Patents

Literature

107 results about "Edge tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

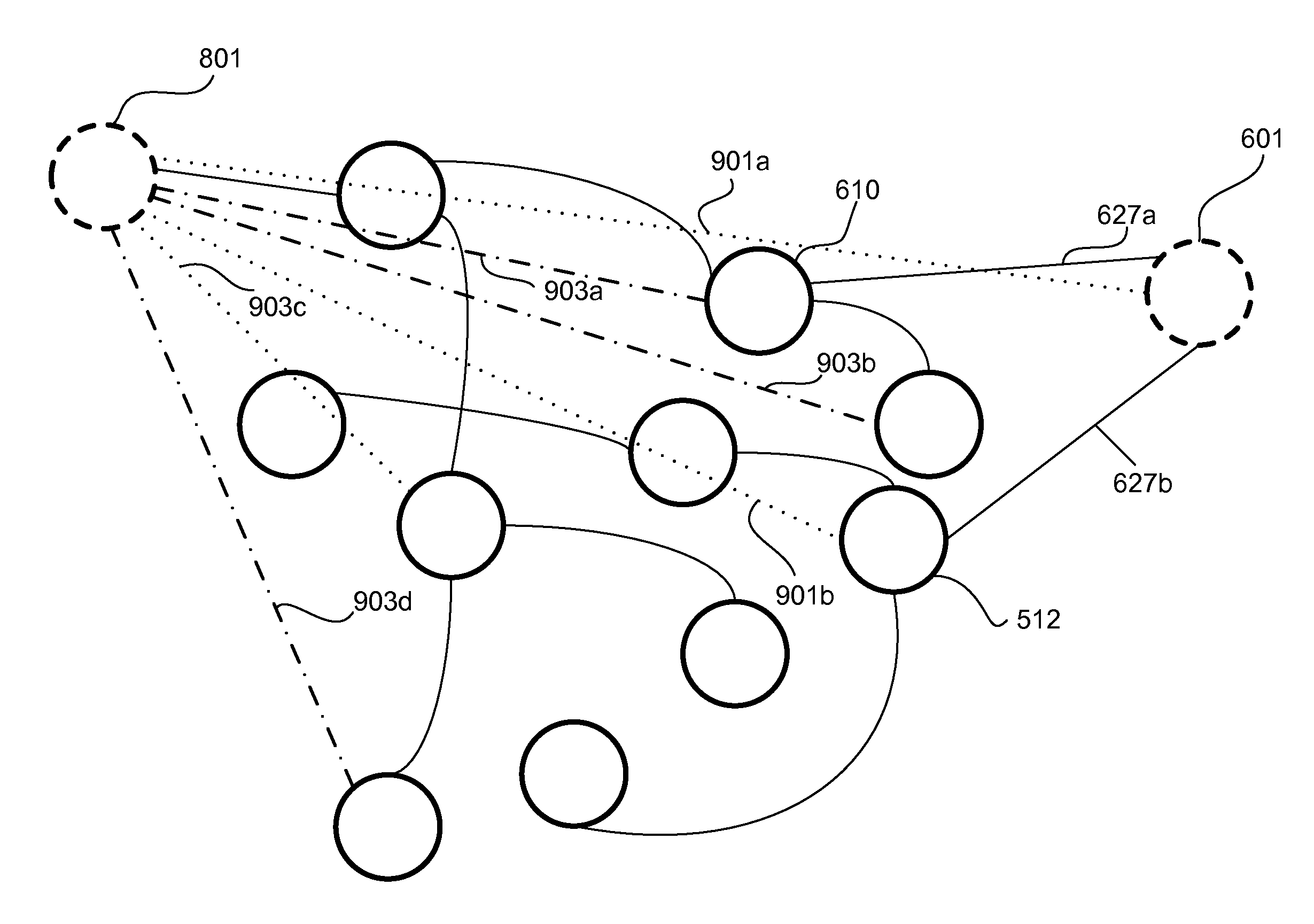

Altering weights of edges in a social graph

ActiveUS8736612B1Cost time and moneyData processing applicationsDrawing from basic elementsNODALSocial graph

A system gathers information on important and influential people and builds a social graph. The social graph can be processed to determine the influence of a node in the graph or a subsection of the graph. For the influence in a subsection of the graph, only nodes with a specific type of relationship or concept is included in the influence calculation. For example, for the concept art, only relationship that have to do with art are included in the influence calculation (e.g., museum, artists, musician). In an implementation, the edge-weight of edges of the system are dependent on a property of the edge. For example, the edge-weight for an edge tracking donations is stronger if the amount of money donated is higher.

Owner:BOARDEX LLC

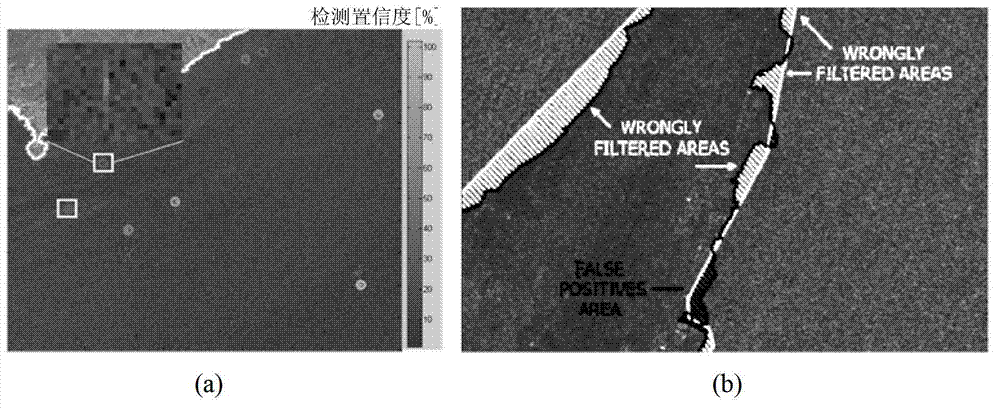

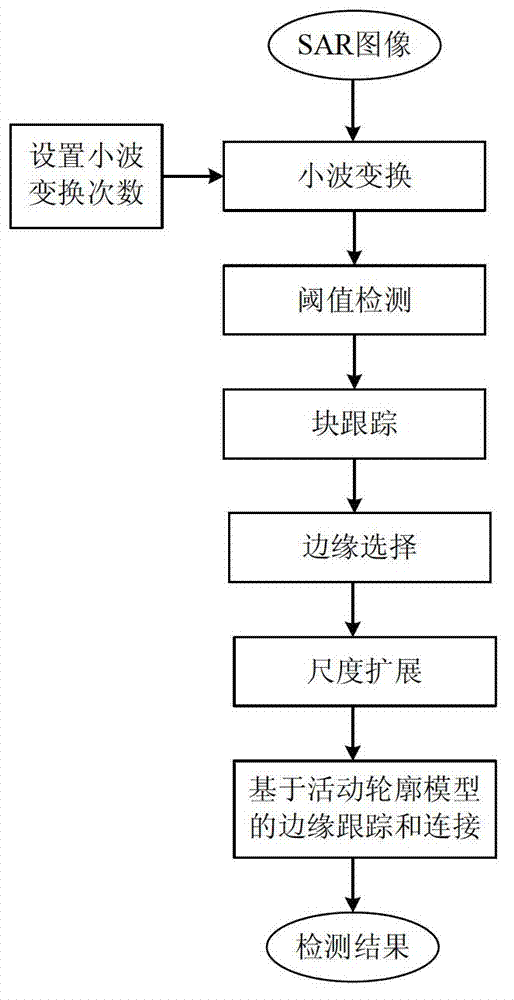

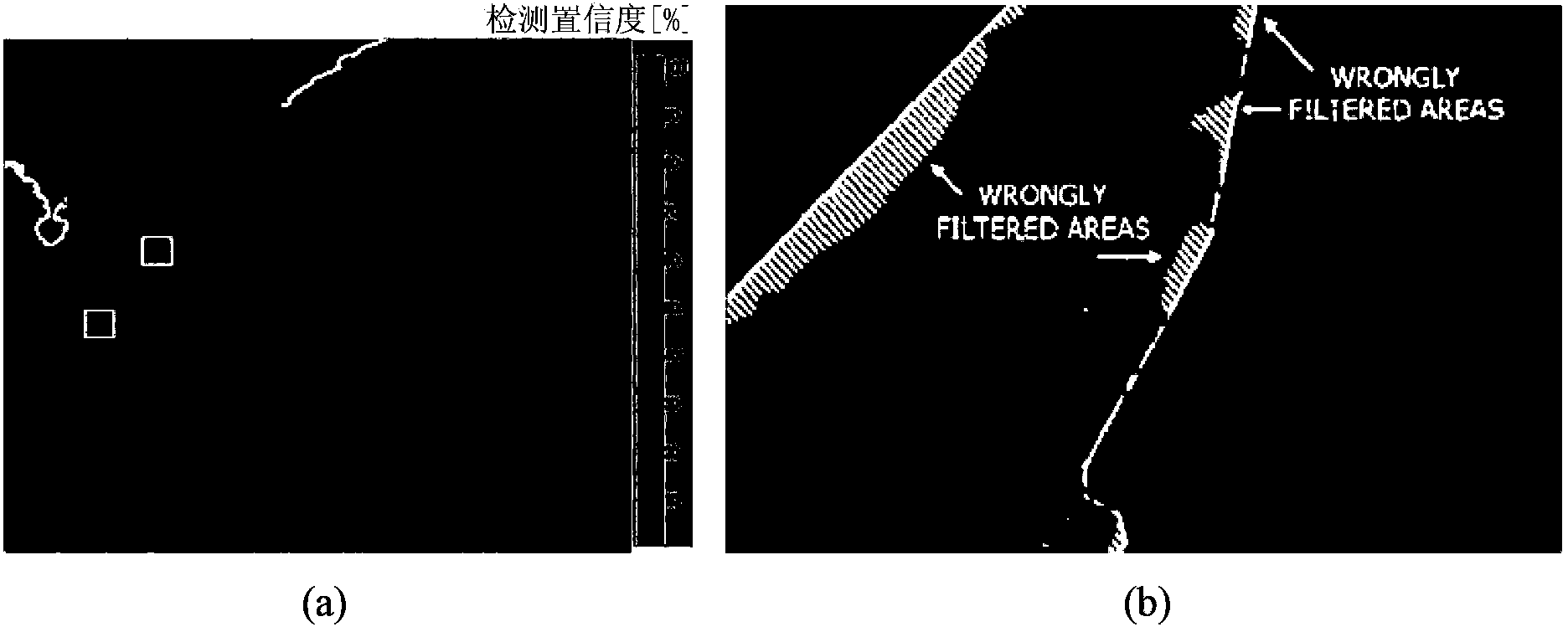

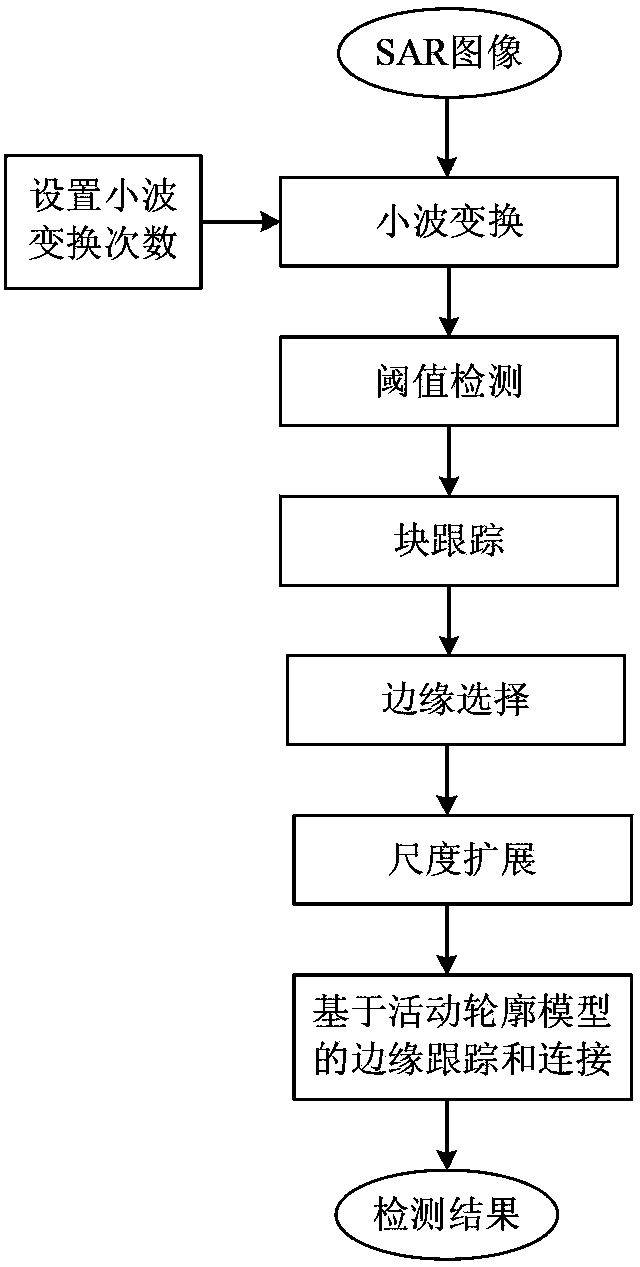

SAR (Synthetic Aperture Radar) image sea-land segmentation method based on wavelet transform and OTSU threshold

ActiveCN102968798ASuppression of speckleImprove applicabilityImage analysis2D-image generationPattern recognitionSynthetic aperture radar

The invention relates to an SAR (Synthetic Aperture Radar) image sea-land segmentation method based on a wavelet transform and OTSU threshold. According to the method, speckle noise in an SAR image is suppressed by using the noise smoothing property of wavelet transform; then land areas are roughly segmented by using an unsupervised optimal OTSU threshold method, and the detection results under each scale are merged based on the multiscale analysis property of wavelet transform; and finally the final coastline detection results are obtained through automatic subsequent treatment and edge tracking. Compared with the prior sea-land segmentation methods, the SAR (Synthetic Aperture Radar) image sea-land segmentation method comprehensively utilizes the speckle noise suppressing and multiscale analysis function of wavelet transform and the self-adaptive, unsupervised and high-robustness properties of the OTSU threshold algorithm, and has great improvement in automation degree, universality, simplicity and applicability of high-resolution SAR images.

Owner:BEIHANG UNIV

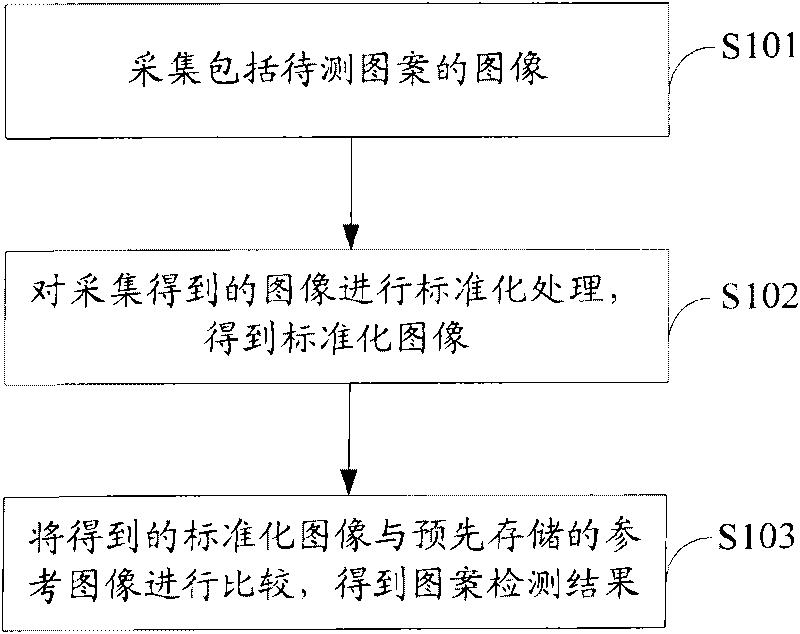

Pattern detection method, device, equipment and system

InactiveCN101751572AReduce testing costsReduce false positive rateCharacter and pattern recognitionPattern recognitionPattern detection

The invention provides a pattern detection method, a device, equipment and a system, which are applicable to the field of detection. The method comprises the following steps: collecting images comprising patterns to be detected; carrying out standardization treatment on the collected images to obtain standardized images; and comparing the standardized images with the pre-stored reference images to obtain image detection results. The standardization treatment comprises the gray scale binaryzation treatment on the collected images and the edge tracking treatment on the images after the binaryzation treatment. The embodiment of the invention avoids various defects caused by adopting a visual measurement method to detect the patterns, reduces the pattern detection cost and the incorrect judging rate, and improves the pattern detection efficiency and the consistency.

Owner:BYD CO LTD

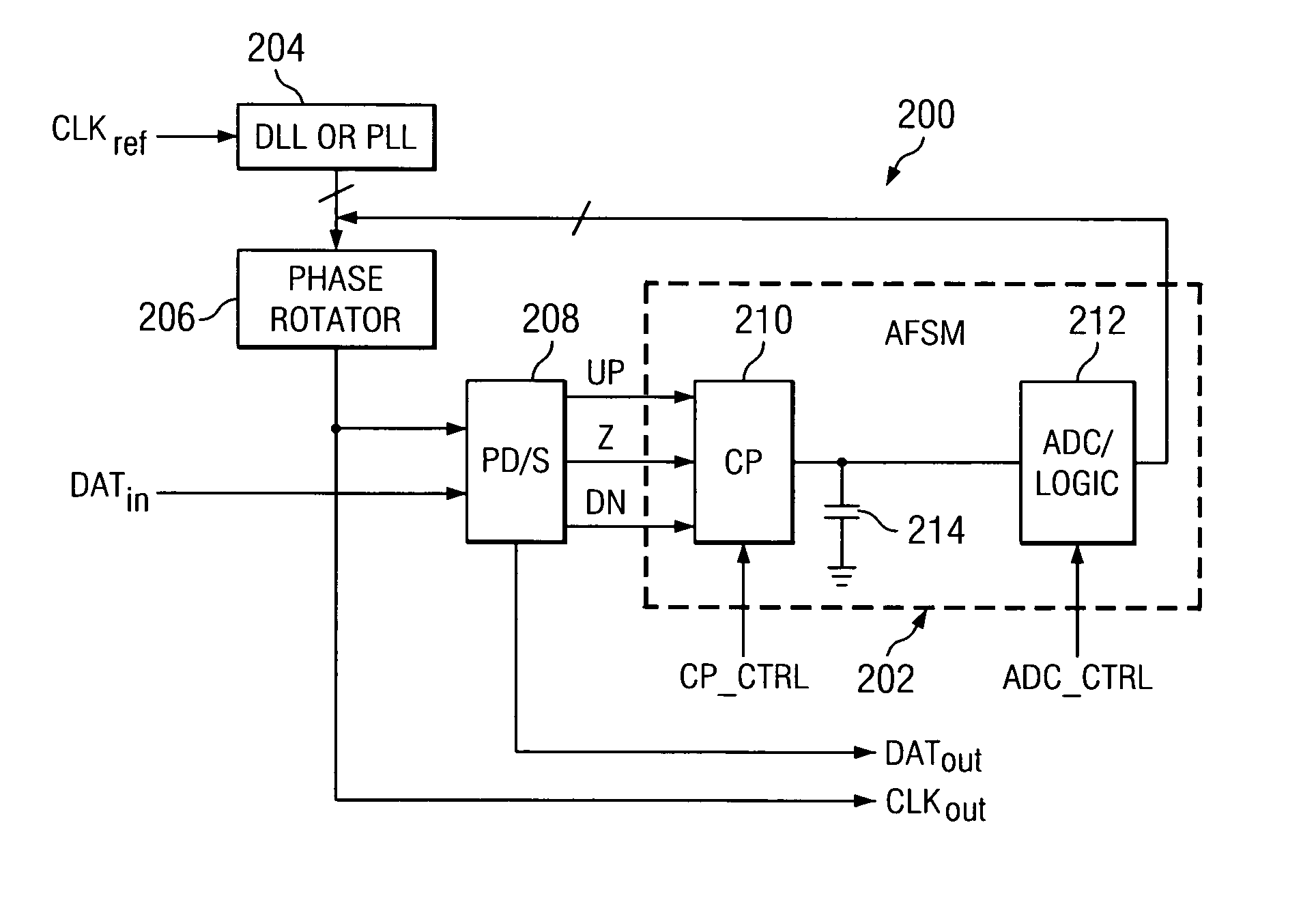

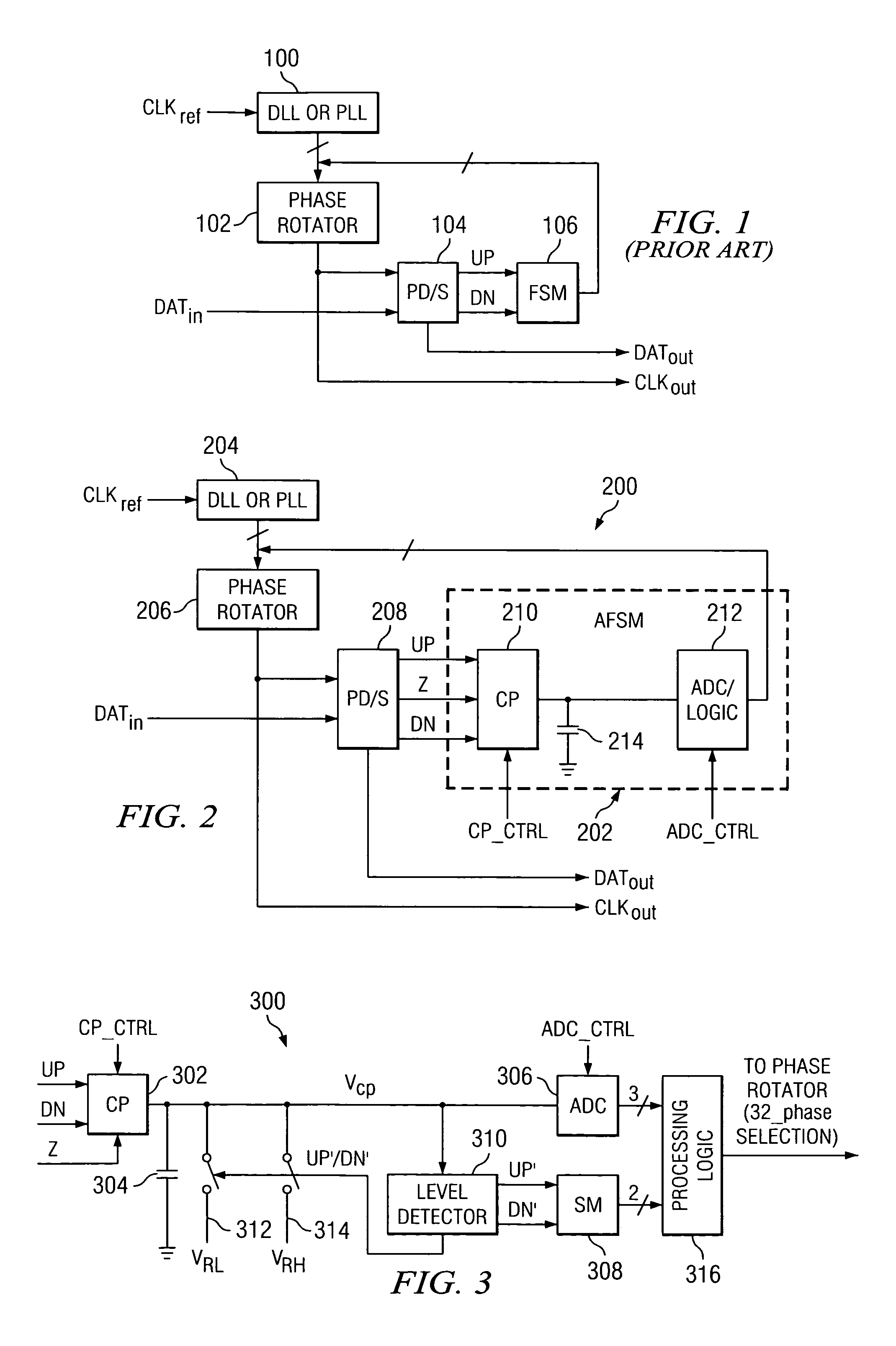

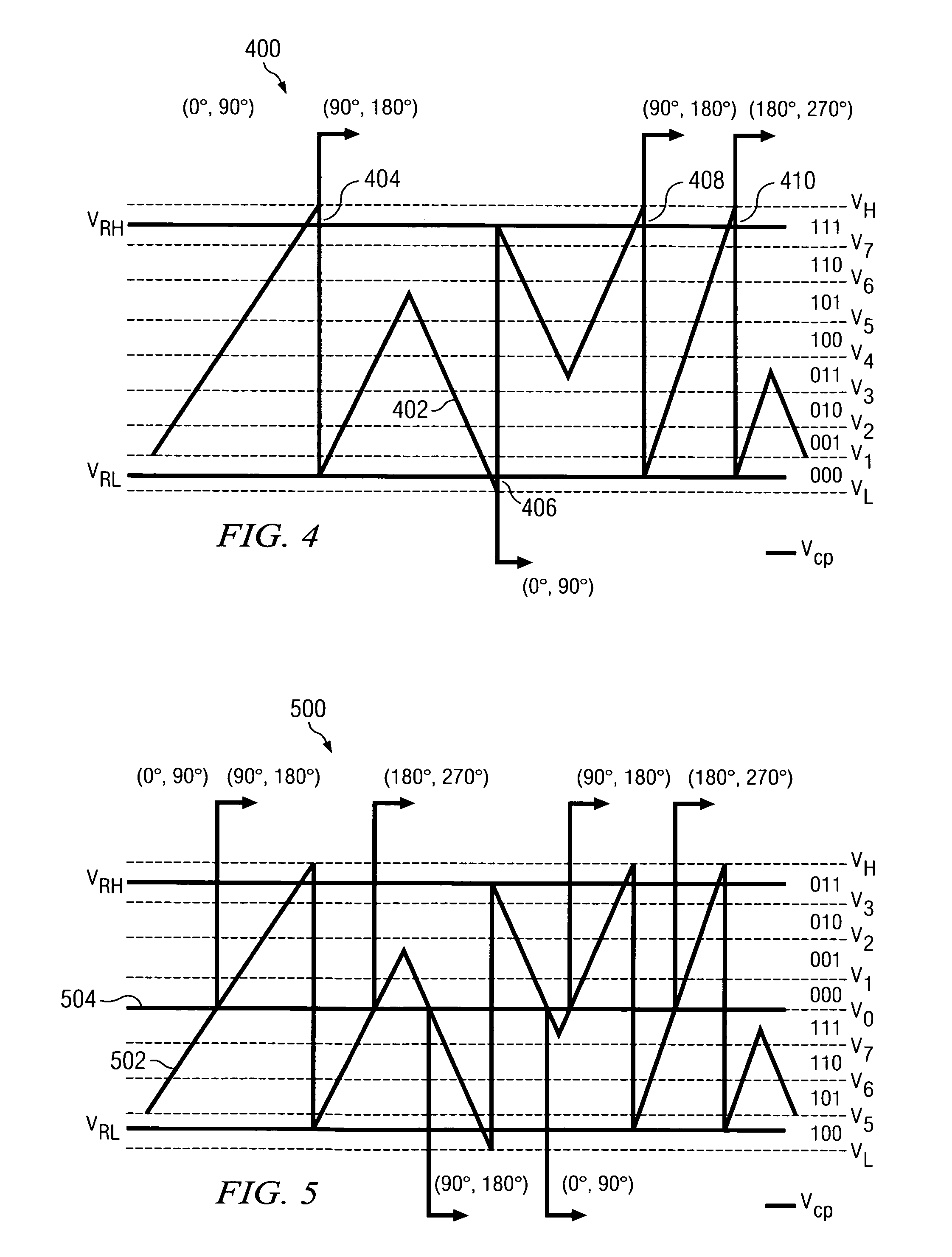

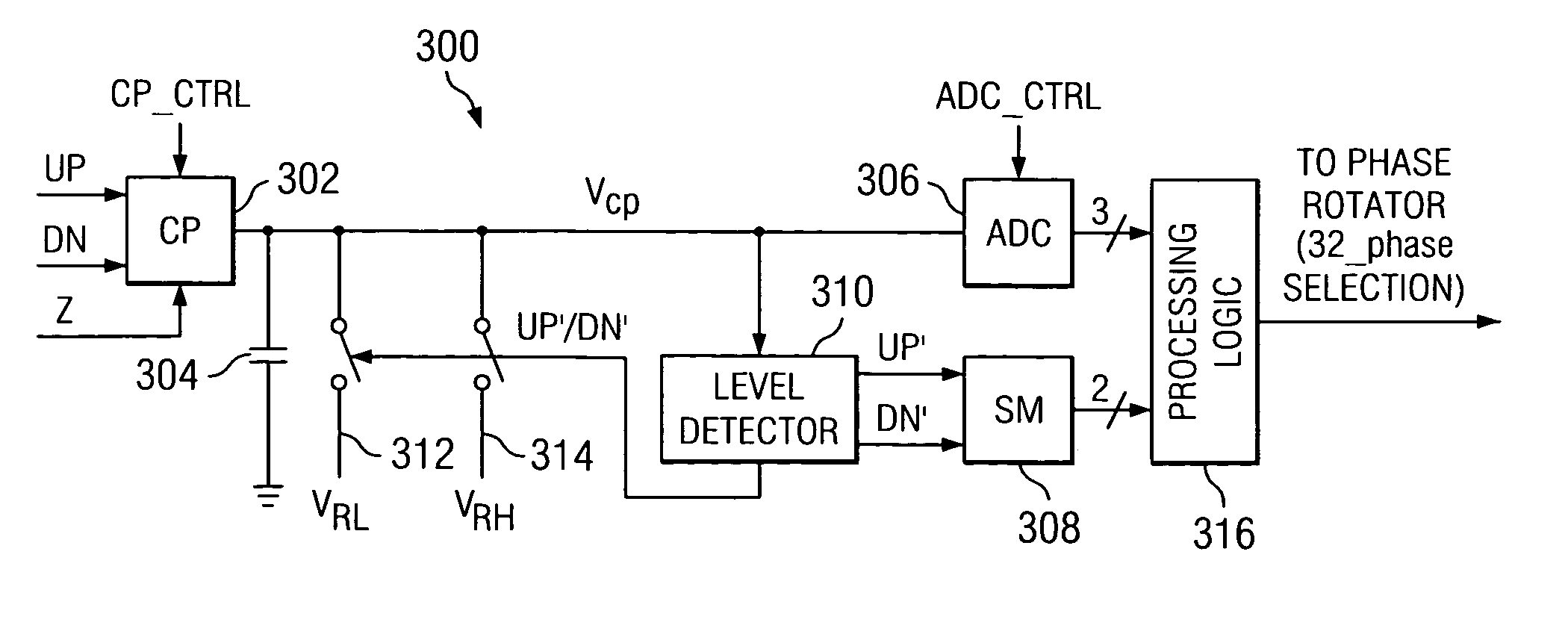

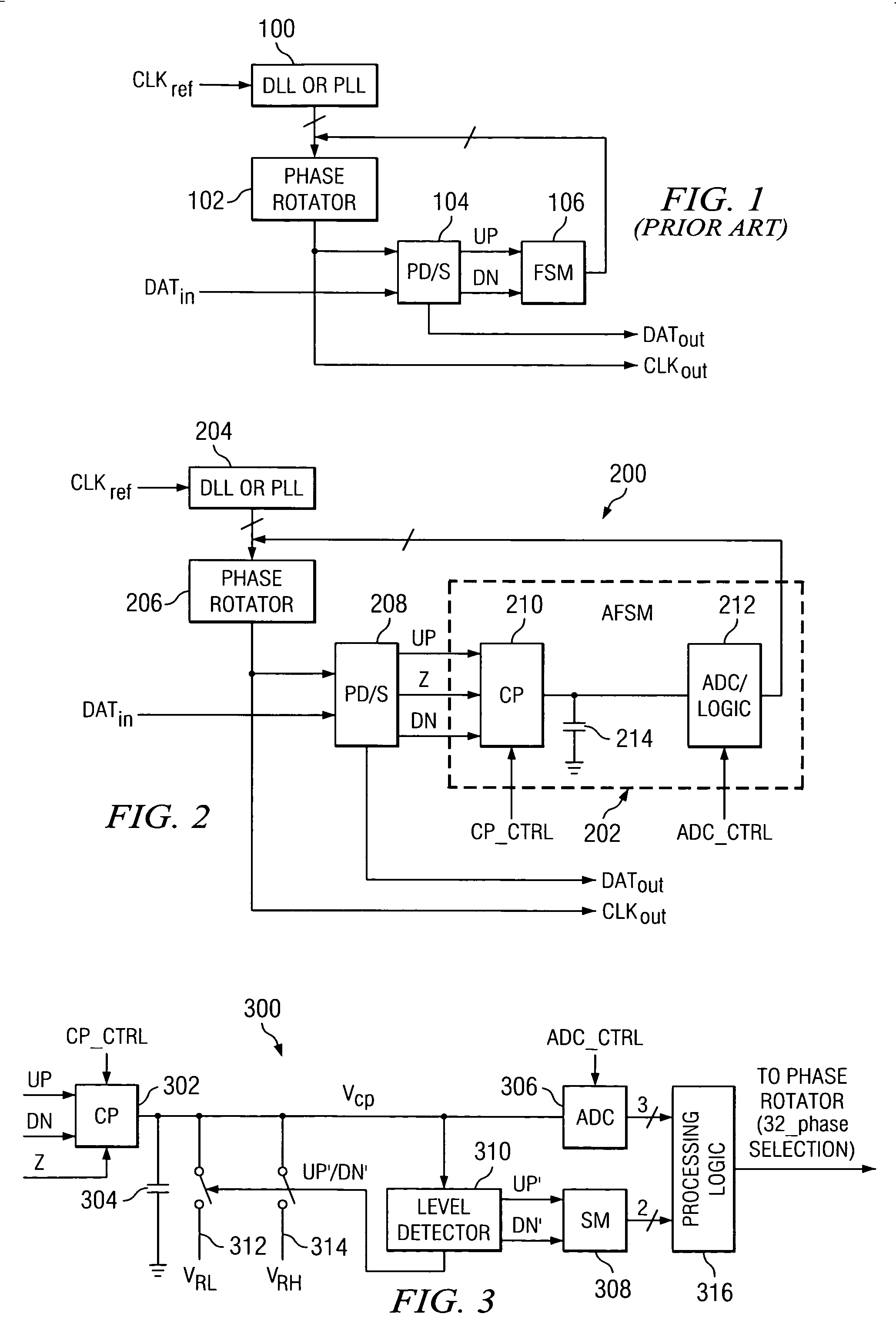

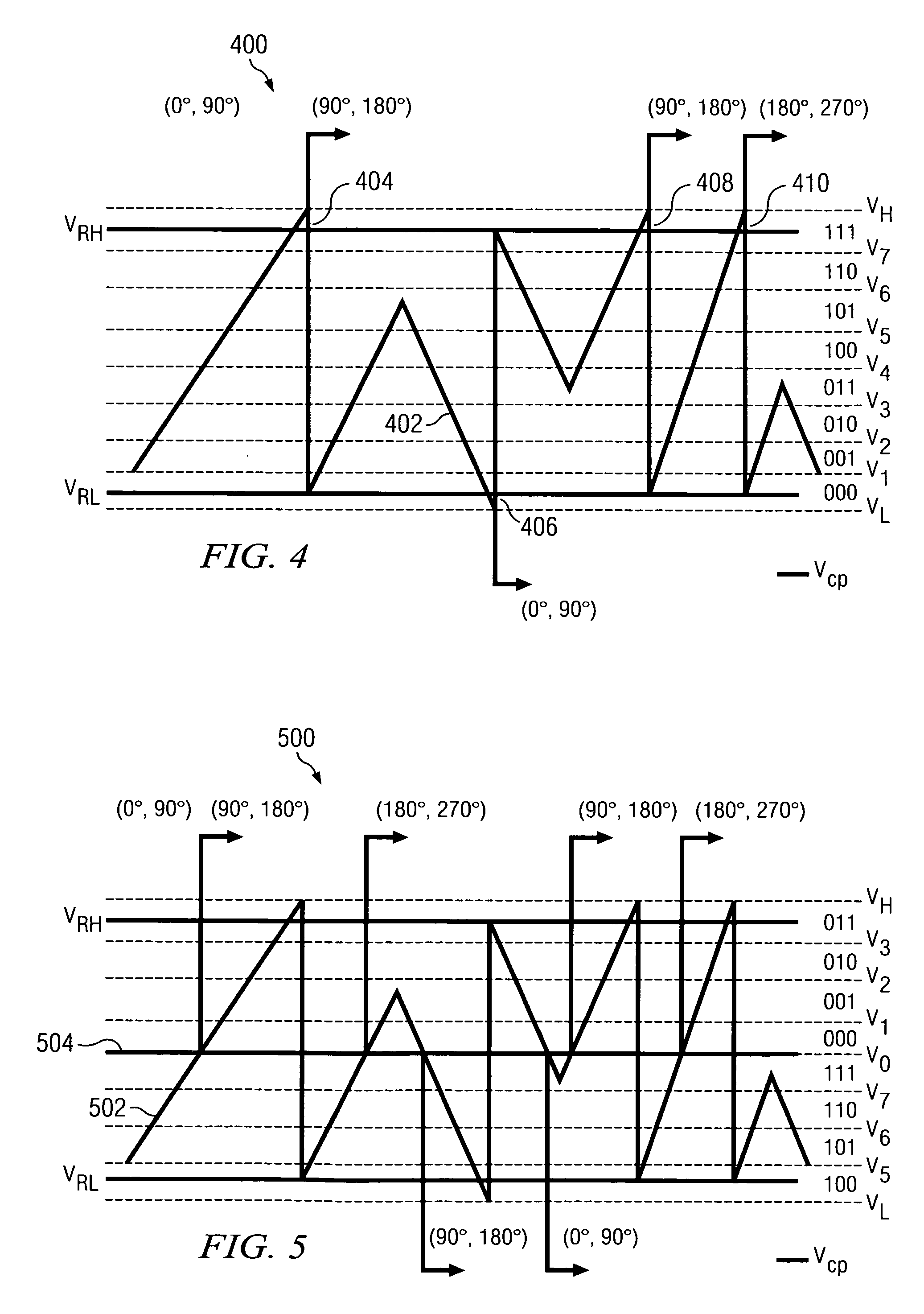

Semidigital delay-locked loop using an analog-based finite state machine

InactiveUS6927611B2Increase powerComplexity of hardwarePulse automatic controlSynchronising arrangementDigital signal processingEngineering

A low-power full-rate semidigital DLL architecture using an analog-based FSM (AFSM). The AFSM is a mixed-mode FSM in which analog integration is substituted for digital filtering, thus enabling a lower power implementation of the clock and data recovery function. An integrated voltage is converted to a digital code by an analog-to-digital converter (ADC), and the digital code is used either directly or after (low frequency) digital signal processing to control a controllable delay element, such as, a phase rotator, for data edge tracking.

Owner:GLOBALFOUNDRIES US INC

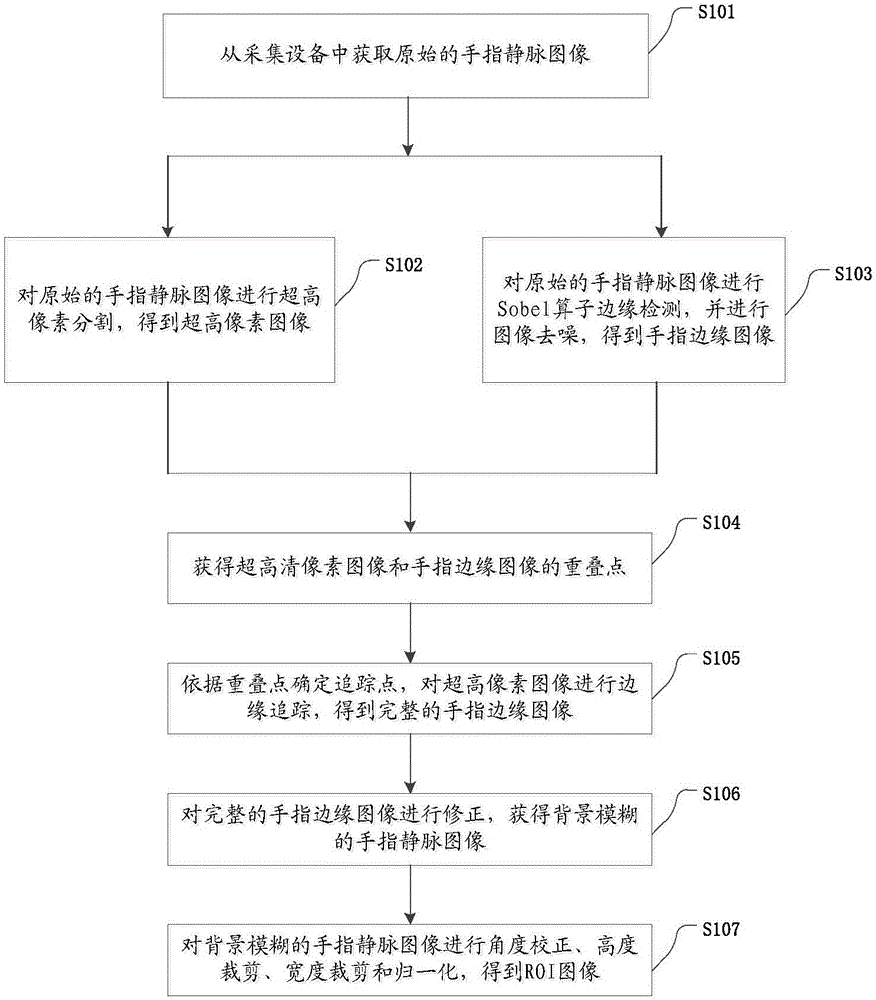

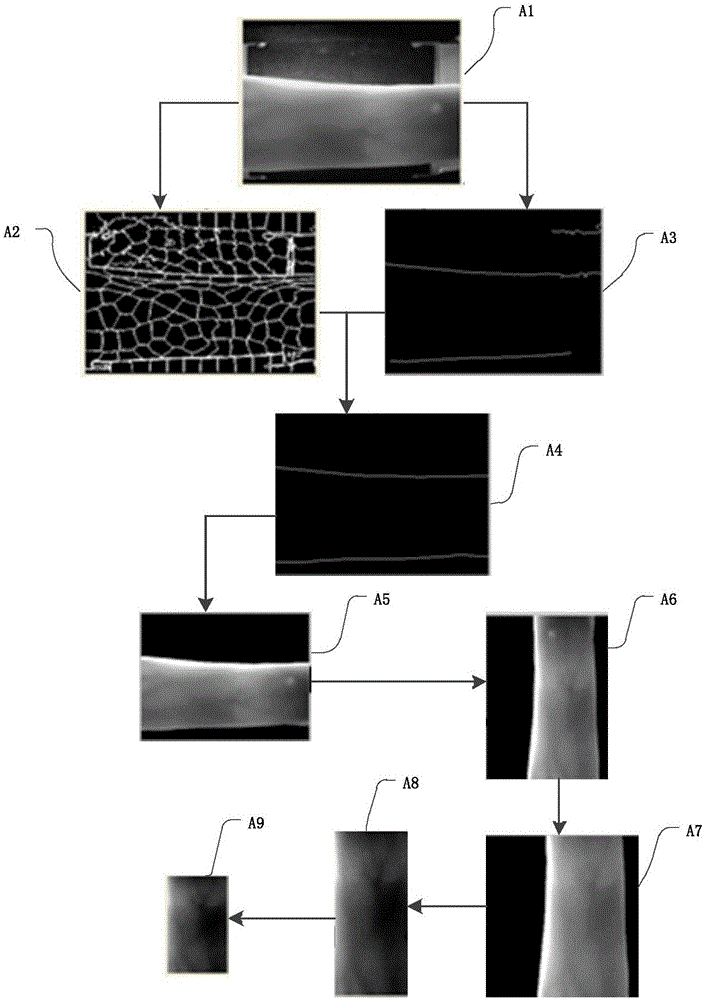

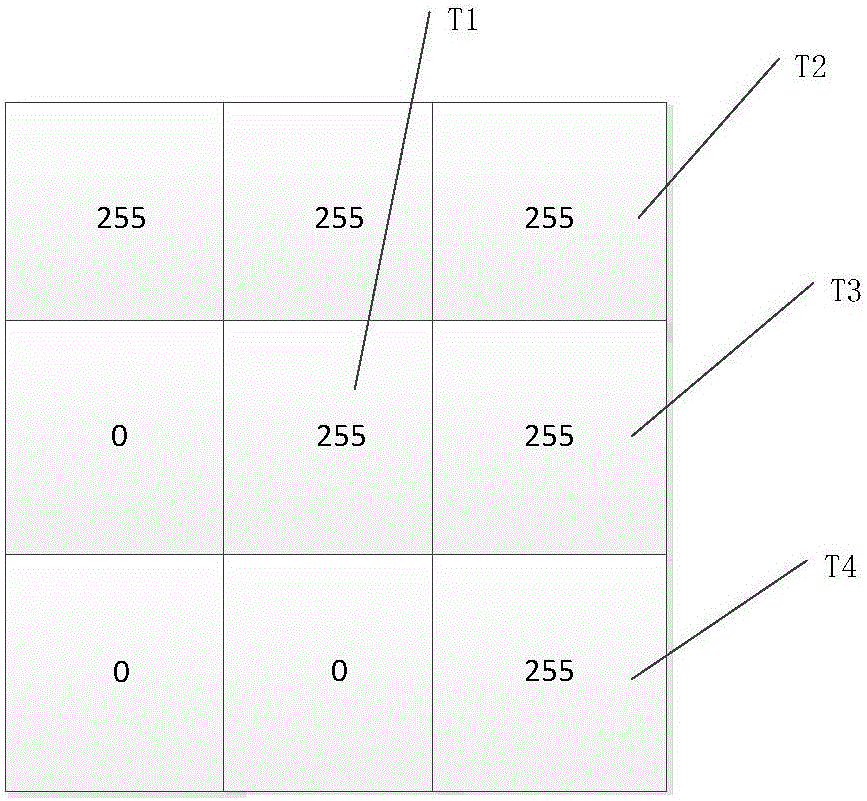

ROI image extraction method in finger vein identification

InactiveCN105975974AGood segmentation effectImprove effectivenessImage enhancementImage analysisBoundary contourImage extraction

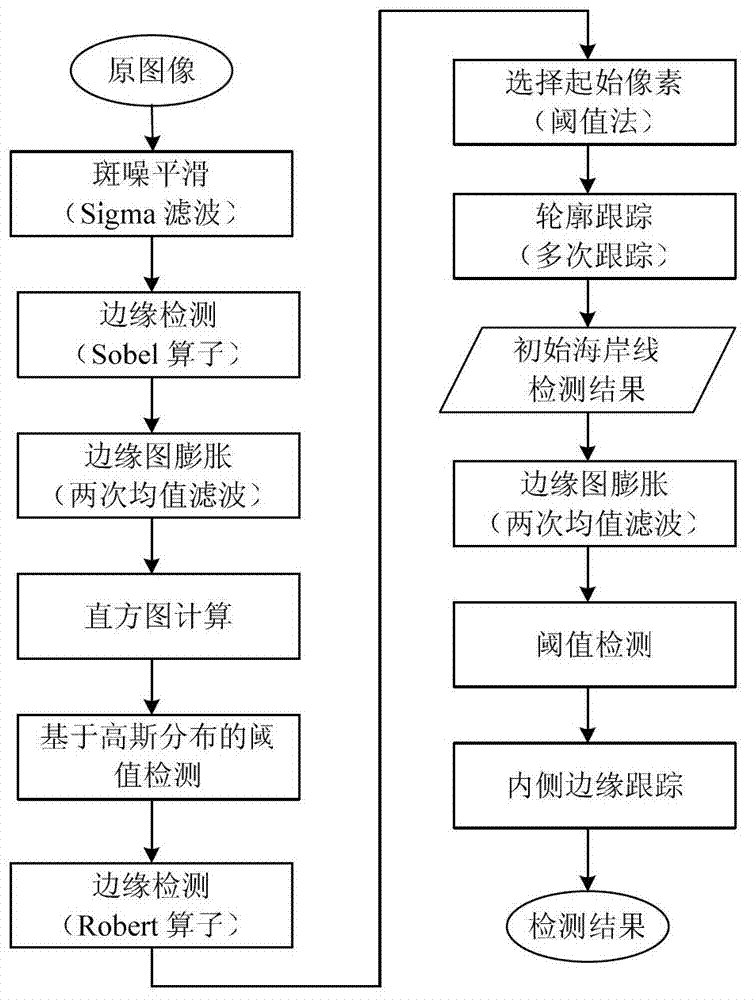

The invention discloses an ROI image extraction method in finger vein identification. The method comprises that an original finger vein image is obtained from a collector; superhigh pixel segmentation is carries out on the original finger vein image to obtain a superhigh pixel image; Sobel operator edge detection is carried out on the original finger vein image to remove noise from the image and obtain a finger edge image; overlapped points of the superhigh pixel image and the finger edge image are obtained; tracking points are determined according to the overlapped points, edge tracking is carried out on the superhigh pixel image, and a complete finger edge image is obtained; the complete finger edge image is corrected to obtain a finger vein image with a fuzzy background; and angle correction, height cutting, width cutting and normalization are carried out on the finger vein image with the fuzzy background to obtain an ROI image. The extracted ROI image includes a complete finger boundary contour, and the segmentation effect is good.

Owner:深圳市金脉智能识别科技有限公司

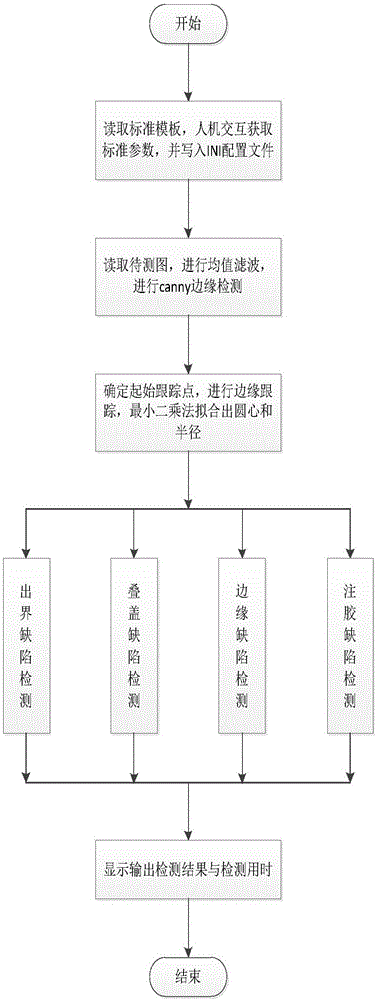

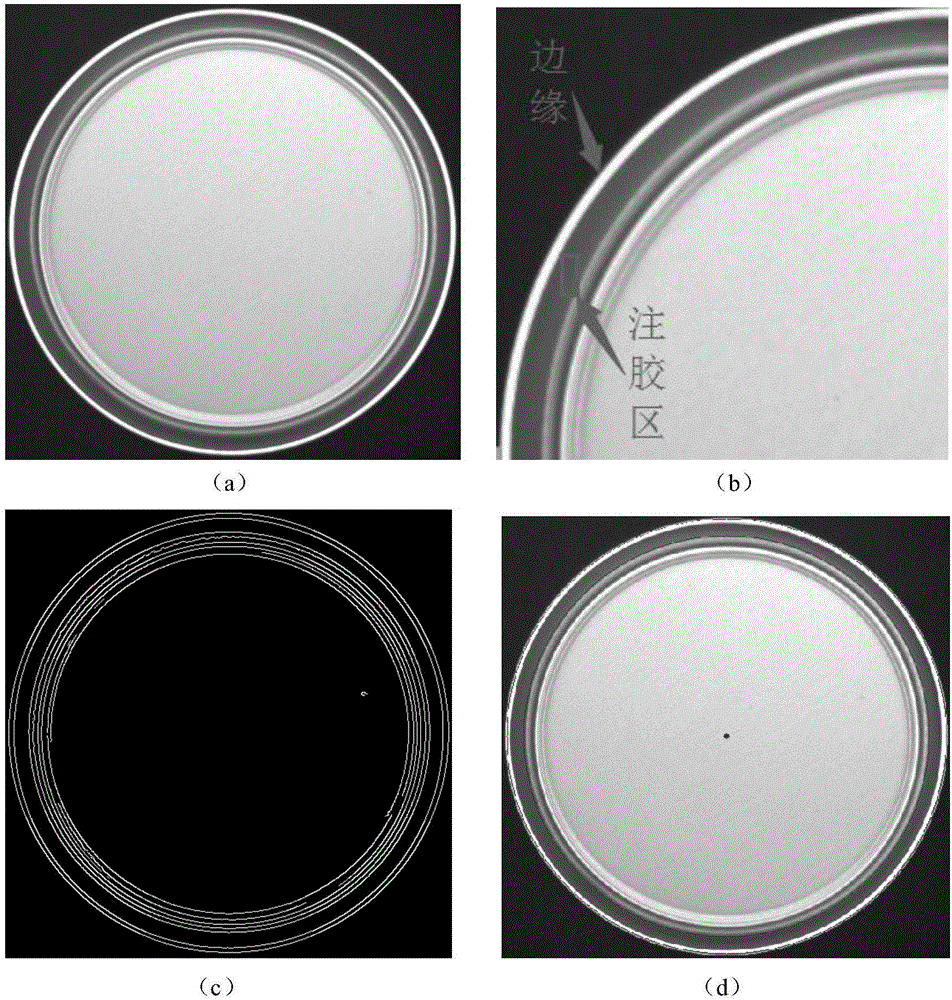

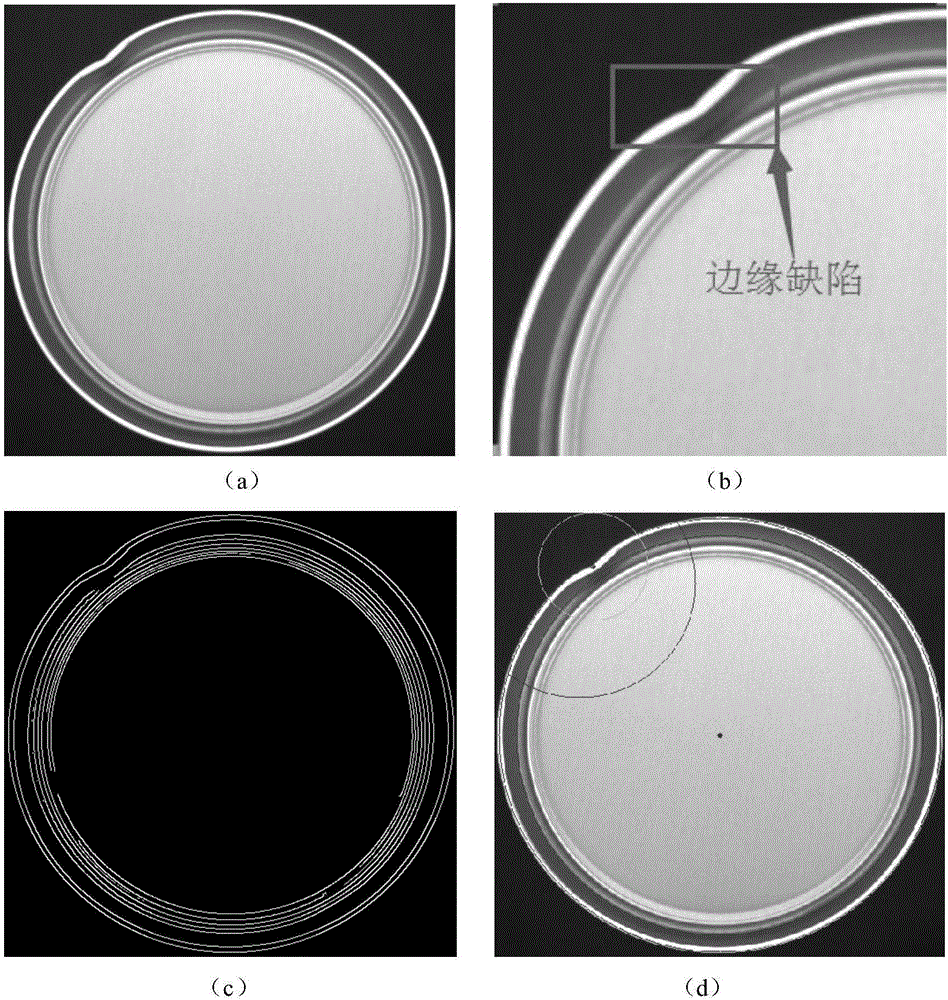

Cover defect detection method based on image processing

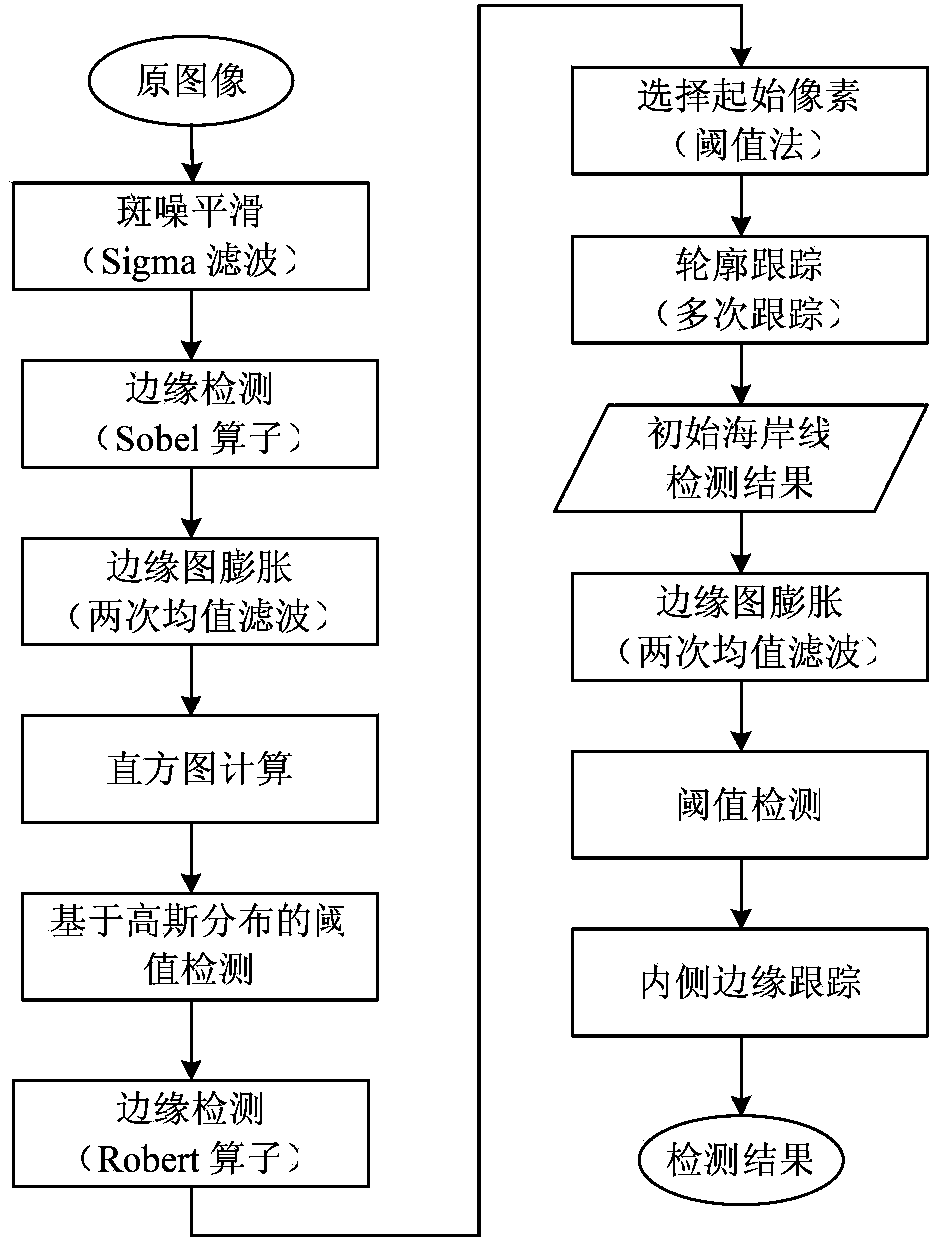

InactiveCN106251352AReal-time online detectionHigh-precision detectionImage enhancementImage analysisProduction lineImaging processing

The invention discloses a cover defect detection method based on image processing. The method comprises steps that S1, an excircle contour radius and glue injection zone width of a standard image are acquired in a man-machine interaction mode; S2, edge detection on a to-be-detected cover image is carried out to determine an edge image; S3, edge tracking of the edge image is carried out to acquire edge points, edge fitting of the edge points is carried out to acquire a fitting circle center position and a fitting radius; in combination with the glue injection zone width of the standard image, the fitting circle center position and the fitting radius, the glue injection zone is determined; and S4, cover defect detection and identification are carried out. Through the method, properties of short time, high efficiency and good timely detection effect are realized, and the excellent detection effect is acquired in an actual production line.

Owner:WUHAN UNIV

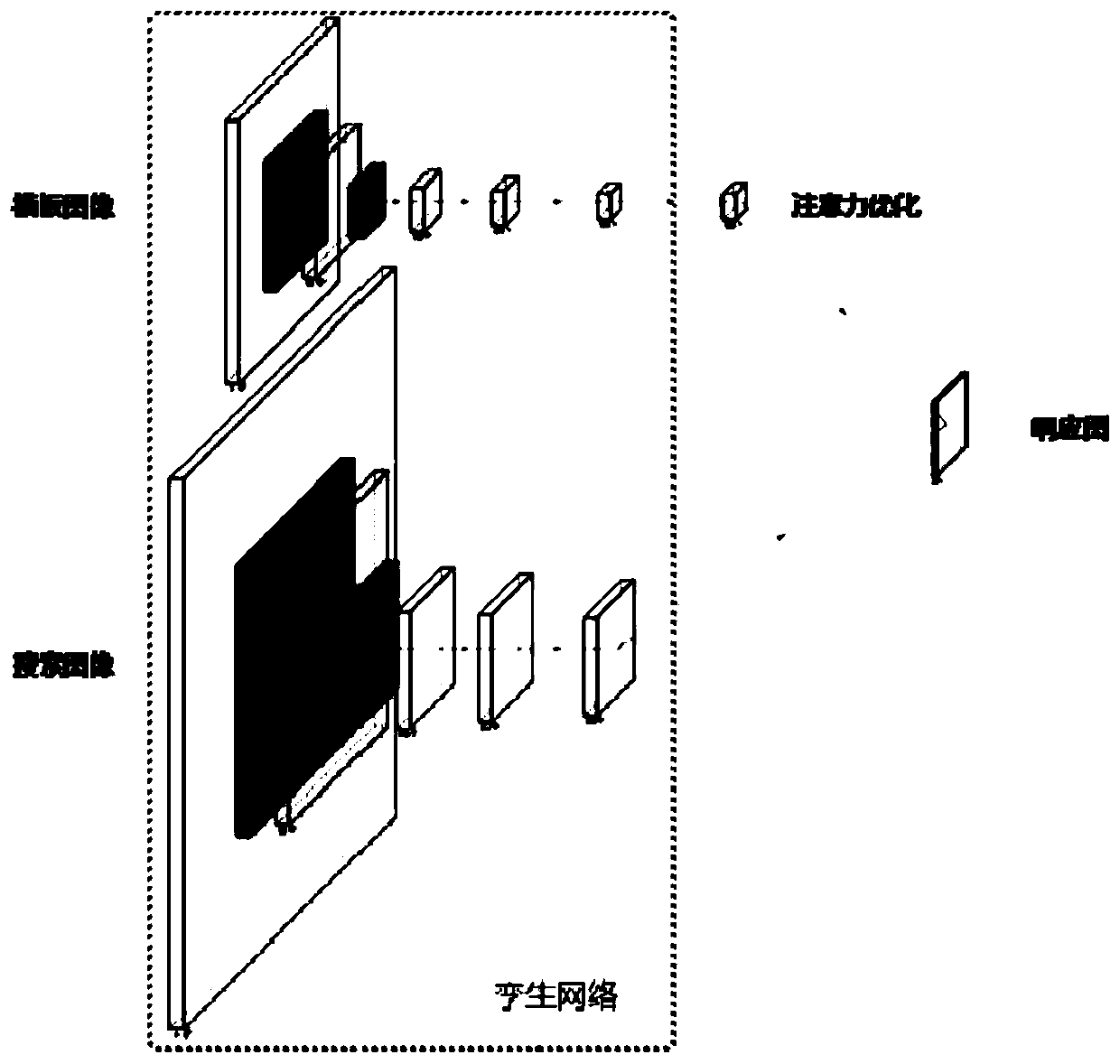

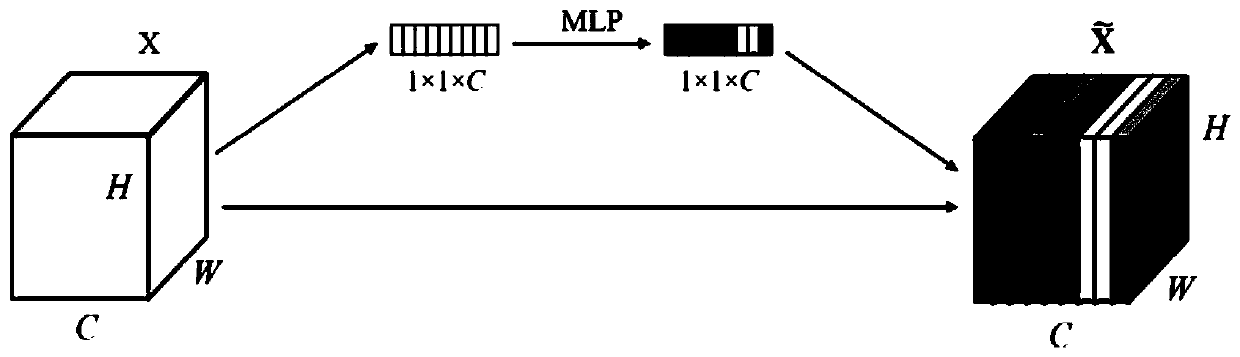

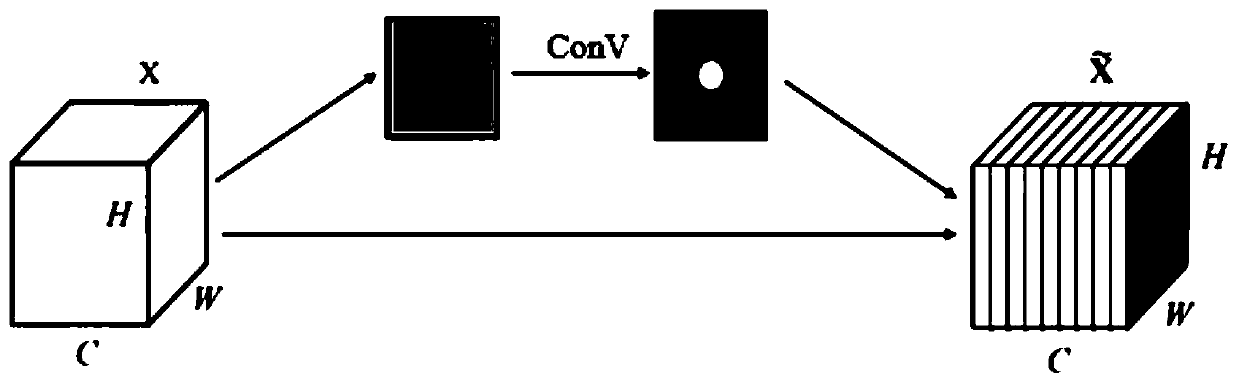

Unmanned aerial vehicle tracking method based on twin neural network and attention model

InactiveCN110675423AImprove generalization abilityImprove universalityImage enhancementImage analysisPattern recognitionAttention model

The invention relates to the technical field of image processing, in particular to an unmanned aerial vehicle tracking method based on a twin neural network and an attention mechanism, which is applied to continuously tracking a visual single-target unmanned aerial vehicle. According to the method, weight redistribution of channel attention and space attention is realized by using two attention mechanisms, and the representation capability of the model on an unmanned aerial vehicle target appearance model is enhanced by using an attention model for template branches of a twin network; and search images are preprocessed in a multi-scale zooming mode, response graph calculations are separately carried out, inverse transformation of scale changes of the unmanned aerial vehicle in a picture issimulated in the mode, search factors capable of generating larger response values serve as scale inverse transformation of the unmanned aerial vehicle so as to correct the size of a frame used for marking a target, and the transverse-longitudinal proportion of the frame is not changed. According to the method, the tracking precision of 0.513 is obtained through testing (the average coincidence rate is used as a quantization precision standard), and compared with other leading-edge tracking methods, the method has the advantage that the performance is obviously improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

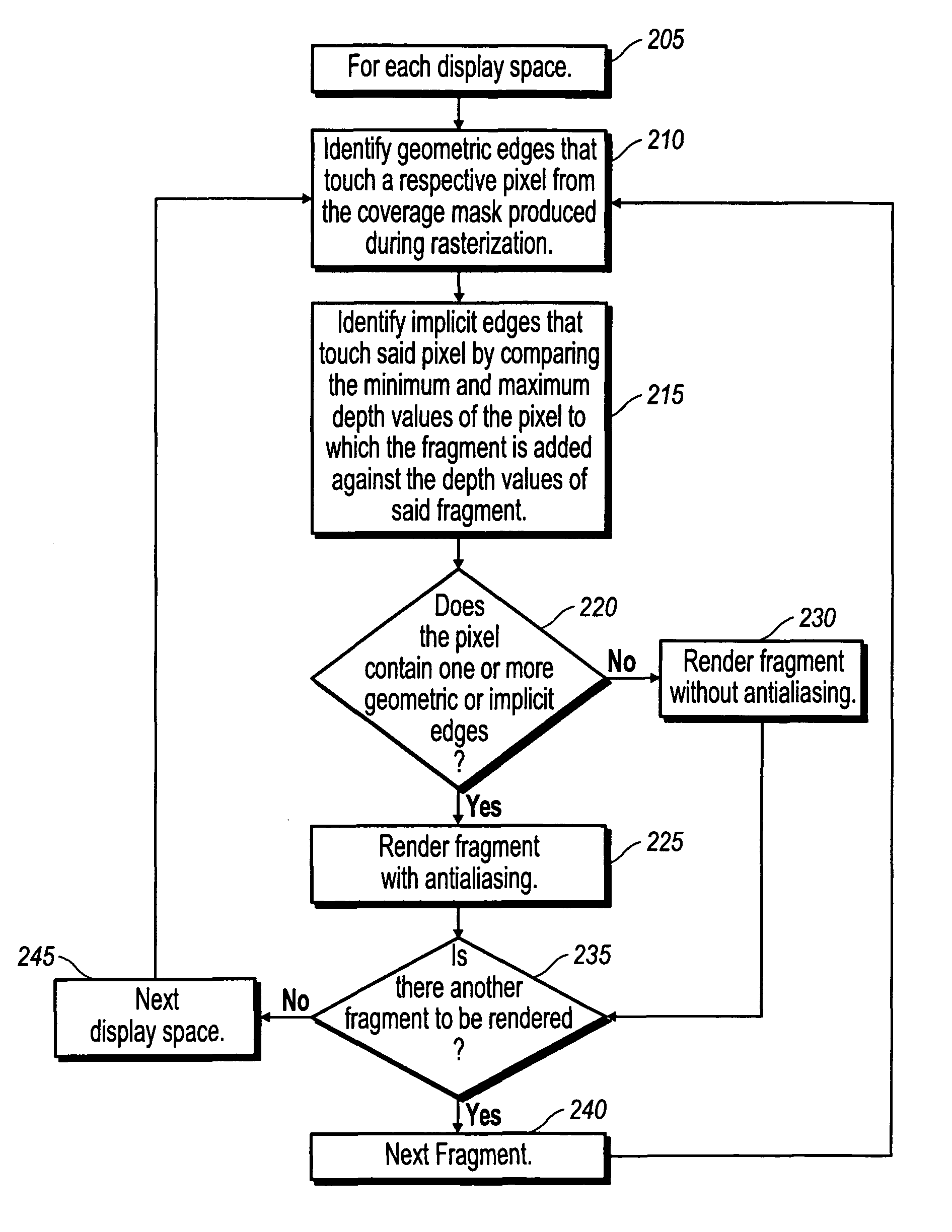

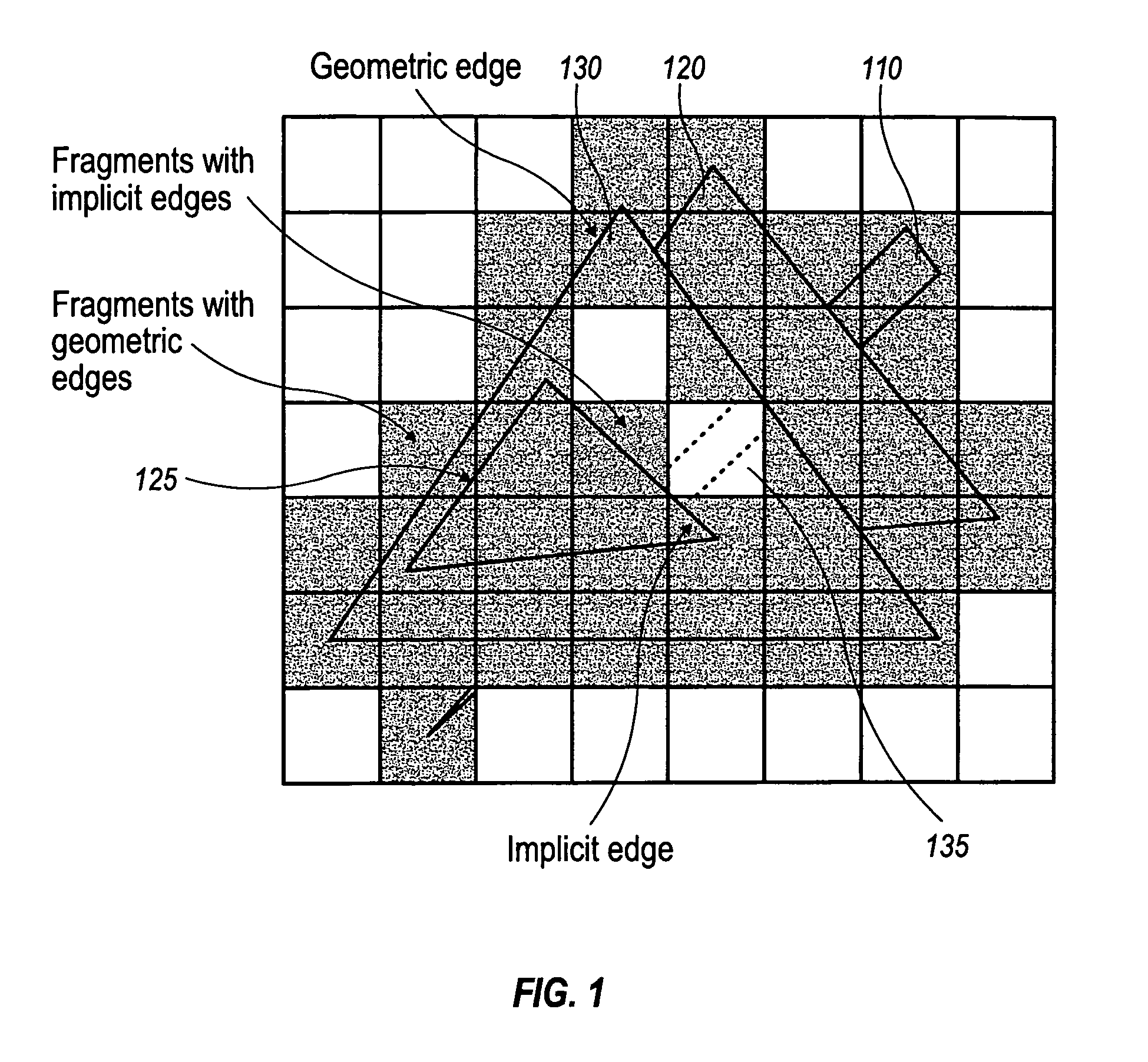

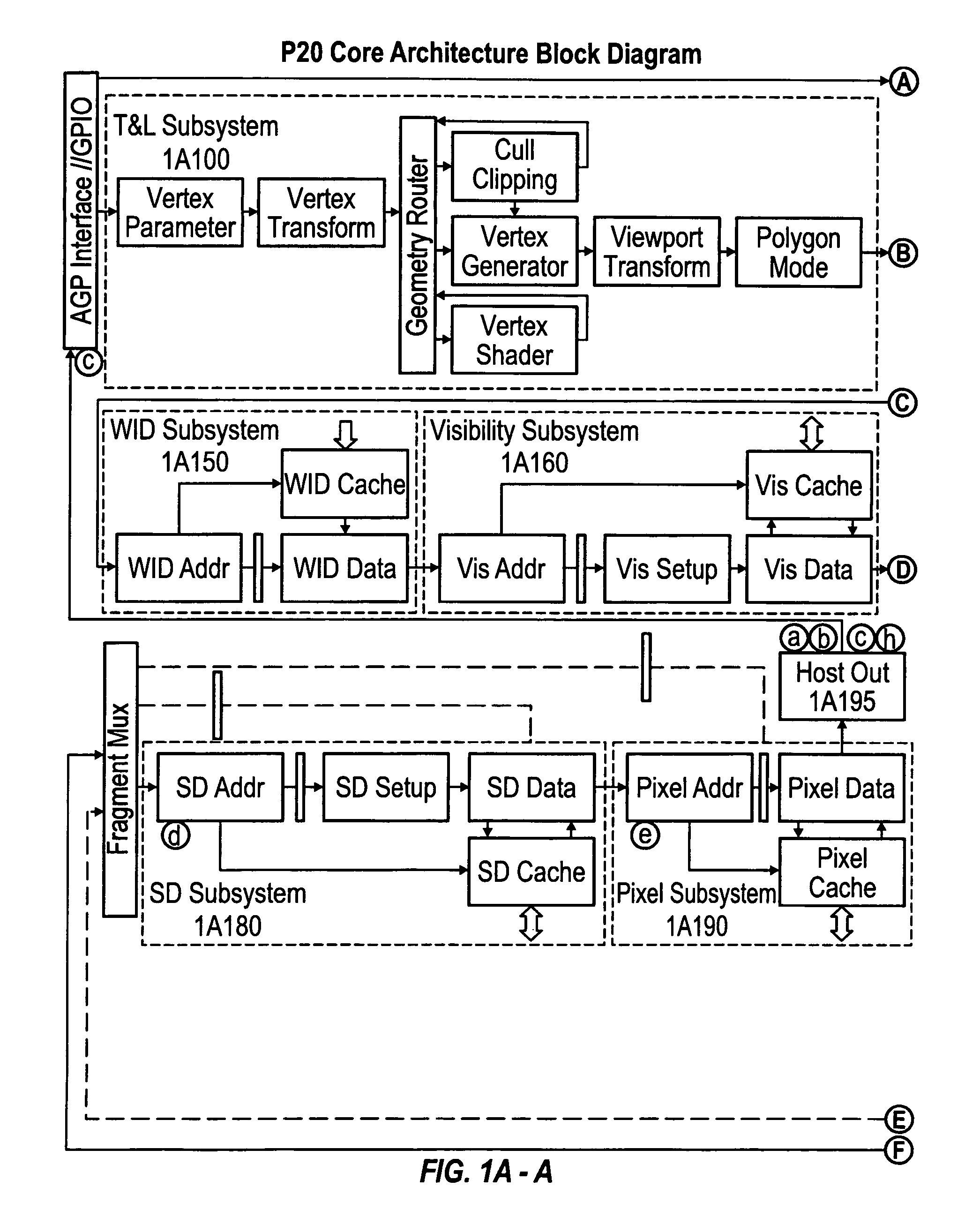

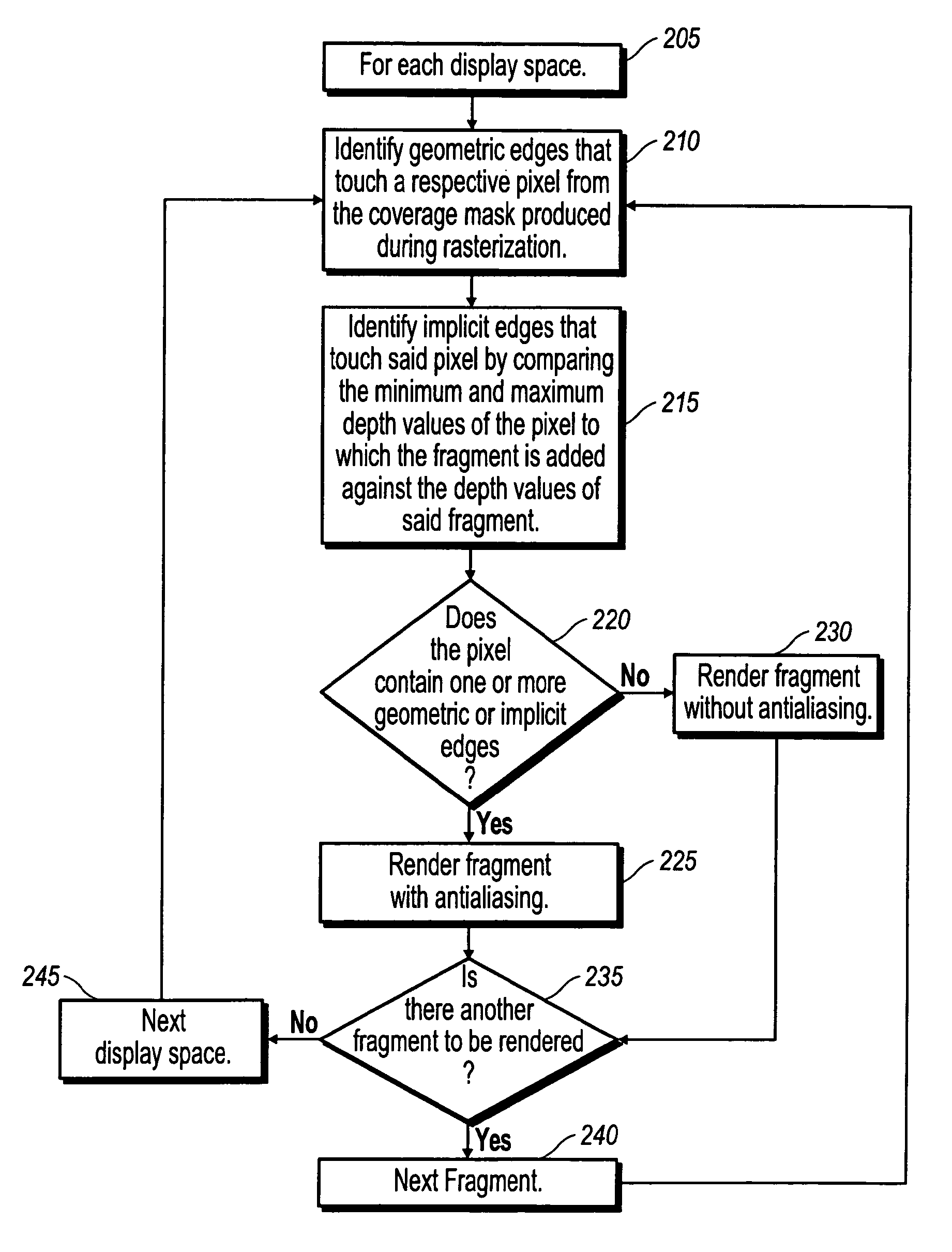

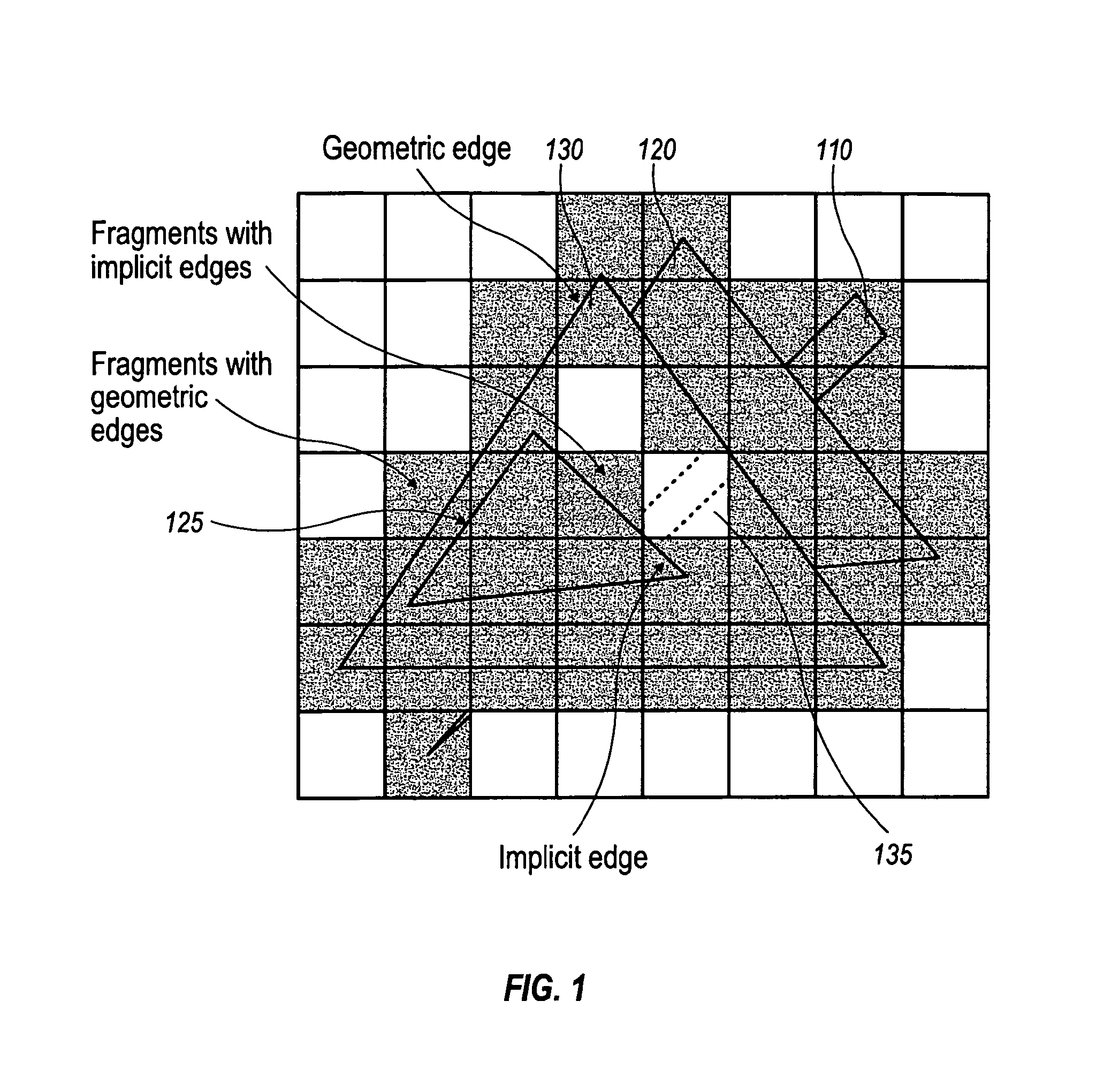

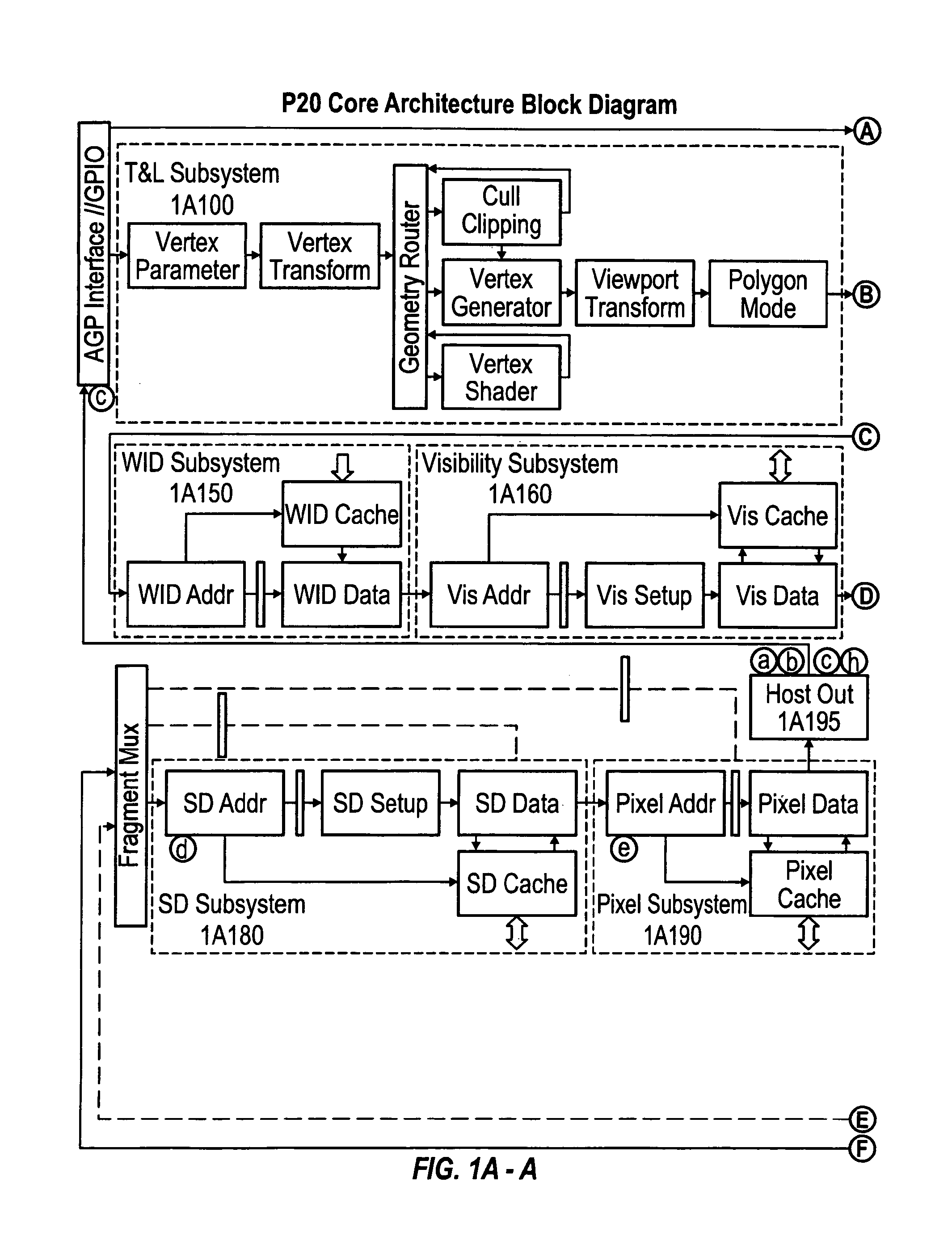

Multi-sample antialiasing optimization via edge tracking

InactiveUS9218689B1Avoids expensive color calculationEasily be parsed twiceImage enhancementImage analysisGraphicsEdge tracking

An efficient method and system for multi-sample antialiasing in graphics processing is described. Geometric edges as well as implicit edges of primitives in a bin are identified by iteratively rendering bins of pixels. Selective multi-sample antialiasing is applied to pixels that are touched by either a geometric edge or an implicit edge; pixels that are fully covered are not antialiased.

Owner:RPX CORP

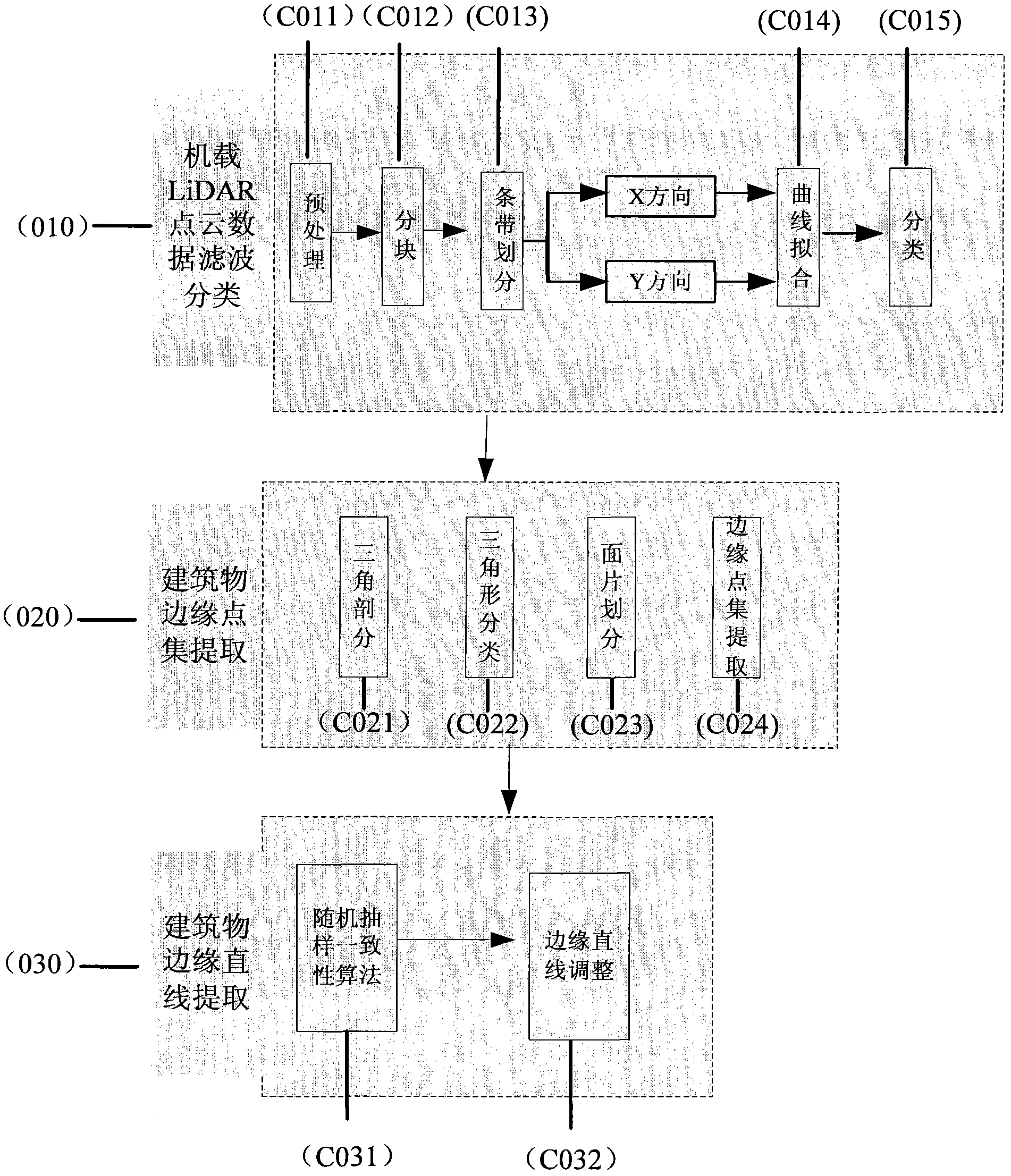

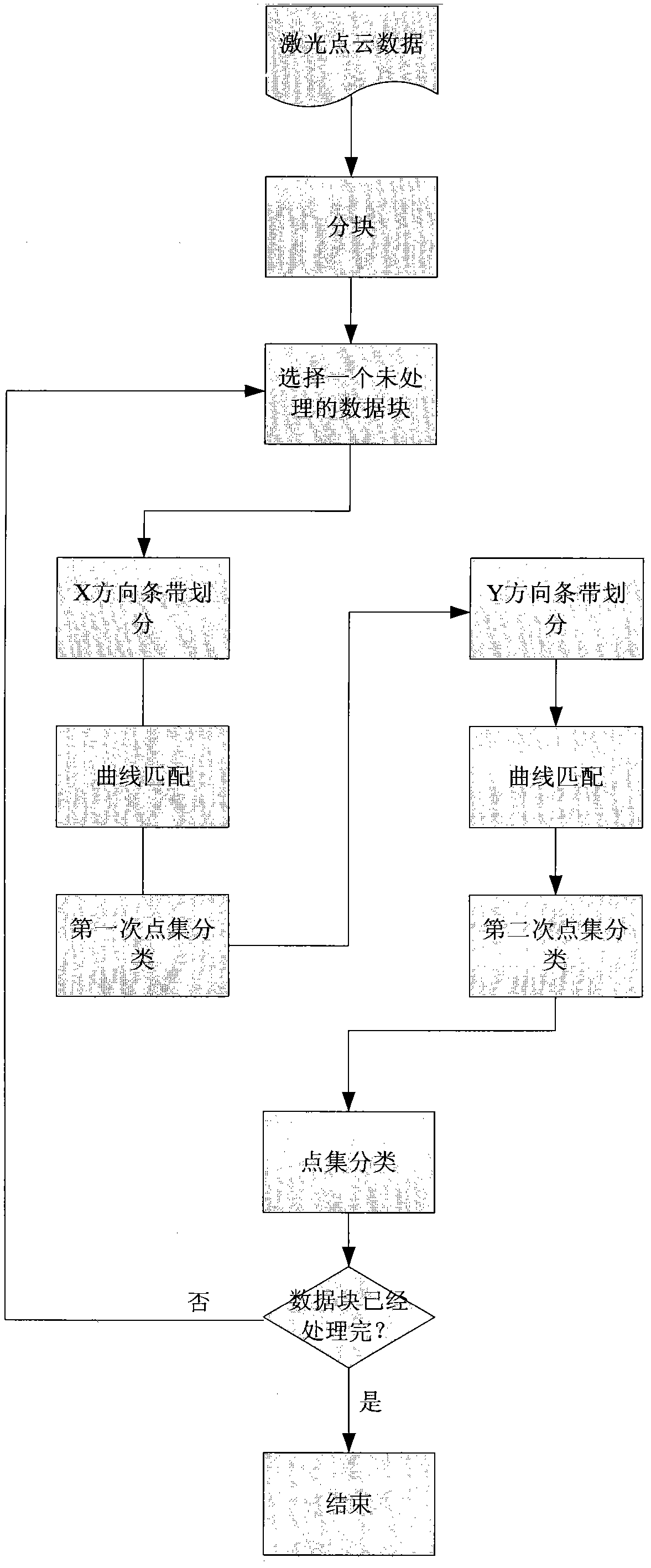

Method for quickly extracting building three-dimensional outline information in onboard LiDAR (light detection and ranging) data

The invention discloses a novel method for extracting building three-dimensional outline information by utilizing a stripe division method to quickly filter onboard LiDAR (light detection and ranging) point cloud data, and based on a random sampling consistency model. In the method, in allusion to high precision of the onboard LiDAR data per se, the mass onboard LiDAR point cloud data is directly processed; the method comprises the steps as follows: firstly performing classification filtering on the onboard LiDAR three-dimensional point cloud data through two-time stripe division in X direction and Y direction, so as to distinguish ground points from non-ground points; then performing triangulation on the non-ground three-dimensional point cloud data, and dividing building roof surface patches through the combination with the classification result, extracting LiDAR point sets contained in each building, and then, obtaining a edge point set of each building through edge tracking; and finally, using the random sampling consistency model to extract building edge straight lines from the edge point sets and form a building outline characteristic curve, so as to meet working requirements of digital city three-dimensional modeling and the like.

Owner:李慧盈 +2

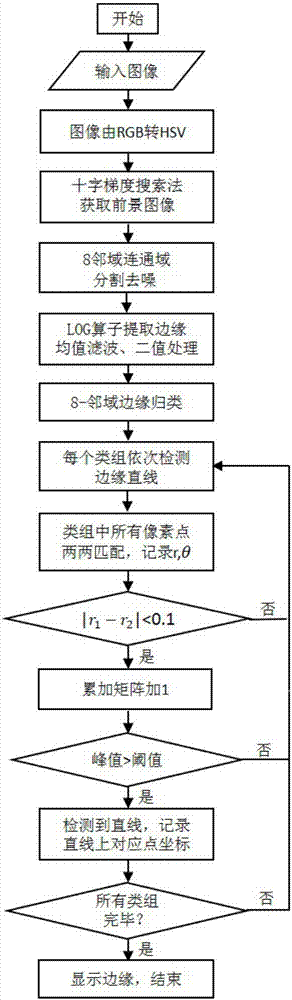

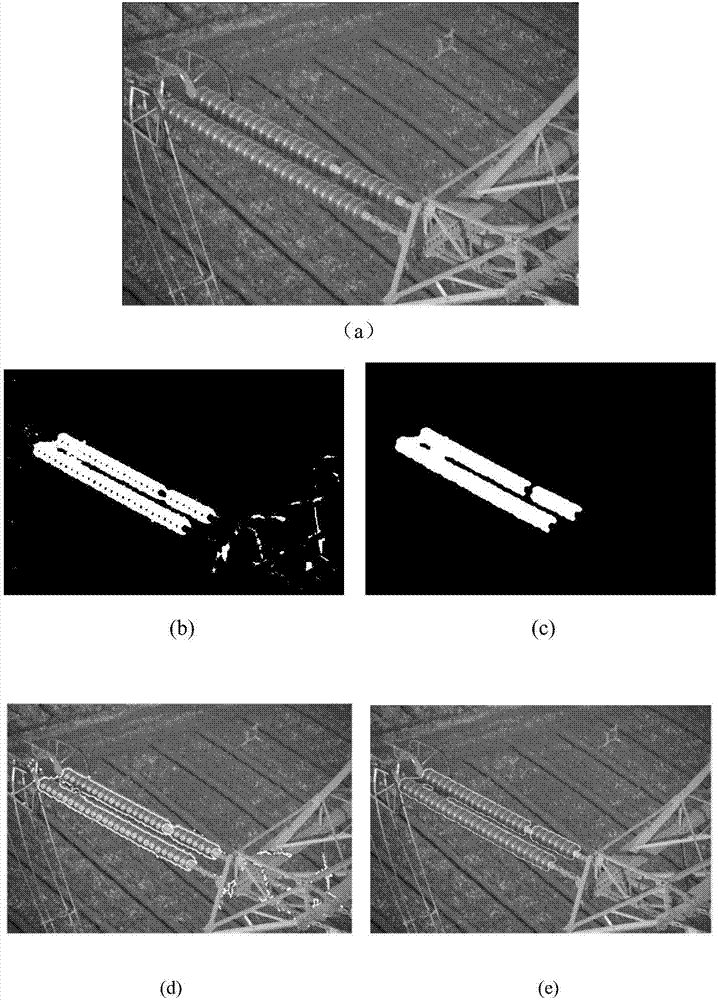

Unmanned aerial vehicle visual detection method for high-voltage line insulators

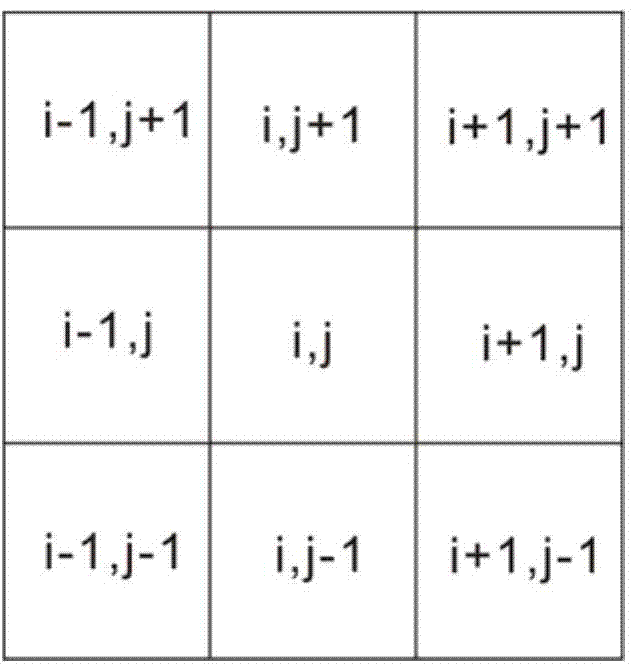

InactiveCN107492094AImprove accuracyRunning slowImage enhancementImage analysisPattern recognitionEdge extraction

The invention discloses an unmanned aerial vehicle visual detection method for high-voltage line insulators. The method comprises the following steps of: obtaining a high-voltage line insulator image; converting the high-voltage line insulator image from an RGB model to an HSV model; detecting a brightness component of the HSV model by adoption of a cross gradient search method, and obtaining a direction gradient and a spatial brightness similarity so as to generate a foreground image; carrying out connected domain segmentation on the foreground image by adoption of a 8-neighborhood connected domain segmentation method so as to obtain an insulator connected domain image; carrying out edge extraction on the insulation connected domain image by adoption of an LOG operator so as to obtain edge information of the image; carrying out 8-neighborhood edge classification on an image edge point by adoption of a 8-neighborhood edge tracking method; for pixel class groups obtained through the 8-neighborhood edge classification, carrying out edge linear detection on the groups, and displaying a recognized insulator profile. According to the method, complete insulator connected domain images can be obtained, so that the insulation recognition correctness is effectively improved, the operation speed is effectively improved and the calculation complexity is reduced.

Owner:CHANGAN UNIV

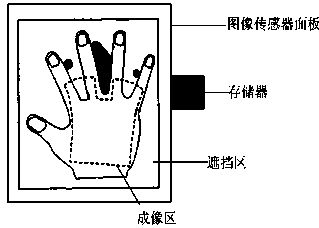

Palm print image acquisition device and palm print image positioning and segmenting method

ActiveCN103955674ASolve problems that are difficult to follow upSmall amount of calculationCharacter and pattern recognitionPattern recognitionImaging processing

The invention provides a palm print image acquisition device and a palm print image positioning and segmenting method. The method comprises the following steps that a trapezoidal marker serves as a template, palm print images are rapidly matched through the image processing algorithm, and a local image required for positioning is found; the optimal threshold value of the local image is worked out, thresholding is conducted on the local image, the local image is converted into a binary image, and the palm contour line of the local image is detected through the eight neighborhood edge tracking algorithm; two contour feature points on the palm contour line are extracted; the connecting line of the two contour feature points serves as the Y axis, the center point of the connecting line serves as O, the perpendicular line of the connecting line serves as the X axis, a reference coordinate system XOY is built, a square box with the fixed size is selected from the position which is parallel to the Y axis and has a fixed distance from the Y axis in the reference coordinate system XOY, the square box servers a template, and a central sub-image is separated from the corresponding position in the original palm print image; normalization is conducted on the central sub-image.

Owner:佛山市瑞德物联科技有限公司

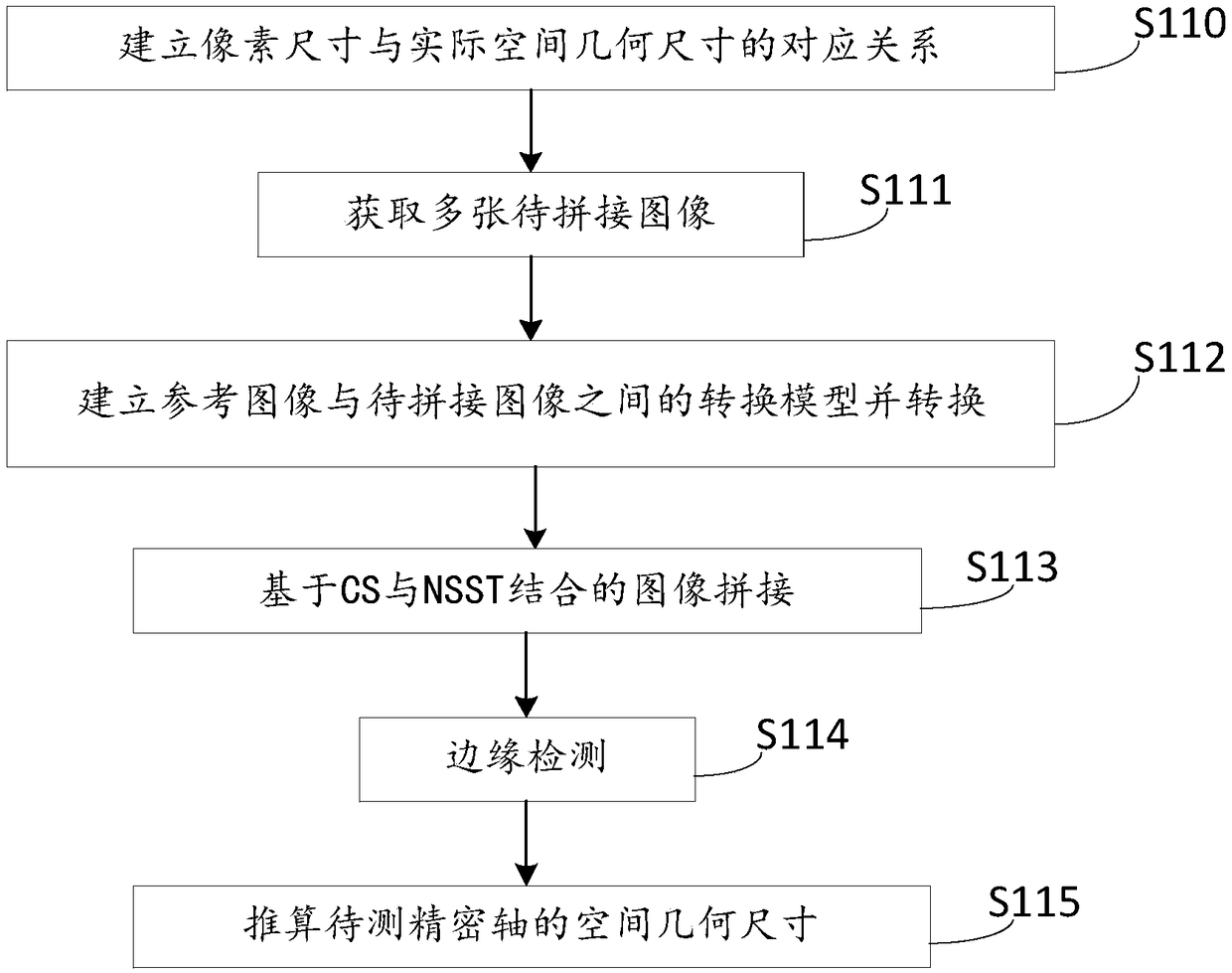

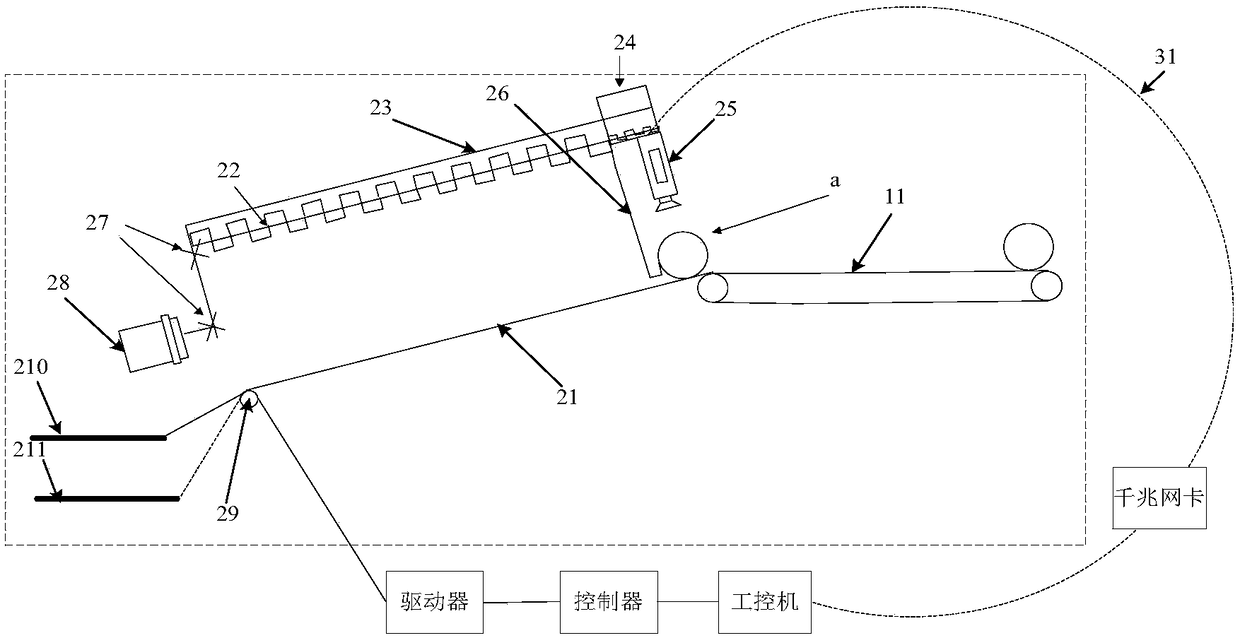

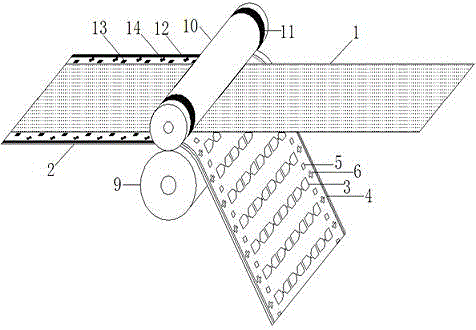

Visual identification-based precise shaft size measurement method, apparatus and system

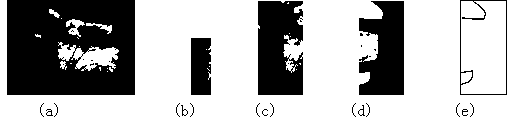

ActiveCN108288288AHigh resolutionReduce processingImage enhancementImage analysisSize measurementVision based

The invention particularly discloses a visual identification-based precise shaft size measurement method, apparatus and system. The method comprises the steps of establishing a mapping relationship between a pixel size and an actual spatial geometric size of a to-be-measured precise shaft; obtaining multiple to-be-spliced precise shaft images; building a conversion model between a reference imageand the to-be-spliced images to perform conversion; based on CS and NSST algorithm combination, performing splicing on the converted to-be-spliced images, and performing fusion to form a whole image of the to-be-measured precise shaft; and for the fused whole image, performing pixel level edge tracking and preliminary locating by using a multilevel filtered interested edge detection method firstly, then based on Sobel operator and least square curve fitting combination, obtaining sub-pixel-precision edges, and according to the detected edges and the mapping relationship, calculating the spatial geometric size of the to-be-measured precise shaft. According to the method, the apparatus and the system, the image splicing data processing amount is effectively reduced; the detection efficiencyis improved; and real-time online detection can be performed.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Laser production technology for radio frequency identification antenna capable of easily discharging waste

ActiveCN105789869ASolve the problem of waste dischargeGood waste discharge effectRadiating elements structural formsLaser beam welding apparatusAntenna designTime transformation

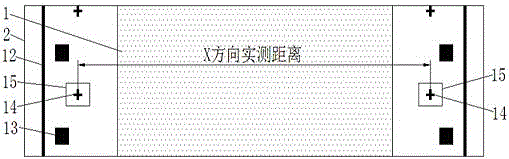

The invention discloses a laser production technology for a radio frequency identification antenna capable of easily discharging waste. In the laser production technology for the radio frequency identification antenna, changes of positions and dimensions of positioning marks at two sides of a radio frequency antenna substrate in X and Y directions are detected; real-time transformation is carried out on the shape, the dimension, the position and the angle of an engraved pattern through an adaptive algorithm according to the materials, the thicknesses, the composite temperatures, the environment temperatures and the humidities of a used metal film and the antenna substrate and the antenna design pattern and composition condition; meanwhile, laser engraving is compensated according to the monitored working temperature in a laser scanning system; and the influence of a temperature drift of the laser scanning system on the dimension and the position of the engraved pattern is reduced, so that the error of the system for overlapping positioning of the engraved pattern and a printed pattern is controlled within 20 microns or to be smaller than 1 / 2 laser spot size; the waste discharge technology is relatively easy to implement; the key problems of pattern positioning and edge tracking in the industrial process of the laser production technology for the radio frequency identification antenna are solved; and the industrialization process of the laser antenna production technology is pushed.

Owner:SUZHOU ZUENS IOT TECH CO LTD

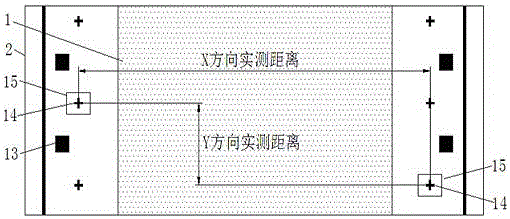

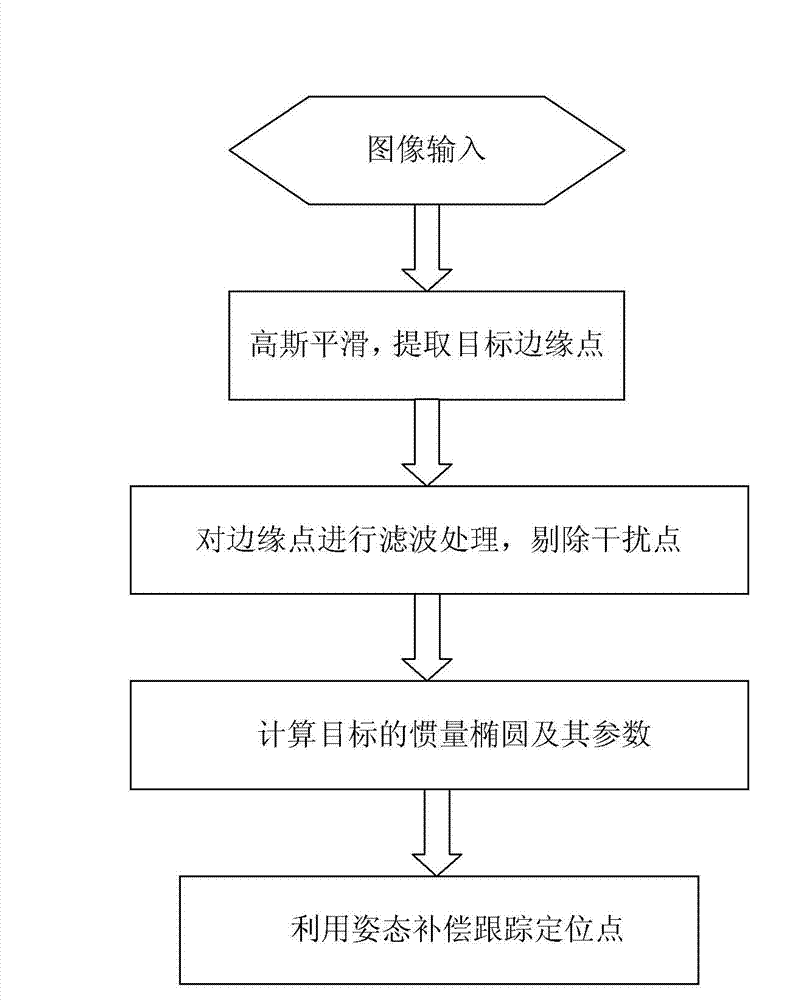

Method for positioning slight expanded target based on gesture compensation

The invention provides a method for positioning a slight expanded target based on gesture compensation. The method comprises the following steps: firstly, pre-processing a to-be-processed image by adopting the Gauss smooth filtering to eliminate the influence of noise on a subsequent algorithm; secondly, obtaining a two-value edge of a single pixel by adopting an edge tracking method, and filtering peripheral points of the profile of a target to eliminate interfering points; thirdly, computing a momental ellipse of the target and parameters of the target by using the peripheral points of the profile of the target to confirm the gesture of the target; and finally, obtaining a translation parameter and a rotation parameter of the target by using the positioning method based on the gesture compensation. Therefore, through the adoption of the method, the fact that the target is positioned in the situations such as rotation, translation and scaling can be realized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

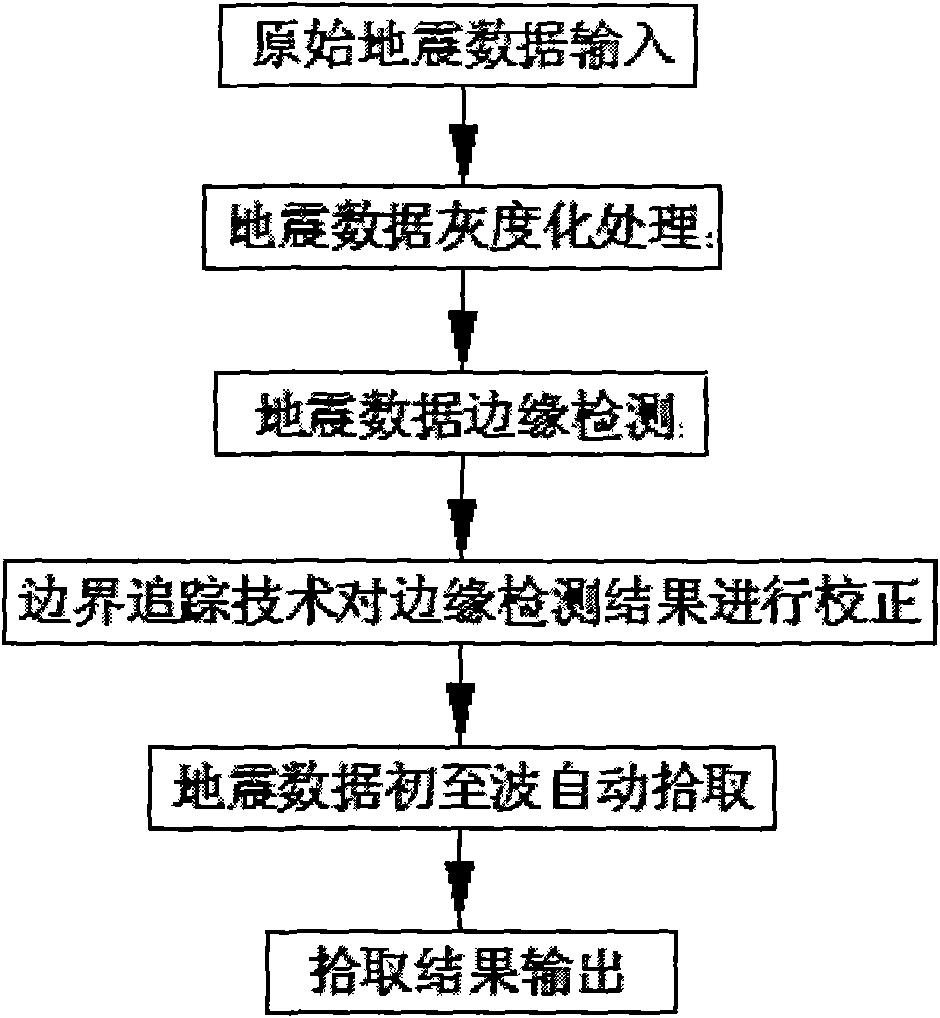

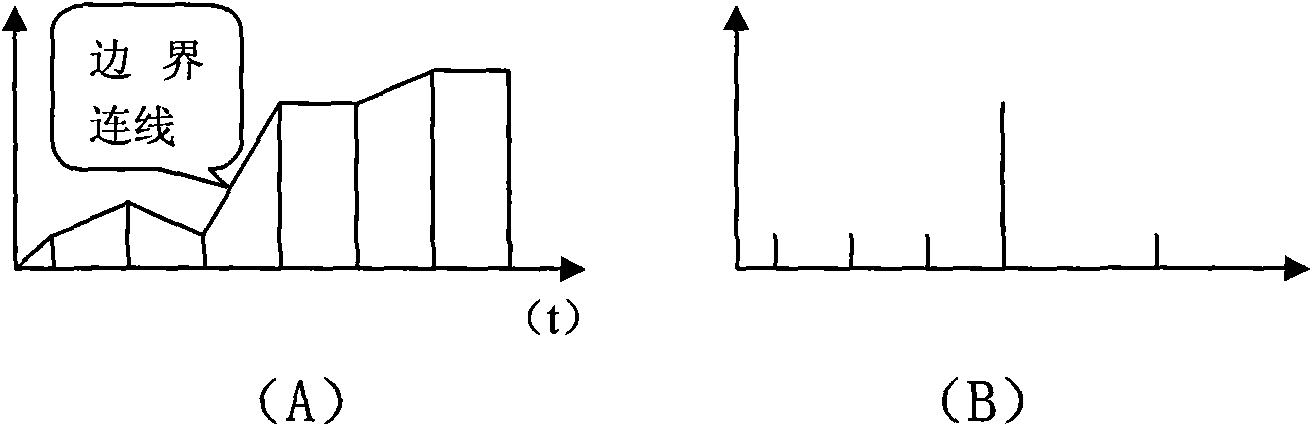

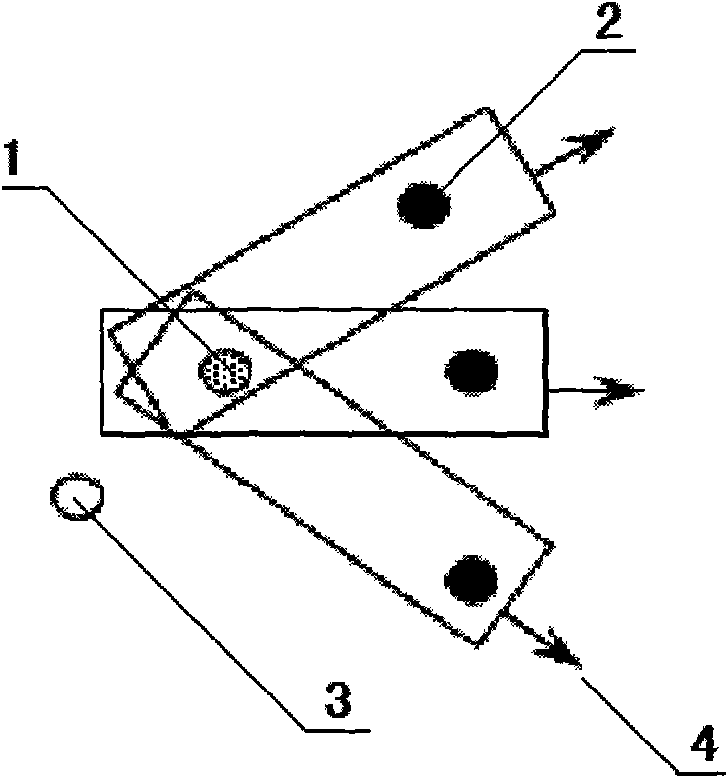

Automatic first break picking method based on edge detection

InactiveCN101551467AImprove timelinessSeismic signal processingBoundary detectionDifferential operator

The invention relates to an automatic first break picking method based on edge detection, in particular to an automatic first break picking technology based on edge detection, which comprises the steps of: first, inputting original seismic data and conducting graying processing on the seismic data, and then, carrying out seismic data edge detection by virtue of airspace differential operators and finishing the edge detection by corresponding templates and image convolution, finally, correcting the edge detection results with an edge tracking technology, completing the automatic picking of seismic data of the first break and outputting picking results; a manual selection method is used for selecting an edge point as a starting point; and the edge tracking technology mainly utilizes tracking 'bug' for tracking. When being used for picking up the first break from three-dimensional seismic data, the automatic first break picking technology based on edge detection can reduce time by 7 days to 10 days. Compared with the existing automatic first break picking technology with the accuracy rate of 80 percent, the automatic first break picking technology based on edge detection can realize the accuracy rate of 99 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

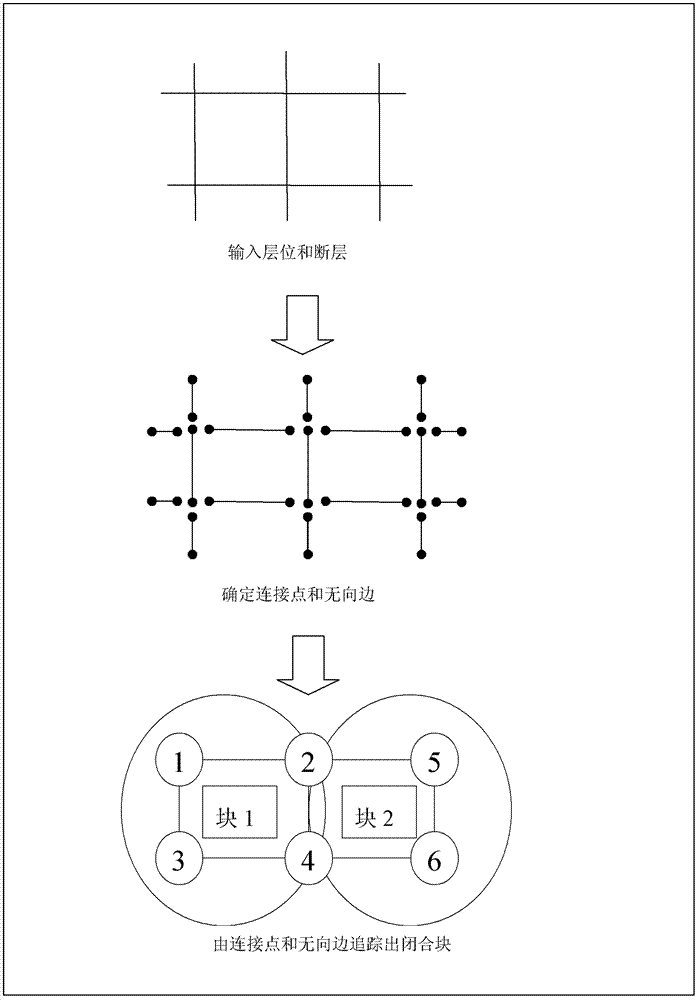

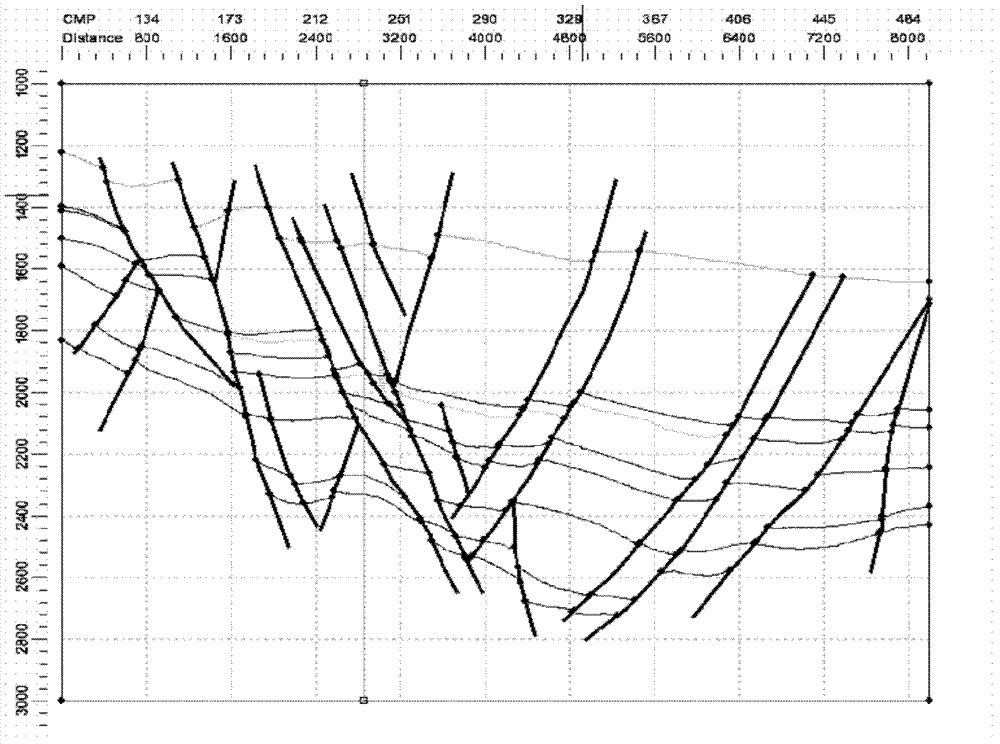

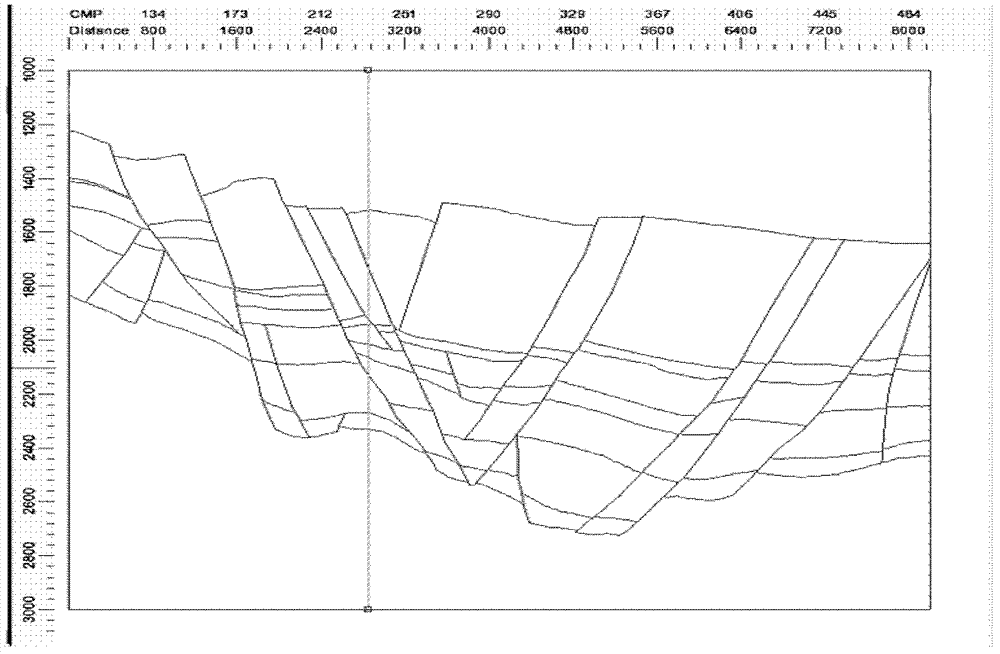

Method for determining complex geologic structure in two-dimensional space

ActiveCN103245972AAccurate structural formImprove forecast accuracySeismic signal processingHorizontal distributionSalt dome

The invention provides a method for determining a complex geologic structure in a two-dimensional space according to seismic data and stratum geological data in petroleum and natural gas exploration. The method comprises the following steps: first, processing the seismic data to obtain overlaid seismic data, so as to determine horizontal distribution of an objective formation and the distribution of faults penetrating the objective formation; then determining fault shapes and contact positions between the faults and the stratum; performing fitting and interpolation on layer data, followed by connection point and undirected edge tracking so as to build a geological model undirected graph; allowing the undirected graph to be subjected to traversal processing according to a depth-first search algorithm to finally obtain a topological structure; and finally, performing traversal tracking for obtaining an inversion result. According to the invention, the method can correctly depict the characteristics of geologic structures including ordinary faults, reverse faults and the like, and depict special geologic bodies such as salt domes and lenses, and the practical geologic structures being subjected to geologic movements, such as extrusion, tension and cutting, and can accurately recognize complex structural hydrocarbon reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

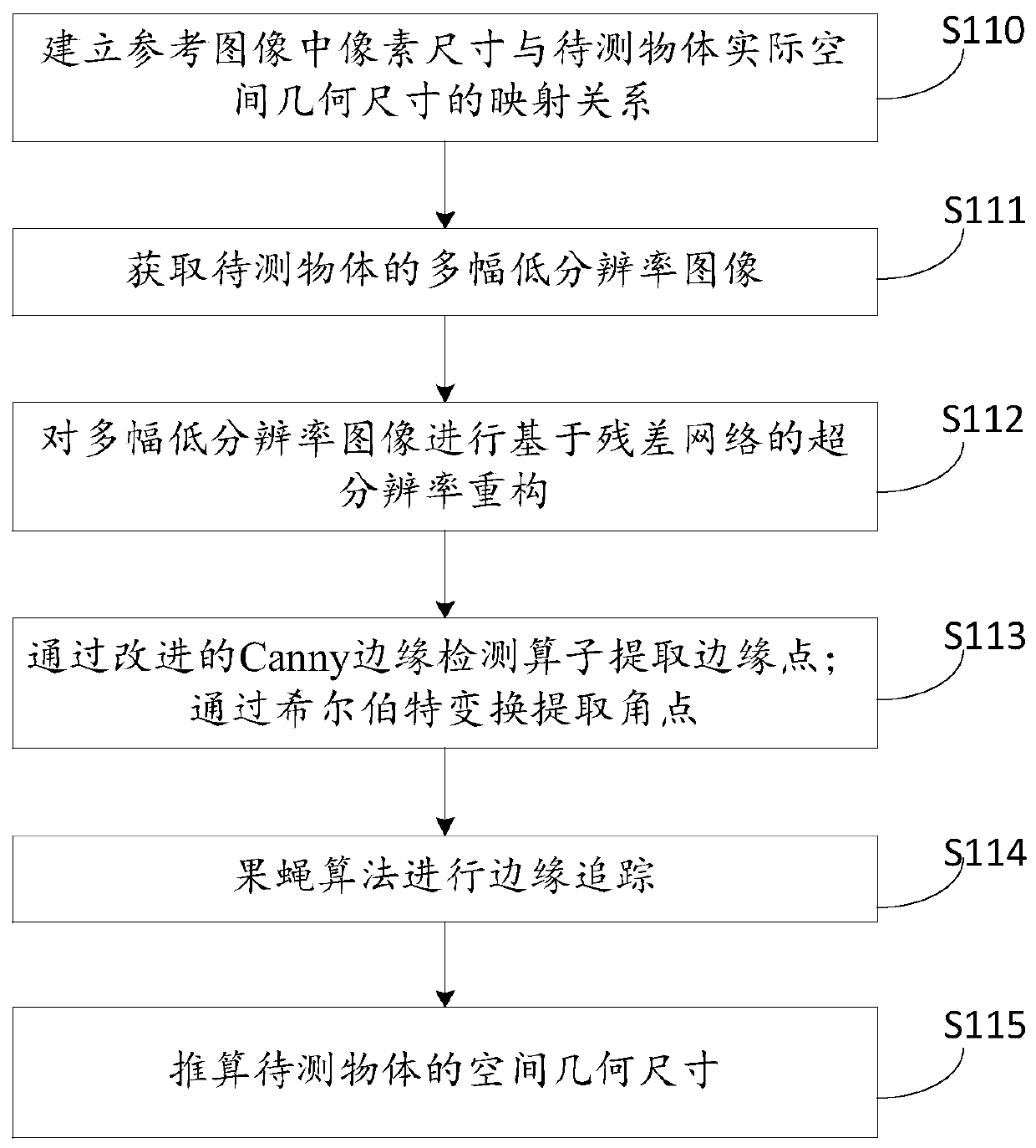

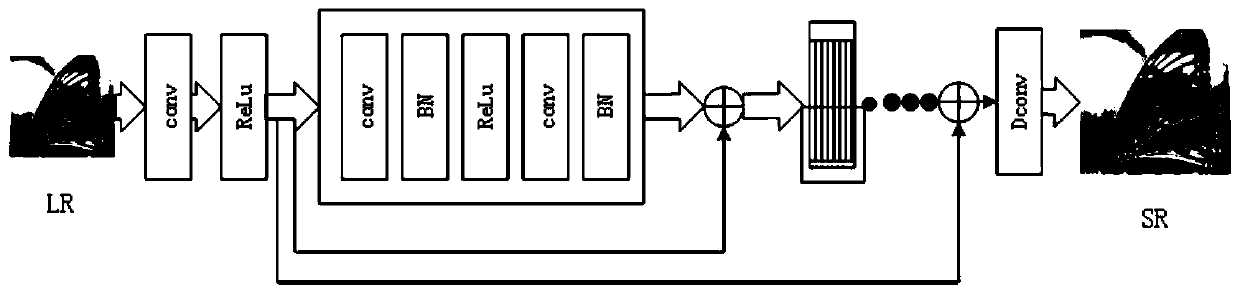

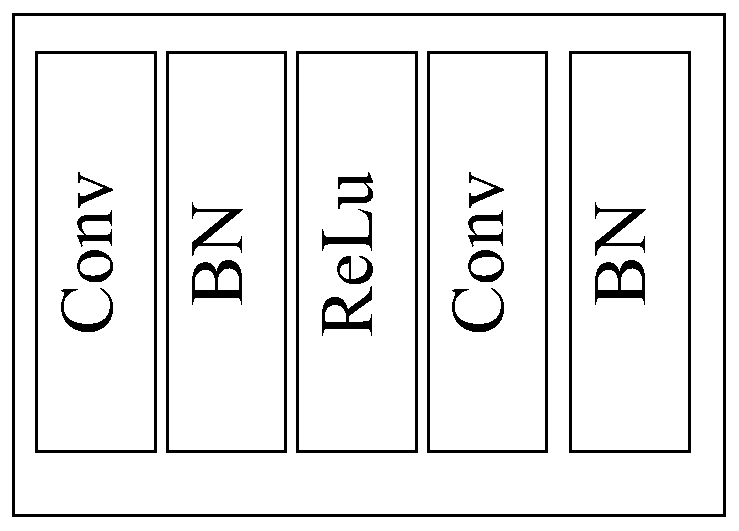

High-precision visual measurement method, device and system based on bionic algorithm

ActiveCN109840889AEasy accessDoes not affect detection accuracyImage analysisGeometric image transformationMeasurement costCcd camera

The invention provides a high-precision visual measurement method, device and system based on a bionic algorithm. The method comprises the following steps: establishing a mapping relation between a pixel size and an actual spatial geometric size of a to-be-measured object; Obtaining low-resolution images of the plurality of to-be-measured objects; Carrying out super-resolution reconstruction through a super-resolution algorithm based on a residual network; For the reconstructed image, extracting edge points by using a Canny edge detection operator, extracting corner points by using Hilbert transform, and carrying out edge tracking by using the edge points and the corner points as heuristic information through a fruit fly algorithm; And finally, obtaining a single-pixel edge by utilizing arelated mechanism, and calculating the spatial geometric dimension of the to-be-measured object. The device comprises a mapping module, an image acquisition module, a reconstruction module, an edge coarse detection module, a fruit fly detection module and a calculation module. The system comprises an objective table, a CCD camera, a two-dimensional workbench and the like. According to the invention, the field of view of single imaging is effectively expanded, the measurement cost is reduced, and the detection efficiency is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

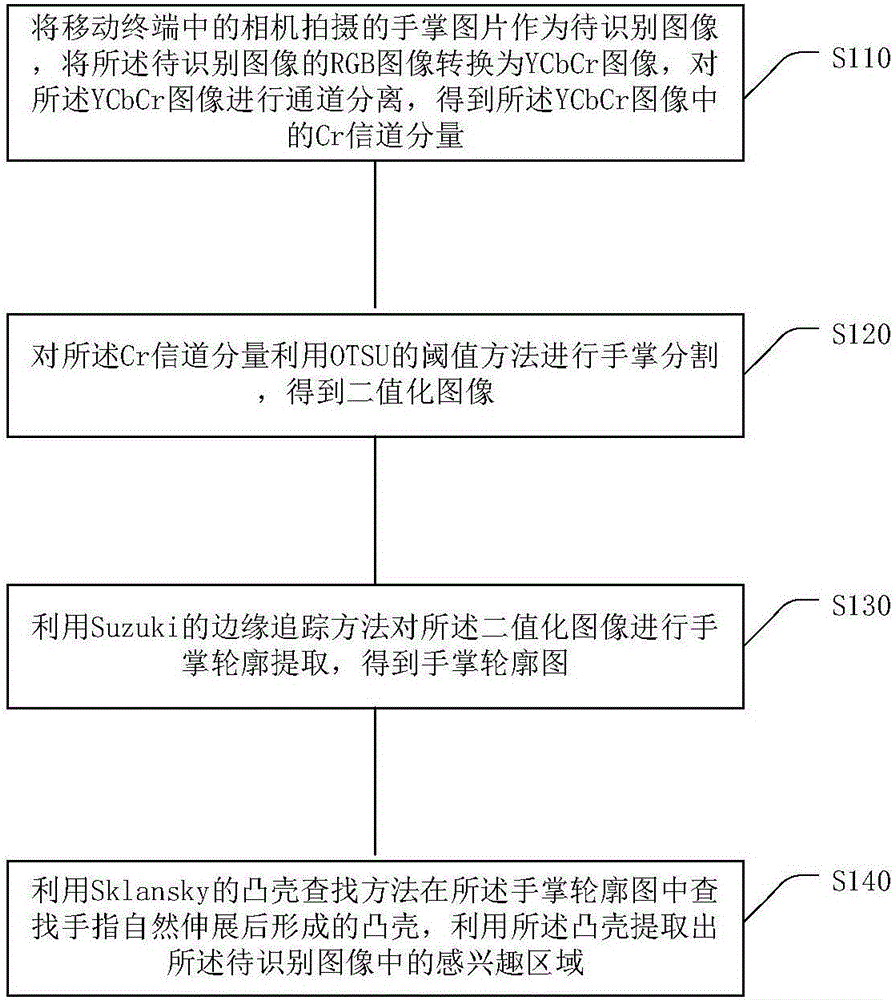

Extraction method for mobile terminal palm print region of interest based on complex scene

ActiveCN106845388AEasy extractionImprove accuracyAcquiring/reconising fingerprints/palmprintsPalm printImage segmentation

The invention provides an extraction method for a mobile terminal palm print region of interest based on a complex scene. According to the method, taking a palm print image photographed by a camera of a mobile terminal as a to-be-identified image and obtaining a Cr channel component in a YCbCr image in the to-be-identified image; carrying out palm segmentation on the Cr channel component through utilization of an OTSU threshold method, thereby obtaining a binarized image; carrying out palm outline extraction on the binarized image through utilization of a Suzuki edge tracking method, thereby obtaining a palm outline image; and searching a convex hull formed by naturally stretching fingers in the palm outline image through a Sklansky convex hull search method and extracting a region of interest in the to-be-identified image through utilization of the convex hull. According to the method, dynamic thresholding is carried out by selecting the Cr channel component, and the influence of illumination on image segmentation is removed. The complete palm outline image can be extracted through the Suzuki method. The palm image segmentation can be effectively finished through utilization of the Sklansky convex hull search method and the region of interest is extracted. The extraction effect of the palm print region of interest is good and the accuracy is high.

Owner:BEIJING JIAOTONG UNIV

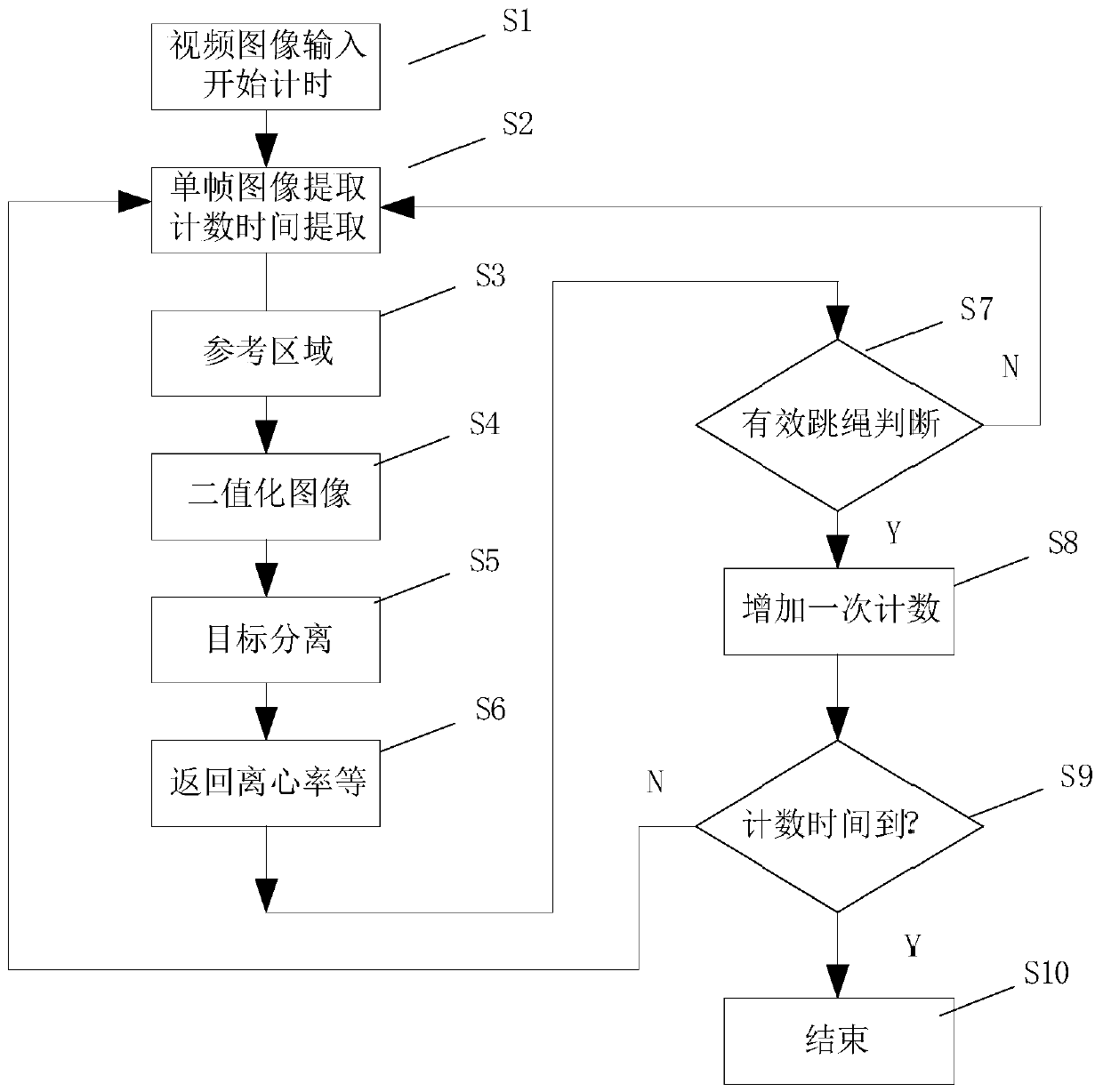

Skipping rope counting method based on image information

ActiveCN109876416ARealize automatic accurate countingPracticalSkipping-ropesReference imageImaging data

The invention discloses a skipping rope counting method based on image information and belongs to the technical field of smart fitness sports. The method comprises the steps of 1, extracting image data from original video data and performing single frame processing on the image data to obtain a group of sequentially arranged single frame image; 2, determining a common reference area of all the single frame images and intercepting the reference area to obtain a group of reference images, wherein a skipping rope passes through the reference area each time; 3, performing binarization processing on each reference image and filtering out interference data; 4, performing edge tracking on each processed reference image to separate out a target; 5, extracting judgment data of the target and judging whether or not the target is the skipping rope according to the judgment data; 6, judging whether or not the time interval between every two adjacent reference images is shorter than the time of 10adjacent frames when the target is the skipping rope, determining the time interval as a repeat count without increasing a count if yes, and otherwise, increasing a count; 7, outputting and displayinga counting result.

Owner:ZHEJIANG UNIV

Semidigital delay-locked loop using an analog-based finite state machine

ActiveUS20050093591A1Doubles hardware complexityIncrease powerPulse automatic controlSynchronising arrangementDigital signal processingEngineering

A low-power full-rate semidigital DLL architecture using an analog-based FSM (AFSM). The AFSM is a mixed-mode FSM in which analog integration is substituted for digital filtering, thus enabling a lower power implementation of the clock and data recovery function. An integrated voltage is converted to a digital code by an analog-to-digital converter (ADC), and the digital code is used either directly or after (low frequency) digital signal processing to control a a controllable delay element, such as, a phase rotator, for data edge tracking.

Owner:GLOBALFOUNDRIES US INC

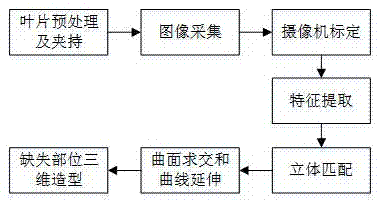

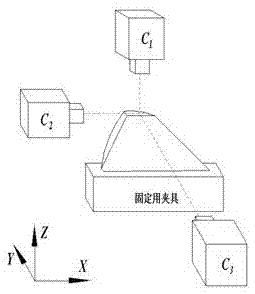

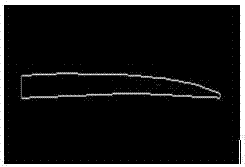

Method for three-dimensional reconstruction of defected part of tip of aeroengine compressor blade

ActiveCN105447910ARealize online measurementPromote recoveryDetails involving processing stepsImage analysisCamera imageStereo matching

The invention discloses a method for the three-dimensional reconstruction of a defected part of the tip of an aeroengine compressor blade, and the method comprises the steps: 1), carrying out the preprocessing and clamping of the blade, removing an oxidation layer of a defected blade, clamping the blade, and enabling the to-be-welded cross section of the blade to be parallel to a horizontal plane; 2), carrying out image collection, building a three-eye stereoscopic vision measurement system, obtaining a three-dimensional gray scale image of the blade, and obtaining an edge image through edge detection; 3), calibrating a camera, completing the three-dimensional calibration of a vision system, and obtaining the conversion relation between camera image coordinates and the world coordinate system; (4), carrying out feature extraction, and obtaining the information of feature points from the edge image in a mode of combining edge tracking and feature point extraction; 5), stereo matching: carrying out the matching of the calibrated vision system, constructing a three-dimensional coordinate system of the blade, and obtaining a three-dimensional edge structure of the blade; 6), carrying out curved surface intersection and extension; 7), carrying out the three-dimensional molding of the defected part, carrying out fitting and reconstruction, and obtaining the structural data of the defected part of the blade.

Owner:HEBEI UNIV OF TECH

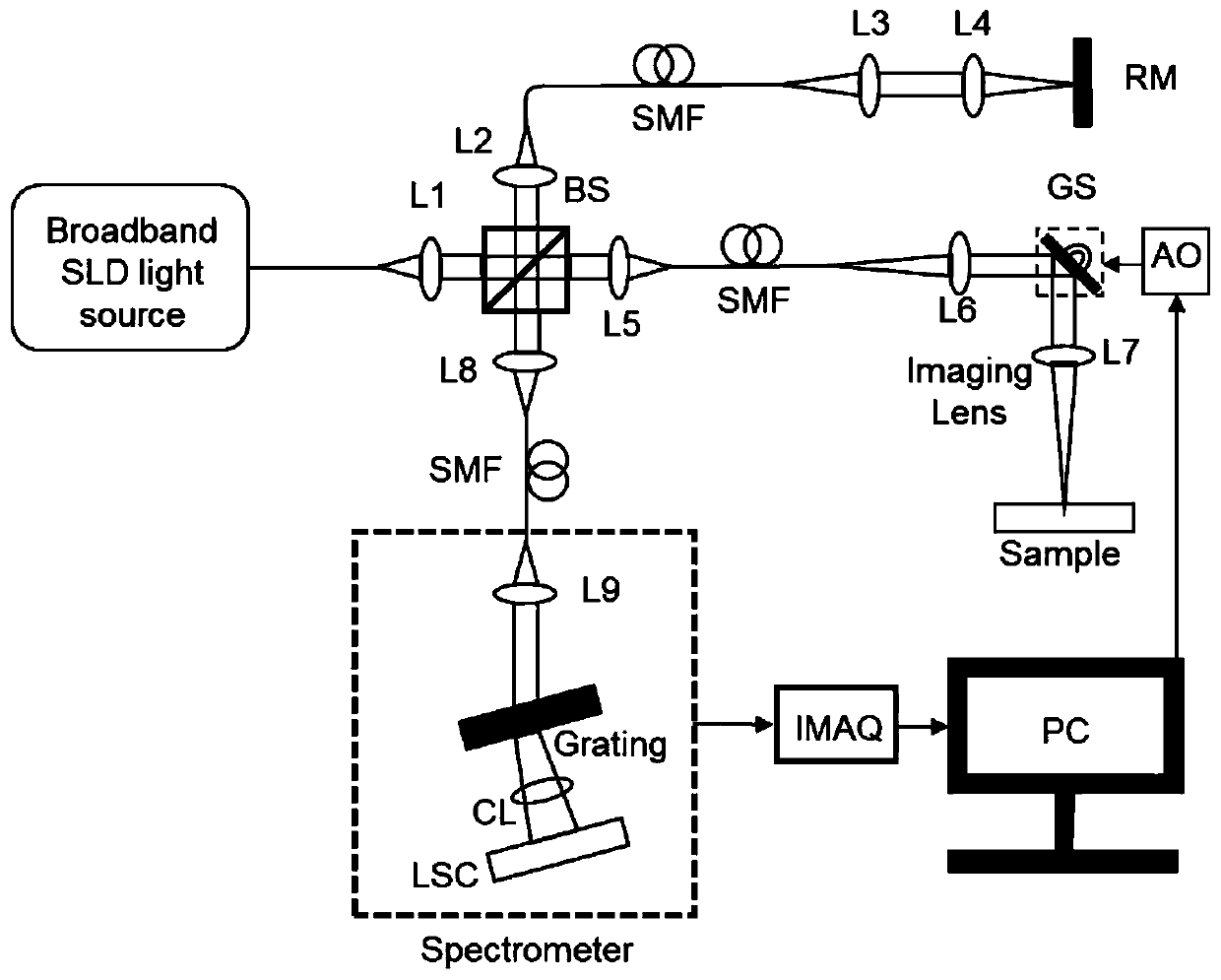

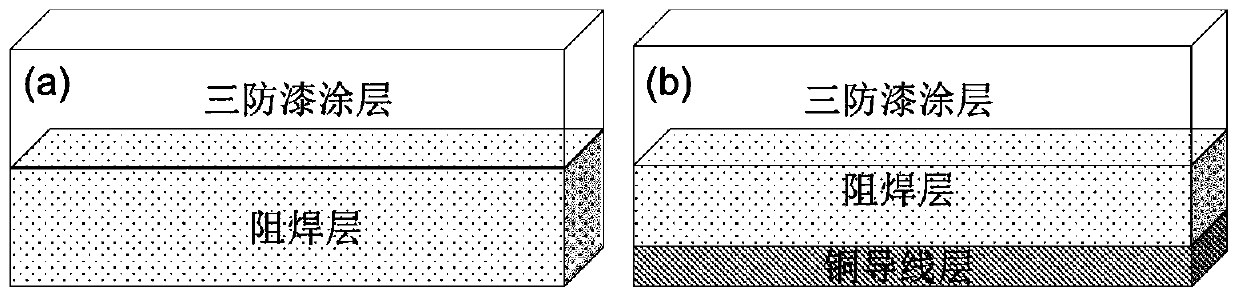

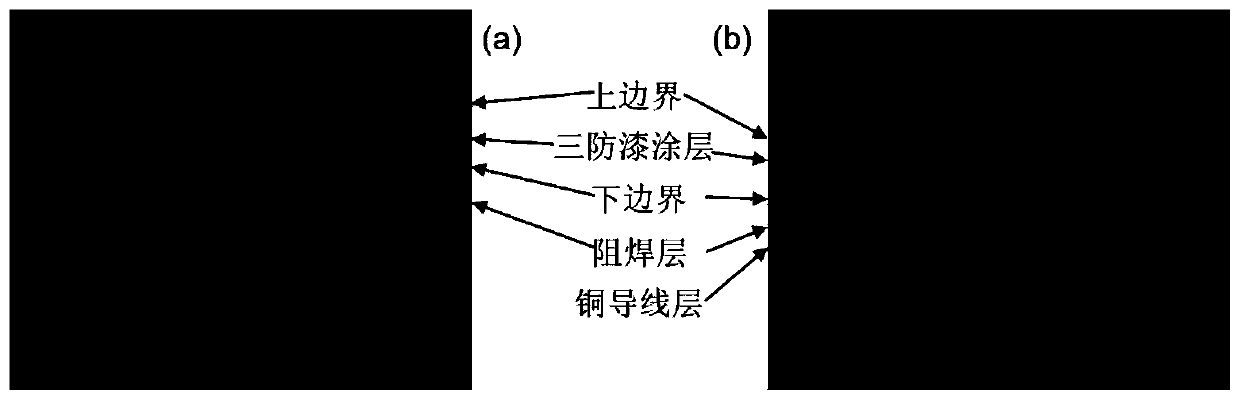

Method for coating thickness measurement based on optical coherence tomography imaging technique and application thereof

InactiveCN110196021ARealize non-destructive automatic inspectionQuick measurementUsing optical meansPrinted circuit boardFilm coating

The invention discloses a method for coating thickness measurement based on optical coherence tomography imaging technique and application thereof. The method comprises the steps of: constructing an optical coherence tomography imaging (OCT) test system; scanning a depth direction and a two-dimensional cross section of the surface of a sample material by using the OCT system and acquiring a three-dimensional scanning image of a measured object; and after denoising processing on the obtained three-dimensional scanning image, carrying out conversion to obtain binary image, carrying out segmentation to obtain an upper boundary and a lower boundary of a coating based on an edge tracking method, and calculating the thickness of the coating. With the disclosed method, the non-destructive automatic detection of the coating is realized; and the rapid, accurate, and wide-range measurement of the thickness of the coating can be realized. The method can be applied to measure the thicknesses of film coatings including tri-proof paint on the surface of a printed circuit board, a pigmented polymer coating, a porcelain protective coating, a plasma sprayed ceramic body, a biodegradable composite coating, a varnish coating, and a transparent or translucent tablet film coating.

Owner:SUZHOU UNIV

Augmented reality technology Implementation method based on physical detection and tracking algorithm

The invention discloses an augmented reality technology Implementation method based on physical detection and tracking algorithm. The method comprises the following steps that a local marker file is generated, an augmented reality system is initialized, an image of a real scene is acquired, the edge of the image is extracted and optimized, template match is conducted on the edge of the image, and if the matching succeeds, a decision window in the region is generated, a position matrix corresponding to the template is imported, the position matrix is conducted to fine adjust and amend, the special effect of the augmented reality is rendered according to the amended position matrix, corners are extracted in the decision window, appropriate tracking algorithms are chosen according to the number of the corners, If the number of the corners is larger than the threshold value, the system enters the feature point tracking algorithm. If the number of the corners is smaller than the threshold value, the system enters the edge tracking algorithm, animation effects of the augmented reality are updated according to the tracking algorithms, different tracking algorithms are adopted according to the number of the corners, then the detection and tracking for three-dimensional physicals are achieved when rich feature points do not exist or without feature points.

Owner:成都弥知科技有限公司

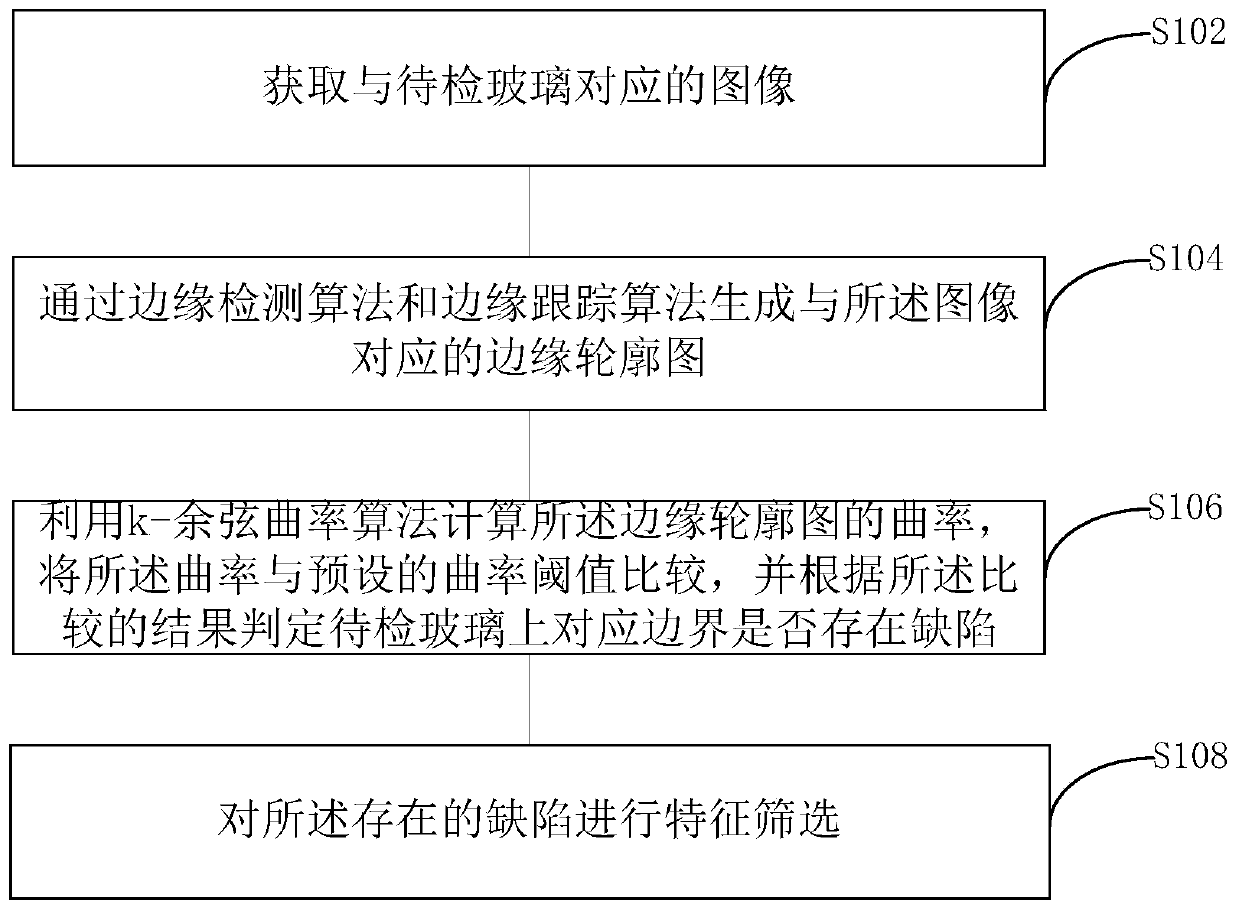

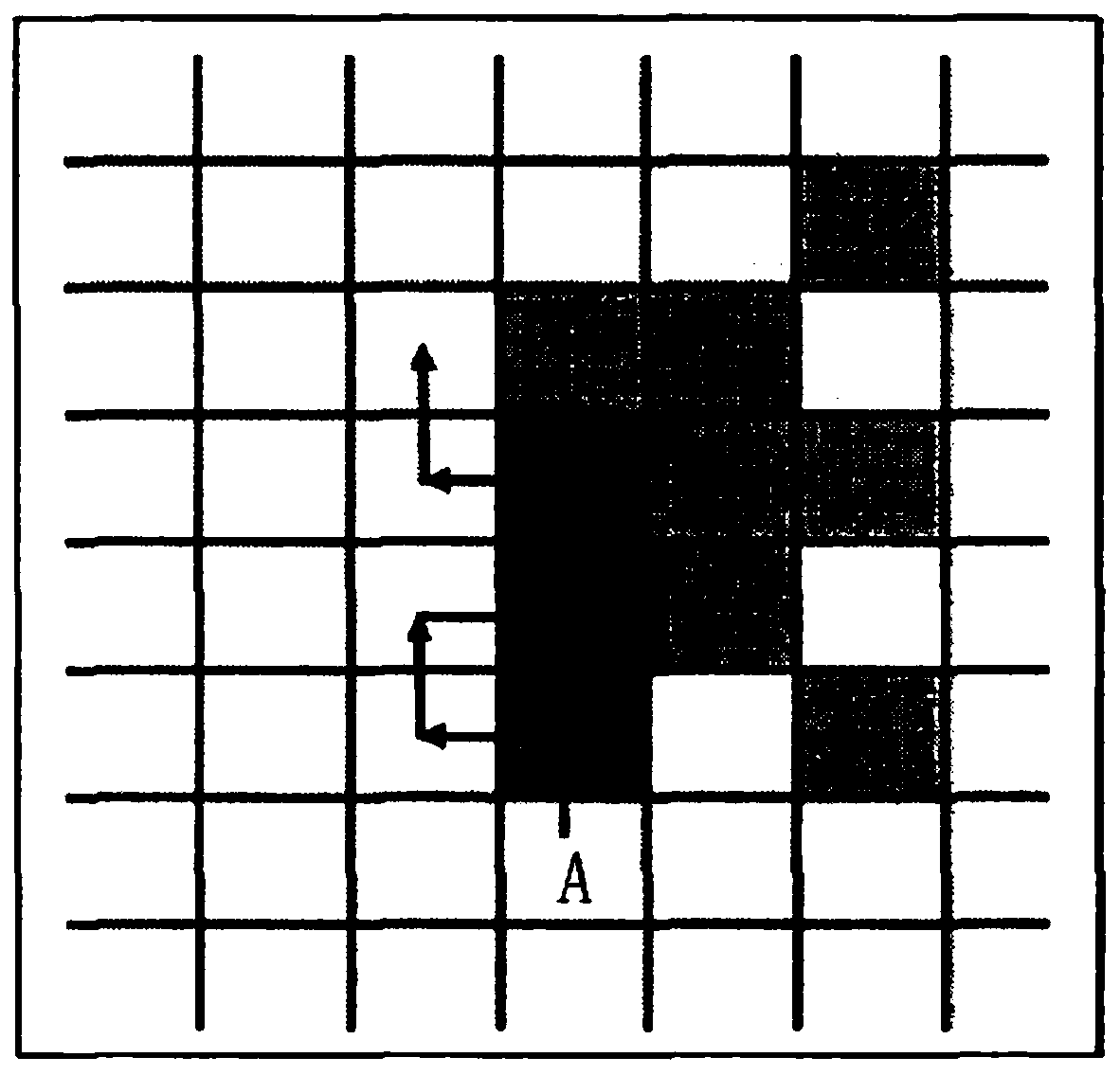

Glass boundary defect detection method and device, terminal and storage medium

InactiveCN110596120AImprove efficiencyHigh precisionImage enhancementImage analysisComputer terminalBoundary detection

An embodiment of the invention discloses a glass boundary defect detection method and device, a terminal and a storage medium, and the method comprises the following steps of acquiring an image corresponding to the glass to be detected; generating an edge contour map corresponding to the image through an edge detection algorithm and an edge tracking algorithm; using a k-cosine curvature algorithmto calculate the curvature of the edge contour map, comparing the curvature with a preset curvature threshold, determining that there are defects in the boundary of the glass to be detected corresponding to the edge contour map if the curvature is less than the curvature threshold, performing feature screening on the defects to determine whether the defects are actually defects on the edges of theglass to be detected; and if the curvature is greater than or equal to the curvature threshold, determining that there is no defect in the boundary of the glass to be detected. In addition, in the embodiment of the invention, a glass boundary defect detection device, a terminal and a storage medium are also disclosed. By adopting the invention, the speed and accuracy of glass boundary detection can be improved.

Owner:SHENZHEN ZVIT TECH CO LTD

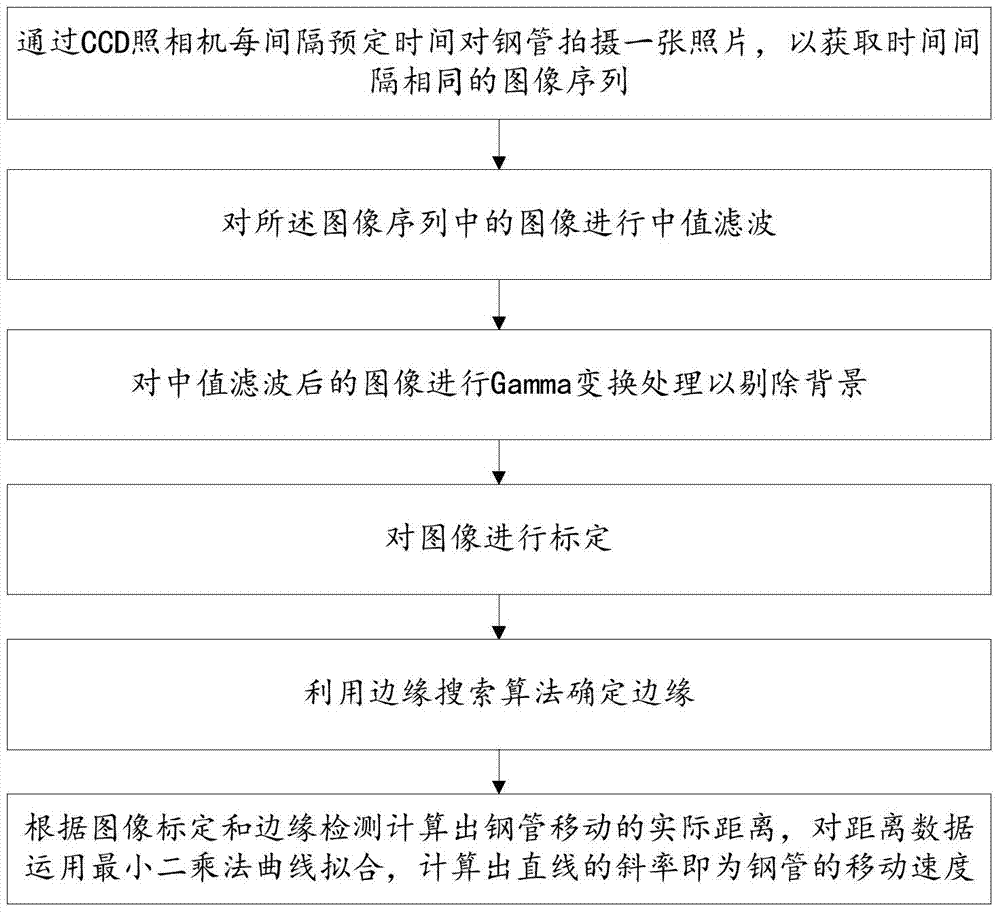

Method for monitoring running speed of steel pipe

ActiveCN103810676ACorrect Radial DistortionEasy to applyImage enhancementImage analysisImage calibrationCurve fitting

The invention provides a method for monitoring a running speed of a steel pipe. The method comprises the steps of taking a photo of the steel pipe with a CCD (Charge Coupled Device) camera at a predetermined time interval and consequently, obtaining an image sequence of equal time interval, performing median filtering on images in the image sequence, performing Gamma transformation on the median-filtered images to remove the background, calibrating the images, determining edges by virtue of an edge tracking algorithm, calculating an actual distance by which the steel pipe moves according to image calibration and edge detection, and performing curve fitting on the distance data by the least square method to obtain the slope of a straight line, namely, the moving speed of the steel pipe. The method is better than the traditional contact and non-contact speed measurement methods, and also well applicable to the severe environment in an industrial field, and furthermore, the measurement accuracy is improved and lots of manpower and material resources are saved.

Owner:桂林珩源科技有限公司

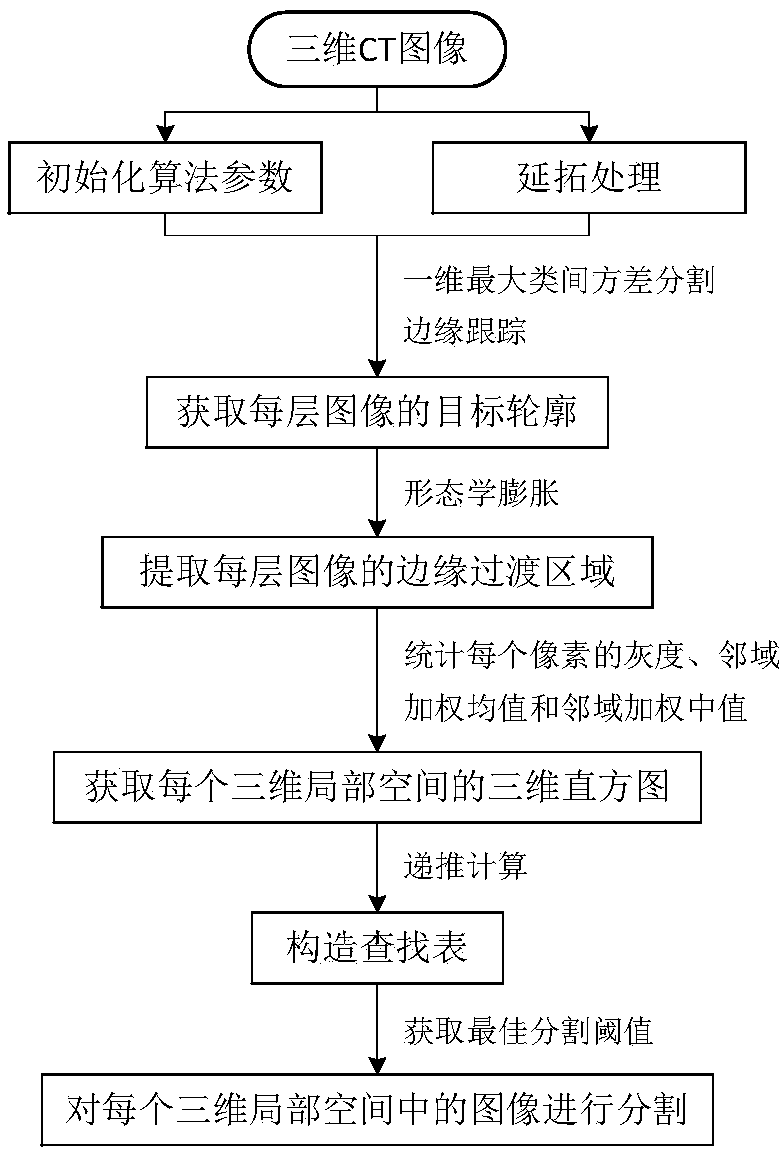

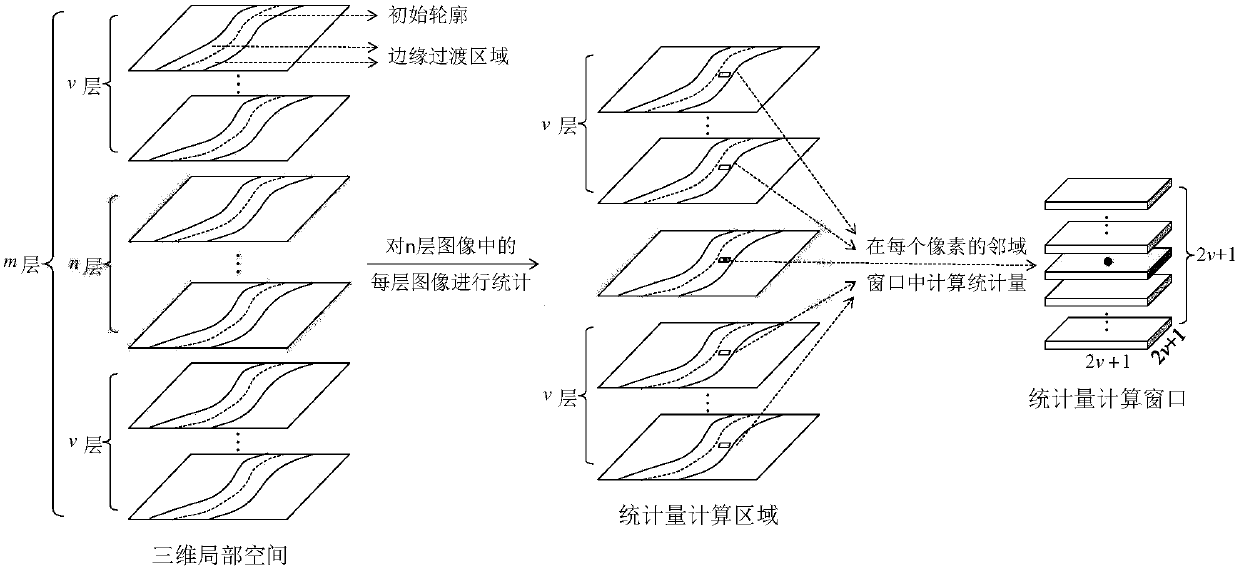

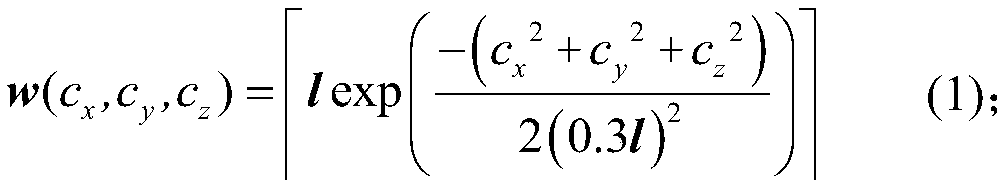

Local three-dimensional maximum inter-class variance segmentation method of three-dimensional CT image

ActiveCN107742297AImprove noise immunityAddressing the impact of computing global thresholdsImage enhancementImage analysisThree dimensional ctContinuation

The present invention discloses a local three-dimensional maximum inter-class variance segmentation method of a three-dimensional CT image, and belongs to the field of image segmentation, in order tosolve difficult segmentation and mis-segmentation problems caused by a non-uniform gray phenomenon of a CT image. The method mainly comprises the following steps: (1) initializing the size of the statistics calculation window, the weight template and the size of the three-dimensional local space, and carrying out continuation processing on the original image; (2) using the one-dimensional maximuminter-class variance segmentation algorithm and the edge tracking algorithm to extract the target contour of each layer of the image, and then using the morphological dilation method to obtain the marker image of the edge transition region; and (3) according to the pixel gray level, the weighted average of the neighborhood, and the weighted median of the neighborhood, calculating the three-dimensional histogram of each three-dimensional local space, and constructing a lookup table by using a recursive method to obtain the optimal segmentation threshold. Compared with the prior art, the methodprovided by the present invention has advantages that a three-dimensional CT image with uneven grayscale can be segmented and the time complexity is O(L3).

Owner:NORTHWESTERN POLYTECHNICAL UNIV

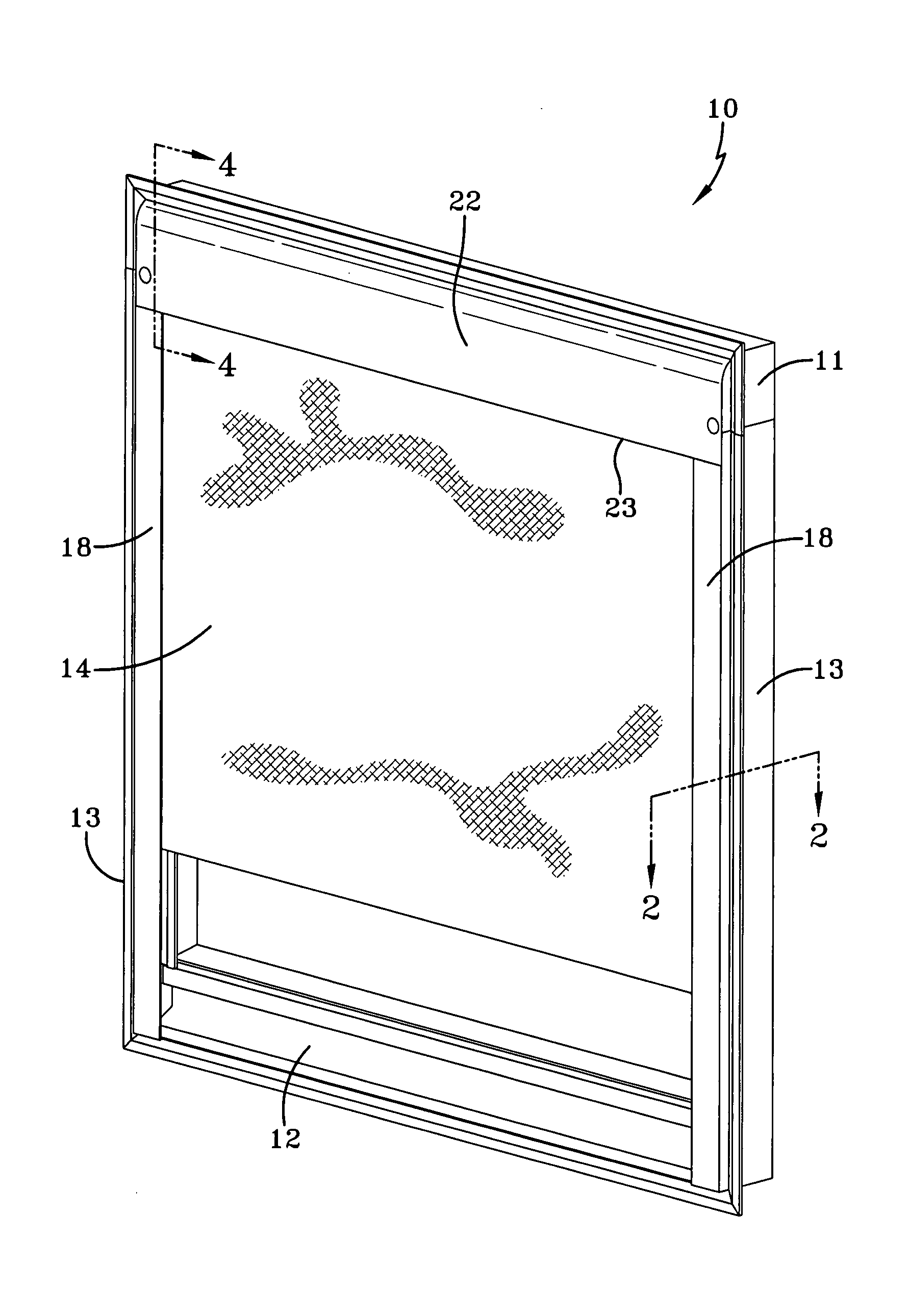

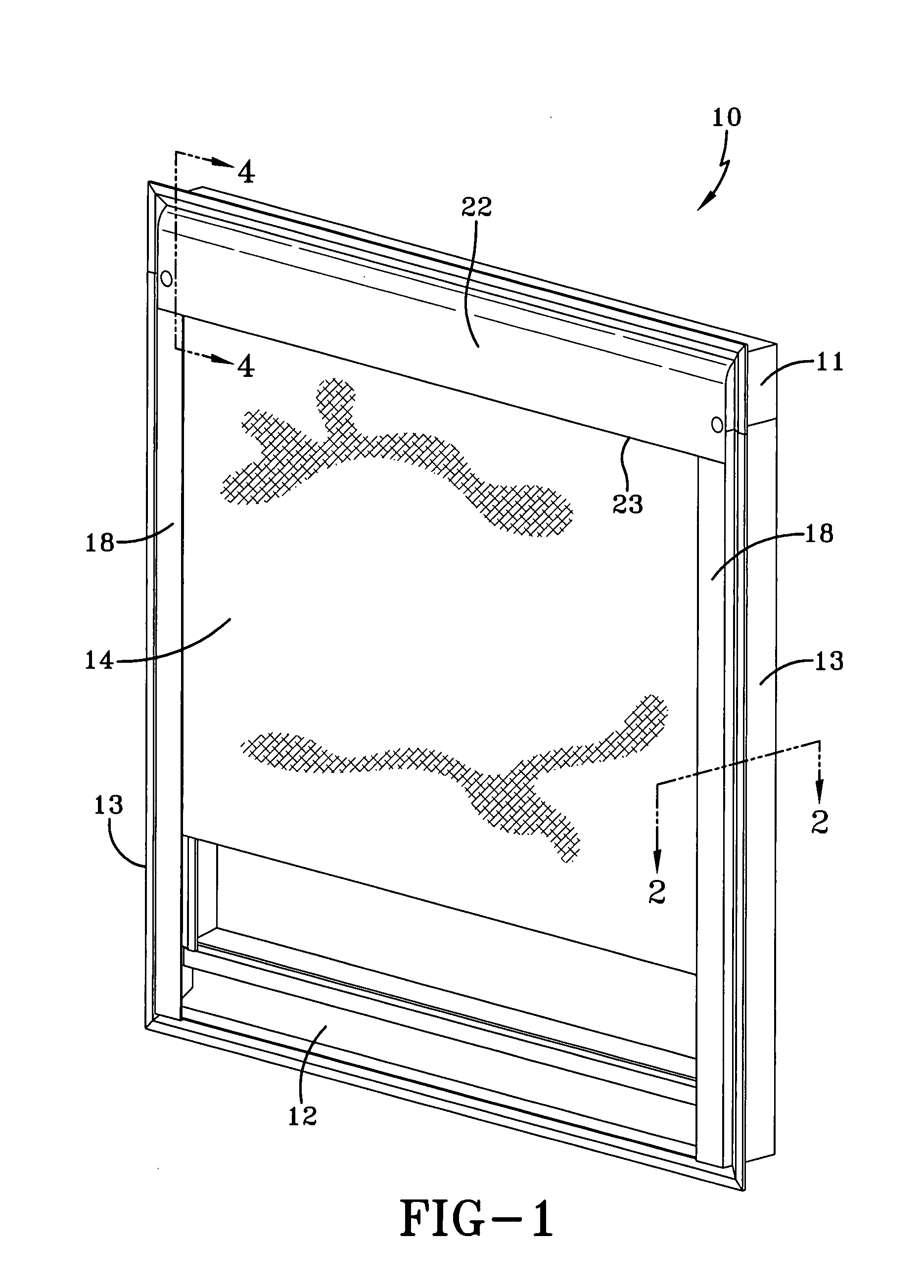

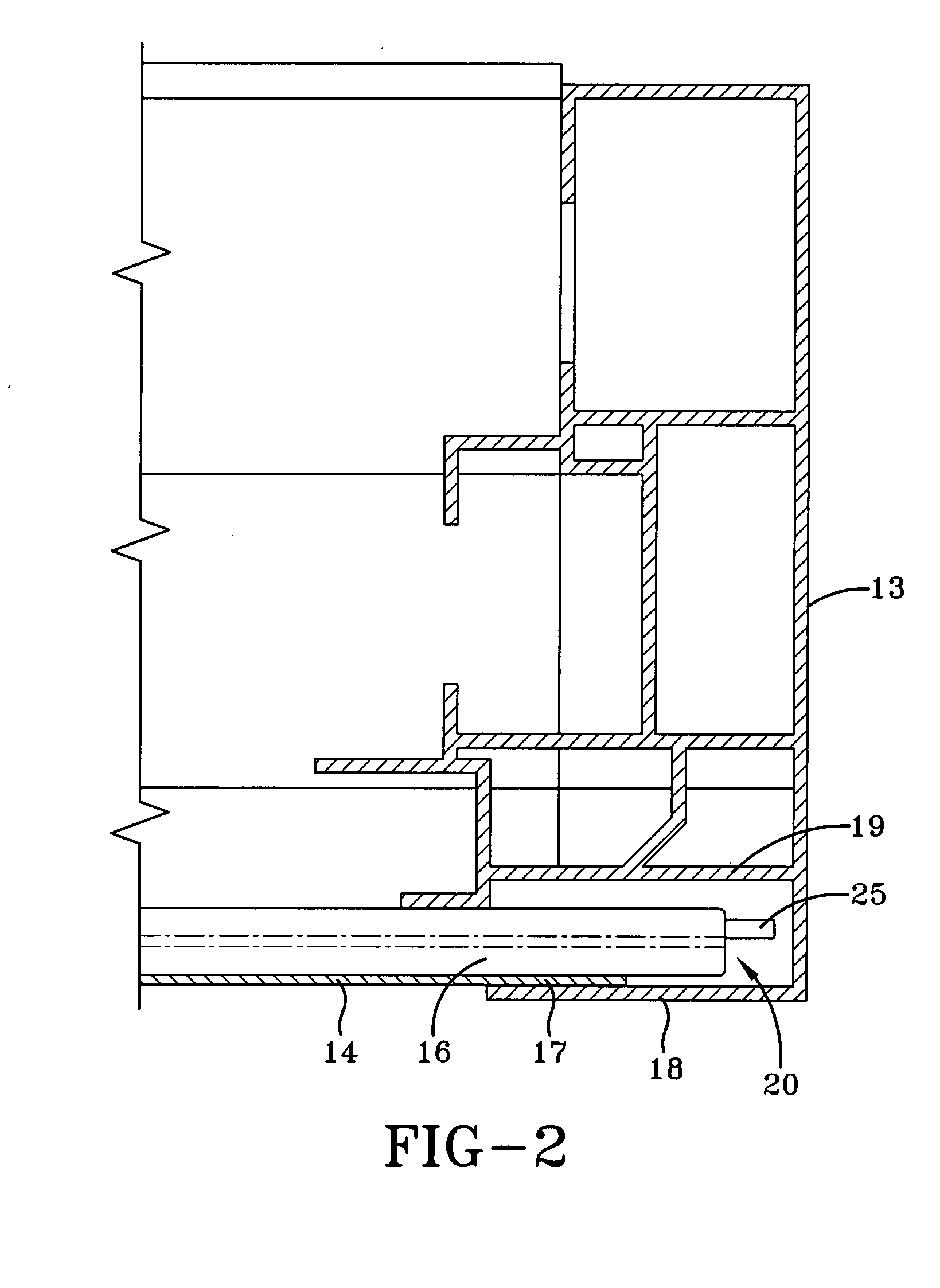

Storm curtain assembly having edge tracking system and roller and lock bar attachment features

InactiveUS20080041537A1Curtain accessoriesShutters/ movable grillesEngineeringMechanical engineering

A storm curtain assembly (10) includes a header (11) and side rails (13) extending downwardly from each end of the header (11). A roll (15) is positioned in the header (11) and carries a fabric curtain (14) which has one end attached to the roll (15). A bar (16) is attached to the other end of the fabric curtain (14). A track (20) is formed on each side rail (13), and the edges of the fabric curtain (14) are normally received in the tracks (20). One of the walls (18) which forms the track (20) terminates at an upper edge (21) which is spaced from the header (11) so that if an edge of the fabric curtain (14) is displaced from the track (20), the displaced edge will be allowed to be received in the track (20) as the fabric curtain (14) is being received on the roll (15).

Owner:WAYNE DALTON CORP

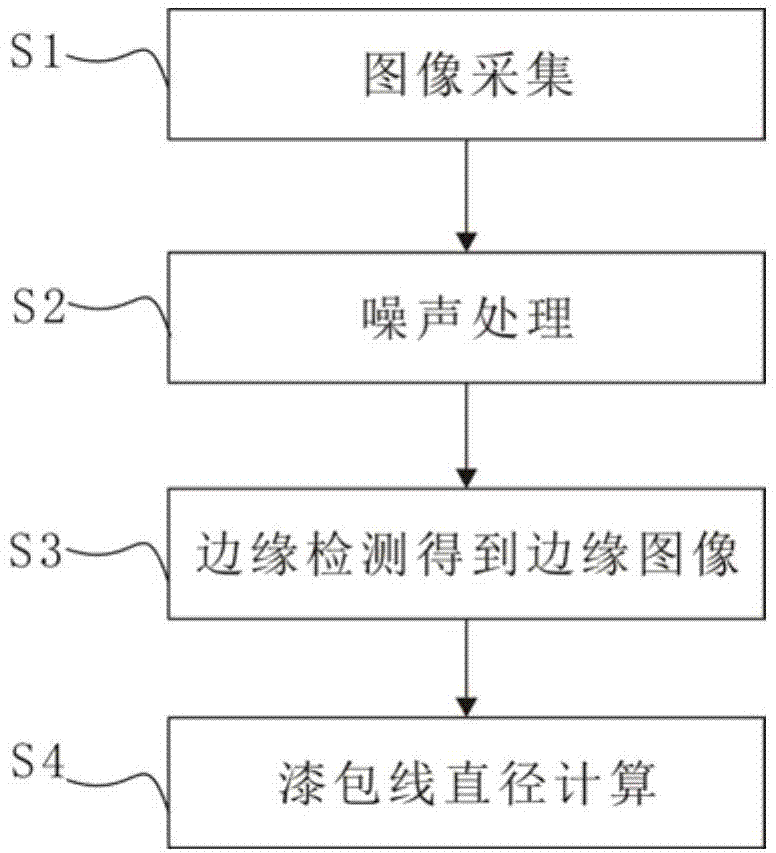

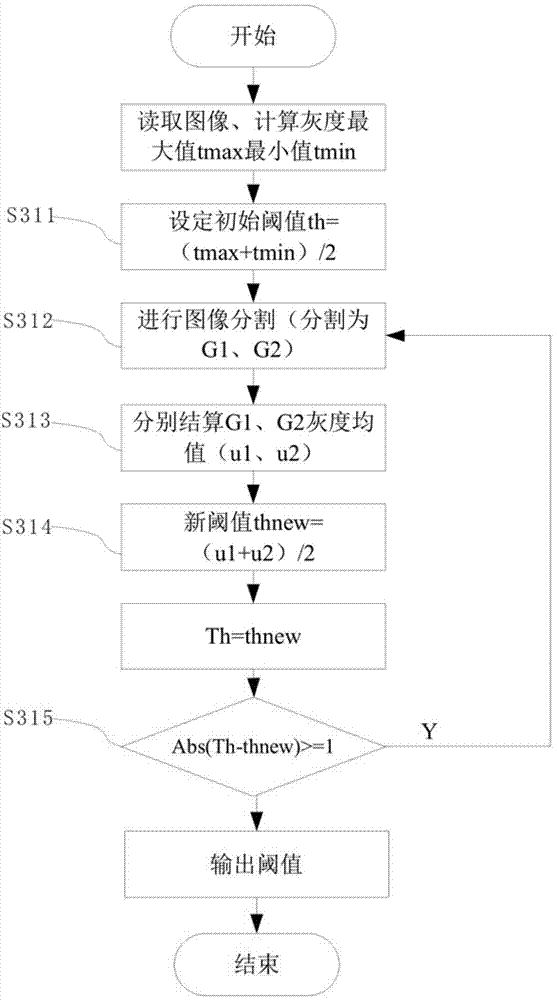

Online diameter detection method of varnished wires

InactiveCN104515473AShort timeEasy to distinguishUsing optical meansPattern recognitionIterative method

The invention discloses an online diameter detection method of varnished wires. The online diameter detection method includes steps of acquiring diameter images of the varnished wires; filtering noise in the diameter images; subjecting the diameter images which are treated by noise filtering to edge detection to obtain edge images; calculating the diameter of the varnished wires according to the edge images. By adopting the edge detection method combining the iteration method to segment threshold of the images and the edge tracking method based on image scanning, background and target of the edge images obtained are well differentiated, edge continuity, no fake edges and burrs are generated, edge width is single pixel, and edge details are well reserved, so that the online diameter detection method has higher detection accuracy. Meanwhile, compared with a conventional edge detecting method, the edge detection method costs less time, so that the online diameter detection method has higher detection speed. In conclusion, the online diameter detection method has high theoretical value and engineering application population value.

Owner:CHENGDU UNIV OF INFORMATION TECH

Multi-sample antialiasing optimization via edge tracking

InactiveUS9406168B1Add visual interestIncrease frame rateImage enhancementDetails involving antialiasingGraphicsComputer vision

An efficient method and system for multi-sample antialiasing in graphics processing is described. Geometric edges as well as implicit edges of primitives in a bin are identified by iteratively rendering bins of pixels. Selective multi-sample antialiasing is applied to pixels that are touched by either a geometric edge or an implicit edge; pixels that are fully covered are not antialiased.

Owner:RPX CORP

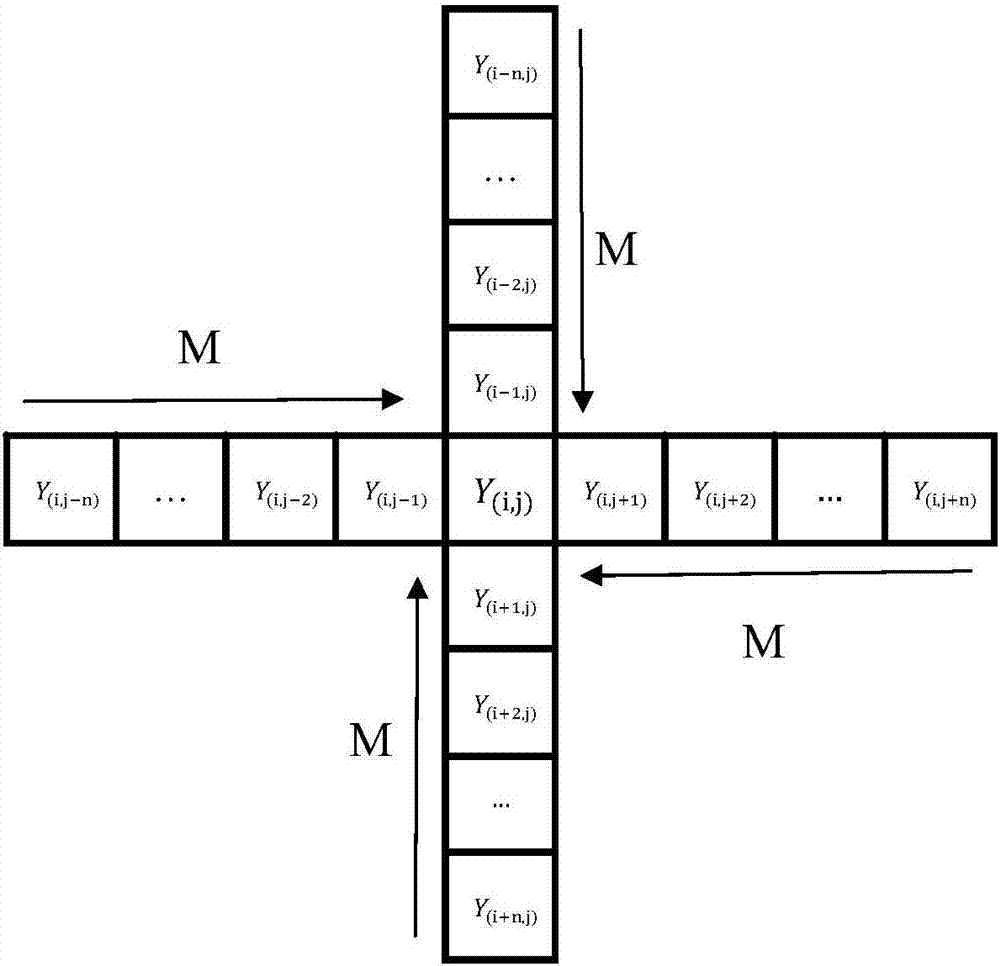

SAR (Synthetic Aperture Radar) image sea-land segmentation method based on wavelet transform and OTSU threshold

ActiveCN102968798BSuppression of speckleImprove applicabilityImage analysis2D-image generationPattern recognitionSynthetic aperture radar

The invention relates to an SAR (Synthetic Aperture Radar) image sea-land segmentation method based on a wavelet transform and OTSU threshold. According to the method, speckle noise in an SAR image is suppressed by using the noise smoothing property of wavelet transform; then land areas are roughly segmented by using an unsupervised optimal OTSU threshold method, and the detection results under each scale are merged based on the multiscale analysis property of wavelet transform; and finally the final coastline detection results are obtained through automatic subsequent treatment and edge tracking. Compared with the prior sea-land segmentation methods, the SAR (Synthetic Aperture Radar) image sea-land segmentation method comprehensively utilizes the speckle noise suppressing and multiscale analysis function of wavelet transform and the self-adaptive, unsupervised and high-robustness properties of the OTSU threshold algorithm, and has great improvement in automation degree, universality, simplicity and applicability of high-resolution SAR images.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com