Preparation method of fusion protein inclusion body

A fusion protein and inclusion body technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as no biological activity, spatial conformation errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

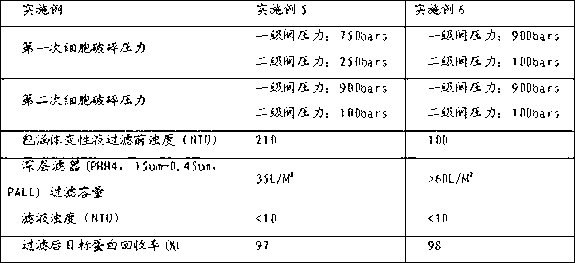

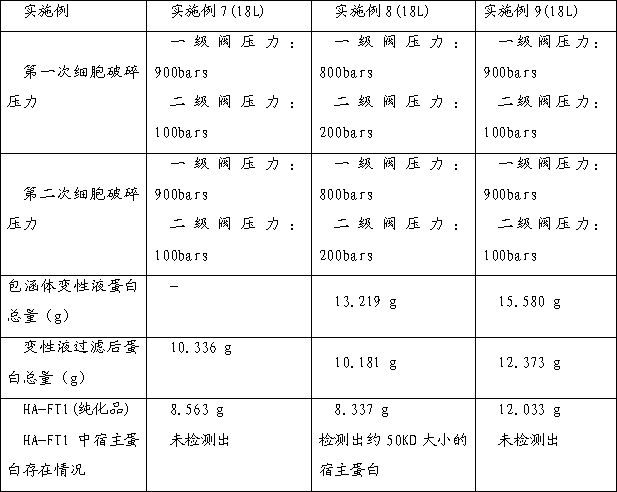

Examples

Embodiment 1

[0020] Bacterial reconstitution:

[0021] The Mtb72f engineering bacteria strain was inoculated into the fermenter to carry out high-density fermentation in a fed-feed mode. When the OD650nm of the fermentation broth was 50, IPTG was added at 37°C for induction, and the cells were harvested after 5 hours of induction. Take a certain amount of bacteria (≥16L of bacteria at the time of fermentation and harvest), add pre-cooled lysis buffer, and adjust the bacteria to reconstitute the solution to OD 650 nm≈60 。 Homogenize the bacterial reconstituted solution with a high-speed homogenizer, and cool it to ≤10°C after homogenization.

Embodiment 2

[0023] Bacteria fragmentation:

[0024] The samples after cooling and homogenizing are crushed with a high-pressure homogenizer. The pressure of the high-pressure homogenizer is adjusted to 100-150 bars for the second stage and 850-900 bars for the first stage, and the total crushing pressure is 1000 ± 50 bars; the inlet sample of the homogenizer The temperature should be controlled at ≤10℃, and the outlet sample temperature must be ≤25℃. The same batch of samples was broken and processed twice, and the bacterial cell broken liquid was obtained after the processing was completed.

Embodiment 3

[0026] Centrifugation and cleaning of bacterial fragmentation liquid:

[0027] Add the same volume of lysis buffer to the cell fragmentation solution, and use an industrial-scale centrifuge (such as a tubular high-speed centrifuge) to collect the inclusion bodies after mixing. The process temperature is less than 15 °C. After centrifugation, the inclusion bodies were collected, and inclusion body washing buffer was added to a volume equivalent to the reconstituted bacterial cells. Homogenize with a high-speed homogenizer (such as Ultra Turrax T50), and then use a centrifuge to collect the inclusion body precipitate. The process temperature is also lower than 15°C. Repeat the inclusion body wash and centrifugation steps. The inclusion bodies were collected, a small amount of washing buffer was added, and a high-speed homogenization treatment was performed to prepare an inclusion body suspension for the purification process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com