Carbon manganese balls and preparation method thereof and continuous casting smelting process for high or medium carbon steel converter

A technology of carbon-manganese balls and carbon-manganese, which is applied in the manufacture of converters, etc., can solve the problems of not being able to meet the technical requirements of short-process production, the cycle mismatch of continuous casting machines, and the uneven melting of recarburizers, etc., and achieve easy and melting of molten steel The effect of short time and simplified steelmaking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

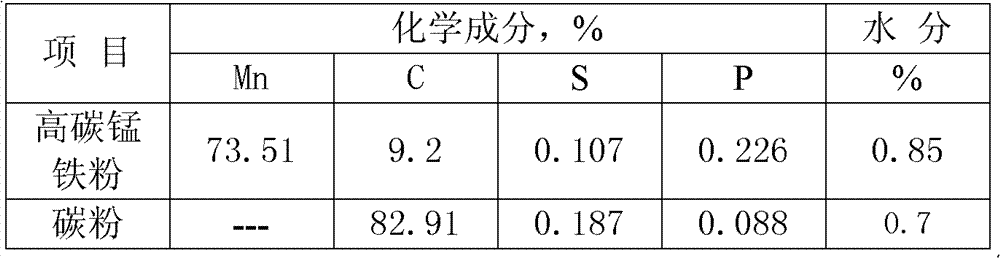

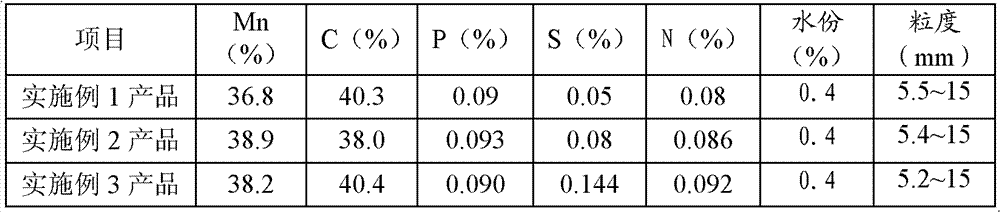

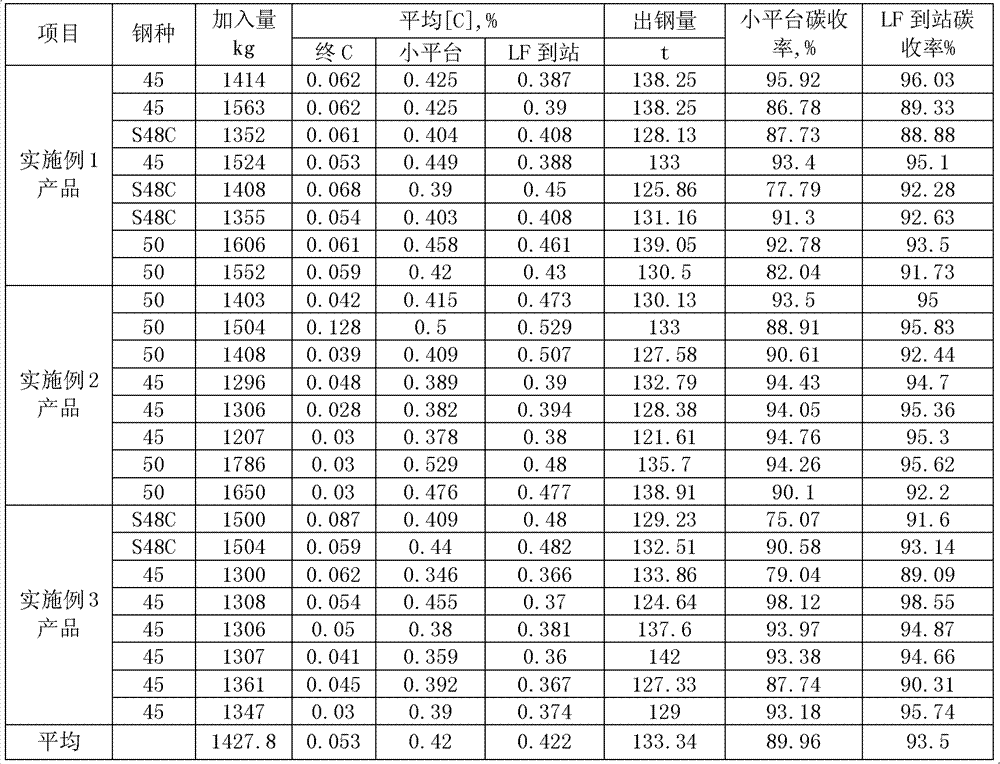

[0042] Embodiment 1 Preparation and use of carbon manganese spheres of the present invention

[0043]First mix 7% of commercially available polyanionic cellulose sodium, 65% of Guangxi white clay, 15% of commercially available dextrin, and 13% of commercially available sodium carbonate according to the weight ratio to prepare the binding agent, and then mix 50 parts by weight of high-carbon After weighing the ferromanganese powder, 43 parts by weight of carbon powder and 7 parts by weight of the binding agent, the weighed high-carbon ferromanganese powder and carbon powder are respectively sent into the mixing mixer for mixing and stirring, and the mixing time is 2min Finally, add the binder and continue mixing and stirring for 2 minutes, then add water and stir according to 6% of the weight of the raw material high-carbon ferromanganese powder, carbon powder and binder. Send the mixed material into LYQ3.0 ball press machine for pressing, and press it into 5-15mm oval carbon-m...

Embodiment 2

[0044] Embodiment 2 Preparation and use of carbon manganese spheres of the present invention

[0045] First mix 7% of commercially available polyanionic cellulose sodium, 65% of Guangxi white mud, 15% of commercially available dextrin, and 13% of commercially available sodium carbonate according to the weight ratio to prepare the binding agent, and then mix 53 parts by weight of high-carbon After weighing the ferromanganese powder, 40 parts by weight of carbon powder and 7 parts by weight of the binder, the high-carbon ferromanganese powder and the carbon powder are respectively sent into the mixing mixer for mixing and stirring. After mixing and stirring for 2 minutes, add the combined Continue to mix and stir the agent for 2 minutes, then add water and stir according to 7% of the weight of the raw material high-carbon ferromanganese powder, carbon powder and binder. Send the mixed material into LYQ3.0 ball press machine for pressing, and press it into 5-15mm oval carbon-mang...

Embodiment 3

[0046] Embodiment 3 Preparation and use of carbon manganese spheres of the present invention

[0047] First mix 7% of commercially available polyanionic cellulose sodium, 65% of Guangxi white mud, 15% of commercially available dextrin, and 13% of commercially available sodium carbonate according to the weight ratio to prepare the binding agent, and then mix 52 parts by weight of high-carbon After weighing the ferromanganese powder, 43 parts by weight of carbon powder and 5 parts by weight of the binder, the high-carbon ferromanganese powder and carbon powder are respectively sent into the mixing mixer for mixing and stirring. After mixing and stirring for 2 minutes, add the combined Continue to mix and stir the agent for 2 minutes, and then add water and stir according to 6% of the weight of the raw material high-carbon ferromanganese powder, carbon powder and binder. Send the mixed material into LYQ3.0 ball press machine for pressing, and press it into 5mm~15mm oval carbon-ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com