High-current-irradiation-resistant cross-linked low-smoke halogen-free flame-retardant polyolefin insulating material for cotton covered wire

A high-current and wire-laying technology, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems that wires cannot withstand large currents or overload non-combustibility, foaming, yellowing, etc., and achieve easy extrusion Produce granulation, improve compatibility, and prolong the effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

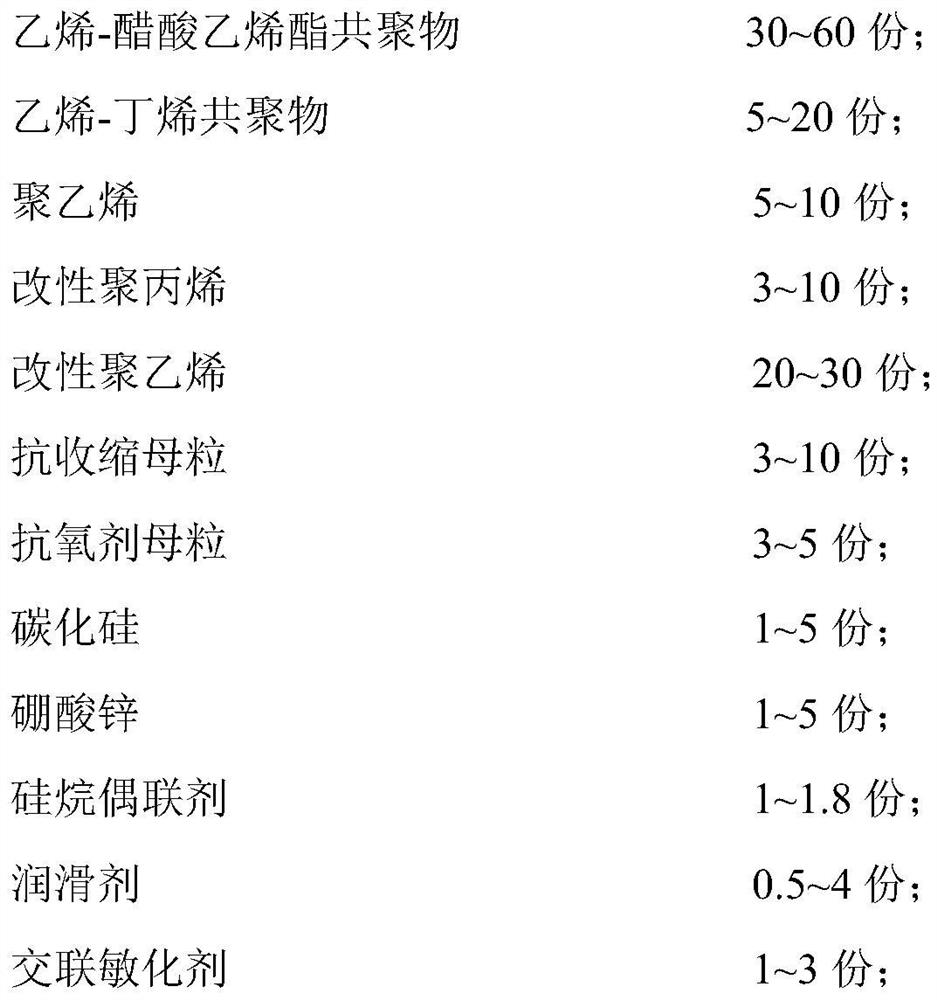

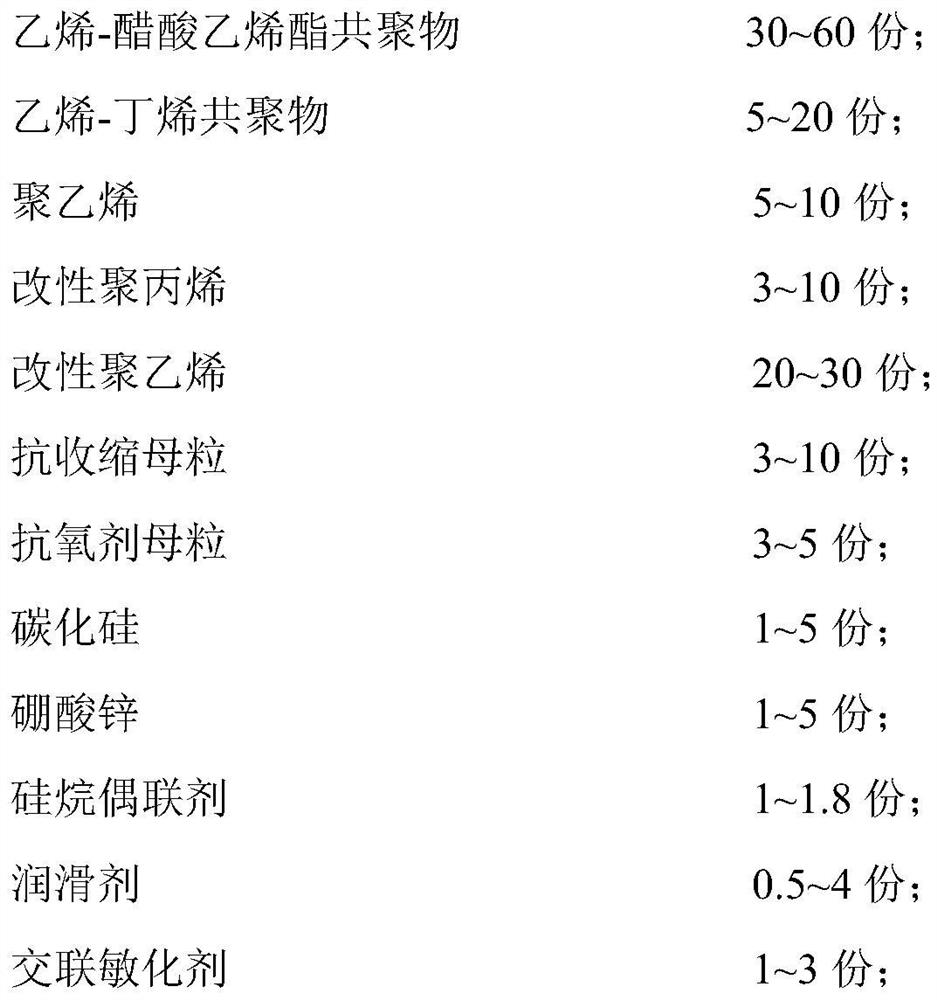

Method used

Image

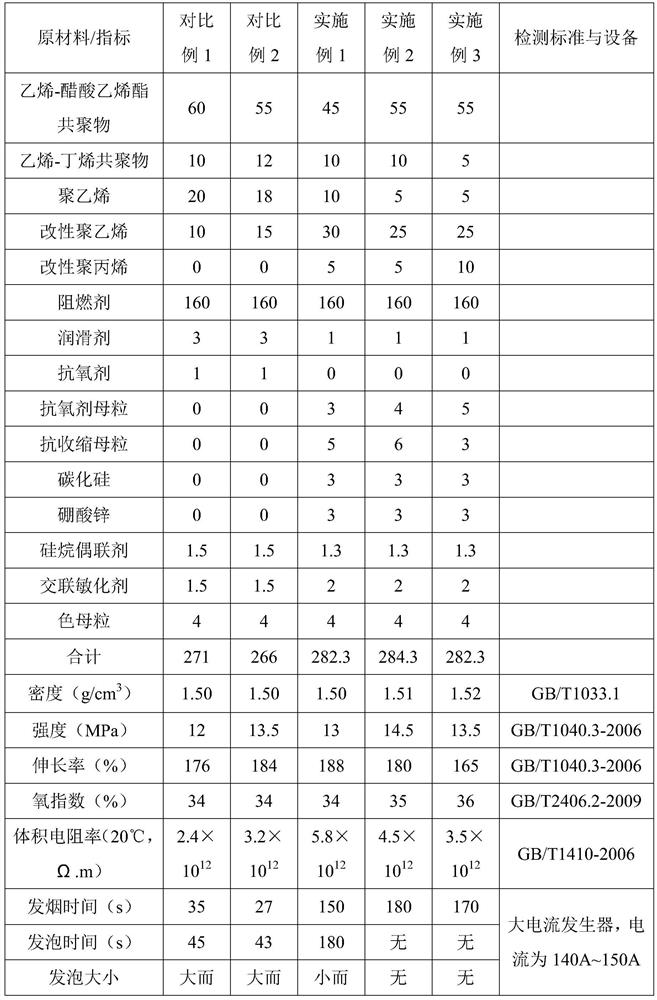

Examples

preparation example Construction

[0056] The preparation method of antioxidant masterbatch is as follows:

[0057] After weighing the antioxidant, polyethylene resin, and silicone masterbatch according to the proportion, add them to the high mixer and mix evenly, mix at low speed for 5 minutes, and mix at high speed for 2 minutes. The temperature of the material is controlled at 60-80°C. Then put the uniformly mixed powder into the feeding hopper of the Buss machine, and use the Buss machine to carry out plasticization, extrusion and granulation. Calculated according to the mass percentage, the material ratio of the masterbatch is as follows:

[0058] Antioxidant: 50%

[0059] Polyethylene resin: 49%

[0060] Silicone masterbatch: 1%;

[0061] The antioxidants are tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, 4,4'-thiobis(6-tert-butyl-3-methylphenol , Three kinds of three [2.4-di-tert-butylphenyl] phosphite, the ratio is 3:1:1.

[0062] Polyethylene resin is powdery linear lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com