Pin pressing device for commutator

The technology of a presser foot device and a commutator is applied in the field of presser foot devices, which can solve the problems of coil breakage and breakage at the bend of hook feet, and achieve the effects of increasing service life, reducing the number of breaks, and reducing the rate of defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

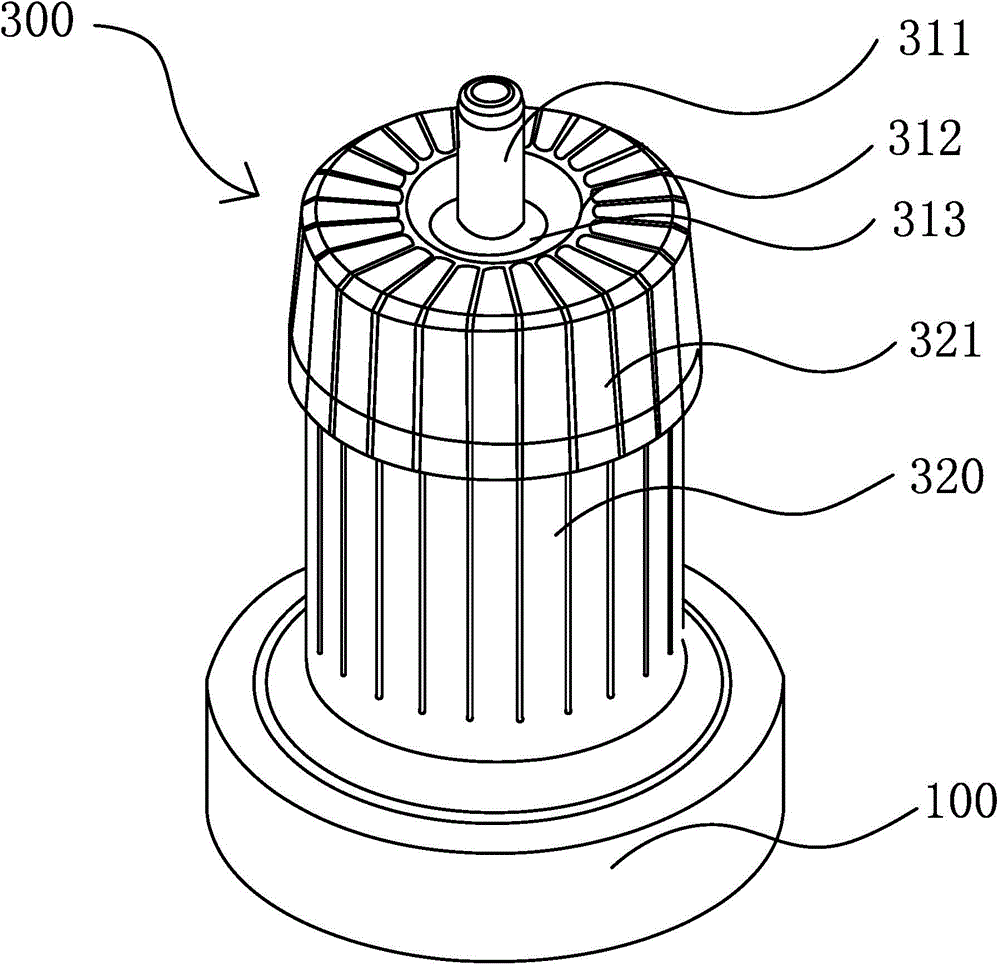

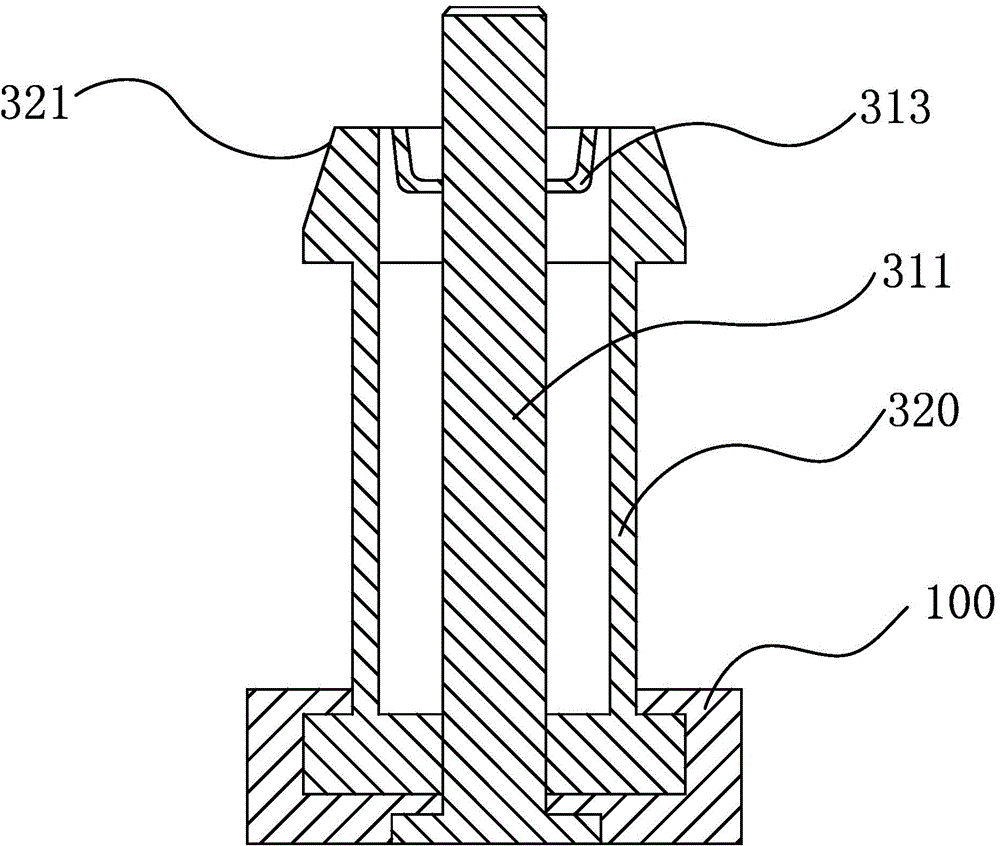

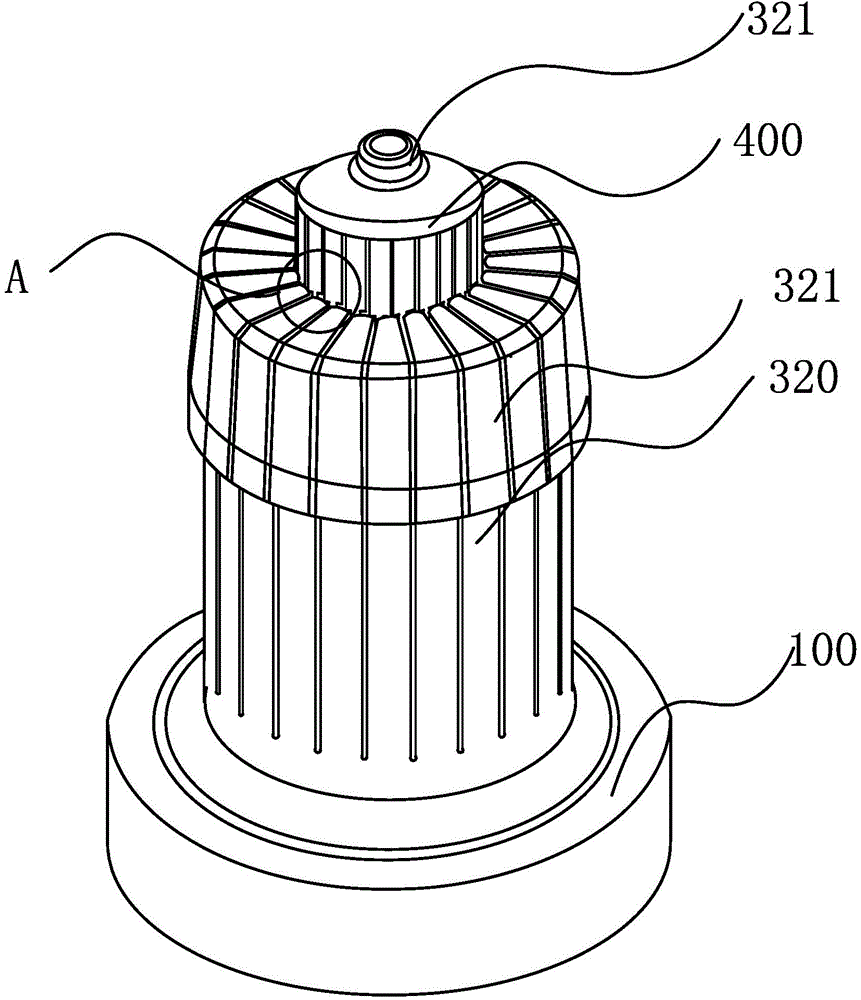

[0017] Such as Figure 1 to Figure 5 As shown, the presser foot device for the commutator 400 includes a base body 100, a lower die 300 disposed on the base body 100 and used for installing the commutator 400, and an upper die 200 matched with the lower die 300, and the upper die 200 Including the pressure cylinder 210 and the connecting shaft 220, the lower mold 300 includes a mold core and a number of mold pieces 320 uniformly surrounding the mold core. There is a gap between the mold pieces 320. When the commutator 400 is set on the lower mold 311 The hook legs of the commutator 400 are clamped in the gap, and the downward movement of the upper mold 200 can make the mold piece 320 move closer to the mold core in the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com