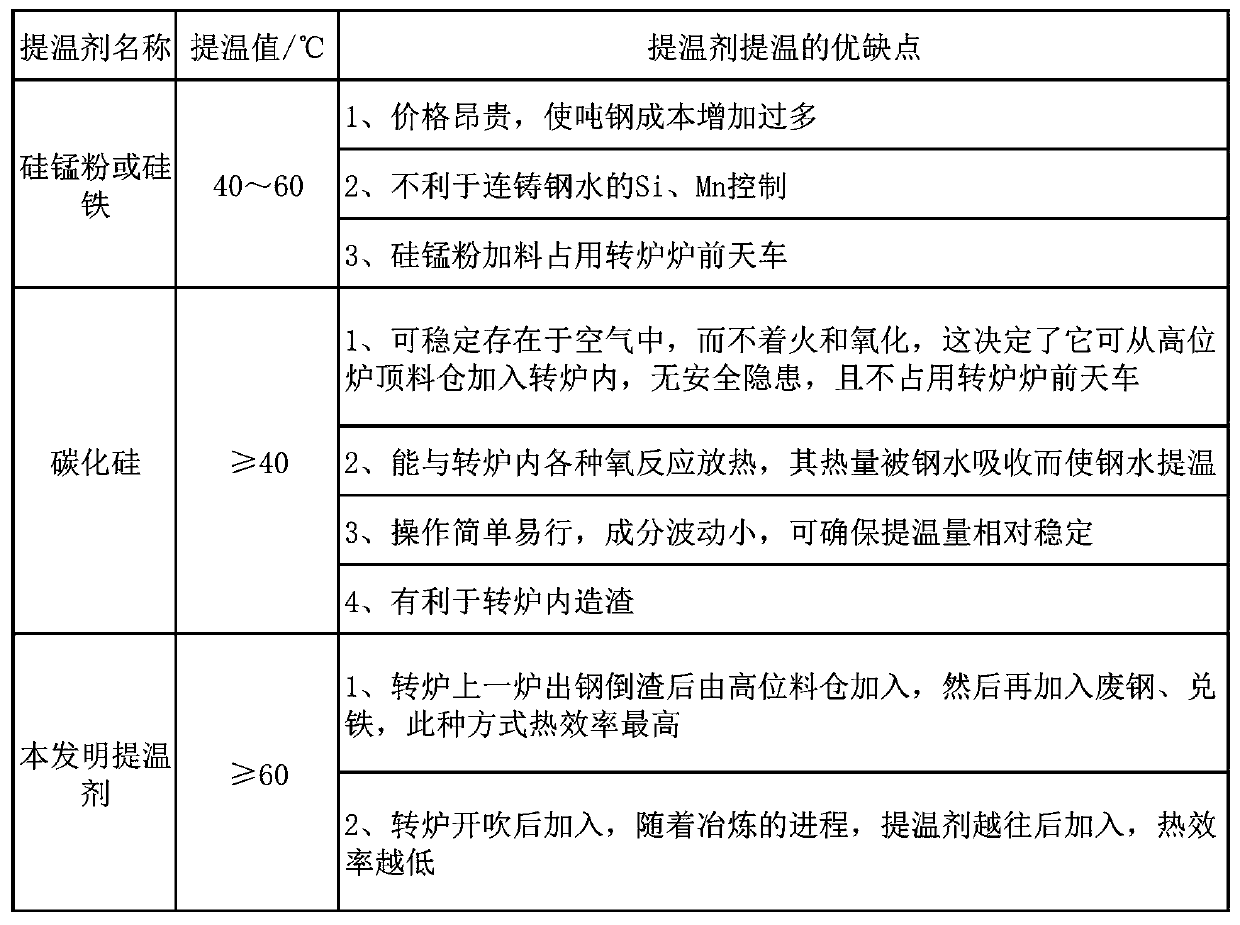

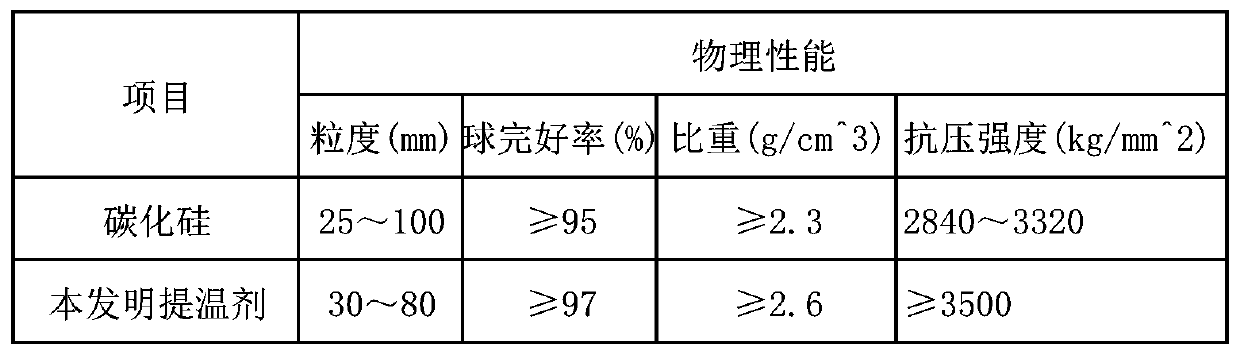

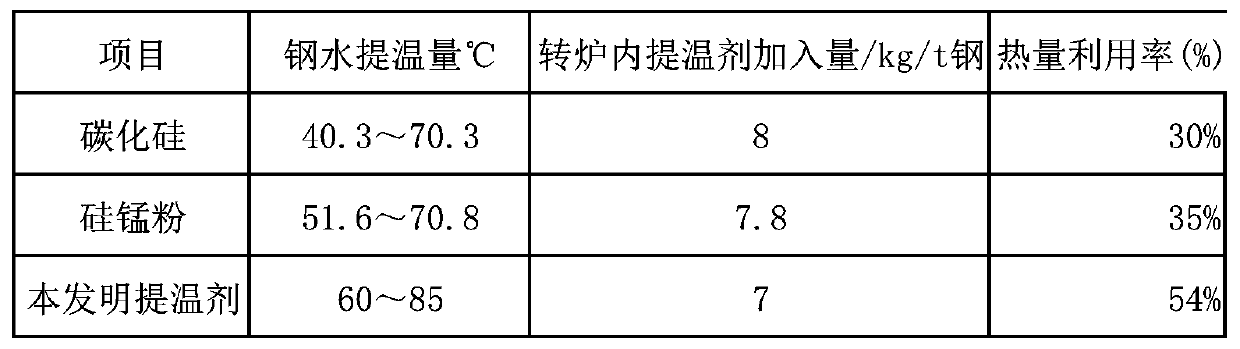

Slow-release high-efficiency carbon-based converter temperature-raising agent and preparation method thereof

The invention relates to the technical field of temperature-raising agents, in particular to a slow-release high-efficiency carbon-based converter temperature-raising agent and a preparation method thereof. The temperature-raising agent is mainly prepared from the following raw materials in parts by weight: 70 to 85 percent of pulverized coal, 10 to 20 percent of caustic-burned magnesia powder, 10to 15 percent of aluminum ash, and an adhesive necessary for forming the temperature-raising agent; the particle size of the temperature-raising agent is 30mm to 60mm; and the temperature-raising agent is in a spherical shape or an ellipsoidal shape. The temperature-raising agent provided by the invention is prepared through adding the caustic-burned magnesia powder, selecting the appropriate adhesive, and using a ball press machine, so that the strength of the temperature-raising agent is greatly improved, the compactness of the temperature-raising agent is improved, and the problem of pooreffect in use caused by low strength and density of an existing temperature-raising agent is solved; and according to the temperature-raising agent provided by the invention, through adding the caustic-burned magnesia powder, the corrosion speed of the temperature-raising agent in molten iron and semisteel is effectively delayed.

Owner:李付霞

Preparation method of high-purity low-hydroxyl quartz glass raw material

ActiveCN111393022AHigh purityLow hydroxylGlass furnace apparatusGlass shaping apparatusPhysical chemistryEconomic benefits

The invention relates to a preparation method of a high-purity low-hydroxyl quartz glass raw material, and the method comprises the following steps: by using high-purity quartz sand melted quartz glass or recovered quartz glass products as an initial raw material, carrying out dehydroxylation treatment on the initial raw material in a high-temperature high-vacuum environment after sand making to finally obtain the high-purity low-hydroxyl quartz glass raw material. The prepared quartz glass raw material sand powder has the characteristics of high purity, high transparency, low hydroxyl and nobubbles, can greatly improve the percent of pass of quartz glass products, reduces the production cost of enterprises, and improves the economic benefits of the enterprises.

Owner:HUANGGANG NORMAL UNIV +1

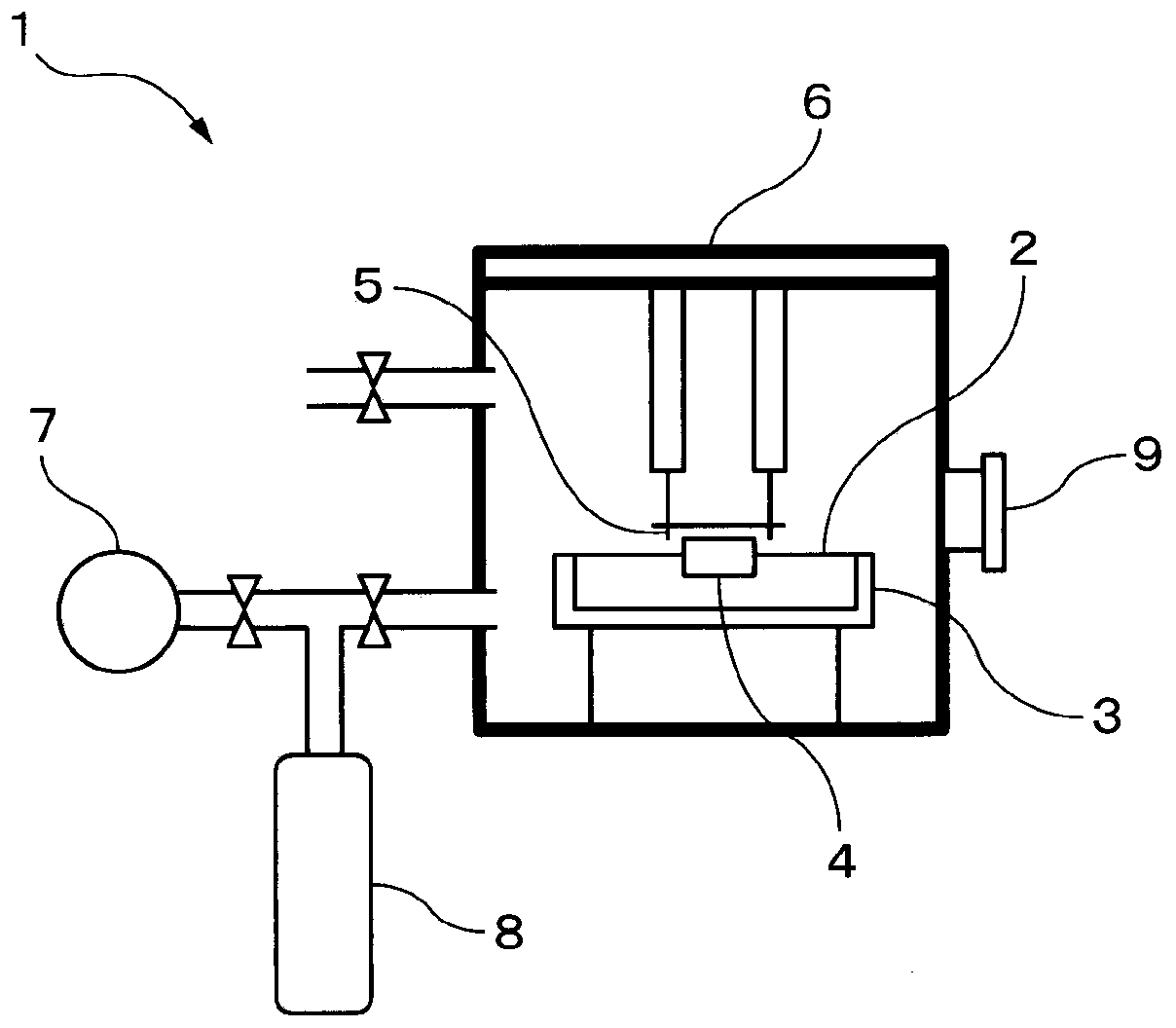

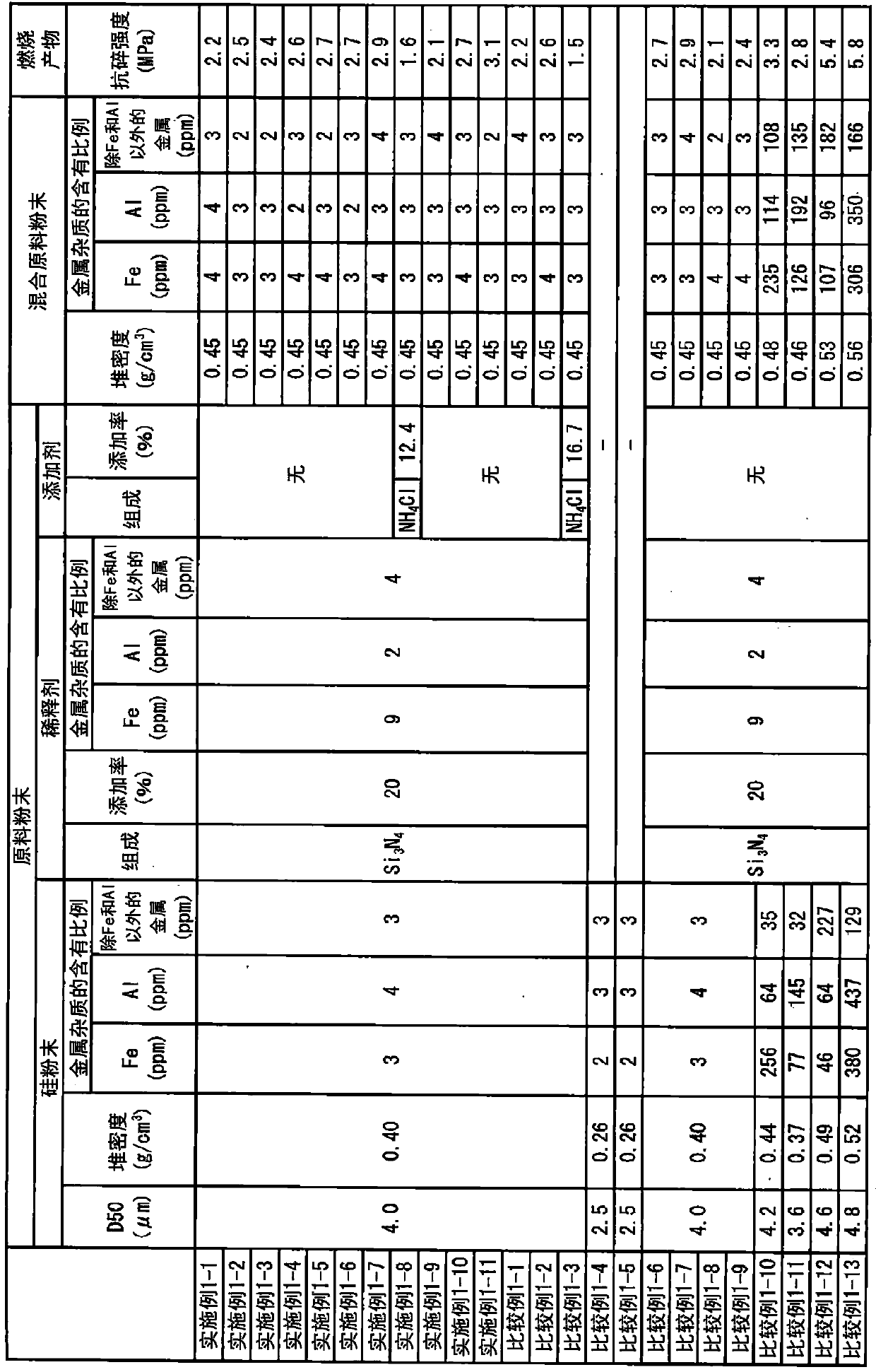

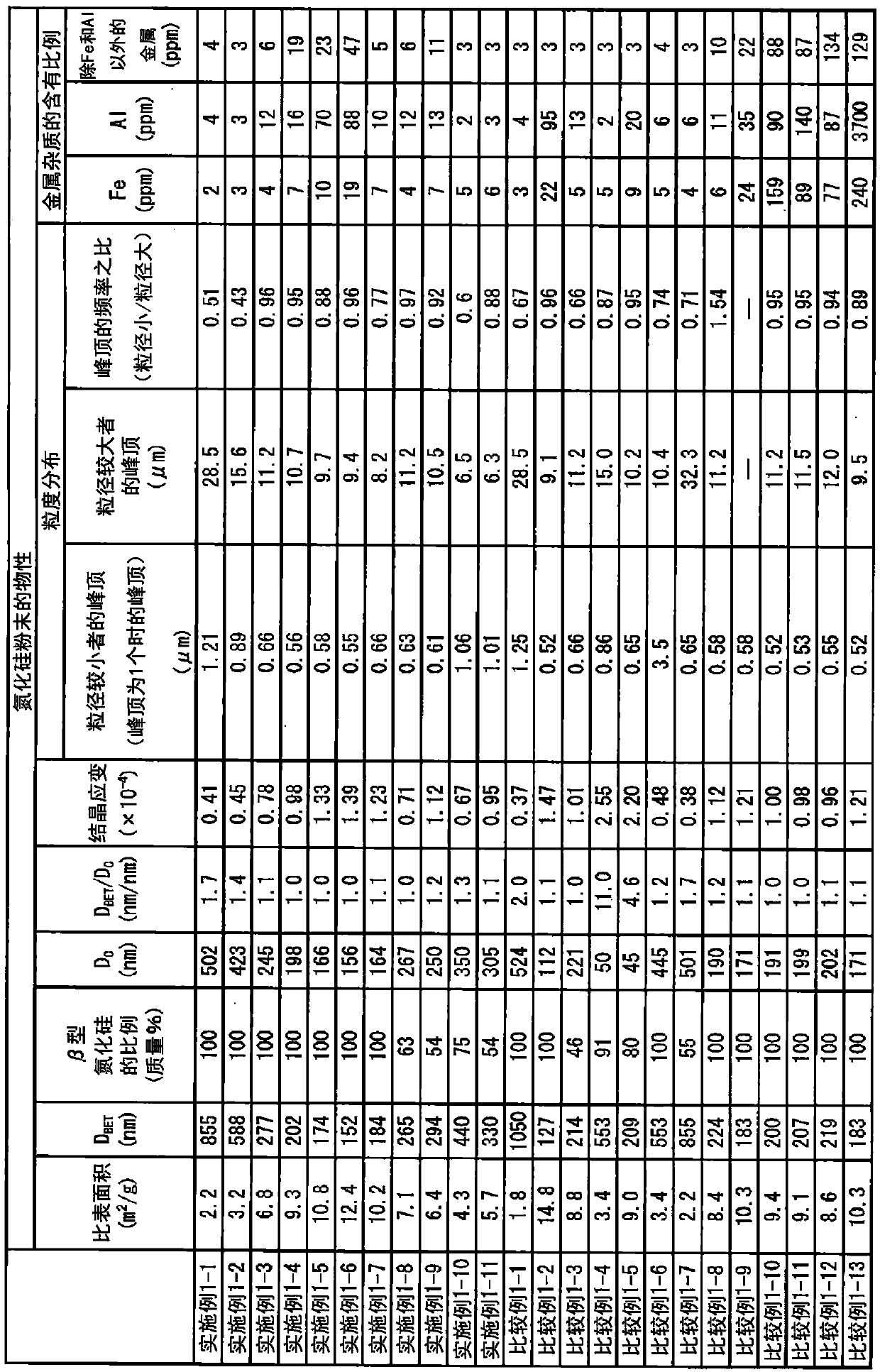

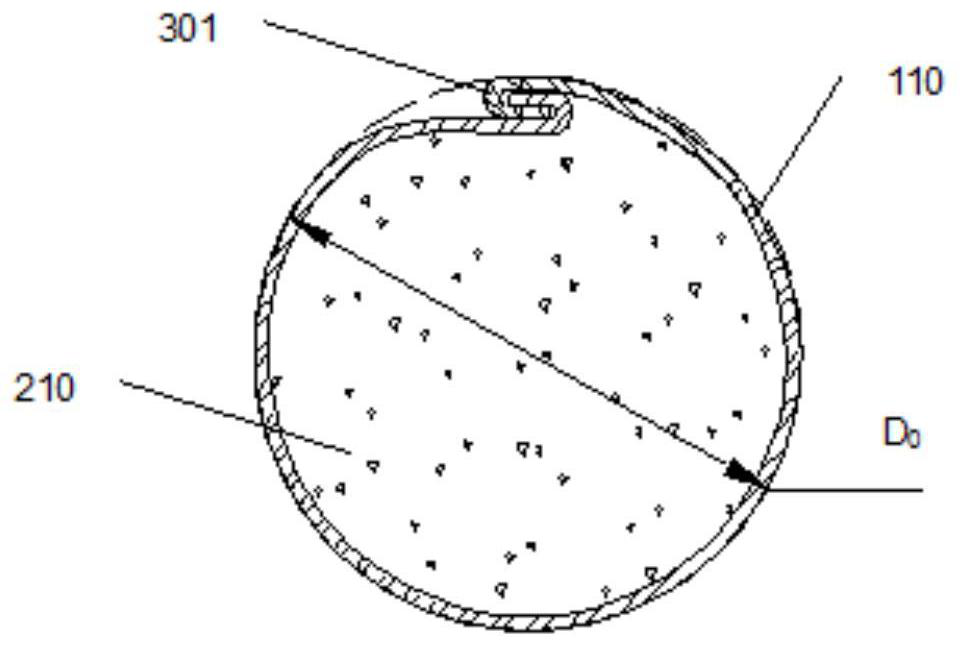

Silicon nitride powder, mold release agent for polycrystalline silicon ingots, and method for producing polycrystalline silicon ingots

InactiveCN110049946AExtended melting timeGood release effectNitrogen compoundsSiliconIngotMelting temperature

The purpose of the present invention is to provide a silicon nitride powder that can be advantageously used as a mold release agent for polycrystalline silicon ingots and that exhibits an excellent mold releasability for polycrystalline silicon ingots even when, during unidirectional solidification, the melting temperature of the silicon is increased or the melting time for the silicon is lengthened. The silicon nitride powder is characterized by having a specific surface area of 2 m2 / g to 13 m2 / g, a [beta]-silicon nitride percentage of at least 50 mass%, a [beta]-silicon nitride crystallite diameter DC of at least 150 nm, and a ratio between the specific surface area-equivalent diameter DBET and DC, i.e., DBET / DC (nm / nm), of not more than 3, and having two peaks in the frequency distribution curve yielded by measurement of the particle size distribution, wherein the peak tops of these peaks are in the range from 0.5 to 2 [mum and in the range from 6 to 30 [mu]m and the ratio of the frequencies for these peak tops is 0.1 to 1.

Owner:UBE IND LTD

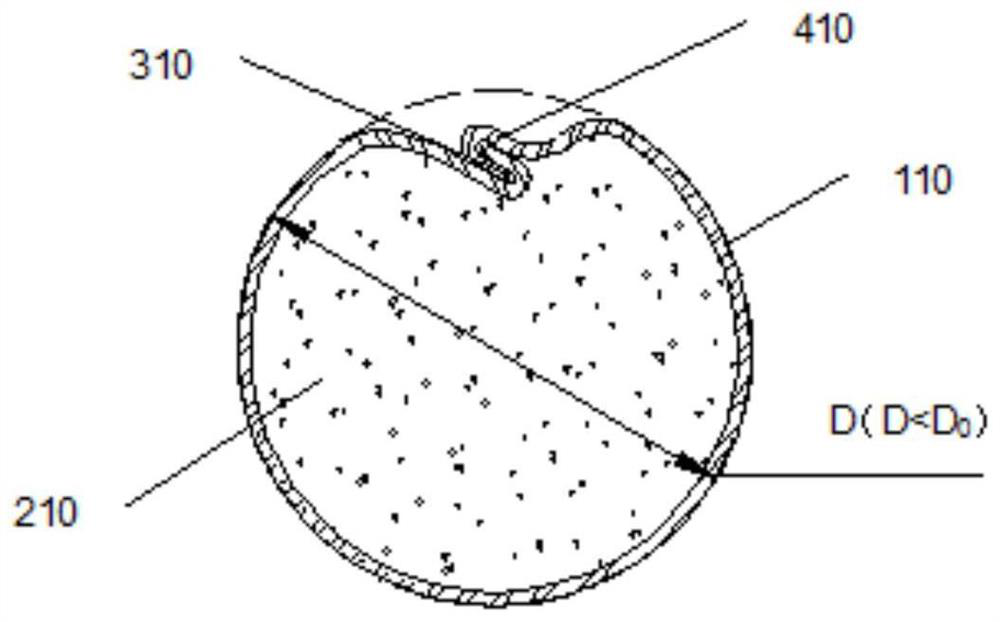

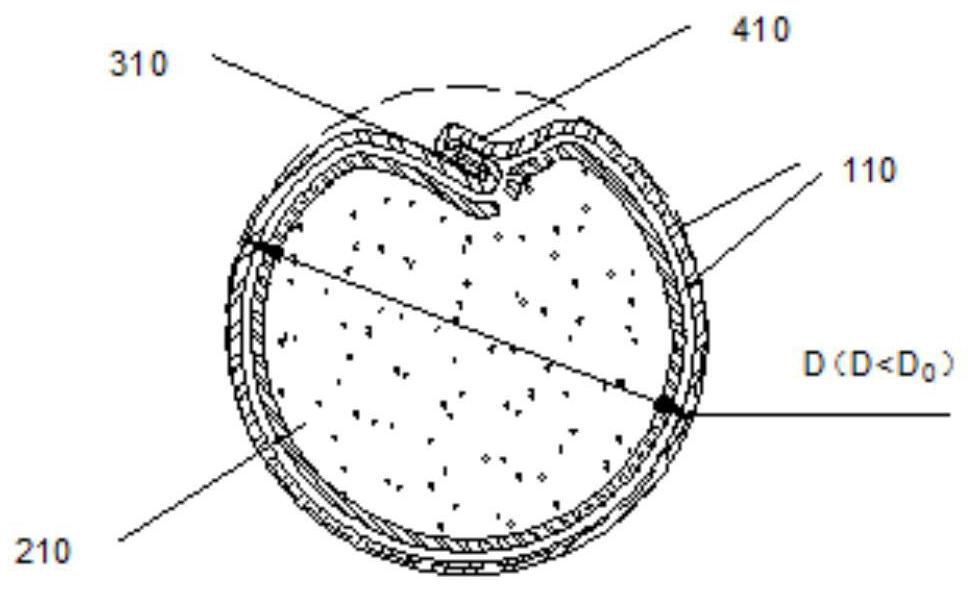

Core-spun yarn product for conducting bulk material wire feeding treatment on molten steel and processing method of core-spun yarn product

The invention discloses a core-spun yarn product for conducting bulk material wire feeding treatment on molten steel and a processing method of the core-spun yarn, and belongs to the technical field of metallurgy. According to the core-spun yarn product and the processing method thereof, when the product is processed, a tubular container steel shell which is subjected to loading and sealing of bulk inner core materials is locally and continuously extruded in the axial direction, and the sunken steel shell cross section formed in the extruded part is subjected to diameter reducing rounding, so that the cross section of the product is reduced due to the fact that the product is provided with a local notch, the internal material filling compactness is high, the contact density with the shell is large, and the internal gas content is low. By adopting the technical scheme of the core-spun yarn product, the sealing time of the shell can be prolonged, rapid evaporation of gas is effectively inhibited, and evaporation and oxidation loss of magnesium or / and calcium are reduced, so that the yield of alloying or inclusion modification treatment elements in steel when a wire feeding process is adopted is improved and stabilized, meanwhile, the pollution to the molten steel and the harm to the field environment during wire feeding (especially magnesium or / and calcium treatment) are reduced.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL +1

Method for preparing polycrystalline silicon layer and light shield

ActiveCN100394548CShorten the timeReduce energy useBy zone-melting liquidsSemiconductor/solid-state device manufacturingAmorphous siliconOptoelectronics

The method includes following steps: firstly in base board, amorphous silicon has first amorphous silicon area and second amorphous silicon area; next a photomask is provided, the photomask consists of partly photo zone and photo zone; the partly photo zone and photo zone each relates to second amorphous silicon area and first amorphous silicon area. Laser is used to illuminate the photomask so that the first amorphous silicon area is entirely melted and the second amorphous is preheated; the melted first amorphous silicon area and the second preheated amorphous silicon are crystallized to form first polycrystalline silicon layer; the photomask and base board are moved to make the photo zone to correspond to the preheated second amorphous silicon area; laser is used to illuminate the photomask for making the preheated second amorphous silicon area to entirely melt so that the melted second amorphous silicon area will crystallize second polycrystalline silicon layer.

Owner:AU OPTRONICS CORP

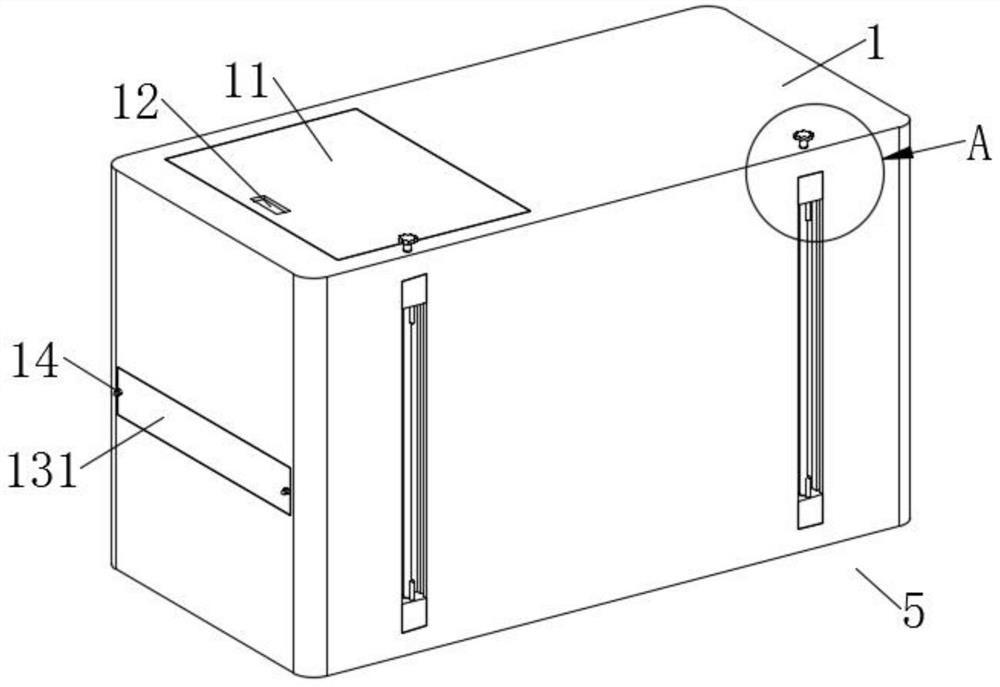

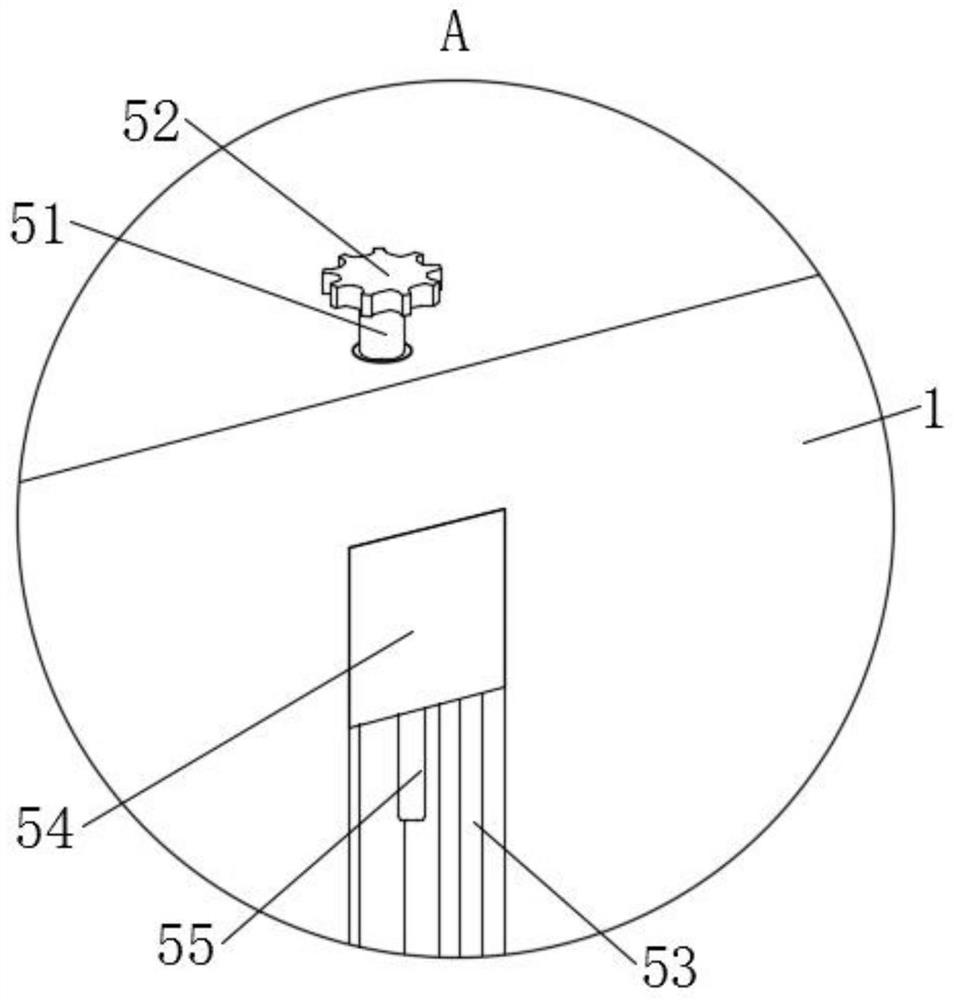

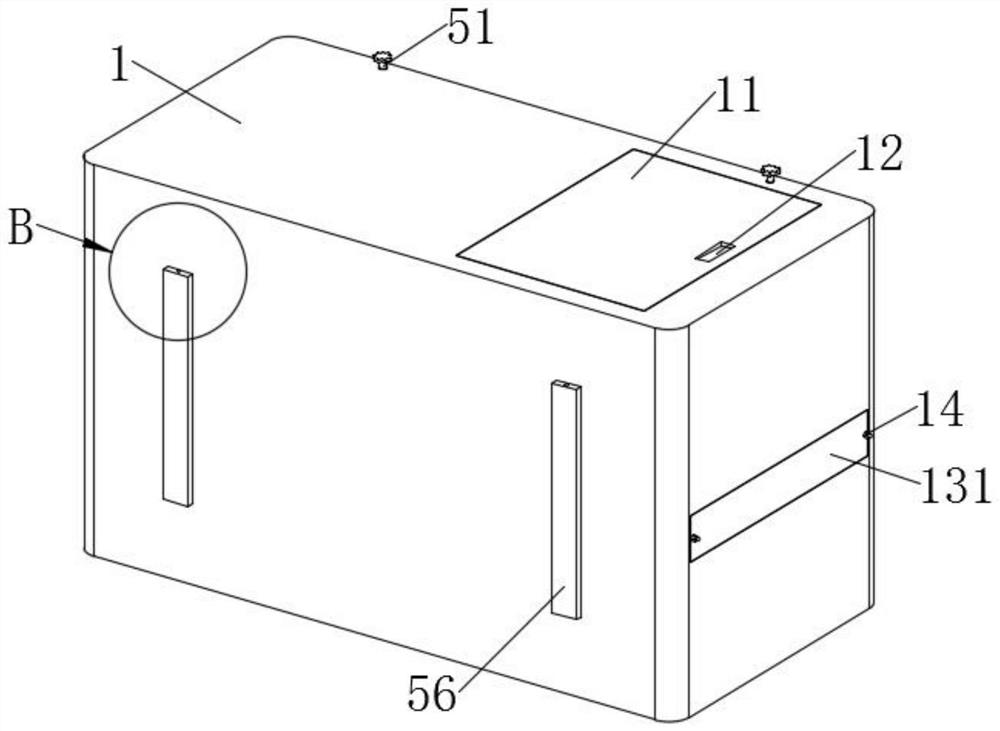

Novel low-temperature storage equipment and preparation process thereof

PendingCN114408328AJack up to achieveImprove convenienceHeat-exchange elementsDischarging meansProcess engineeringMechanical engineering

Owner:深圳汇莱新材料科技有限公司

Printing material cementing device

The invention relates to the technical field of printing, and particularly discloses a printing material cementing device. The printing material cementing device comprises a cementing box, wherein a feeding hopper is arranged at the top of the cementing box, a heating plate is arranged in the middle of the cementing box, a plurality of first heating holes are formed in the heating plate, the firstheating holes communicate with the side wall of the cementing box, a discharging unit is arranged in the cementing box, the discharging unit comprises a glue discharging cylinder, a spiral shaft is rotationally connected to the cementing box, one end of the spiral shaft penetrates through the cementing box and is connected with a driving unit, a middle tube is arranged on the heating plate, a screen cylinder is rotationally connected in a glue discharging cylinder, a plurality of screen holes are formed in the screen cylinder, the sizes of the apertures of the screen holes are different, thescreen holes with different apertures are distributed on the screen cylinder in a staggered mode, soft brushes are uniformly distributed on the inner wall of the glue discharging cylinder, a transmission unit is arranged on the spiral shaft, and a guide pipe communicating with the glue discharging cylinder is arranged on the cementing box. By the adoption of the technical scheme, the problem thatafter hot melt adhesive remained in a conveyor is solidified in the prior art, cannot be fully melted, and is fed to a conduit, the conduit is blocked is solved.

Owner:重庆市骏煌印务有限公司

Anti-freezing device and method for air energy water heater

InactiveCN112212528ASpeed up heat lossSpeed up the melting timeSolar heating energySolar heat collector controllersFrost (temperature)Engineering

The invention discloses an anti-freezing device and method for an air energy water heater, and relates to the technical field of water heater freezing prevention. The anti-freezing device and method aim at solving the problem that the anti-freezing effect is poor. The anti-freezing device specifically comprises an evaporation coil pipe, wherein an installing plate is fixed to the outer wall of oneside of the evaporation coil pipe through bolts, and a temperature sensor is fixed to the outer wall of one side of the installing plate through threads; the inner walls of the top and the bottom ofthe evaporation coil pipe are connected with the same flow guiding pipe through threads, and two symmetric anti-seepage gaskets are fixed to the circumferential outer walls of the two ends of the flowguiding pipe through sealants; the outer walls of one sides of the two anti-seepage gaskets on the same side are connected with flow dividing pipes through threads; and the outer wall of one side ofthe flow guiding pipe is connected with a flow collecting pipe through threads, the circumferential outer wall of the flow collecting pipe is sleeved with an installing sleeve, and an adjusting mechanism is arranged in the flow collecting pipe. According to the anti-freezing device and method, heat losses are effectively accelerated, the temperature of surrounding air is rapidly increased, accordingly, the frost melting time is shortened, and the defrosting and unfreezing efficiency is improved.

Owner:衡阳晟达信息技术有限公司

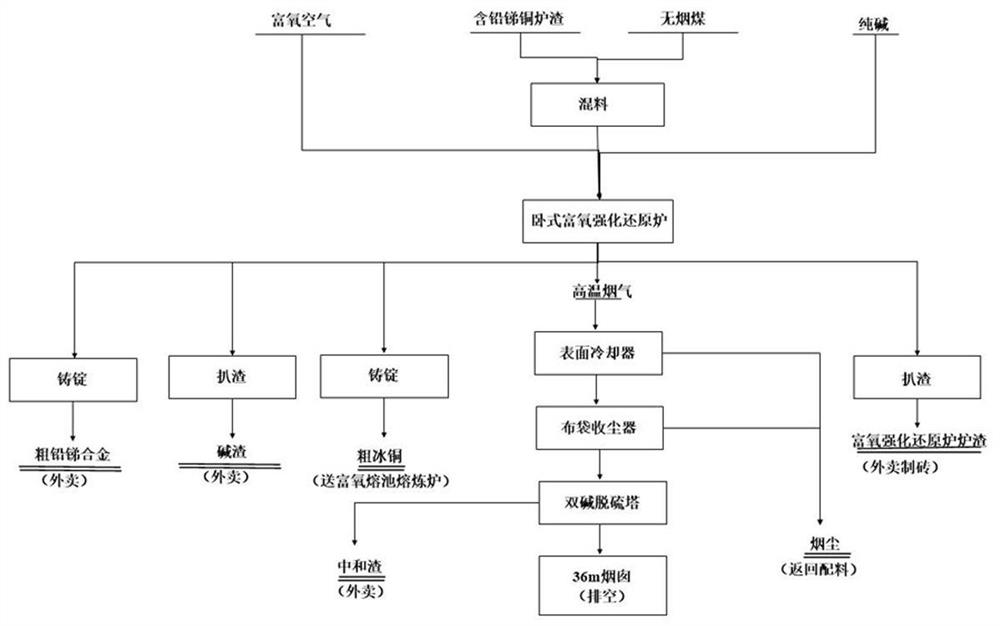

Oxygen-enriched strengthening smelting method for horizontal reduction furnace

InactiveCN111719045AShorten smelting timeReduce energy consumptionProcess efficiency improvementSlagAnthracite

The invention aims to provide an oxygen-enriched strengthening smelting method for a horizontal reduction furnace. The method is characterized in that lead-antimony-copper-containing slag and anthracite are uniformly compounded, two feeding funnels are adopted for feeding in two batches, the addition of the two batches of materials and the spraying-in of matched oxygen-enriched air are correspondingly controlled, the materials are gradually heated to the smelting temperature, smelting is conducted, and soda ash is added after smelting is completed for slagging; due to the fact that a 10-degreedip angle is formed between the oxygen-enriched smelting furnace and the ground, firstly, alkali slag is removed from a lead opening of the oxygen-enriched strengthening reduction furnace, and then oxygen-enriched reinforced reduction furnace slag is removed; and finally, an lead-antimony alloy is made into a casting ingot by a lead pump, matte copper on the surface of the lead-antimony alloy isremoved, and separate piling is conducted, so that the smelting time can be shortened, and the energy consumption can be reduced.

Owner:个旧市锦星锑业有限公司

Portable freezing cabinet

ActiveCN102022879BExtended melting timeProlong the freezing timeDomestic cooling apparatusLighting and heating apparatusThermodynamicsRefrigerant

Owner:NANTONG WEALTH MASCH TECH CO LTD

Water-cooled external mixing pure oxygen gas burner for rotary transformation iron furnace

InactiveCN105240850BImprove cooling effectAvoid heat damageCombustion technology mitigationGaseous fuel burnerEngineeringConvection heat

Owner:殷黎丽 +1

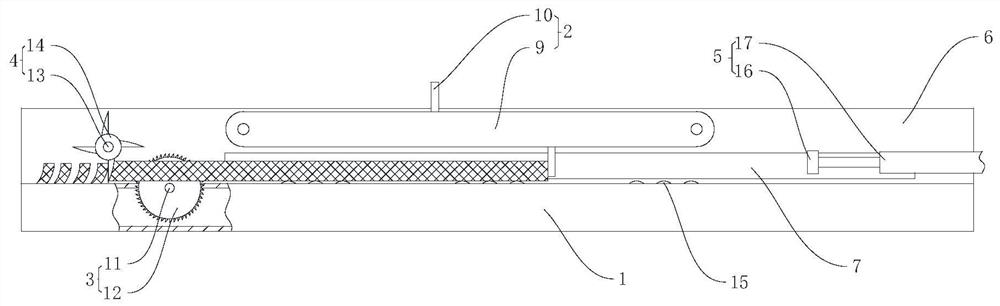

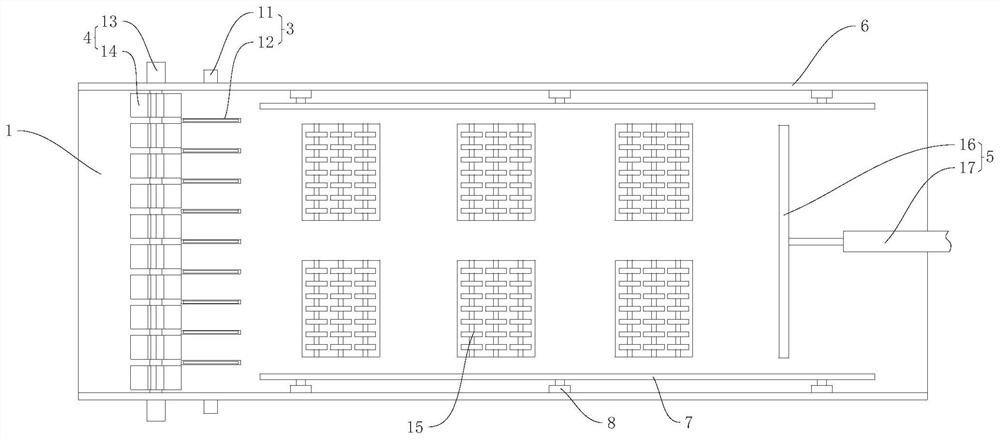

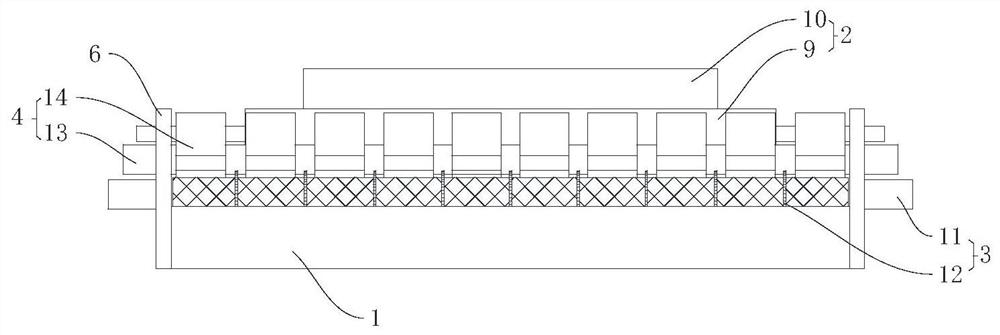

template divider

The invention provides a formwork slicing machine, and belongs to the technical field of crushing equipment. The formwork slicing machine comprises a workbench, a driving assembly arranged above the workbench, a slicing assembly arranged at the left end of the workbench and a cutting-off assembly arranged at the left end of the workbench. The cutting-off assembly is located on the left side of theslicing assembly. According to the formwork slicing machine provided by the invention, formworks are placed on a horizontal working face at the upper end of the workbench, and the driving assembly isfixedly arranged above the workbench and used for driving the formworks to move on the workbench; the driving assembly drives the formworks on the workbench to move towards the left side of the workbench, and the formworks pass through the slicing assembly at first and then are cut into strips by the slicing assembly; and the driving assembly continuously drives the strip-shaped formworks to movetowards the left side of the workbench, the strip-shaped formworks pass through the cutting-off assembly, the cutting-off assembly cuts the strip-shaped formworks into the same blocks, it can be ensured that the melting rates of the same block-shaped formworks are basically consistent in the melting process, no extra melting time is required, and energy is saved.

Owner:HEBEI COLLEGE OF IND & TECH

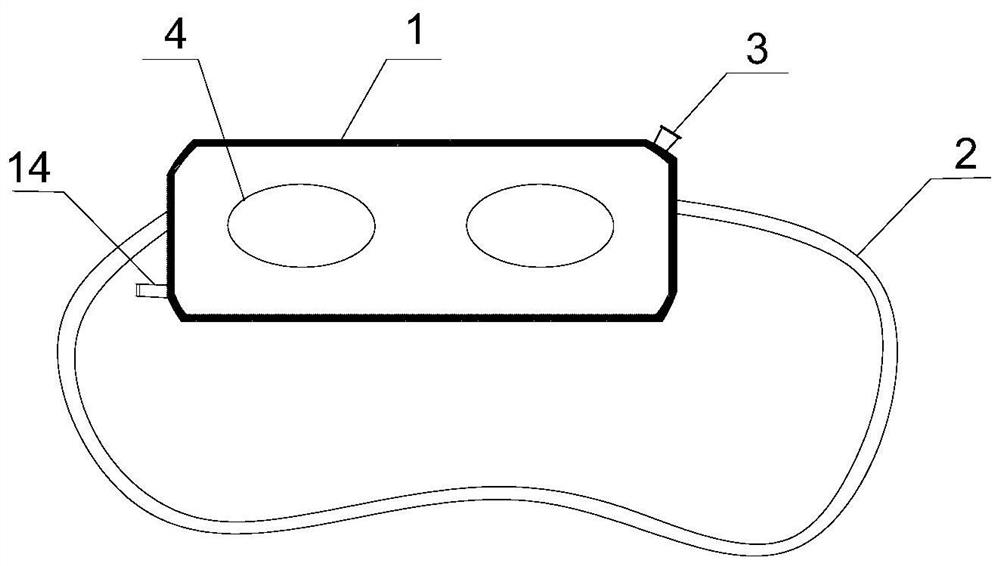

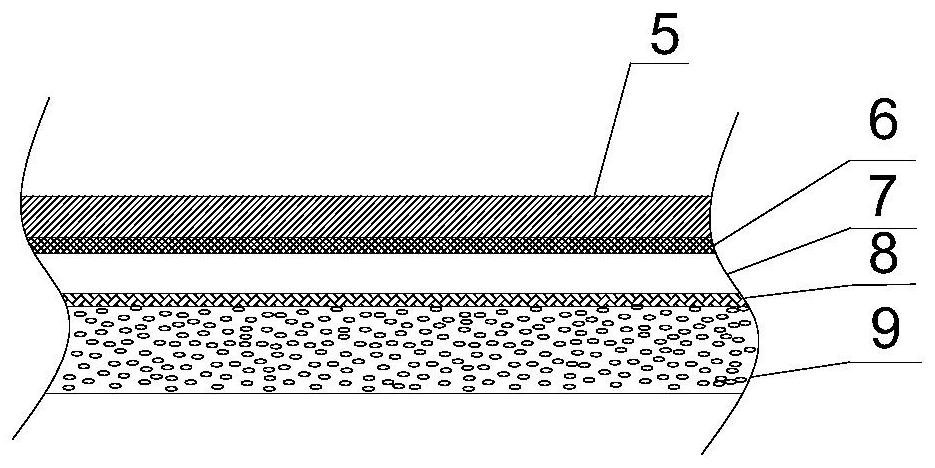

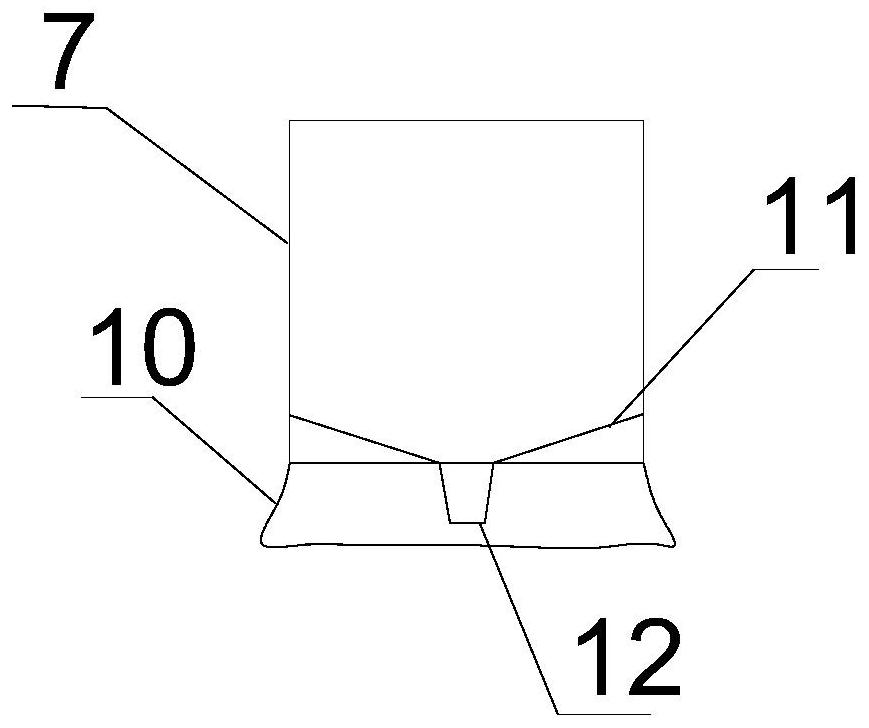

An ophthalmic ice compress detumescence device

ActiveCN110215335BImprove use comfort performancePrevent outflowTherapeutic coolingTherapeutic heatingIce waterInsulation layer

The invention discloses an ice compress detumescence device for ophthalmology, which comprises a casing and a strap; the casing is a six-sided box structure, and straps are connected to both sides of the casing; the strap is an elastic rope, There are two eye contour cavities on the front side of the shell to avoid eye contact with the ice layer; an insulation layer is set on the front side of the inside of the shell, and the surface of the insulation layer is wrapped with cotton cloth to increase the comfort of the patient when using it , so that the device and the eyes are more fit; the inner side of the thermal insulation layer is provided with a waterproof layer, and the inner side of the waterproof layer is provided with a diversion layer, and the diversion layer allows the melted ice water to flow into the water bag; An interlayer is arranged on the side, and holes are arranged on the interlayer to separate ice cubes and melted ice water. A frozen layer is arranged on the inner side of the interlayer, and the frozen layer includes water and silica gel particles; Tube; the invention can freely adjust the degree of fit with the eye through the expansion tube, effectively prevent frostbite, fill with silica gel particles, increase flexibility, and have better therapeutic effect.

Owner:XIANGYANG CENT HOSPITAL

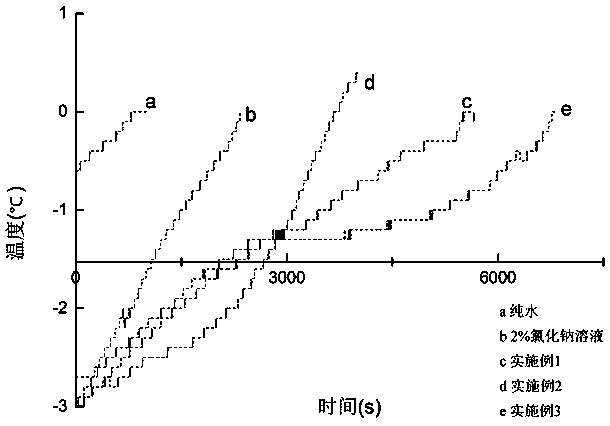

Preservation ice used for sliced salmon sushi, and preparation method for preservation ice

PendingCN111165558AExtended melting timeReduce oxidation rateFood ingredient as antioxidantFood freezingRosmarinusInulin

The invention provides preservation ice used for sliced salmon sushi, and a preparation method for the preservation ice. The preservation ice comprises the following preparation raw materials: inulin,rosemarinus officinalis extracts, natamycin, potassium sorbate, sodium chloride, Arabic gum and water, wherein the water is optimally lemon-ginger juice prepared from lemon and fresh ginger. Under asituation that a cold refrigeration agent is not used, the preservation ice is completely prepared from edible and nontoxic ingredients, ice melting time is effectively prolonged, the periphery of thesliced salmon sushi guarantees to be continuously kept at a low temperature state, an oxidization rate of the sliced salmon sushi is alleviated, and the problem that salmons are likely to rot in a preservation process is solved.

Owner:BOHAI UNIV

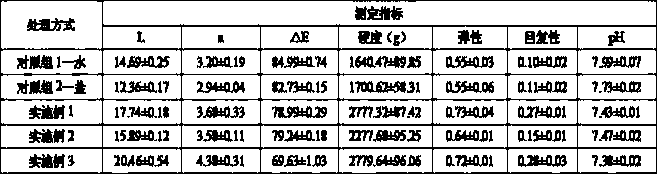

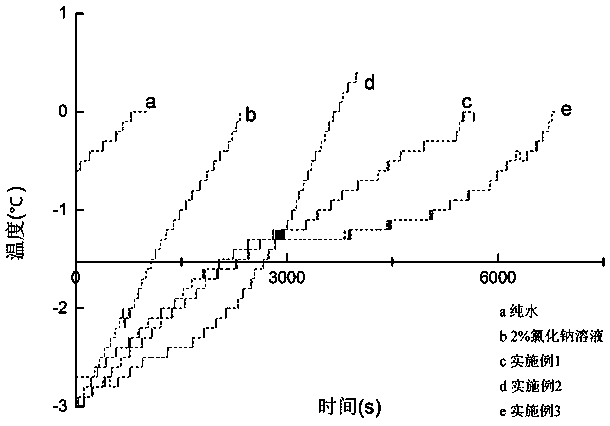

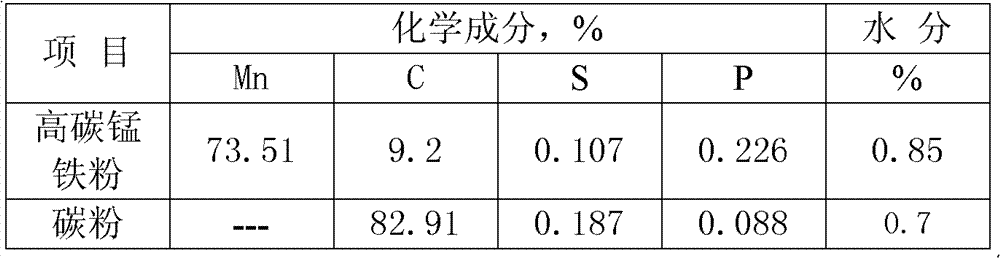

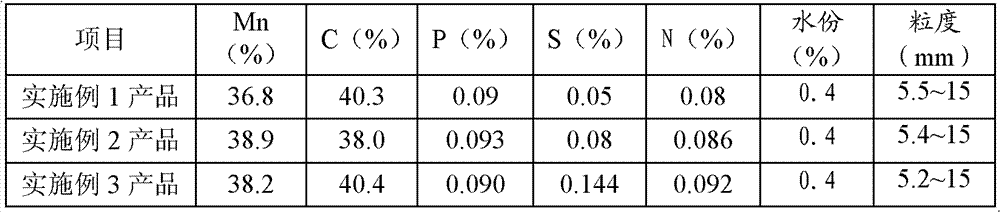

Carbon manganese balls and preparation method thereof and continuous casting smelting process for high or medium carbon steel converter

InactiveCN102091779BEasy to prepareExtended melting timeManufacturing convertersCelluloseSteelmaking

The invention discloses carbon manganese balls and a preparation method thereof and a continuous casting smelting process for a high or medium carbon steel converter, and belongs to the technical field of steelmaking. The invention aims to solve the problems of long melting time of common carburant, low carbon yield and difficult molten steel component control. The carbon manganese balls are prepared from the following raw materials in percentage by weight: 50 to 53 percent of high carbon ferromanganese powder, 40 to 43 percent of carbon powder, and 5 to 7 percent of bonding agent, wherein the high carbon ferromanganese powder contains 6 to 10 weight percent of carbon and 70 to 77 weight percent of manganese; the carbon powder contains more than or equal to 82 weight percent of carbon; the bonding agent is a bonding material and contains the following components in percentage by weight: 5 to 9 percent of polyanionic sodium cellulose, 63 to 67 percent of Guangxi white clay, 13 to 17 percent of dextrin, and 11 to 15 percent of sodium carbonate. The carbon manganese ball preparation method is simple, has short melting time and high yield of carbon and manganese, is easy to control the molten steel components, simplifies the steelmaking process, and saves energy.

Owner:PANZHIHUA GANGCHENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com