Online diameter detection method of varnished wires

A detection method and enameled wire technology, applied in the field of control and instrumentation, can solve problems such as limited manual measurement efficiency, influence on measurement results, and measurement result errors, and achieve the effects of strong engineering application promotion value, strong theoretical value, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings of the description.

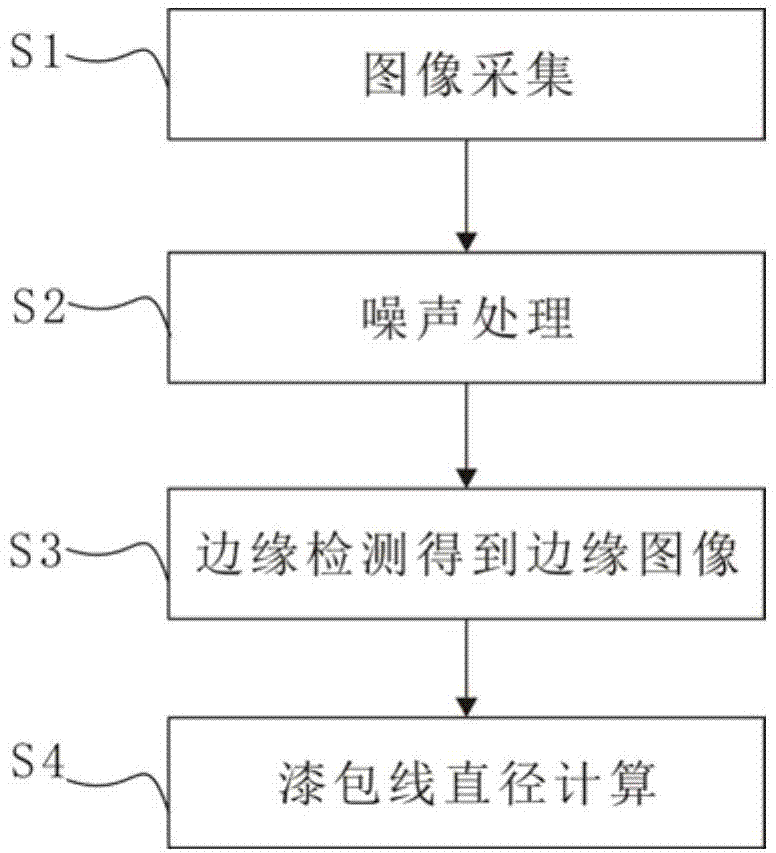

[0043] Such as figure 1 Shown, a kind of online detection method of enameled wire diameter comprises the following steps:

[0044] S1, collecting the diameter image of the enameled wire;

[0045] S2. Perform noise filtering processing on the diameter image;

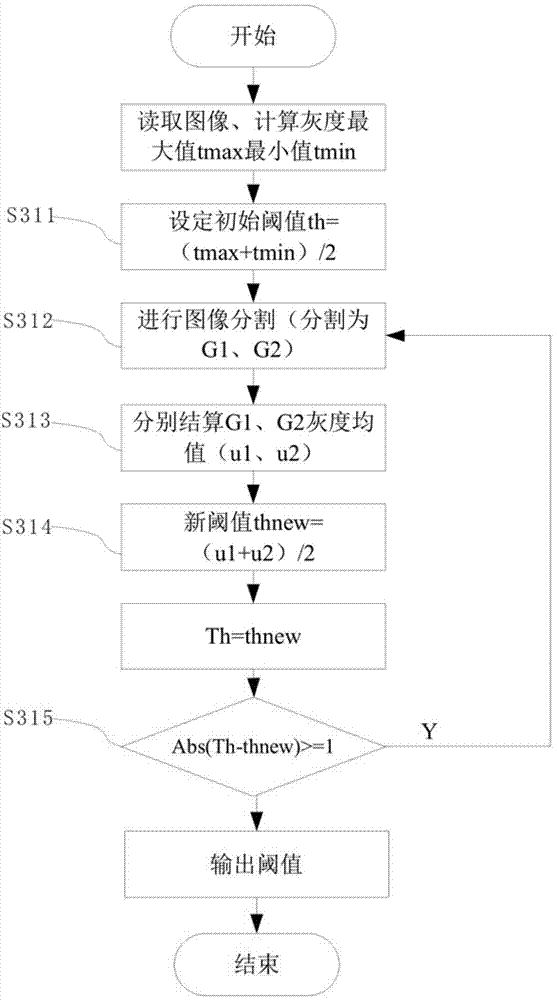

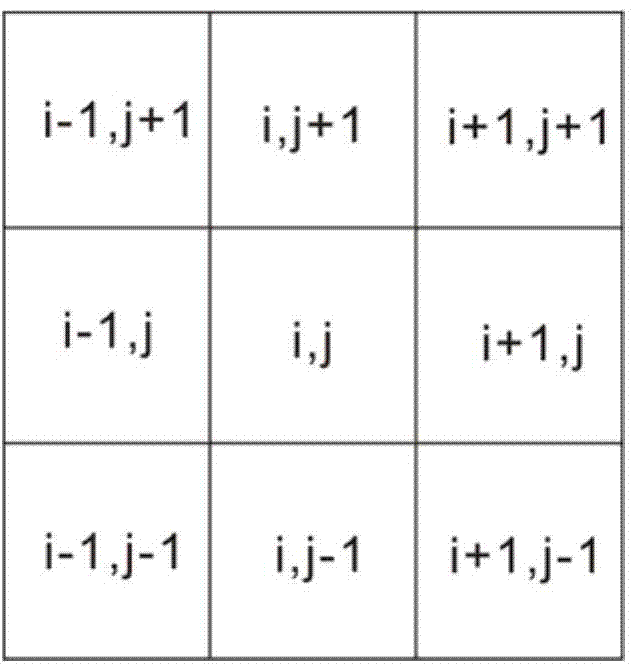

[0046] S3. Performing edge detection on the diameter image processed by noise filtering in step S2 to obtain an edge image;

[0047] S4. Calculate the diameter of the enameled wire according to the edge image.

[0048] Wherein, when collecting the diameter image of the enameled wire in step S1, a linear array CCD industrial camera is used to collect the image, and the light source is selected as a high-brightness LED parallel light source; when collecting the diameter image of the enameled wire, environmental conditions and the quality of the sensing components themselves will cause image noi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com