Connecting method of displacement transducer magnetic head and connecting jackcatch

A technology of displacement sensor and connection method, which is applied in length measuring device, metal processing equipment, metal rolling, etc., can solve the problems of broken safety ring of transmission shaft, abnormal roll gap control, affecting normal production, etc., and save equipment maintenance. cost, the effect of reducing cumulative damage, and reducing consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

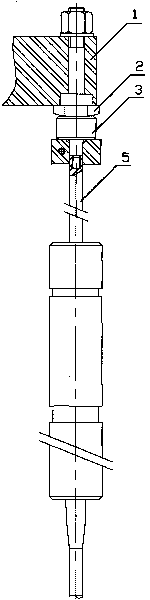

[0017] as attached Figure 5 Shown: a connection method of a displacement sensor, which is to install a connecting claw 4 between the magnetic head 3 on the extension rod 5 of the displacement sensor and the bolt 2 on the bolt mounting block 1 connected to the servo cylinder, and connect the claw The opening slot 4-3 on the connecting plate 4-1 of 4 is stuck on the screw rod of the bolt 2, and is fixed on the bolt installation block 1 through the bolt 2, and the two claw hooks on the connecting plate 4-1 of the connecting claw 4 are connected. 4-2 Hook the bottom of the head 3. After the connecting claw 4 is installed, it should be ensured that there is a gap of 0.3 mm between the two symmetrical hooks 4 - 2 of the connecting claw 4 and the bottom of the magnetic head 3 .

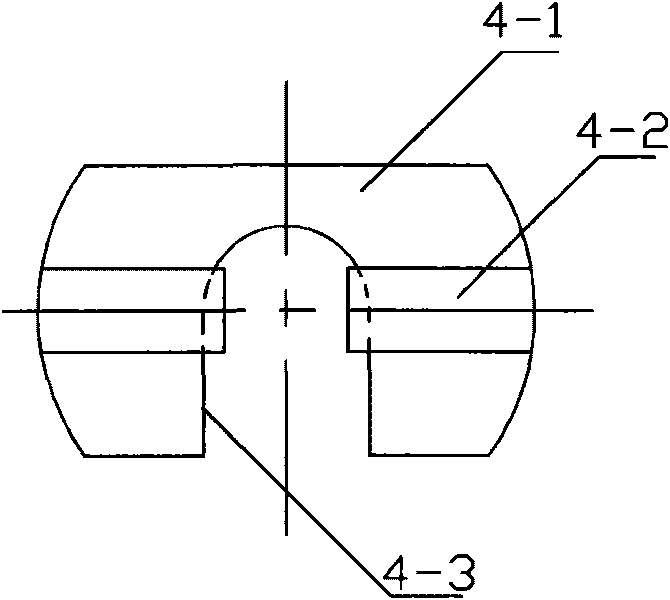

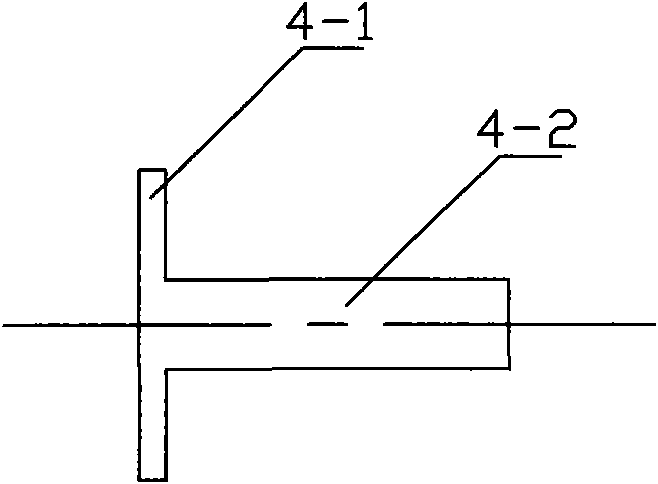

[0018] as attached figure 2 , 3 , Shown in 4: a kind of displacement sensor magnetic head connects claw, and it comprises a connecting plate 4-1, is provided with an opening groove 4-3 on connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com