A push rod

A push rod and anchor rod technology, which is applied to the push rod field of filler tools, can solve the problems of increased assembly and maintenance costs, embedded surface damage, production loss, etc., and achieves the effect of reducing the number of push rods broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] At the outset it should be noted that a device for embedding a retaining element in a bore of a brush head by means of a push rod is known from DE 195 28 762 C1 and EP 1 088 495 A1 and has been described in great detail in the above two articles describe them. Therefore, no further description is necessary at this point. The disclosures in both applications should be incorporated by reference into this application.

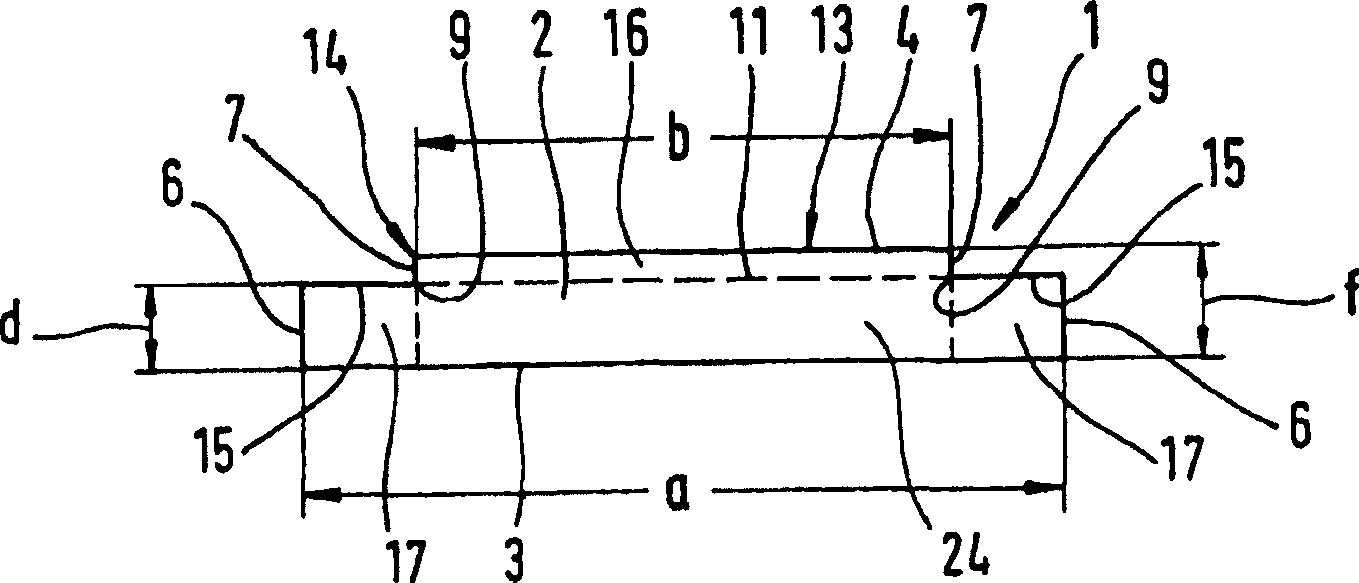

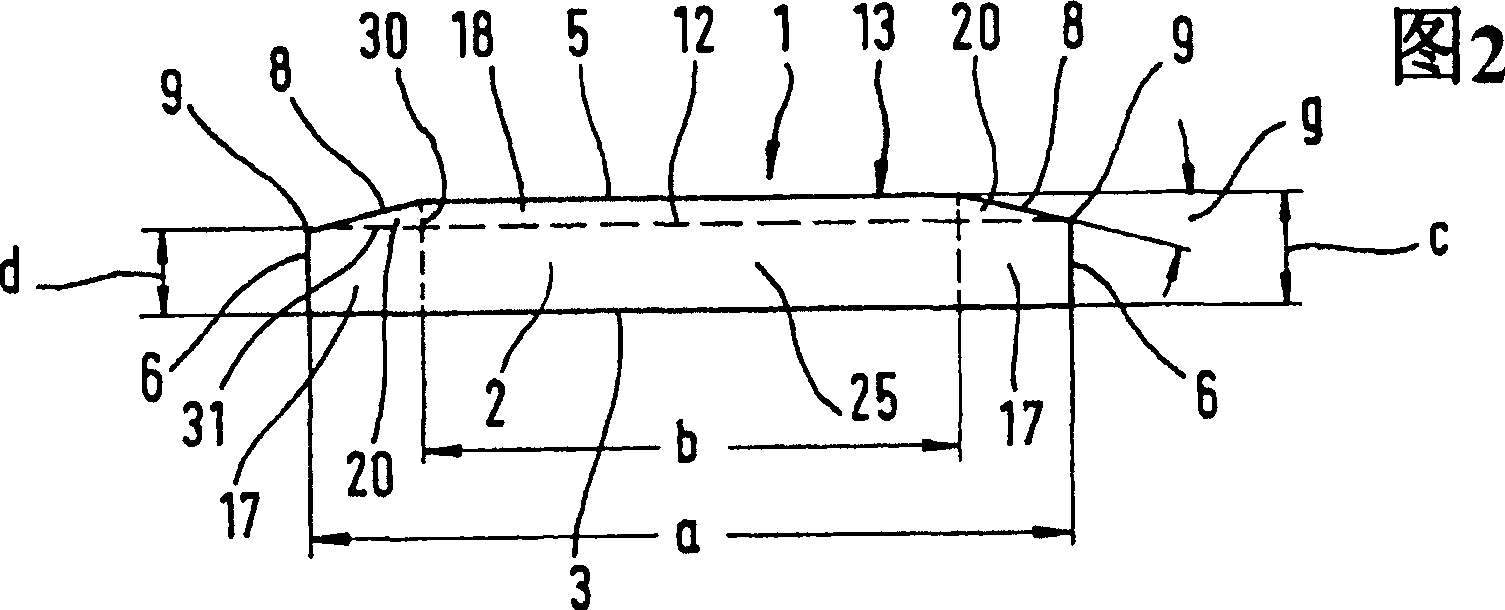

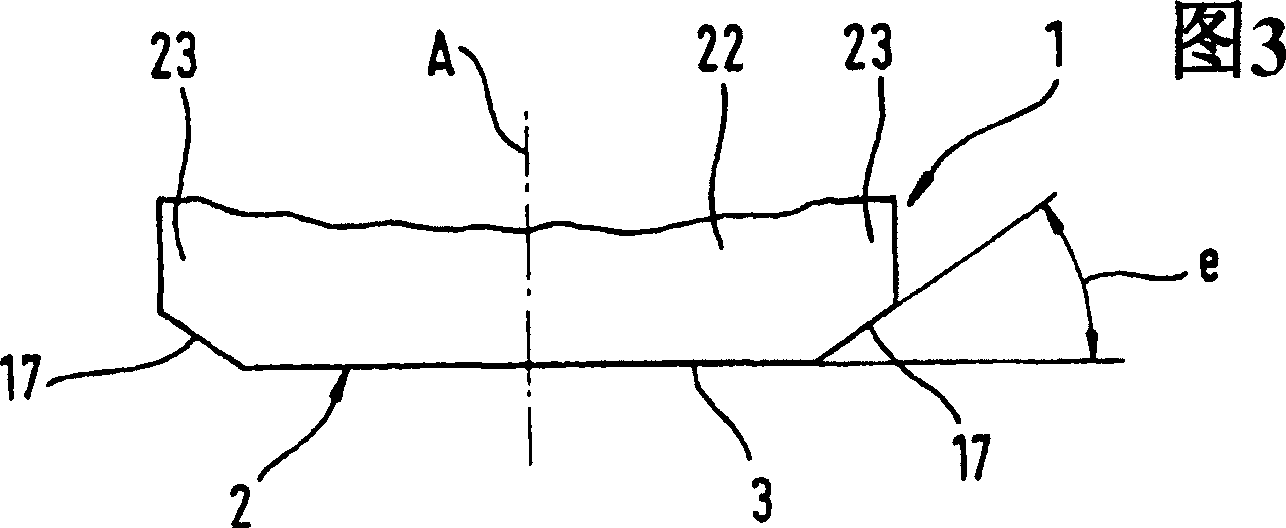

[0021] Therefore only illustrate the innovative design of push rod 1 below, it is in figure 1 , 2 and 4 are represented by embedded surface 2. In Figure 3 the push rod 1 is shown along the Figure 4 Lateral cross-sectional view in the X direction. The longitudinal axis A of the push rod 1 in Fig. 3 corresponds to that in DE 195 28 762 C1 figure 1 , 5 and 9 and are designated by the same reference numerals, ie the plunger 1 extends vertically upwards according to FIG. 3 , but its embedded surface 2 is perpendicular to the drawing plane.

[0022] exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com