LF furnace refining method with high scrap ratio

A scrap steel ratio and scrap steel technology, which is applied in the field of iron and steel metallurgy, can solve the problems of prolonging the refining treatment cycle, damaging the ladle breathable brick and the ladle drain, the fluidity of molten steel, and the impact of refining desulfurization, deoxidation, and alloying, so as to increase the number of enterprises The effect of operating benefits, reducing carbon emissions from scrap steel, and shortening the refining cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

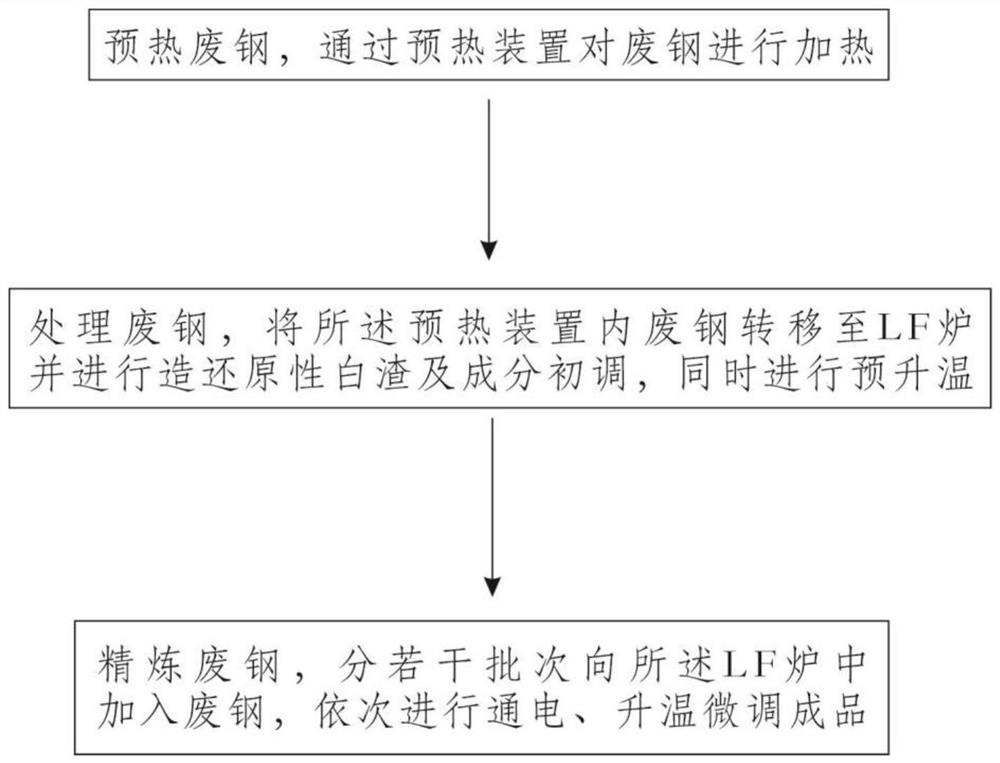

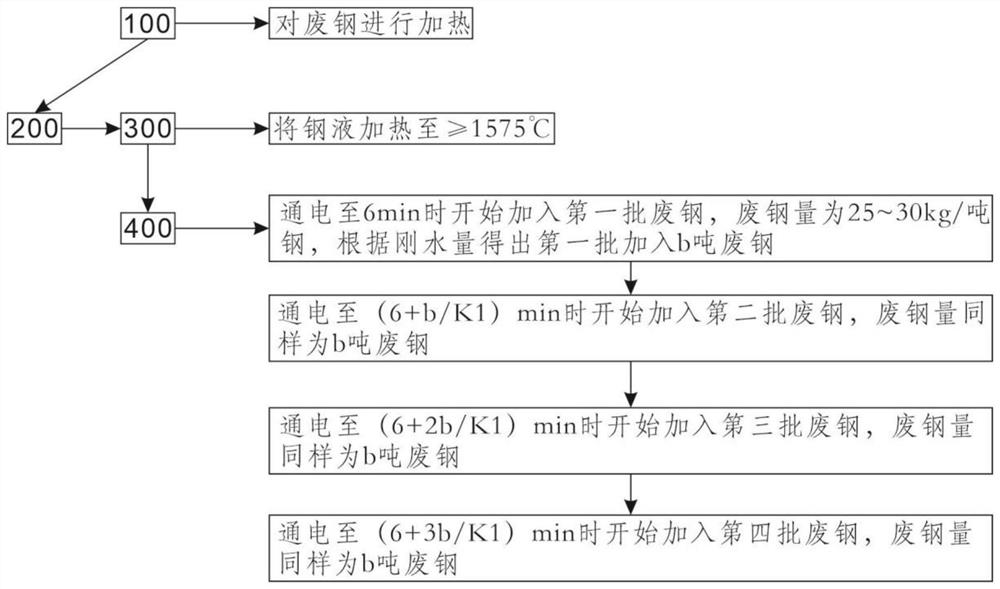

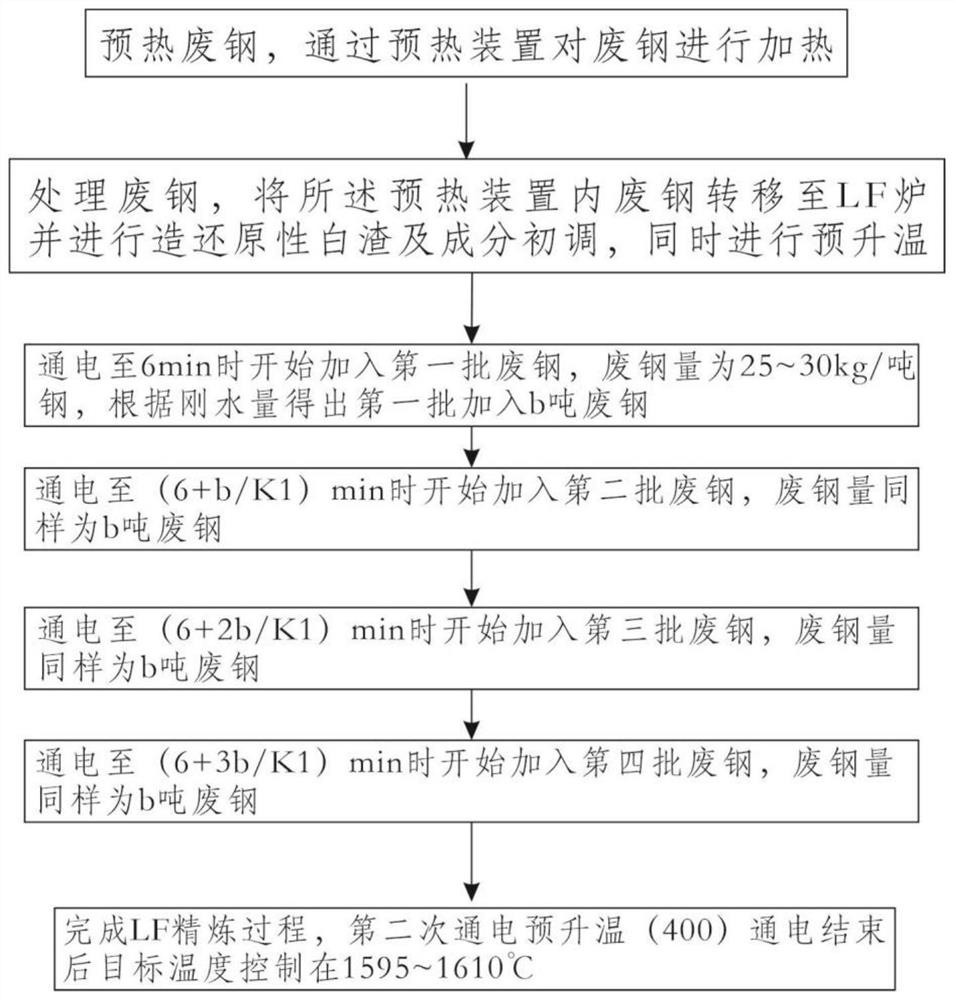

[0028] refer to Figure 1~3 , is the first embodiment of the present invention, provides a kind of high steel scrap ratio LF furnace refining method, this method comprises preheating steel scrap, the steel scrap is heated by preheating device 100; Processing scrap steel, described preheating device 100 The internal steel scrap is transferred to the LF furnace 200 for the production of reducing white slag and the initial adjustment of the composition, and at the same time, the temperature is pre-raised; and, for refining the scrap steel, adding scrap steel to the LF furnace 200 in several batches, and sequentially electrifying, heating and fine-tuning the finished product .

[0029] The LF furnace 200 adopts an LF refining furnace with an LF electrode heating efficiency of 4-6° C. / min. The preheating device 100 heats the steel scrap to 580-620° C., and the ladle clearance of the converter tapping of the preheating device 100 is controlled at 800-1000 mm. Reducing white slag a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com