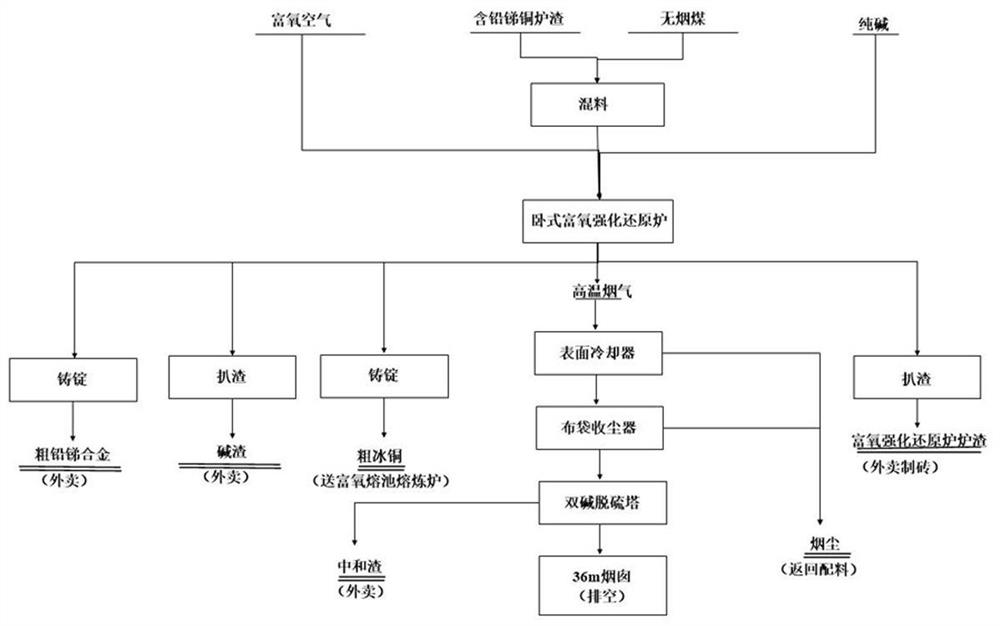

Oxygen-enriched strengthening smelting method for horizontal reduction furnace

A reduction furnace and oxygen-enriched technology, applied in the fields of metallurgy and chemistry, can solve the problems of high investment in the pulverized coal preparation system, slow temperature raising, and difficulty in compounding, so as to speed up the compounding and melting time, facilitate the distribution of materials, and achieve uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

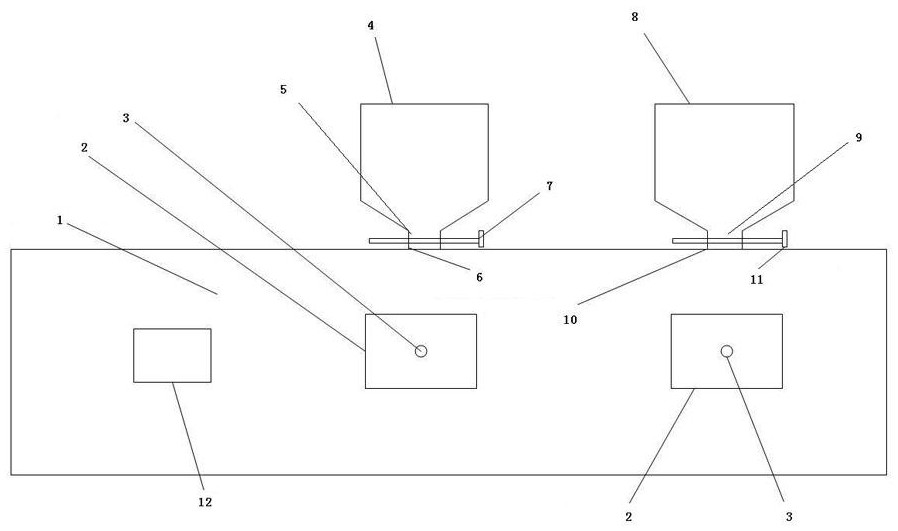

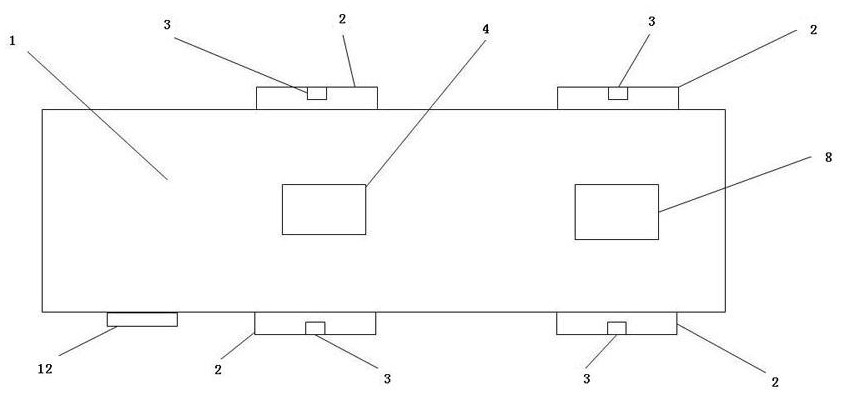

[0027] 1) Lead-antimony-copper slag contains 60% lead, 10% antimony, 10% copper, and 5% sulfur; the particle size of pulverized coal is -200 mesh 80%, which contains 80% carbon, 1.5% sulfur, and 14% ash. Volatile content 5%; Lead-containing antimony-copper slag and anthracite are evenly proportioned according to a weight ratio of 100:3, and the prepared materials are loaded into the first feeding funnel 4 and the second feeding funnel 8, the first feeding funnel 4 And the second feeding funnel 8 is a square funnel, the first feeding funnel 4 bottoms are provided with the first feeding pipe 5, the second feeding funnel 8 bottoms are provided with the second feeding pipe 9, and the first feeding funnel 5 bottoms are provided with the first feeding pipe 5. A feeding port 6, the bottom of the second feeding pipe 9 is provided with a second feeding port 10, the first feeding pipe 5 and the second feeding pipe 9 are square, the length is 300mm, and the side length is 300mm, the first...

Embodiment 2

[0032]1) Lead-antimony-copper slag contains 70% lead, 6% antimony, 6% copper, and 3% sulfur; the particle size of pulverized coal is -200 mesh 85%, which contains 85% carbon, 0.7% sulfur, and 11% ash. The volatile matter is 3.5%, and the lead-containing antimony-copper slag and anthracite are evenly proportioned according to the weight ratio of 100:3, and the prepared materials are loaded into the first feeding funnel 4 and the second feeding funnel 8, the first feeding funnel 4 And the second feeding funnel 8 is a square funnel, the first feeding funnel 4 bottoms are provided with the first feeding pipe 5, the second feeding funnel 8 bottoms are provided with the second feeding pipe 9, and the first feeding funnel 5 bottoms are provided with the first feeding pipe 5. A feeding port 6, the bottom of the second feeding pipe 9 is provided with a second feeding port 10, the first feeding pipe 5 and the second feeding pipe 9 are square, the length is 400mm, the side length is 400mm...

Embodiment 3

[0037] 1) Lead-antimony-copper slag contains 80% lead, 2% antimony, 2% copper, and 1% sulfur; the particle size of pulverized coal is -200 mesh 90%, which contains 90% carbon, 0.1% sulfur, and 7% ash. The volatile matter is 2%, and the lead-containing antimony-copper slag and anthracite are evenly proportioned according to the weight ratio of 100:3, and the prepared materials are loaded into the first feeding funnel 4 and the second feeding funnel 8, the first feeding funnel 4 And the second feeding funnel 8 is a square funnel, the first feeding funnel 4 bottoms are provided with the first feeding pipe 5, the second feeding funnel 8 bottoms are provided with the second feeding pipe 9, and the first feeding funnel 5 bottoms are provided with the first feeding pipe 5. A feeding port 6, the bottom of the second feeding pipe 9 is provided with a second feeding port 10, the first feeding pipe 5 and the second feeding pipe 9 are square, the length is 500mm, the side length is 400mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com