Covering yarn spinning cake special clamp

A special fixture and core-spun yarn technology, used in the textile industry, can solve the problem of high strength, improve the efficiency of pipe rewinding, and reduce the number of breakages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

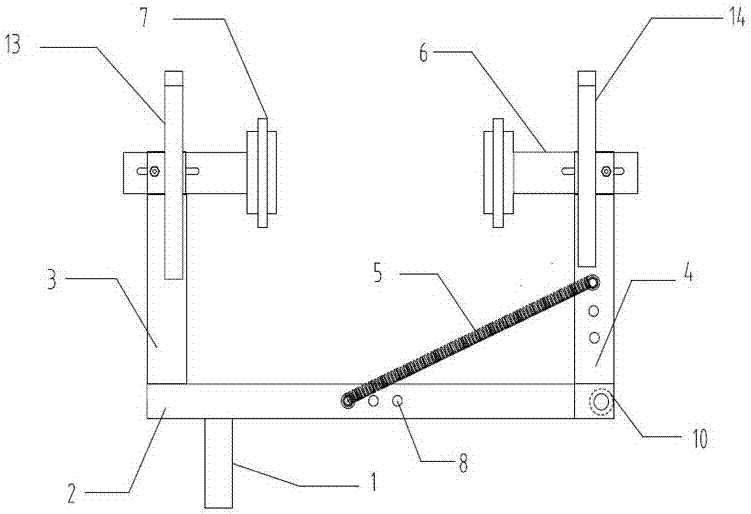

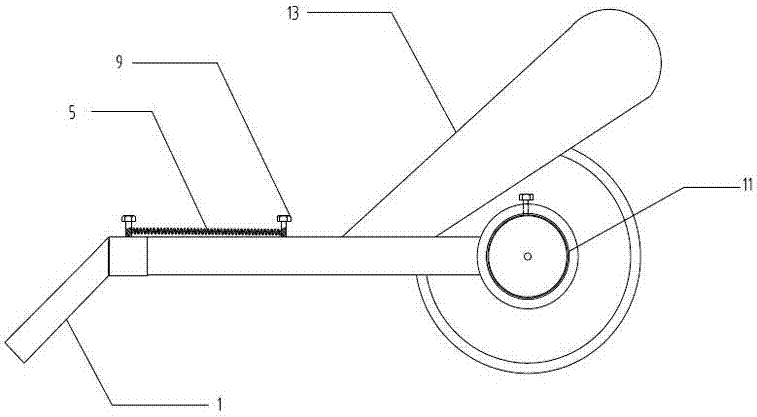

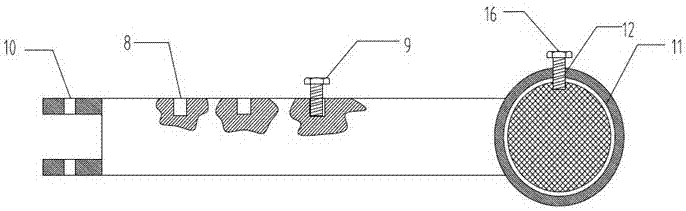

[0020] Such as Figure 1 to Figure 4 Shown is a special clamp for core-spun yarn cake, which is used on an automatic rewinding machine, and includes a T-shaped main body, a fixed clamp arm 3, a movable clamp arm 4, a spring 5, a movable shaft 6 and Chuck 7.

[0021] The T-shaped main body is a T-shaped structure composed of a vertical connecting rod 1 and a horizontal horizontal bar 2. The vertical connecting rod 1 is cylindrical. One end of the vertical connecting rod 1 is connected with a hoop. The rotating shaft of the barrel machine is connected, and the vertical connecting rod 1 rotates around the rotating shaft. The other end of the vertical connecting rod 1 is vertically fixedly connected to the side of the horizontal bar 2. The upper end of bar 2 has some screw ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com