Agricultural film recovery dry-method granulation preparation technology

A technology of dry granulation and preparation process, applied in the field of plastic granulation, which can solve the problems of high operating cost, easy pollution of sewage, mechanical wear of fusion granulation, etc., and achieve the effect of reducing secondary pollution and improving the purity of granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

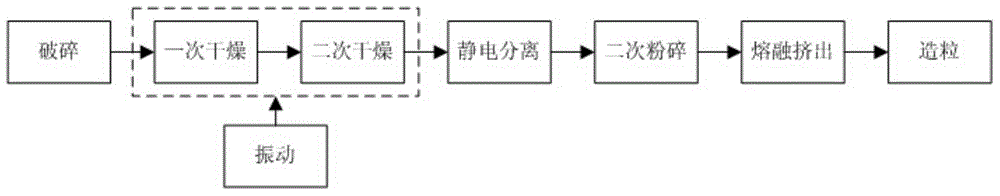

Image

Examples

Embodiment 1

[0026] The dry granulation preparation process of agricultural film recycling includes the following steps: Crushing: After recycling the waste agricultural film, it is crushed once, and broken into pieces of about 50mm. The first drying: Place the coarsely crushed agricultural film fragments in a low-temperature drying oven for drying at a drying temperature of 42°C and a drying time of 6 hours. The second drying: the agricultural film fragments that have been dried for the first time are subjected to the second drying, the drying temperature is 46°C, and the drying time is 5 hours. Vibration: The agricultural film is vibrated during the two dryings at the same time, and the vibration frequency is 280 times / min. Electrostatic separation: The vibration-dried agricultural film fragments are subjected to 120KV electrostatic separation. Secondary crushing: The material obtained after electrostatic separation is subjected to secondary crushing and crushed into fragments of about ...

Embodiment 2

[0028] The dry granulation preparation process of agricultural film recycling includes the following steps: Crushing: After recycling the waste agricultural film, it is crushed once, and broken into pieces of about 50mm. The first drying: Place the coarsely crushed agricultural film fragments in a low-temperature drying oven for drying at a drying temperature of 40°C and a drying time of 5.5 hours. The second drying: the agricultural film fragments that have been dried for the first time are subjected to the second drying, the drying temperature is 45°C, and the drying time is 4 hours. Vibration: The agricultural film is vibrated during the two dryings, and the vibration frequency is 265 times / min. Electrostatic separation: The vibration-dried agricultural film fragments are subjected to 120KV electrostatic separation. Secondary crushing: The material obtained after electrostatic separation is subjected to secondary crushing and crushed into fragments of about 8mm. Melt extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com