Ultrahigh-strength and high-toughness steel for pumping rod and production process thereof

An ultra-high-strength, production process technology, applied in the field of alloy structural steel, can solve the problems of reduced strength, excessive performance differences, broken rod accidents, etc., to reduce the number of fractures, improve fatigue life, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

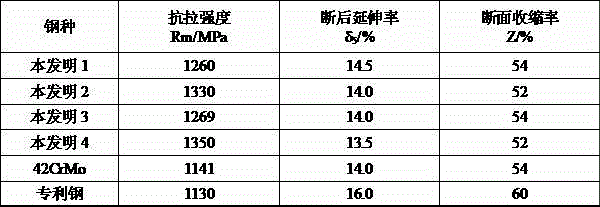

Examples

Embodiment Construction

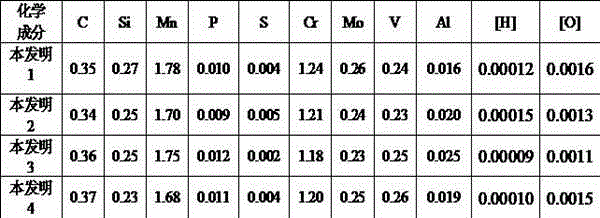

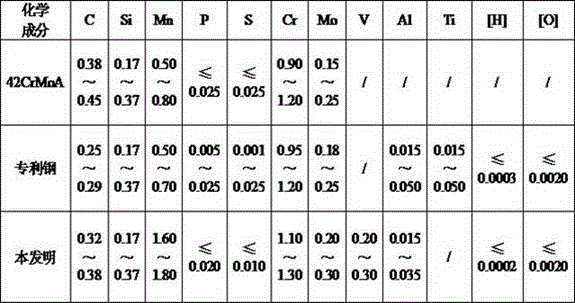

[0031] The chemical composition comparison between the ultra-high-strength sucker rod steel 42CrMoA and patented steel (patent publication number CN101962737A) currently used in China and the present invention is shown in Table 1 below.

[0032] Table 1 Chemical composition comparison wt%

[0033]

[0034] Prepared by the following production process:

[0035](1) LD converter smelting: smelting in a 90-ton top-bottom combined blowing converter, using molten iron and scrap steel as raw materials for primary smelting to achieve pre-removal of P, adding special synthetic refining slag, composite deoxidizer and high-purity The alloy is pre-deoxidized and the composition is initially adjusted, and the slag is retained to prevent the steel from returning to P;

[0036] (2) LF refining: deep deoxidation and alloying of molten steel are carried out in LF furnaces of more than 90 tons, and high-basicity slag (R≥3.0) is strengthened to remove S and impurities. Promote the float...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com