Photovoltaic glass production process

A production process and photovoltaic glass technology, applied in photovoltaic power generation, glass tempering, glass rolling, etc., can solve the problems of poor thickness uniformity and poor continuity of the original sheet, so as to improve rolling uniformity, reduce reflectivity, and improve anti-corrosion The effect of impact power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

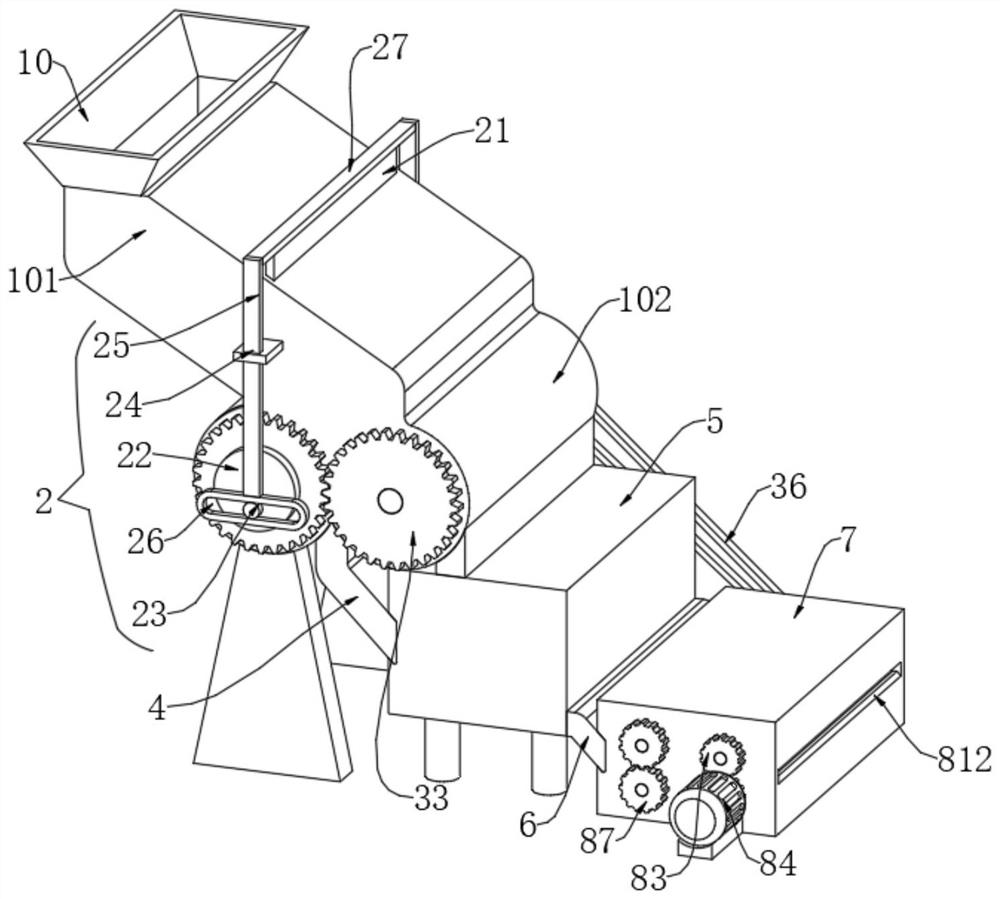

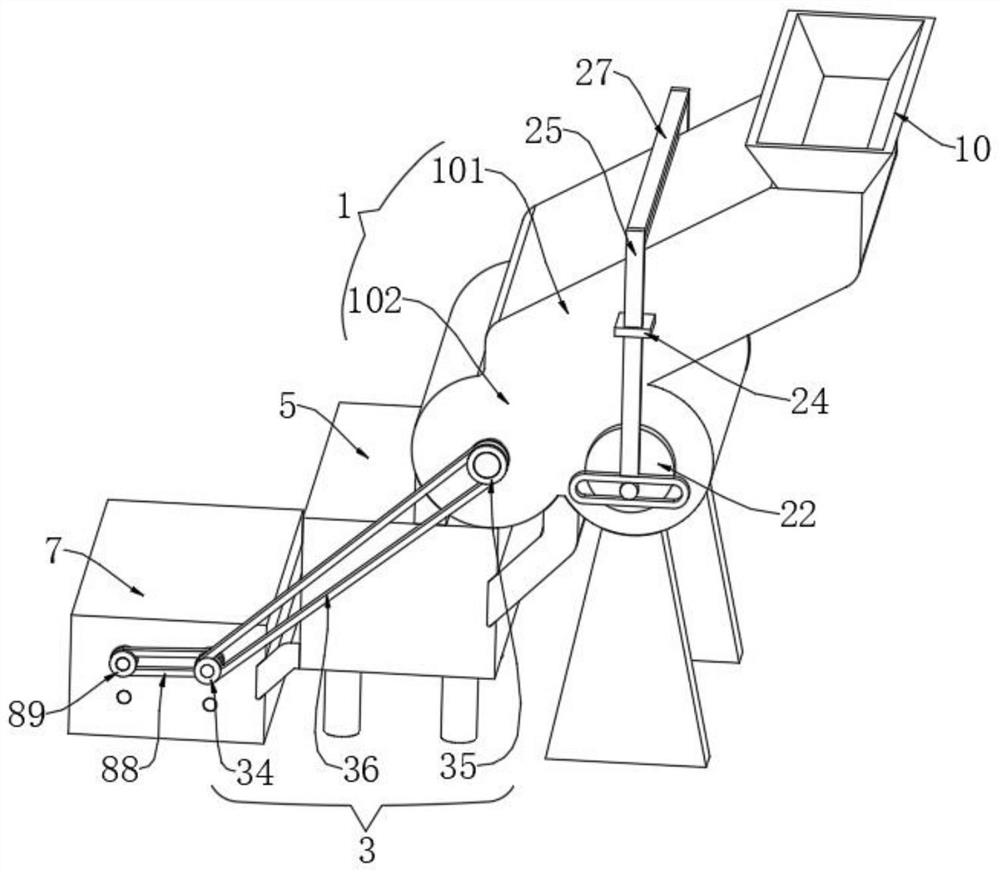

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

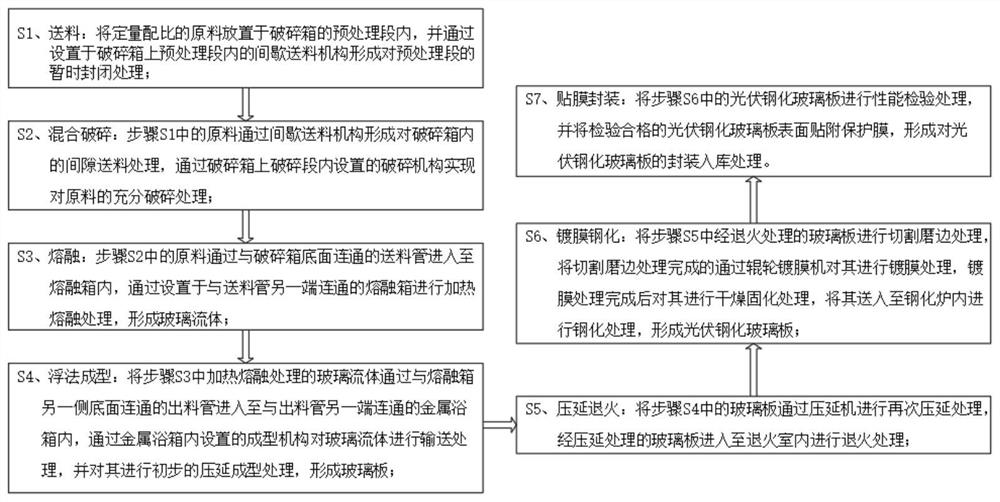

[0035] refer to Figure 1-9 , a photovoltaic glass production process, comprising the following steps:

[0036] S1. Feeding: Place the quantitatively proportioned raw materials in the pre-processing section 101 of the crushing box 1, and form a temporary closure to the pre-processing section 101 through the intermittent feeding mechanism 2 arranged in the pre-processing section 101 on the crushing box 1 deal with;

[0037] S2. Mixing and crushing: the raw materials in step S1 are processed by the intermittent feeding mechanism 2 to form a gap feeding process in the crushing box 1, and the crushing mechanism 3 provided in the crushing secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com