High-strength carbon nanofiber membrane and preparation method thereof

A carbon nanofiber, high-strength technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of small molecular effects, expensive equipment, fiber breakage, etc., to reduce fiber breakage and avoid Effects of Structural Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

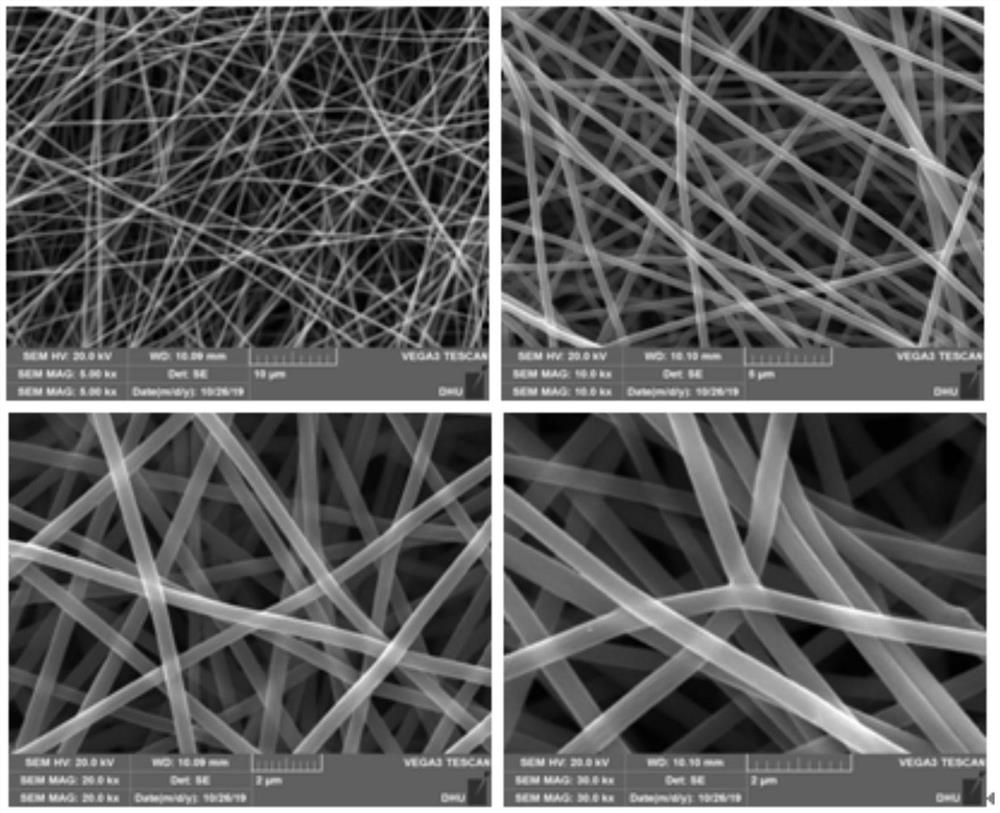

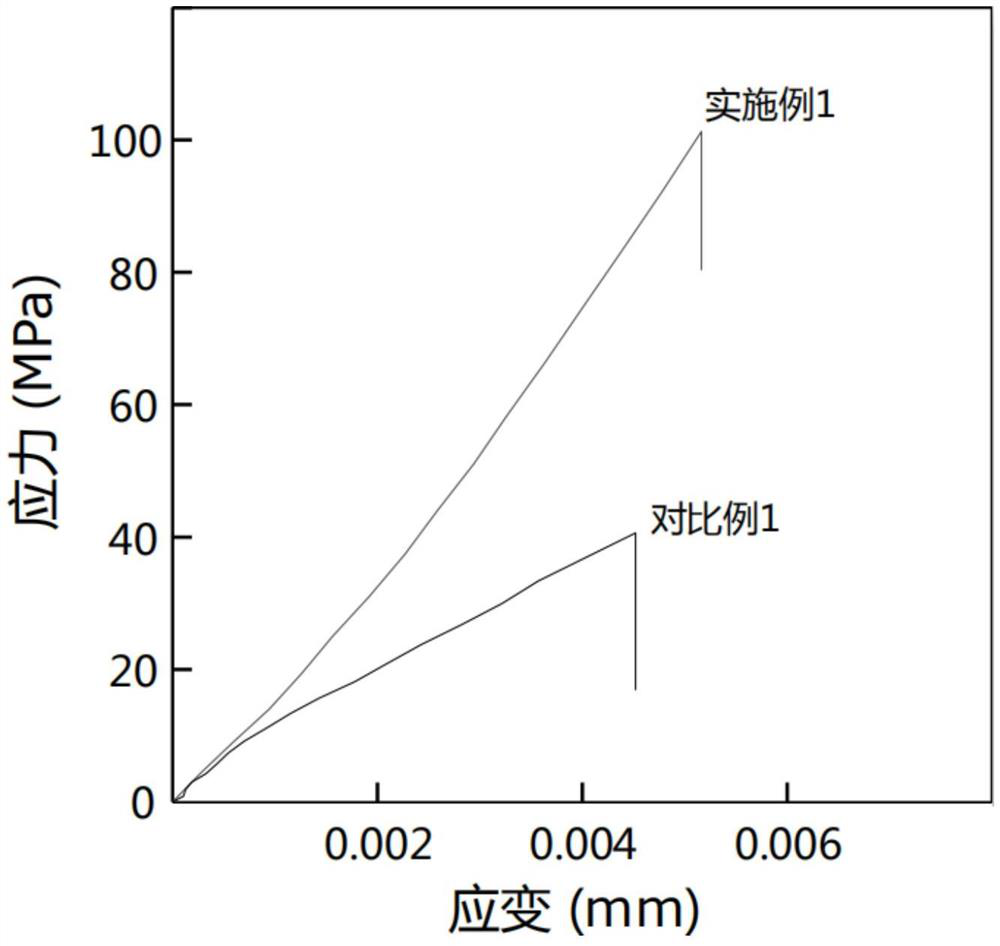

Embodiment 1

[0028]A method for preparing a high-strength carbon nanofiber membrane, the specific process is: preparation of spinning solution→electrospinning→preheating treatment→preoxidation treatment→carbonization; wherein, the spinning solution is composed of polymer and solvent, the concentration is 12wt%, the polymer is PAN homopolymer, and the solvent is DMF; the process parameters of electrospinning are: spinning solution perfusion speed 0.5mL / h, voltage 22kV, humidity 35%, temperature 27°C, spinning distance 20cm, The roller speed is 100rpm; the preheating process is: heat the fiber film from 25°C to 155°C at a heating rate of 1°C / min and then keep it warm for 1h; the preoxidation treatment process is: heating the fiber film at a heating rate of 1°C / min The fiber membrane is heated from 155°C to 280°C and then kept for 1 hour, and then naturally cooled to 30°C; the carbonization process is as follows: the fiber membrane is heated from 30°C to 900°C at a heating rate of 5°C / min, the...

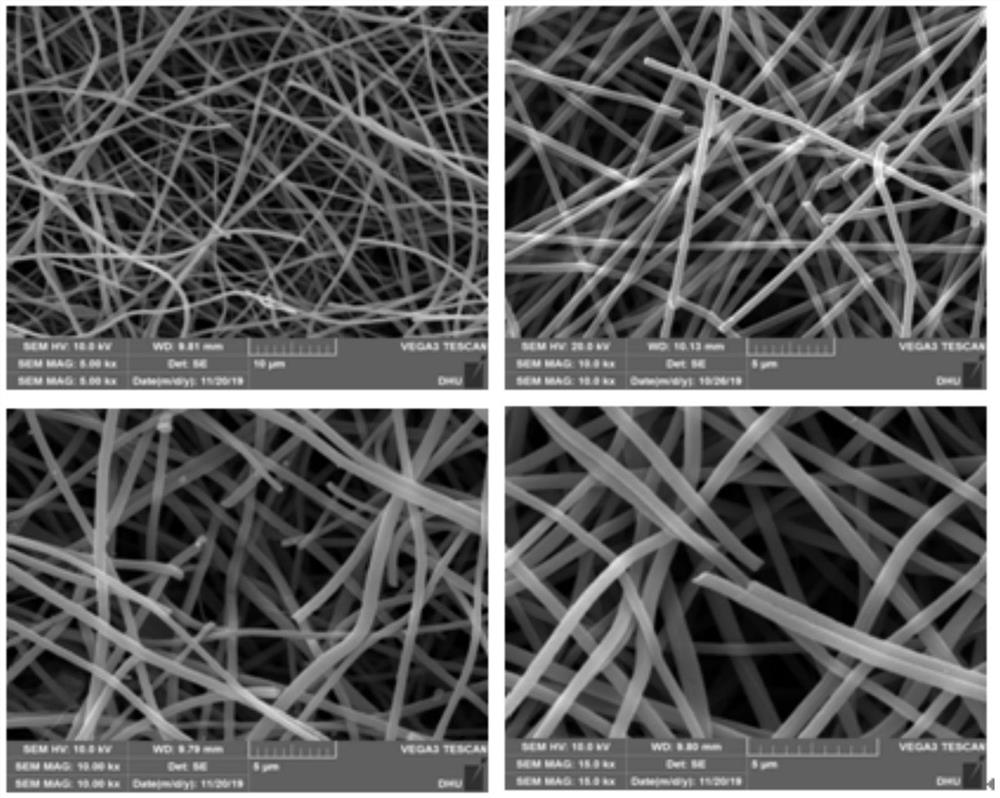

Embodiment 2

[0035] A method for preparing a high-strength carbon nanofiber membrane, the specific process is: preparation of spinning solution→electrospinning→preheating treatment→preoxidation treatment→carbonization; wherein, the spinning solution is composed of polymer and solvent, the concentration The polymer is PVP homopolymer, the solvent is a mixture of ethanol and DMAc with a mass ratio of 1:1; the process parameters of electrospinning are: spinning solution perfusion speed 0.6mL / h, voltage 20kV, humidity 40 %, the temperature is 30°C, the spinning distance is 18cm, and the roller speed is 118rpm; the preheating process is as follows: the fiber membrane is heated from 28°C to 165°C at a heating rate of 2°C / min and then kept for 1.1h; The process is: heat the fiber membrane from 165°C to 281°C at a heating rate of 2°C / min, hold it for 1.2 hours, and then cool it down to 32°C naturally; the carbonization process is: heat the fiber membrane at a heating rate of 5°C / min from Heat at 3...

Embodiment 3

[0037] A method for preparing a high-strength carbon nanofiber membrane, the specific process is: preparation of spinning solution→electrospinning→preheating treatment→preoxidation treatment→carbonization; wherein, the spinning solution is composed of polymer and solvent, the concentration is 10wt%, the polymer is poly(acrylonitrile-methyl acrylate), and the solvent is DMF; the process parameters of electrospinning are: spinning solution perfusion speed 0.7mL / h, voltage 24kV, humidity 30%, temperature 28°C, The spinning distance is 17cm, and the roller speed is 132rpm; the preheating process is: heating the fiber membrane from 30°C to 110°C at a heating rate of 3°C / min and then keeping it warm for 1.5h; the preoxidation process is: heating at 3°C Heat the fiber membrane from 110°C to 282°C at a heating rate of 1.6 hours, then cool it down to 38°C naturally; the carbonization process is: heat the fiber membrane from 38°C to 1500°C at a heating rate of 10°C / min Then keep it warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com