Noodles packing paper and production method thereof

A production method and wrapping paper technology, applied in the direction of wrapping paper, wrapping paper, packaging, etc., to achieve the effects of reducing the number of broken noodles, reducing production equipment conditions, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, dried noodle wrapping paper and production method thereof

[0036] The production method of the vermicelli wrapping paper of the present invention is adopted to produce the vermicelli wrapping paper, and the production capacity of the production device is 20t / d.

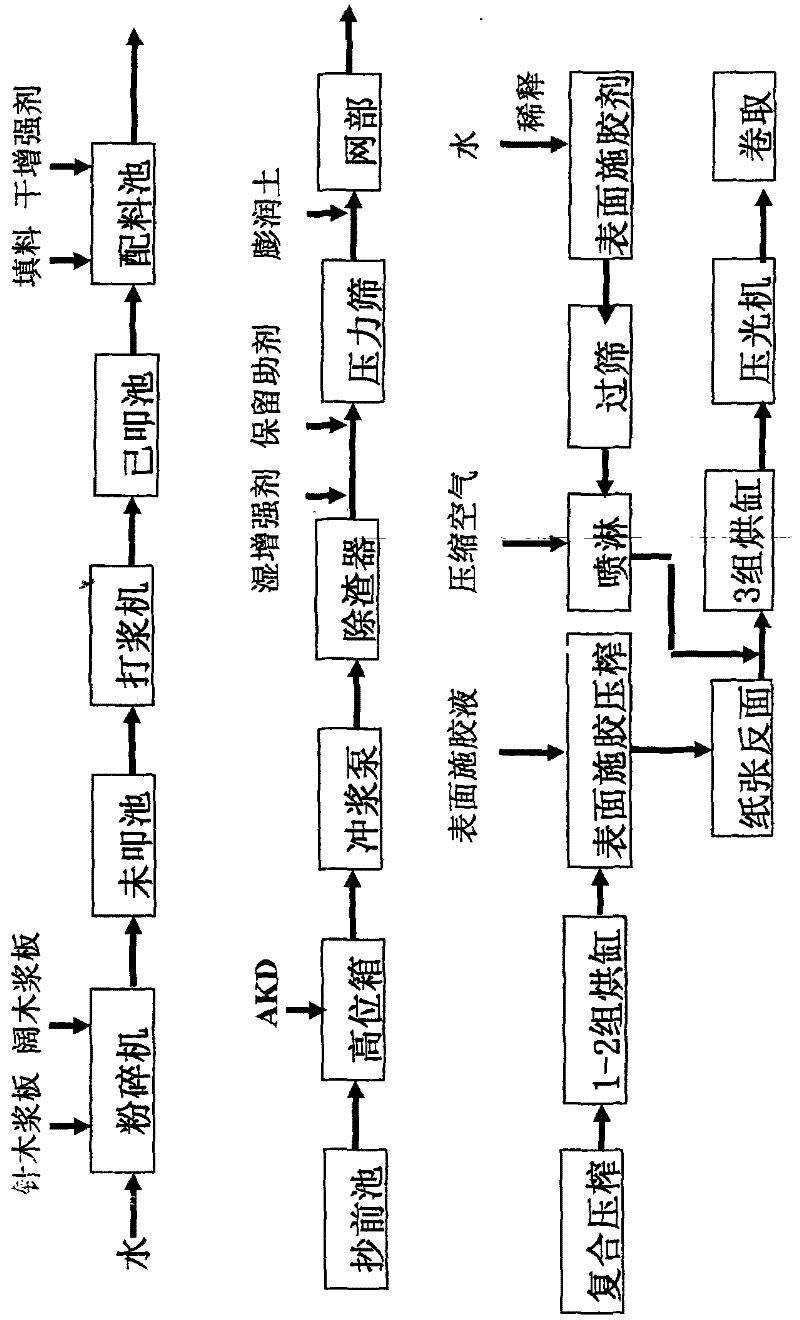

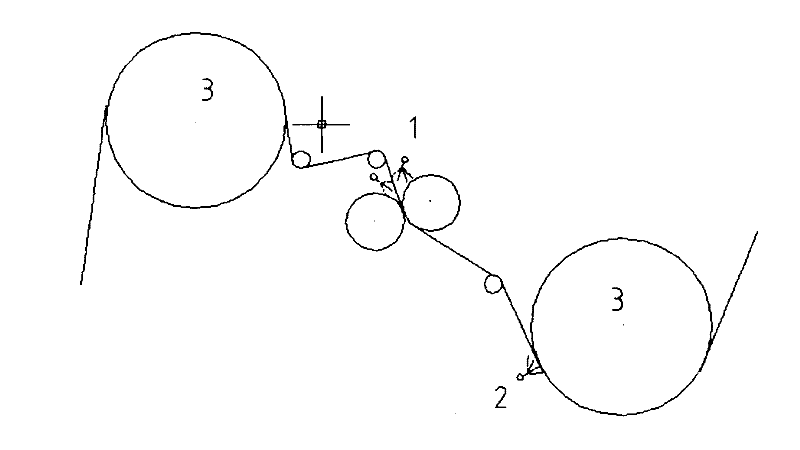

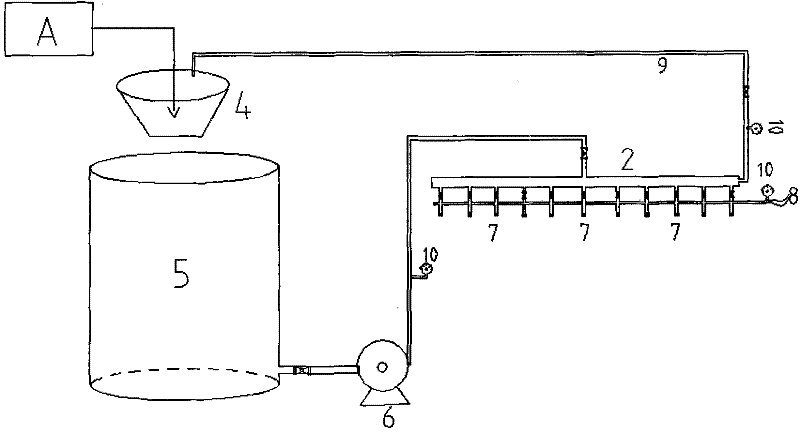

[0037]The production of vermicelli wrapping paper uses ordinary fourdrinier multi-cylinder paper machines and adds spraying process equipment for production. The pulp made of hardwood pulp and softwood pulp, filler heavy calcium carbonate and chemical additive cationic starch dry strengthener, AKD pulp Sizing agent, cationic polyacrylamide retention aid, bentonite and polyamide epichlorohydrin wet strengthening agent are used as base paper raw materials, and the surface is composed of gelatinized oxidized starch LS-2 and polyvinyl alcohol (PVA) mixture The sizing solution is the raw material of the surface sizing layer. The AKD synthetic surface sizing agent produced by Shanghai Hercules Chemical...

Embodiment 2

[0059] Embodiment 2, dried noodle wrapping paper and production method thereof

[0060] The production method of the vermicelli wrapping paper of the present invention is adopted to produce the vermicelli wrapping paper, and the production capacity of the production device is 20t / d.

[0061] The production of vermicelli wrapping paper uses ordinary fourdrinier multi-cylinder paper machines and adds spraying process equipment for production. The pulp made of hardwood pulp and softwood pulp, filler heavy calcium carbonate and chemical additive cationic starch dry strengthener, AKD pulp Sizing agent, cationic polyacrylamide retention aid, bentonite and polyamide epichlorohydrin wet strengthening agent are used as base paper raw materials, and the surface is composed of gelatinized oxidized starch LS-2 and polyvinyl alcohol (PVA) mixture The sizing solution is the raw material of the surface sizing layer. The AKD synthetic surface sizing agent produced by Shanghai Hercules Chemica...

Embodiment 3

[0077] Embodiment 3, dried noodle wrapping paper and production method thereof

[0078] The production method of the vermicelli wrapping paper of the present invention is adopted to produce the vermicelli wrapping paper, and the production capacity of the production device is 20t / d.

[0079] The production of vermicelli wrapping paper uses ordinary fourdrinier multi-cylinder paper machines and adds spraying process equipment for production. The pulp made of hardwood pulp and softwood pulp, filler heavy calcium carbonate and chemical additive cationic starch dry strengthener, AKD pulp Sizing agent, cationic polyacrylamide retention aid, bentonite and polyamide epichlorohydrin wet strengthening agent are used as base paper raw materials, and the surface is composed of gelatinized oxidized starch LS-2 and polyvinyl alcohol (PVA) mixture The sizing solution is the raw material of the surface sizing layer. The AKD synthetic surface sizing agent produced by Shanghai Hercules Chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com