A method for producing parts of an automobile spare tire compartment

A technology for parts and automobiles, which is applied in the production of automobile spare tire compartment parts, can solve the problems of reduced stamping efficiency and increased costs, and achieve the effects of improving production efficiency, reducing costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A method for producing spare tire compartment parts of an automobile needs to go through four processes of drawing, shaping and punching, trimming and punching, and flanging and shaping.

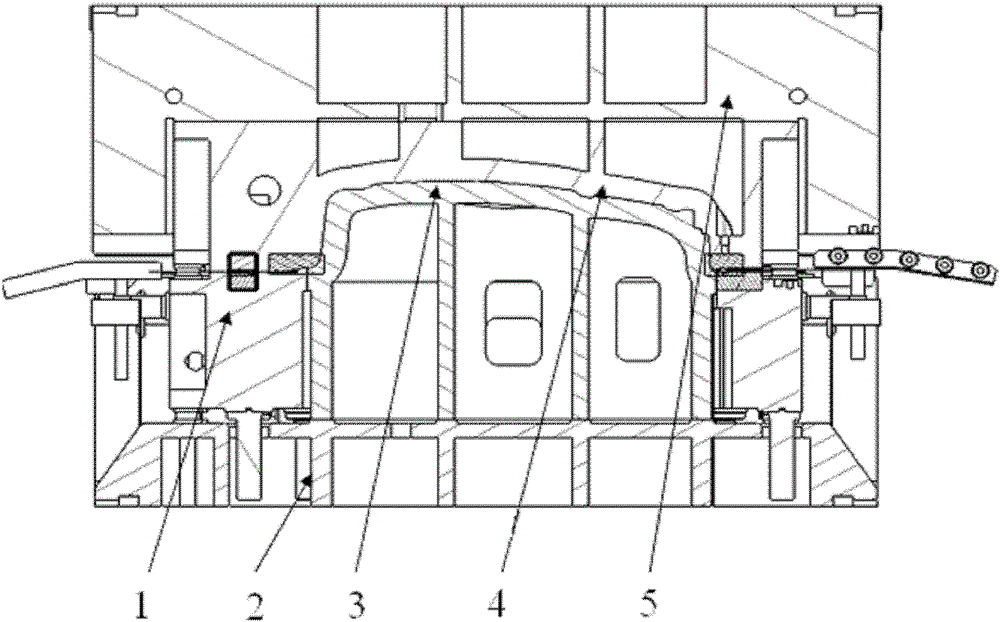

[0023] The molds required for the drawing process such as figure 1 As shown, it consists of a drawing lower die, a blank holder and a drawing upper die. The drawing lower die is composed of a binder plate 1, a lower template 2, and a drawing punch core 3. The drawing upper die is composed of a die core 4 Composed of the upper die base 5, there are 6-8 drawing guide plates between the drawing die and the blank holder for guidance and connection, and there are 6-8 drawing guide plates between the drawing die and the drawing lower die and 4 drawn guide pillars are used as guides and connections.

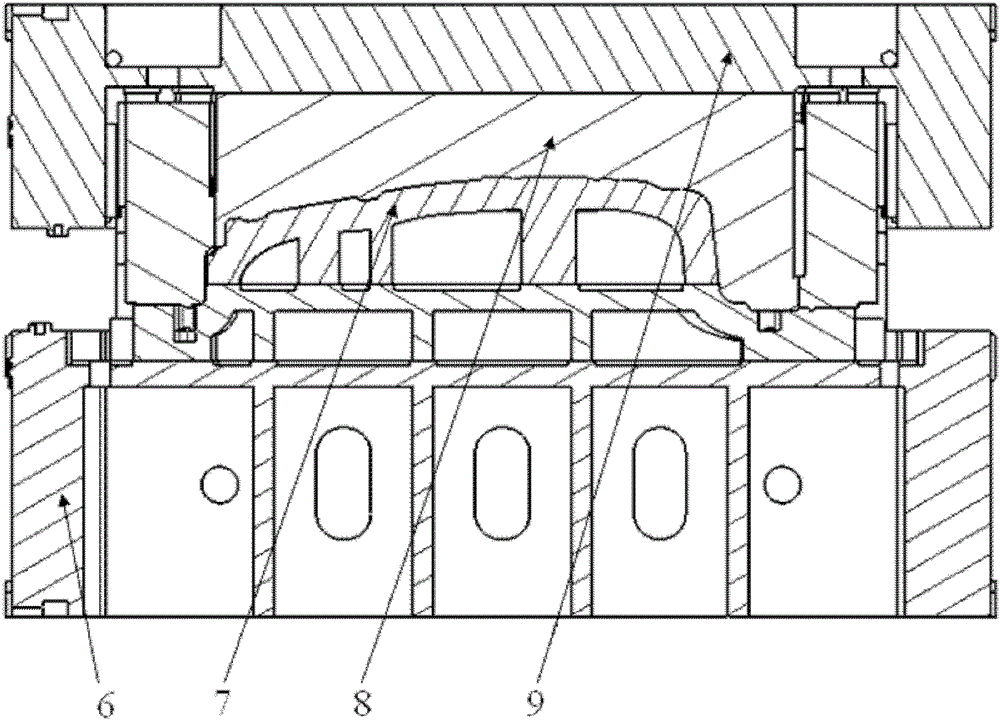

[0024] The molds required for the shaping and punching process are as follows: figure 2 As shown, it is composed of a shaping lower mold and a shaping upper mold. The shaping lower mold is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com