Water-cooled external mixing type pure oxygen gas burner for rotary iron-melting furnace

A technology for converting iron furnaces and gas burners, applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of poor mixing performance of the burners, separation from the furnace, separation, ineffective heating and fuel, etc., to improve power density. , Enhance cooling, prevent thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

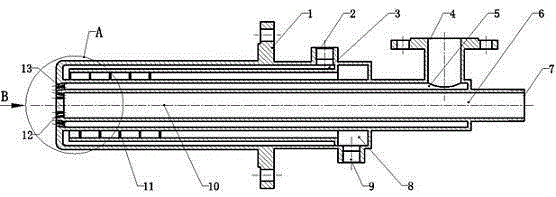

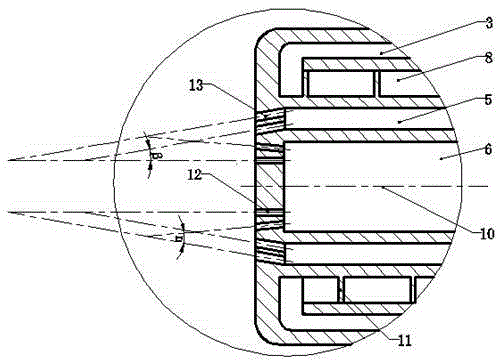

[0043] The present invention has multiple embodiments, which are combined below Figure 7 An embodiment of the present invention is described.

[0044] Figure 7 As an embodiment of the present invention, there is a furnace lining 16 inside the furnace shell 15, and the burner is fixed on the furnace shell 15 by connecting bolts 14; The water chamber spiral channel blade 17; the gas and oxygen nozzle 19 are connected with the burner body as a whole through the thread 20. The isolation ribs 18 in the oxygen flow channel 5 play a certain role in fixing and strengthening the adjacent flow channels, especially the gas flow channel 6 .

[0045] Figure 8 for Figure 7 Partial enlarged view of part D of , more clearly shows the structure of gas and oxygen nozzle 19 and the screw connection relationship with the burner body.

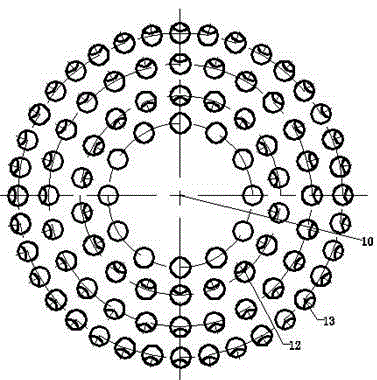

[0046] Figure 9 for Figure 7 The E-direction view of the figure more clearly shows the structural details of the gas and oxygen nozzle 19. Gas inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com