Printing material cementing device

A technology for printing and plastic packaging, which is applied in the field of devices for printing plastic packaging, and can solve problems such as failure to melt, blockage of pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

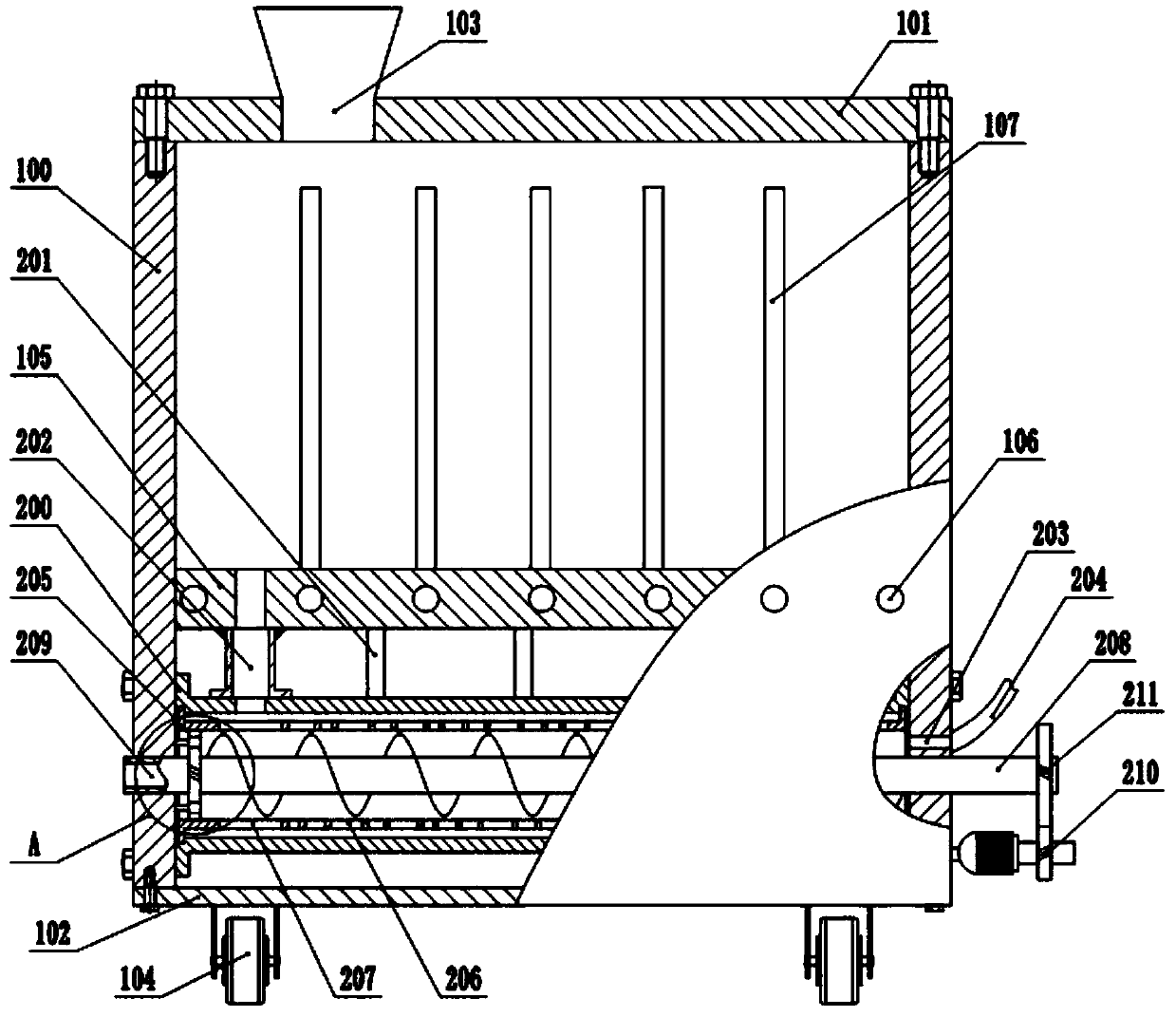

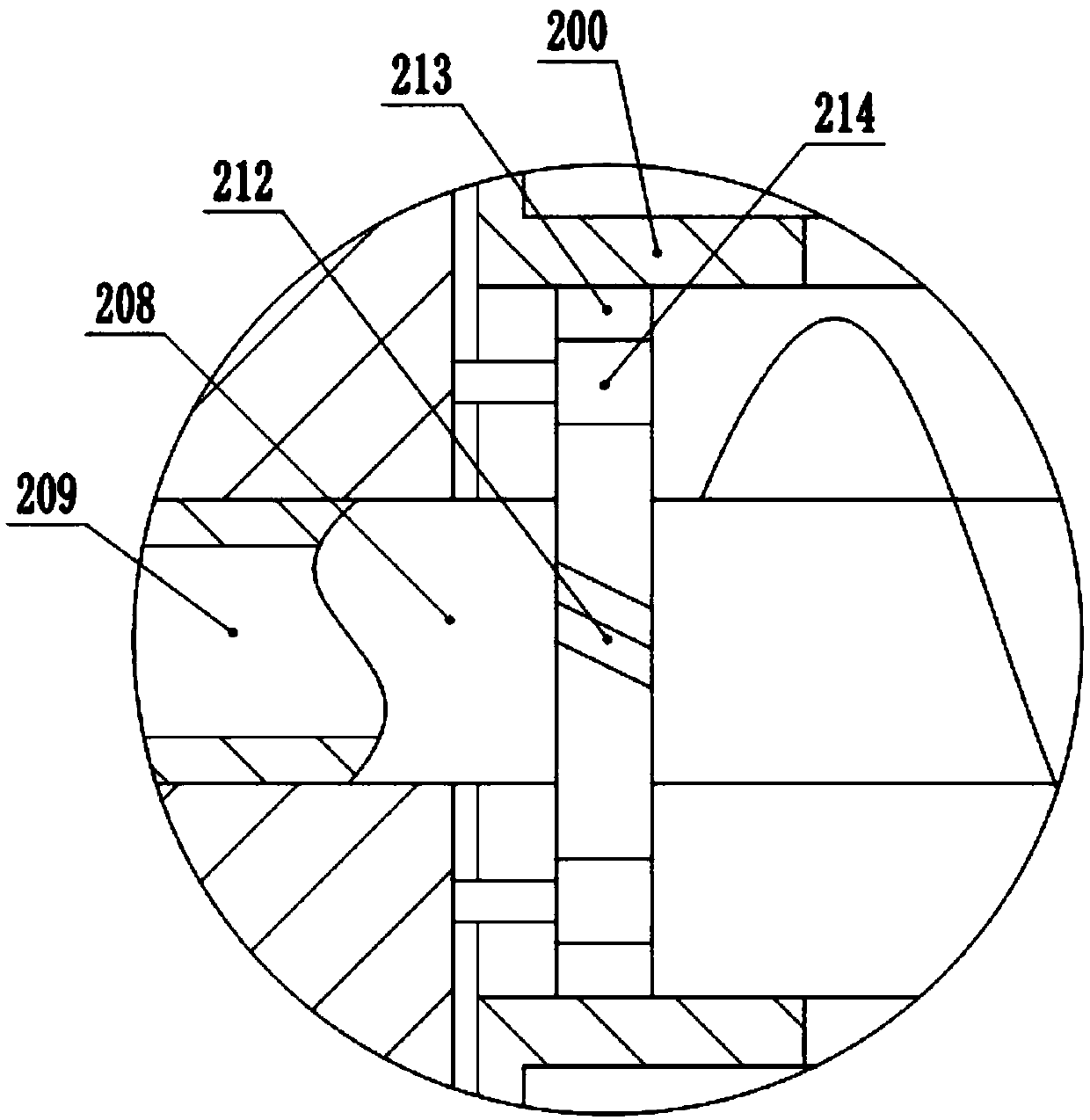

[0028] The reference numerals in the accompanying drawings of the description include: glue box 100, top cover 101, bottom cover 102, feed hopper 103, traveling wheels 104, heating plate 105, first heating hole 106, heat conduction plate 107, glue outlet cylinder 200 , heat conduction rod 201, intermediate pipe 202, hot glue hole 203, conduit 204, screen drum 205, screen hole 206, through hole 207, screw shaft 208, second heating hole 209, driving gear 210, driven gear 211, sun gear 212, ring gear 213, planetary gear 214.

[0029] The embodiment is basically as attached figure 1 Shown:

[0030] The device for plastic packaging of printed matter includes a plastic box 100, the top of the plastic box 100 is connected with a top cover 101 by bolts, the bottom of the plastic box 100 is connected with a bottom cover 102 by bolts, and the top cover 101 is provided with a connecting plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com