High-temperature alloy wire straightening and shearing device

A high-temperature alloy wire and shearing device technology, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of easily scratched threads on the product surface, graphite dust pollution, and difficult operation, so as to reduce the labor intensity of personnel, Improve product quality and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

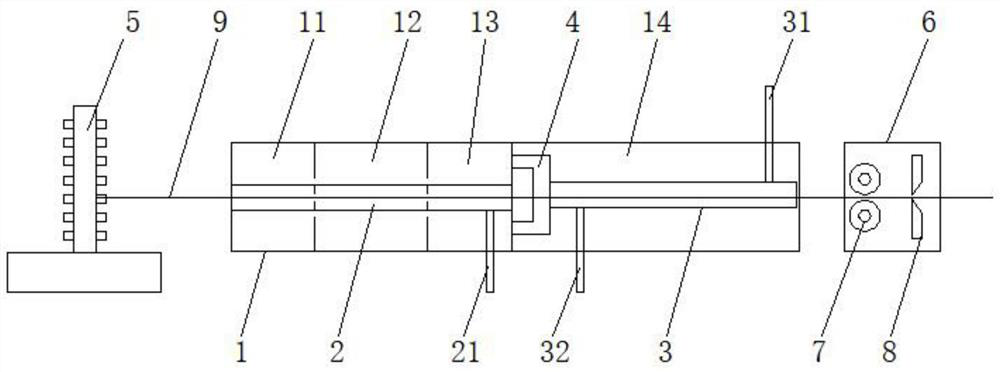

[0031] The invention provides a high-temperature alloy wire straightening and shearing device, specifically as figure 1 As shown, it includes a hot straightening furnace 1, a first interlayer cooling pipeline 2, a second interlayer cooling pipeline 3, a shaping die 4 and a cutting device.

[0032] The inside of the hot straightening furnace 1 is provided with a heating zone 11, a heat preservation zone 12, a shaping zone 13 and a cooling zone 14 in sequence along the direction in which the alloy wire enters; Zone 12 and shaping zone 13, the interlayer of the first interlayer cooling pipeline 2 is filled with high-purity argon; the second interlayer cooling pipeline 3 is arranged in the hot straightening furnace 1 and runs through the cooling zone 14, and the interlayer of the second interlayer cooling pipeline 3 Filled with liquid cooling medium. Specifically, in this embodiment, both the first interlayer cooling pipe 2 and the second interlayer cooling pipe 3 are made of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com