Oil pumping technology based on javelin valve anti-gas pump

A javelin and gas-proof technology, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, and can solve problems such as reducing the fullness of the pump chamber, accelerating damage, and lagging the opening of the oil pump valve ball. Reach the effect of reducing the number of breaking off, short life, and reducing deformation factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The oil pumping process based on the javelin valve anti-air pump that the present invention relates to comprises the following steps:

[0026] Up stroke: the sucker rod drives the center rod up, the javelin valve closes, drives the plunger up, lifts the oil in the upper part of the plunger to the ground, and at the same time, the space under the plunger becomes larger, the pressure drops, and the pump is filled with oil;

[0027] Downstroke: The sucker rod drives the central rod to move, pushes the plunger downward, and at the same time forcibly opens the javelin valve, and the oil-air mixture in the lower chamber of the pump can smoothly enter the oil pipe through the plunger, thereby achieving the effect of preventing gas.

[0028] The upstroke and downstroke are completed once respectively, and the oil well pump completes one cycle, and so on, and the cycle is repeated.

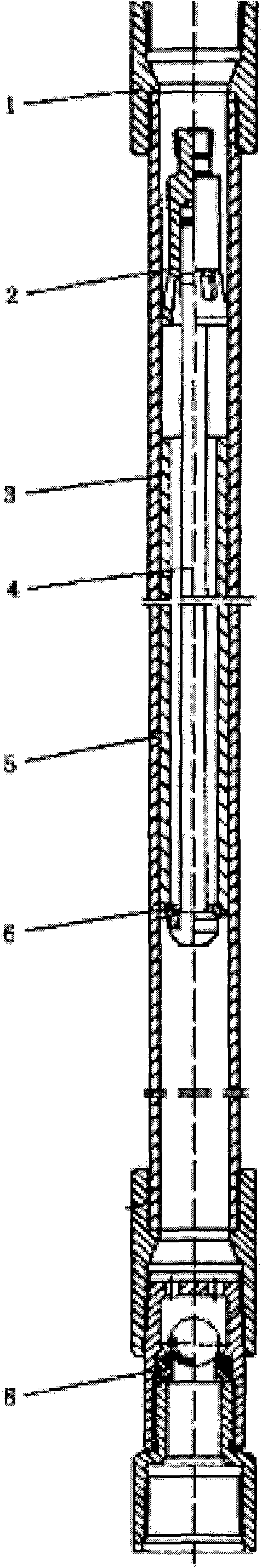

[0029] The used javelin valve anti-air pump of the present invention is as figure 1 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com