A kind of anti-deformation turning and grinding processing method of cylinder inner cavity

A processing method and anti-deformation technology, applied in the direction of grain processing, etc., can solve the problems of reducing eccentricity, which is difficult to achieve, and achieve the effects of avoiding bending deformation, good balance effect, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

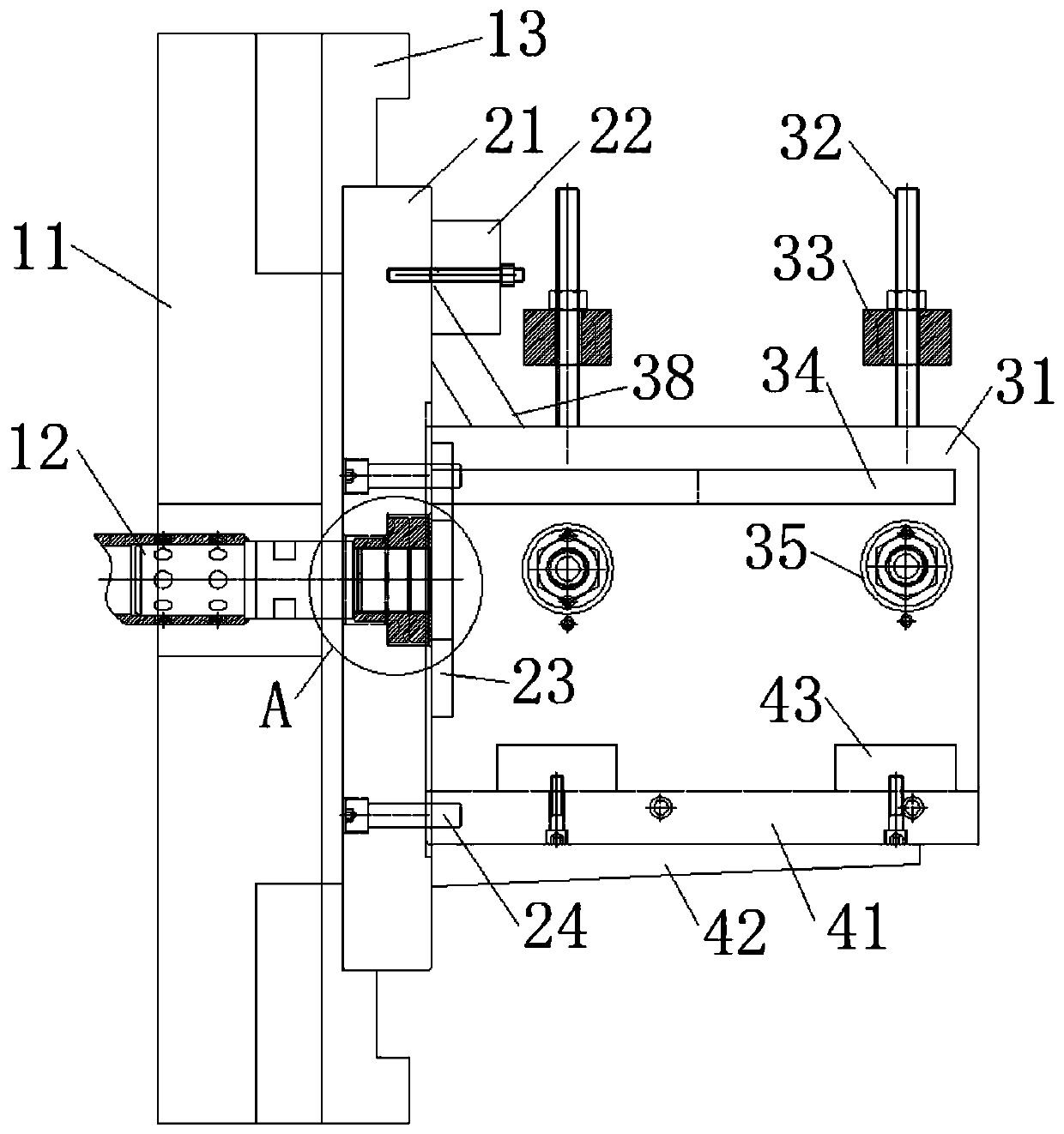

[0056] combine figure 2 , the anti-deformation car-grinding method of the inner cavity of the cylinder in this embodiment, the cylinder body 6 is fixed by the cylinder body fixing mechanism during machine tool processing, and the grinding support device is used for auxiliary support during the grinding process. combine Figure 15 , the specific processing process is:

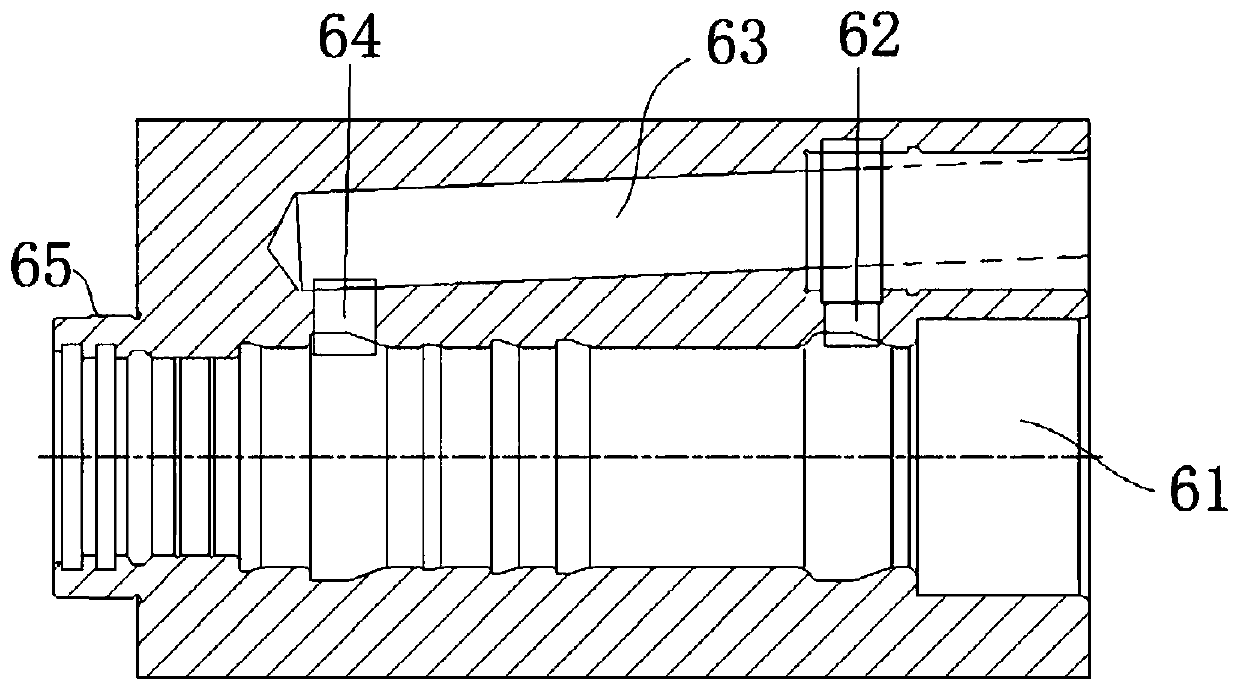

[0057] 1) Process the outer surface of the middle cylinder body blank to the required size, then fix the middle cylinder body blank on the boring machine table, initially drill the piston hole 61; then adjust the angle, and process the oil inlet hole 63 to the required size.

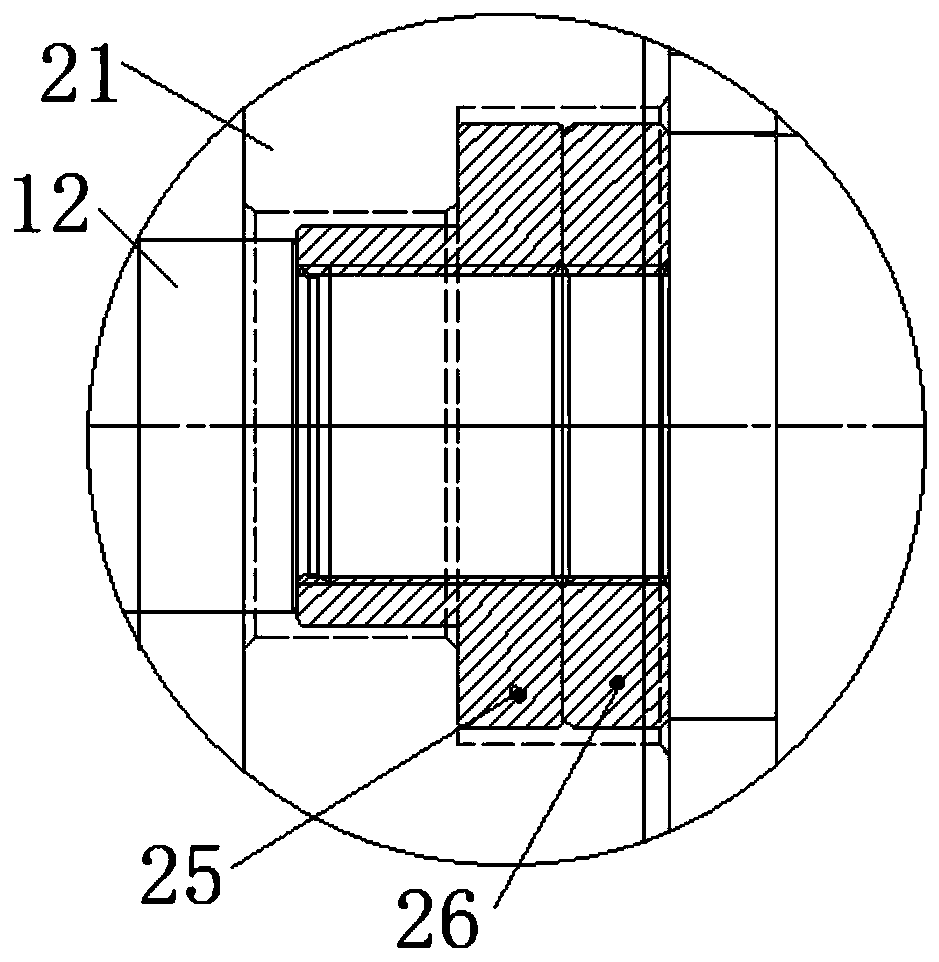

[0058] 2) Hoist the middle cylinder body into the cylinder body fixing mechanism, place it on the bottom surface reference block 43, and make the inner end of the middle cylinder body stick to the end surface reference block 23, and pre-tighten the middle cylinder body through the fastening bolt 37. The side sticks to the side wall refe...

Embodiment 2

[0088] The basic structure of the cylinder fixing mechanism in this embodiment is the same as that in Embodiment 1, the difference is that four end face reference blocks 23 are arranged on the connection plate 21, and the distance between the end face reference blocks 23 and the axis of the rotating shaft 12 is the same , the end face reference blocks 23 are equally spaced along the circumferential direction, that is, the central angle between two adjacent end face reference blocks 23 is 90°.

[0089] The upper surface of the supporting plate 41 is provided with a bottom reference block 43, such as figure 2 As shown in , the bottom reference block 43 is arranged in two rows along the length direction of the pallet, and the position of the bottom reference block 43 and the position of the pressure plate 33 correspond up and down. When the pressing force is applied by the pressure plate 33, the bottom of the middle cylinder is Supported by the reference block 43, the point of a...

Embodiment 3

[0095] The basic structure of the cylinder fixing mechanism in this embodiment is the same as that of Embodiment 2, the difference is that: Figure 5 , in the present embodiment, a reinforcement bolt 24, a first rib 34 and a second rib 38 are arranged between the side wall baffle 31 and the connection plate 21, and the second rib 38 is perpendicular to the side wall baffle 31; the first rib The plate 34 is connected to the surface where the screw rod 32 is located on the side wall baffle plate 31 . The first rib 34 and the second rib 38 fix the side wall baffle from different directions, and the height of the second rib 38 from the supporting plate 41 is greater than the height of the axis of the piston hole relative to the supporting plate 41, which is closer to the overall structure The central position, the support strength is higher.

[0096] In order to reduce the overall weight, the side wall baffle 31 is provided with a first lightening hole 39, such as Image 6 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com