Integrated cleaning and drying mop bucket

An all-in-one, mop bucket technology, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc., can solve the problems of large space occupation, inconvenient storage and movement, etc., and achieve small space occupation, convenient storage and movement, and reduced horizontal width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

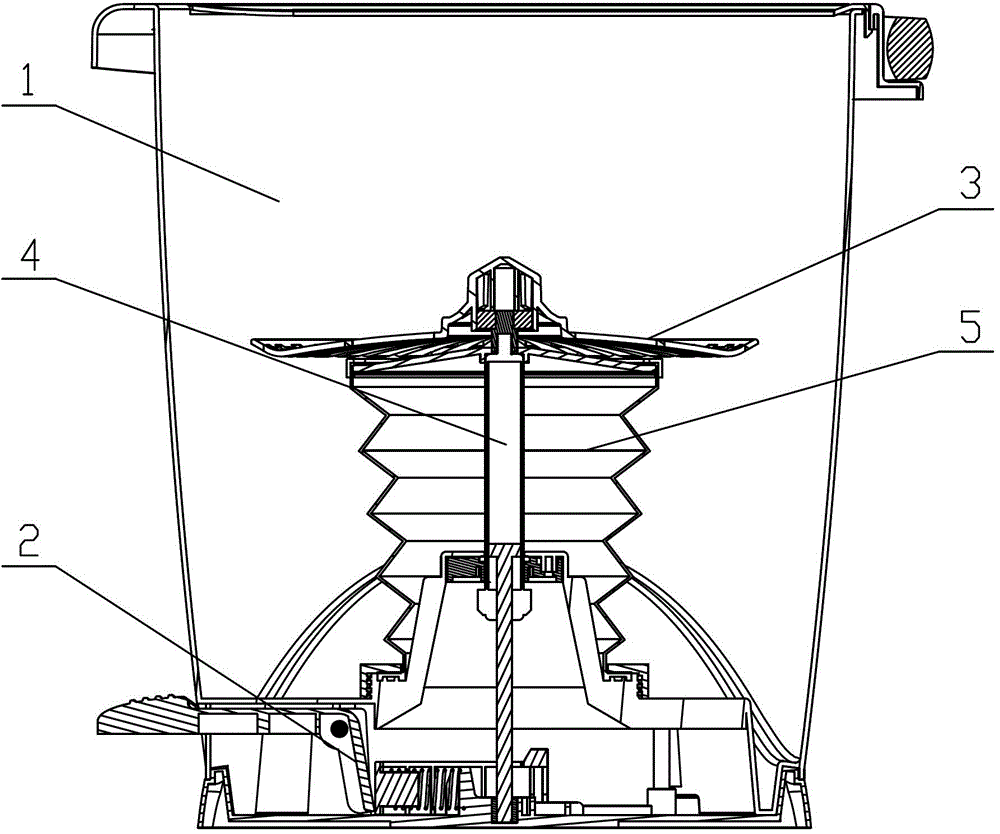

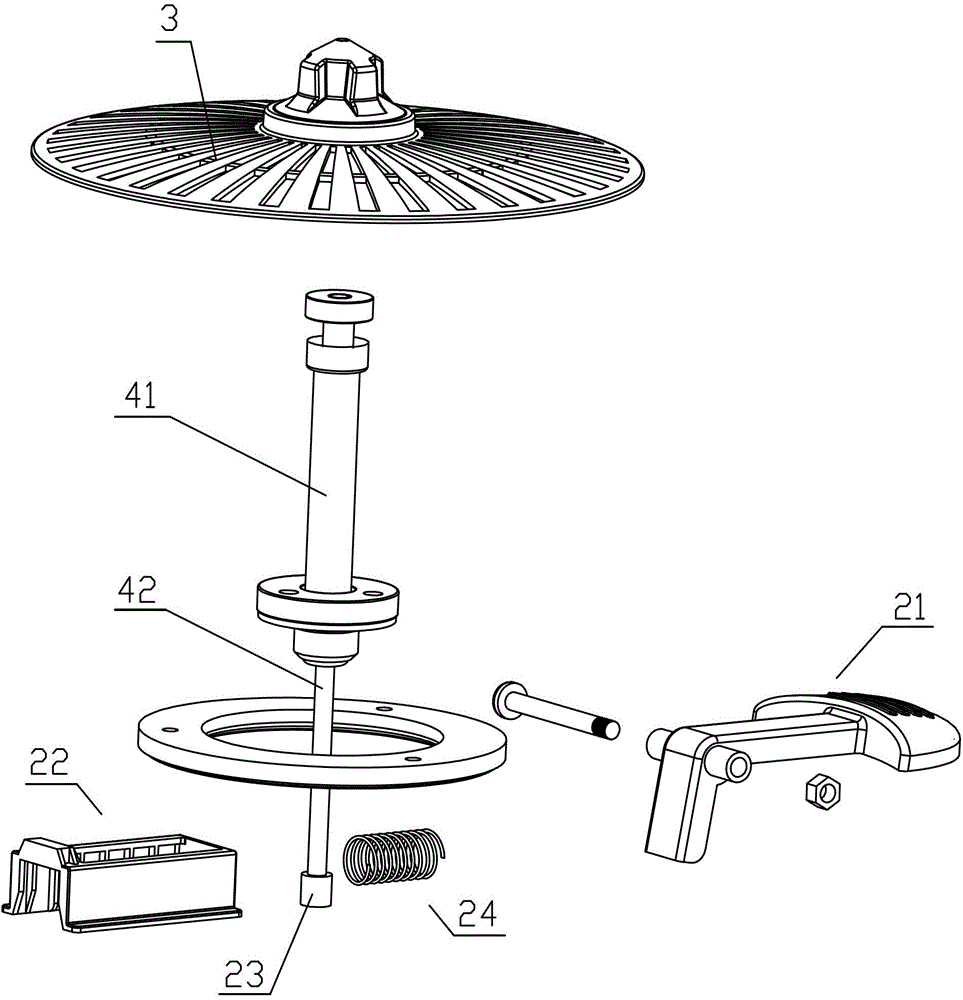

[0015] Examples, see figure 1 with figure 2 Shown: an integrated cleaning and drying mop bucket, including a bucket body 1, a power unit 2 and a drying tray 3. A synchronously rotating telescopic tube 4 is pivotally connected to the bottom of the inner cavity of the bucket body 1 , and the power unit 2 is connected to the bottom end of the synchronously rotating telescopic tube 4 , and the drying disc 3 is fixed to the top end of the synchronously rotating telescopic tube 4 . Wherein, the so-called synchronously rotating telescopic cylinder 4 means that when one end of the telescopic cylinder rotates, the other end of the telescopic cylinder is driven to rotate simultaneously. Its form can take many common forms, for example, a spring is provided between the two ends of the telescopic cylinder, and an anti-rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com