Selective phenol reduction paper coating material, preparation method and application thereof

A selective, coating technology, applied in paper coating, papermaking, coating, etc., can solve the problems of reducing smoke aroma, reducing smoke aroma, and ineffective phenol effect, achieving obvious effect, cheap price, and widely popularized and used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Formulation (unit: gram)

[0024] Polyethylene glycol 50g

[0025] Absolute ethanol 24.8g

[0026] Deionized water 24.8g

[0027] Honey 0.12g

[0028] Maltodextrin 0.15g

[0029] n-Butanol 0.12g

[0030] Terpinyl acetate 0.01g

[0031] Preparation method:

[0032] First, melt the polyethylene glycol crystals in the formula into liquid at 25-30°C;

[0033] In the second step, the honey, maltodextrin and n-butanol in the formula are dissolved in deionized water at a temperature of 25-30°C;

[0034] The third step is to dissolve terpineol acetate in absolute ethanol at room temperature;

[0035] Finally, under the agitation of the disperser, slowly add the ethanol solution and the deionized aqueous solution into the melted polyethylene glycol liquid along the wall in sequence, and disperse with the disperser for 10 minutes (500 rpm), and then the tobacco choice is obtained. Non-phenolic forming paper coating.

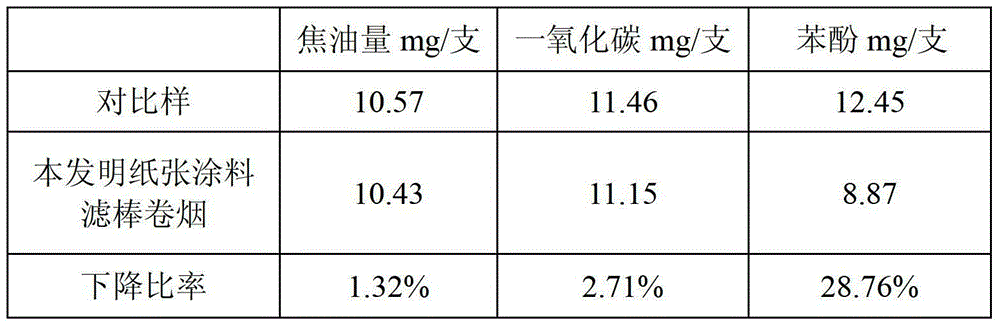

[0036] The selective phenol-reducing paper is prepar...

Embodiment 2

[0042] Formulation (unit: gram)

[0043] Polyethylene glycol 30g

[0044] Absolute ethanol 20g

[0045] Deionized water 20g

[0046] Honey 0.25g

[0047] Maltodextrin 0.5g

[0048] n-Butanol 0.12g

[0049] Terpinyl Acetate 0.02g

[0050] Preparation method:

[0051] First, melt the polyethylene glycol crystals in the formula into liquid at 25-30°C;

[0052] In the second step, the honey, maltodextrin and n-butanol in the formula are dissolved in deionized water at a temperature of 25-30°C;

[0053] The third step is to dissolve terpineol acetate in absolute ethanol at room temperature;

[0054] Finally, under the agitation of the disperser, slowly add the ethanol solution and the deionized aqueous solution into the melted polyethylene glycol liquid along the wall in sequence, and disperse with the disperser for 15 minutes (300 revolutions / minute) to obtain the cigarette selection Non-phenolic forming paper coating.

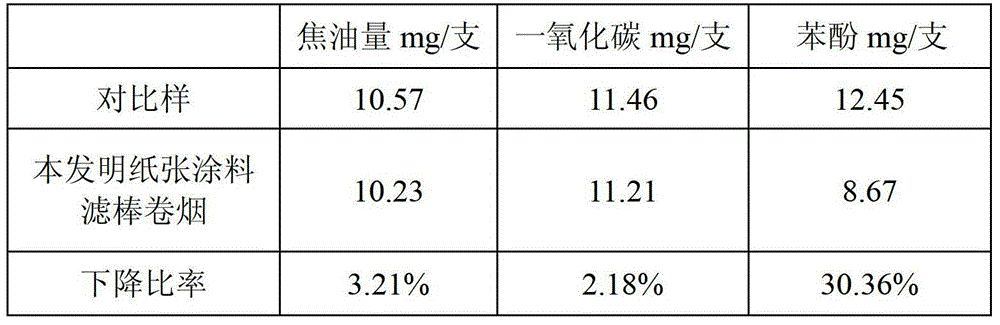

[0055] The selective phenol-reducing paper is prep...

Embodiment 3

[0061] Formulation (unit: gram)

[0062] Polyethylene glycol 70g

[0063] Absolute ethanol 30g

[0064] Deionized water 30g

[0065] Honey 0.5g

[0066] Maltodextrin 0.1g

[0067] n-Butanol 0.4g

[0068] Terpinyl Acetate 0.02g

[0069] Preparation method:

[0070] First, melt the polyethylene glycol crystals in the formula into liquid at 25-30°C.

[0071] In the second step, the honey, maltodextrin and n-butanol in the formula are dissolved in deionized water at a temperature of 25-30°C.

[0072] The third step is to dissolve terpineol acetate in absolute ethanol at room temperature.

[0073] Finally, under the agitation of the disperser, slowly add the ethanol solution and the deionized aqueous solution into the molten polyethylene glycol liquid along the wall in turn, and disperse with the disperser for 20 minutes (400 revolutions / minute), and then the tobacco choice is obtained. Non-phenolic forming paper coating.

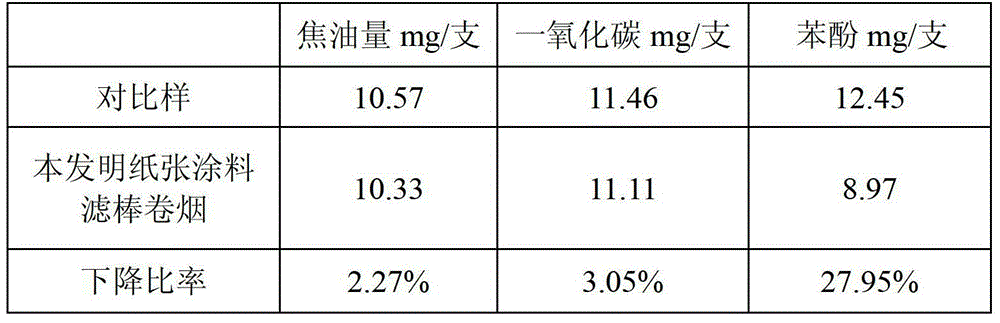

[0074] The selective phenol-reducing paper is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com