Production line for harmless treatment and efficient resource recovery for waste refrigerators

A harmless treatment, refrigerator technology, applied in the direction of electronic waste recycling, grain processing, recycling technology, etc., can solve the problems of increasing the risk of fire and burning, increasing the difficulty of crushing, and poor crushing efficiency, so as to reduce crushing The effect of reducing the number of times, reducing the risk of fire and burning, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

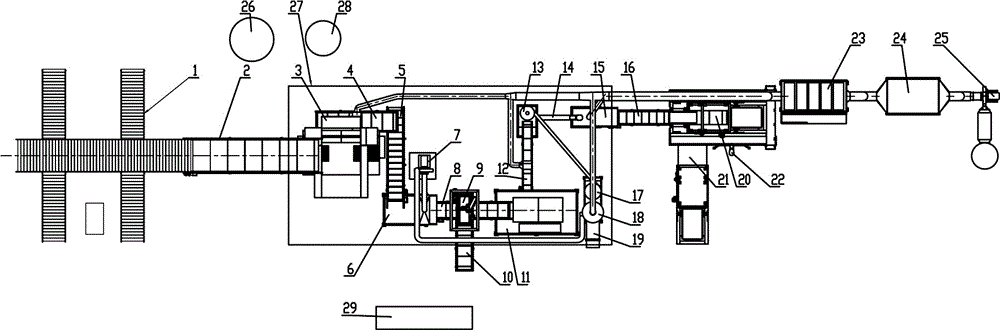

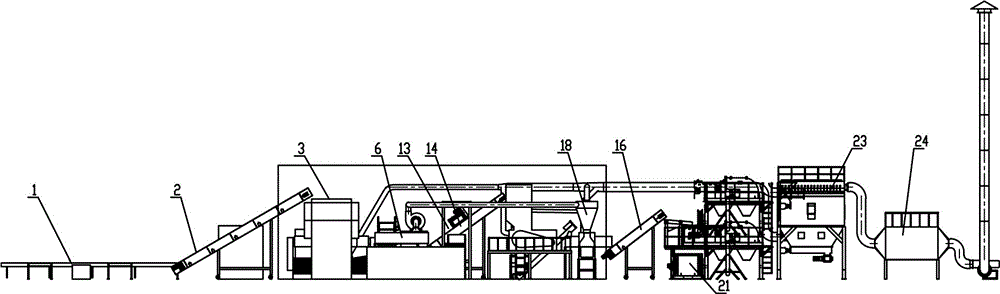

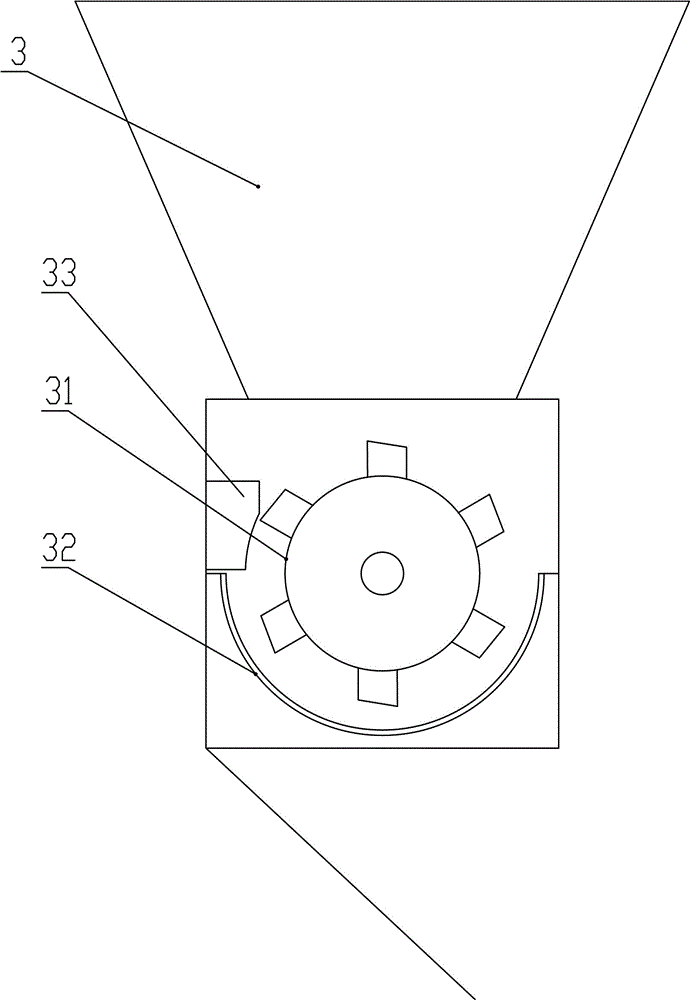

[0032] Such as Figure 1~7 Among them, a production line for the harmless treatment of waste refrigerators and the efficient recovery of resources, the first crushing device is connected to the second crushing device through a conveying device, and the conveying device between the first crushing device and the second crushing device is equipped with a Iron device, the second crushing device is connected with the distributor 13, and the bottom discharge port of the distributor 13 is connected with the metal sorting device;

[0033] At least one foam suction device is further provided between the first crushing device and the metal sorting device, and the foam suction device is connected with a foam compressor 19 . With this structure, the iron removal operation is carried out after the first crushing device, which reduces the probability of iron blocks participating in crushing again. At the same time, foam suction starts after the first crushing, which also reduces the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com