Synthetic method of medicinal acetyl trioctyl citrate

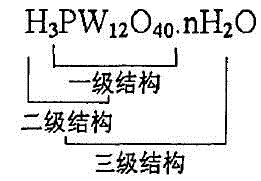

A technology for the synthesis of acetyl trioctyl citrate and its synthesis method, which is applied in the field of catalyzed synthesis of medicinal acetyl trioctyl citrate and medicinal acetyl trioctyl citrate supported by heteropolyacids loaded on mesoporous molecular sieves, and can solve the problem of specific surface area The range of improvement is limited, the ion exchange resin is easy to swell and deactivate, and the structure of the heteropoly acid is greatly damaged, so as to reduce the temperature and reaction time, increase the reuse rate, and improve the utilization rate of the catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 2g P123 is dissolved in the hydrochloric acid that concentration is 2mol / L, after fully dissolving, 40 o C, 10ml of tetraethyl orthosilicate and 1.3g of Pd-H 4 SiW 12 o 40 The solution was slowly added dropwise to the P123 solution, and the constant temperature stirring was continued for 5h. then at 80 o Stand at C for 36 hours to crystallize. After taking it out, wash the product until neutral, filter to obtain a solid, and dry it at room temperature. Finally, at 500 o C roasting for a period of time to obtain the finished catalyst.

Embodiment 2

[0057] 10g P123 is dissolved in the hydrochloric acid that concentration is 2mol / L, after fully dissolving, 40 o C, 50ml of tetraethyl orthosilicate and 6.5g of Pd-H 3 PW 12 o 40 The solution was slowly added dropwise to the P123 solution, and the constant temperature stirring was continued for 5h. then at 80 o Stand at C for 36 hours to crystallize. After taking it out, wash the product until neutral, filter to obtain a solid, and dry it at room temperature. Finally, at 500 o C is roasted for a period of time to obtain the finished catalyst.

Embodiment 3

[0059] 30g P123 is dissolved in the hydrochloric acid that concentration is 2mol / L, after fully dissolving, 40 o C, 50ml of tetraethyl orthosilicate and 39g of Pd-H 3 PM o12 o 40 The solution was slowly added dropwise to the P123 solution, and the constant temperature stirring was continued for 4h. then at 80 o Stand at C for 36 hours to crystallize. After taking it out, wash the product until neutral, filter to obtain a solid, and dry it at room temperature. Finally, at 500 o C is roasted for a period of time to obtain the finished catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com