Silicon nitride powder, mold release agent for polycrystalline silicon ingots, and method for producing polycrystalline silicon ingots

A technology of silicon nitride powder and silicon nitride, which is applied in the field of silicon nitride powder, can solve the problems of adhesion and poor mold release of polysilicon ingots, and achieve the effect of improving mold release performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046]

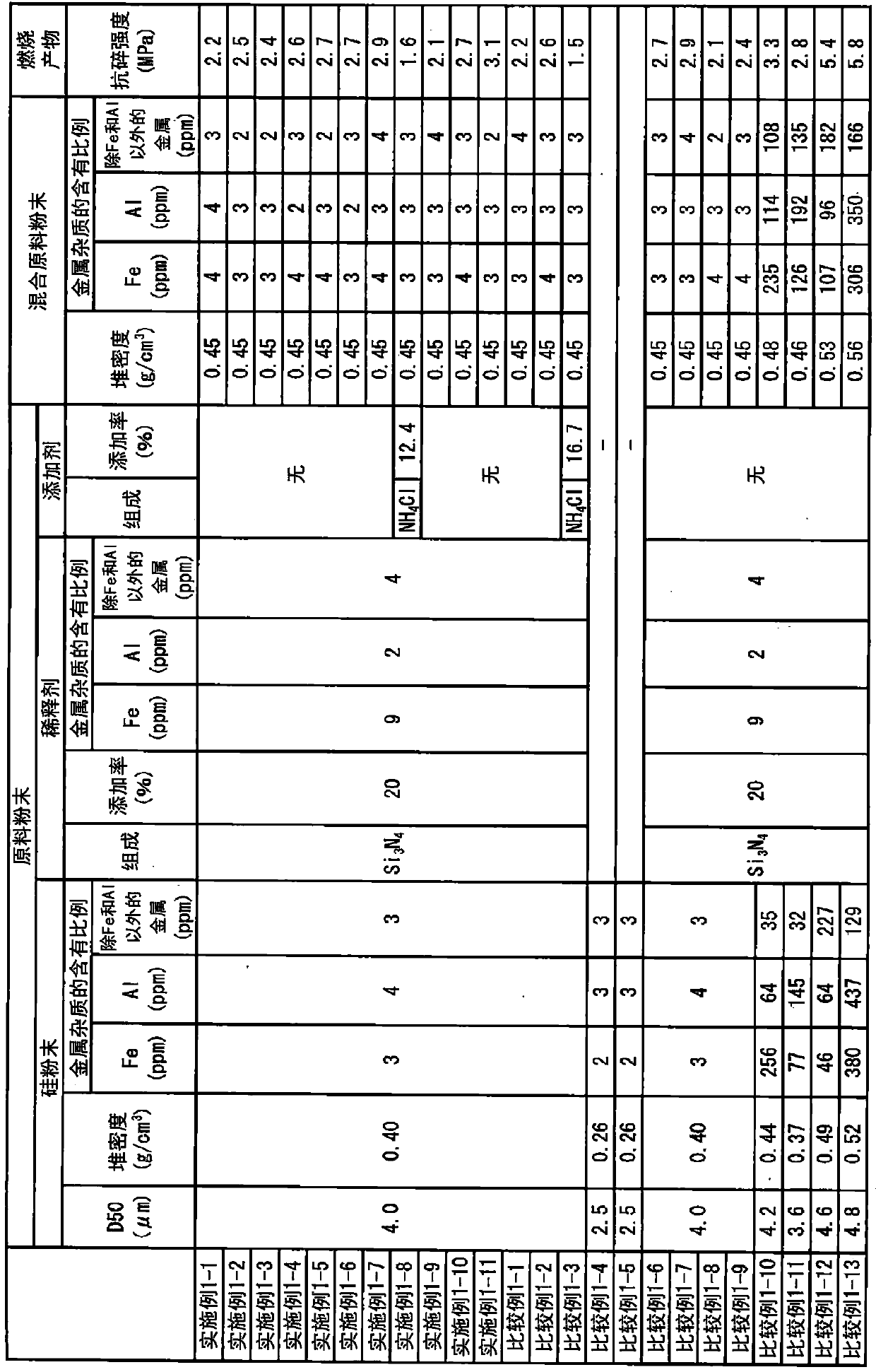

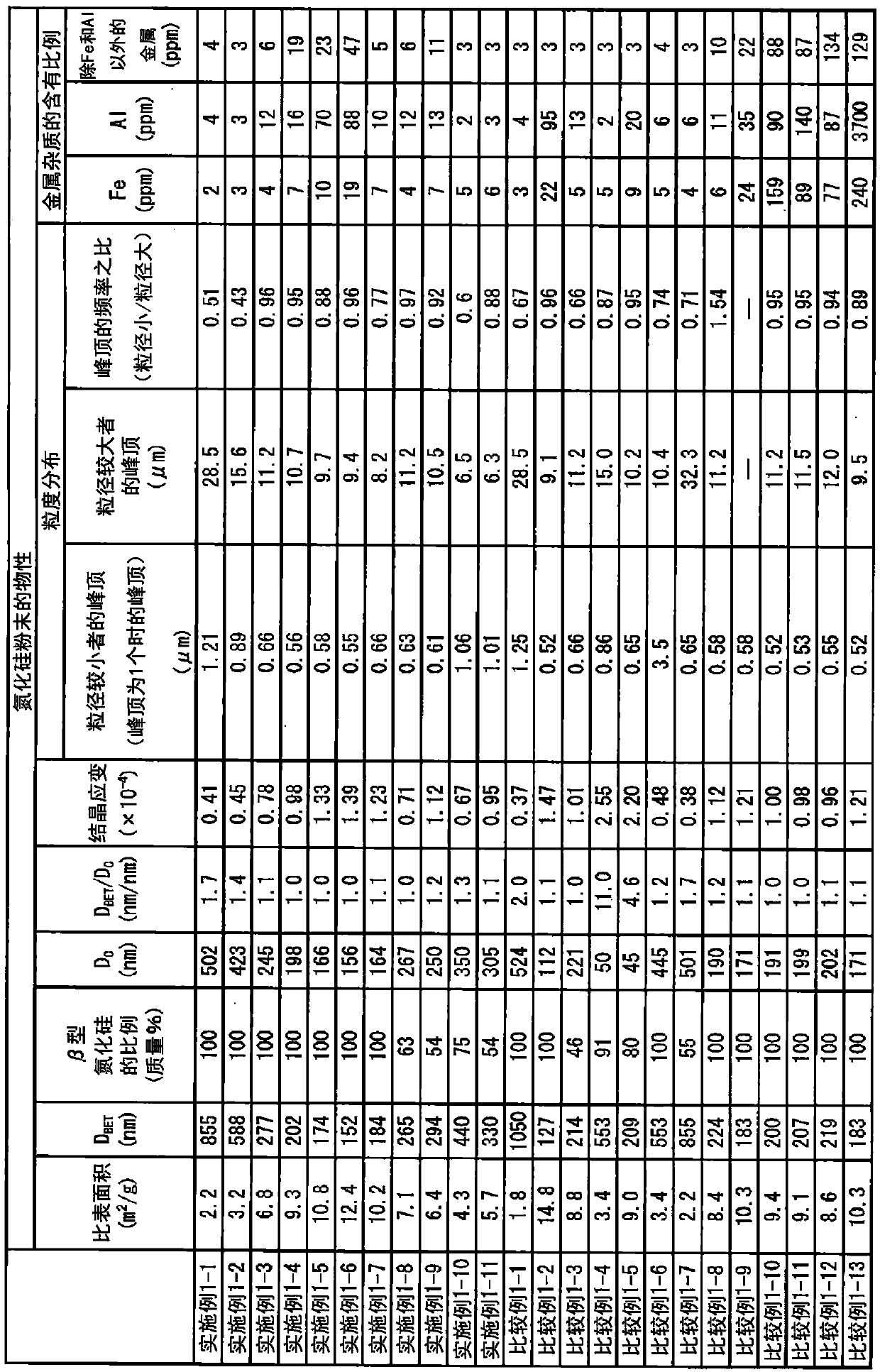

[0047] First, silicon powder is mixed with silicon nitride powder as a diluent to prepare mixed raw material powder. Since the combustion synthesis reaction is at a high temperature of 1800° C. or higher, melting / welding of silicon may occur in a portion where the combustion reaction occurs. For the purpose of suppressing this, it is preferable to add silicon nitride powder as a diluent to the raw material powder within the range that does not hinder the self-propagation of the combustion reaction. The addition rate of the diluent is usually 10 to 50% by mass (the mass ratio of silicon:silicon nitride is 90:10 to 50:50), and further 15 to 40% by mass. In addition, on the basis of adjusting the proportion of β-type silicon nitride in the combustion product obtained in the combustion synthesis reaction, NH 4 Cl, NaCl, etc. These additives have the effect of lowering the reaction temperature through sensible heat, latent heat, and endothermic reactions. Here, the Fe...

Embodiment 1-1

[0085] D50 is 4.0μm, bulk density is 0.40g / cm 3 , the content ratio of Fe is 3ppm, the content ratio of Al is 4ppm, and the content ratio of metal impurities other than Fe and Al is 3ppm, the addition ratio of silicon nitride is 20% by mass (silicon: silicon nitride Silicon nitride powder (manufactured by Ube Industries, Ltd., product name "SN-E10" (Fe content ratio: 9ppm, Al content ratio: 2ppm, except The content rate of metal impurities other than Fe and Al: 4 ppm)) was used as a raw material powder. The above-mentioned raw material powder was accommodated in a nylon cylinder filled with silicon nitride balls and the inner wall surface was lined with urethane, and mixed for 0.5 hours at a vibration frequency of 1200 cpm and an amplitude of 8 mm using a batch vibrating mill to obtain a mixed raw material. powder.

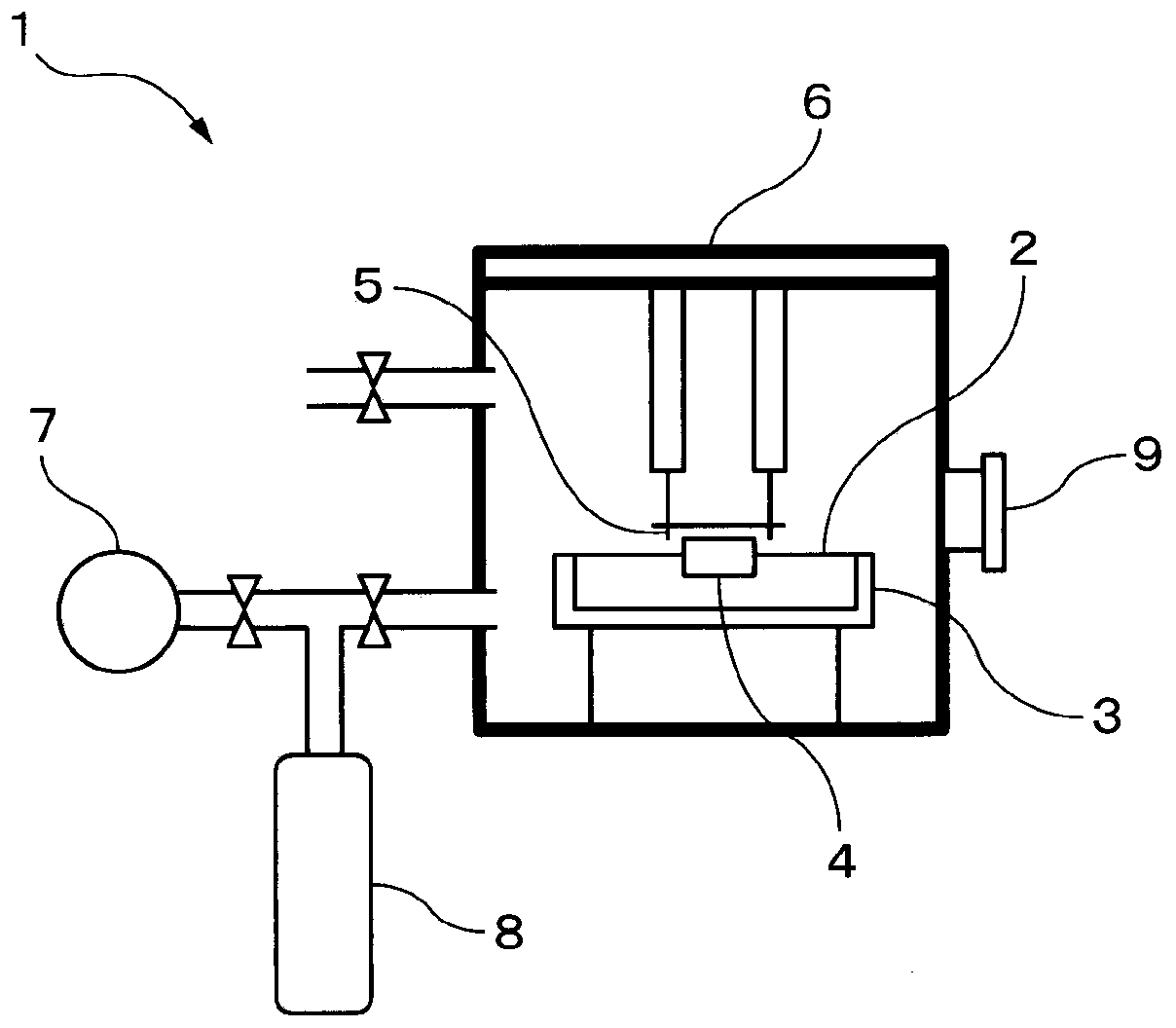

[0086] figure 1 The combustion synthesis reaction apparatus 1 used for the combustion synthesis reaction of silicon in this example is shown in . The mixed r...

Embodiment 1-2~1-6

[0102] The time of the fine pulverization of Examples 1-2 to 1-6 is sequentially set to 0.30 hours, 1.50 hours, 2.50 hours, 4.00 hours, and 6.00 hours from Example 1-2. In addition, the same as Example 1-1 The same operation was performed to obtain the silicon nitride powders of Examples 1-2 to 1-6. Then, using the silicon nitride powder obtained in each of the examples as a mold release agent, two molds for casting polycrystalline silicon ingots were produced in the same manner as in Example 1-1. In each embodiment, use these molds, utilize the same method as embodiment 1-1 to carry out the unidirectional solidification experiment under the same two furnace temperatures as embodiment 1-1, utilize the same method as embodiment 1-1 Methods Evaluation of molds for polysilicon ingot casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com