Enhanced starch based packaging composite material and preparation method thereof

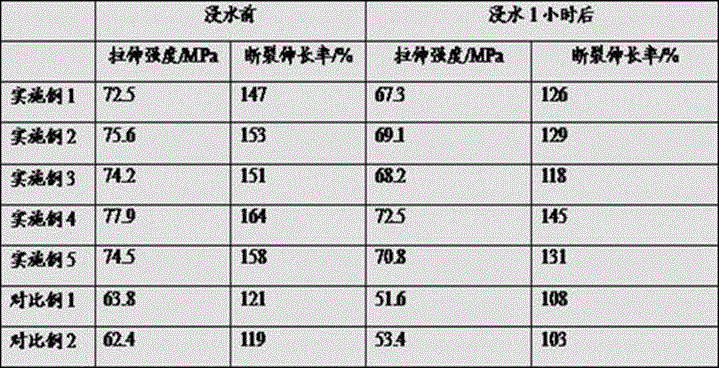

A composite material and starch-based technology, applied in the field of materials, can solve problems such as poor mechanical properties, failure to meet application requirements, and decline in mechanical properties, and achieve the effect of solving performance deficiencies, good application value, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of enhanced starch-based packaging composite material, comprising the following preparation steps:

[0023] 1) Weigh and proportion the raw materials of each component according to the above parts by weight: 22 parts of tapioca starch, 18 parts of corn starch, 15 parts of nightshade seed powder, 5 parts of calcium chloride, 4 parts of nano-attapulgite, 5 parts of boric acid, 20 -4 parts of 100 mesh wood fish stone powder, 2 parts of guanidine phosphate, 5 parts of calcium lignosulfonate, 3 parts of erucamide, 2 parts of beeswax, 4 parts of acetyl trioctyl citrate, 3 parts of methyl oxirane, hard 2 parts of zinc fatty acid, 4 parts of castor oil, 3 parts of silane coupling agent KH-560;

[0024] 2) Add tapioca starch, corn starch, nightshade seed powder, calcium lignosulfonate, erucamide, methyl oxirane and boric acid into the mixer, stir at 110°C for 20 minutes, take it out and cool it down to get Mixture A;

[0025] 3) Add nano-attapulgite, woody...

Embodiment 2

[0028] A preparation method of enhanced starch-based packaging composite material, comprising the following preparation steps:

[0029] 1) Weigh and proportion the raw materials of each component according to the above parts by weight: 37 parts of tapioca starch, 24 parts of corn starch, 23 parts of nightshade seed powder, 13 parts of calcium chloride, 9 parts of nano-attapulgite, 8 parts of boric acid, 20 parts -10 parts of Muyu stone powder of 100 mesh, 7 parts of guanidine phosphate, 11 parts of calcium lignosulfonate, 9 parts of erucamide, 5 parts of beeswax, 8 parts of acetyl trioctyl citrate, 6 parts of methyl oxirane, hard Zinc fatty acid 5 parts, castor oil 8 parts, silane coupling agent KH-171 3-6 parts;

[0030] 2) Add tapioca starch, corn starch, nightshade seed powder, calcium lignosulfonate, erucamide, methyl oxirane and boric acid into the mixer, stir at 135°C for 35 minutes, take it out and cool it down to get Mixture A;

[0031] 3) Add nano-attapulgite, woody...

Embodiment 3

[0034] A preparation method of enhanced starch-based packaging composite material, comprising the following preparation steps:

[0035] 1) Weigh and proportion the raw materials of each component according to the above parts by weight: 30 parts of tapioca starch, 21 parts of corn starch, 16 parts of nightshade seed powder, 9 parts of calcium chloride, 6 parts of nano-attapulgite, 6 parts of boric acid, 20 parts -7 parts of Muyu stone powder of 100 mesh, 3 parts of guanidine phosphate, 8 parts of calcium lignosulfonate, 6 parts of erucamide, 3 parts of beeswax, 6 parts of acetyl trioctyl citrate, 4.5 parts of methyl oxirane, hard Zinc fatty acid 3.5 parts, castor oil 6 parts, silane coupling agent KH-560 4.5 parts;

[0036] 2) Add tapioca starch, corn starch, nightshade seed powder, calcium lignosulfonate, erucamide, methyl oxirane and boric acid into the mixer, stir at 122°C for 27min, take it out and cool it, and get Mixture A;

[0037] 3) Add nano-attapulgite, woody stone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com