Patents

Literature

37results about How to "Reduce phenol content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

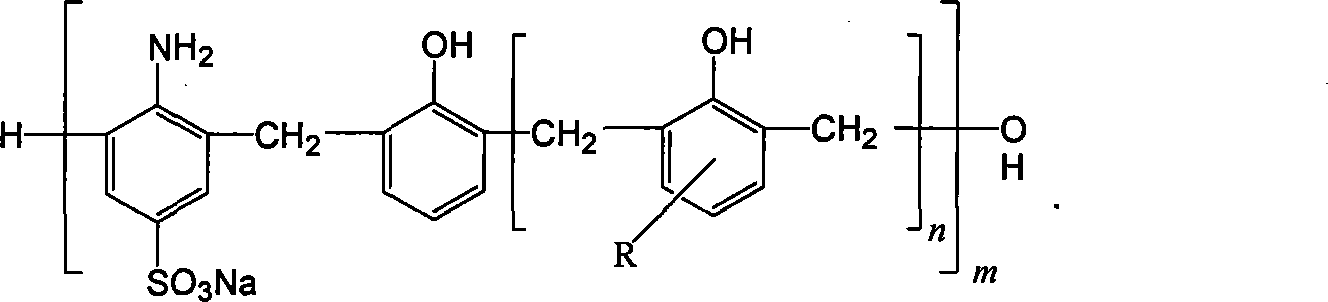

Alkali lignin modified sulfamate high-effective water reducer and preparation method thereof

The invention discloses a preparation method of alkali lignin modified sulfamate highly effective water reducing agent, which includes the steps that: firstly, alkali lignin, phenol and water are evenly mixed, and an alkaline regulator is used to adjust the pH value of a reaction system to 8.0-10.0 and heat the temperature to 80-100 DEG C for half an hour to two hours; secondly, the pH value is adjusted to 9.0-11.0, and aminobenzene sulfonic acid sodium is added to react under the temperature of 60 to 80 degrees for half an hour to one hour; thirdly, the temperature is heated to 75-95 DEG C, and condensing agent is dropped. After that, the reaction continues for three to six hours and then the temperature is lowered. The obtained water reducing preparation, having low cost and small content of free formaldehyde and phenol, can improve the fluidity of concrete and compressive strength significantly. The preparation method is a simple technique without the discharge of three wastes in production.

Owner:SOUTH CHINA UNIV OF TECH

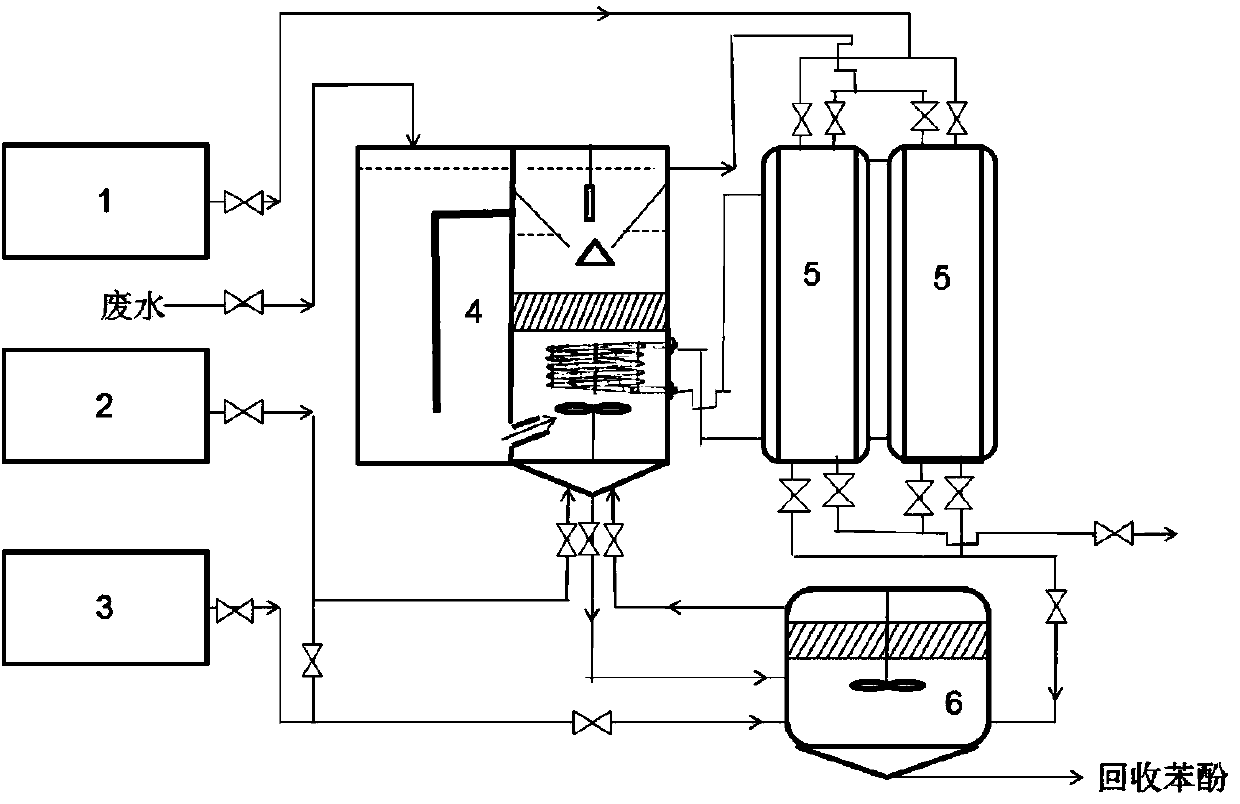

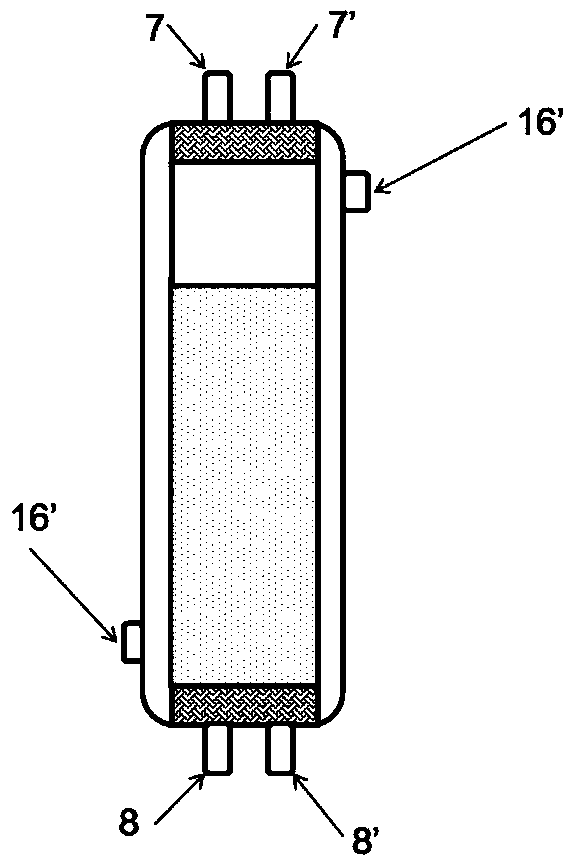

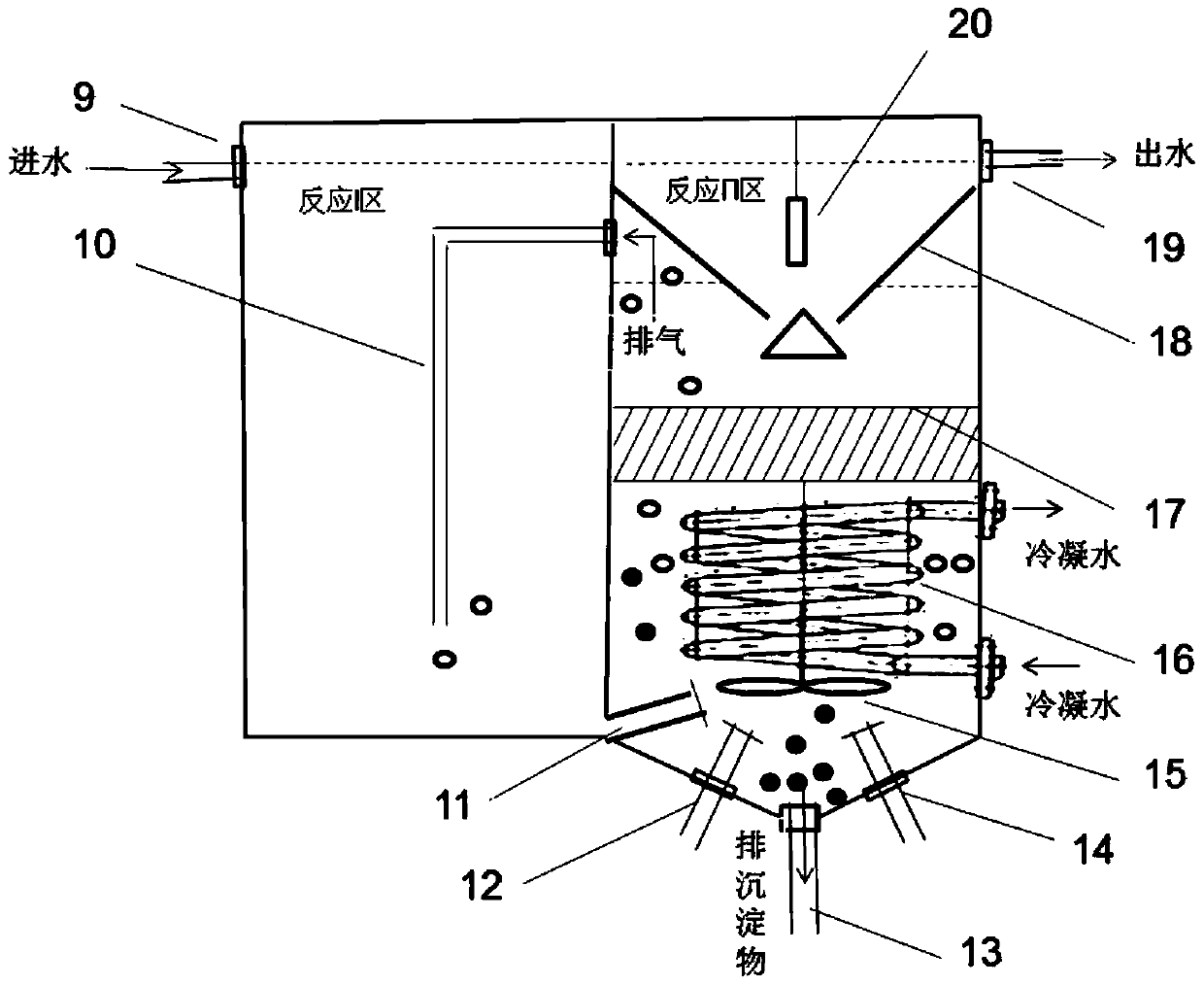

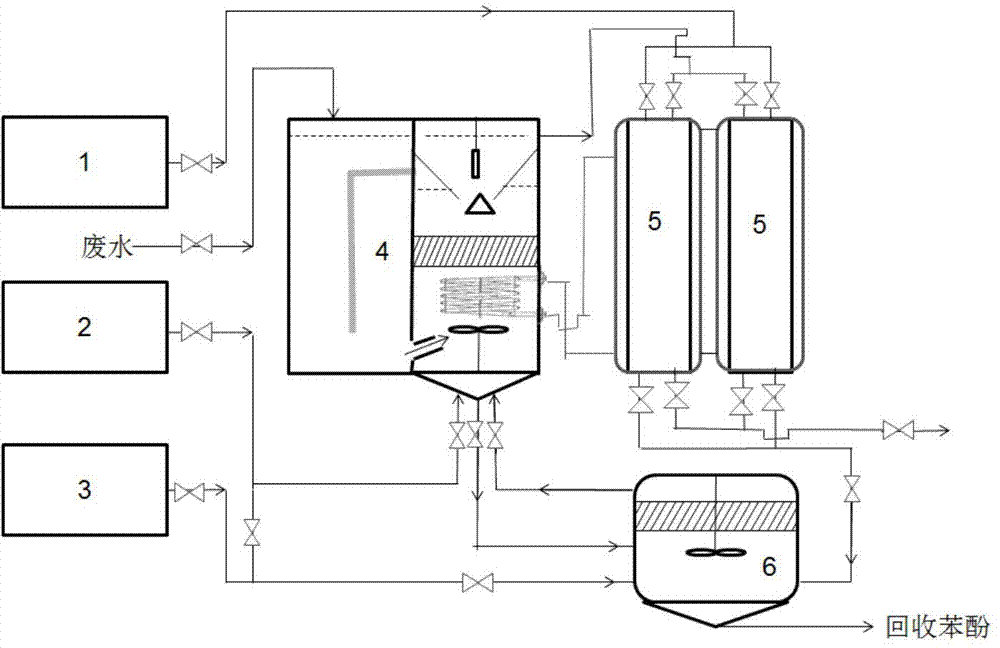

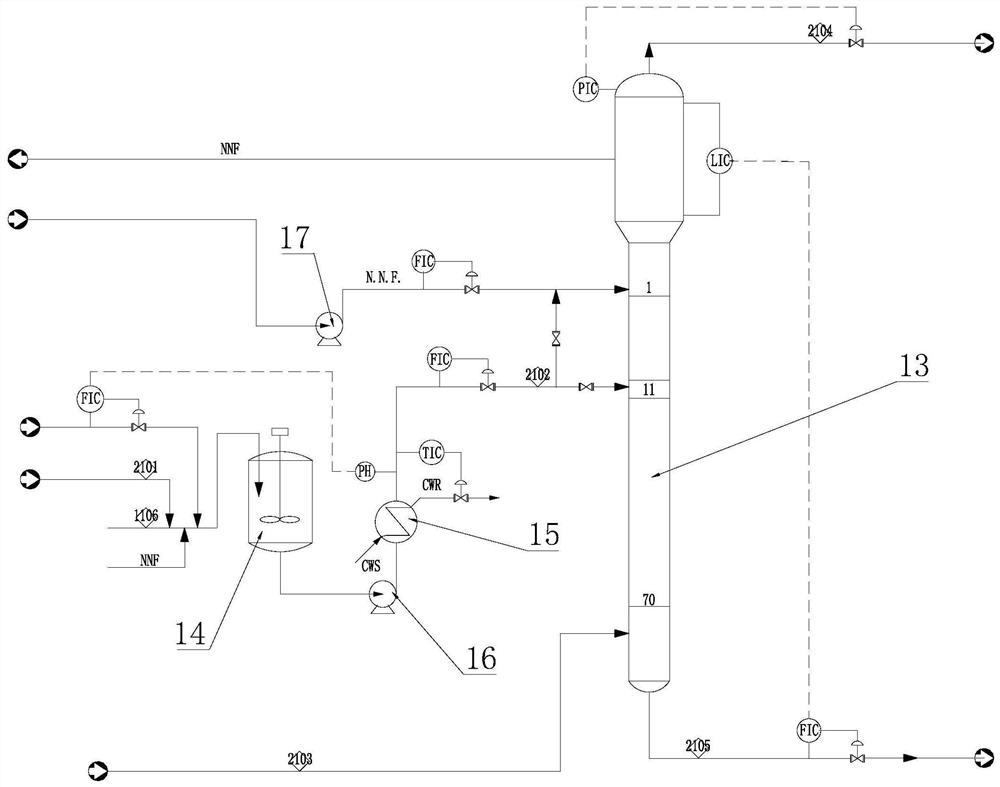

Condensation mother liquid waste water pretreatment and resource system and method in compound neutralization reactor in disperse blue 56 production process

ActiveCN103588329AReduce dosageAvoid harmOrganic chemistryOrganic compound preparationLiquid wasteNitrite ion

The invention discloses condensation mother liquid waste water pretreatment and a resource system and a method in a compound neutralization reactor in a disperse blue 56 production process, which belongs to the waste water treatment field. The method comprises the following steps: highly basic condensation mother liquid waste water in the disperse blue 56 production process and a mixed acid solution (sulfuric acid and sulfamic acid) in the compound neutralization reactor are neutralized, three purposes of reducing the pH value of waste water, precipitating phenol and removing nitrite can be simultaneously realized; the neutralized waste water passes through a fixed bed adsorption column filled with adsorption resin, so that residual phenol in the waste water can absorb on the resin column. Resin after adsorption saturation is carried out with desorption and regeneration by using a NaOH solution and then the resin is repeatedly usable, and the desorption liquid passes through the processes of acidity adjusting and vacuum distillation of phenol to realize recycling of phenol. According to the condensation mother liquid waste water which is pretreated in the disperse blue 56 production process, CODCr value is decreased from about 55000mg / L to less than 500mg / L, the phenols substance concentration is decreased from about 19000mg / L to less than 20mg / L, the nitrite ion is decreased from 87000mg / L to less than 20mg / L; thereby the treatment and resource utilization of waste water can be effectively realized.

Owner:江苏吉易达环保科技有限公司

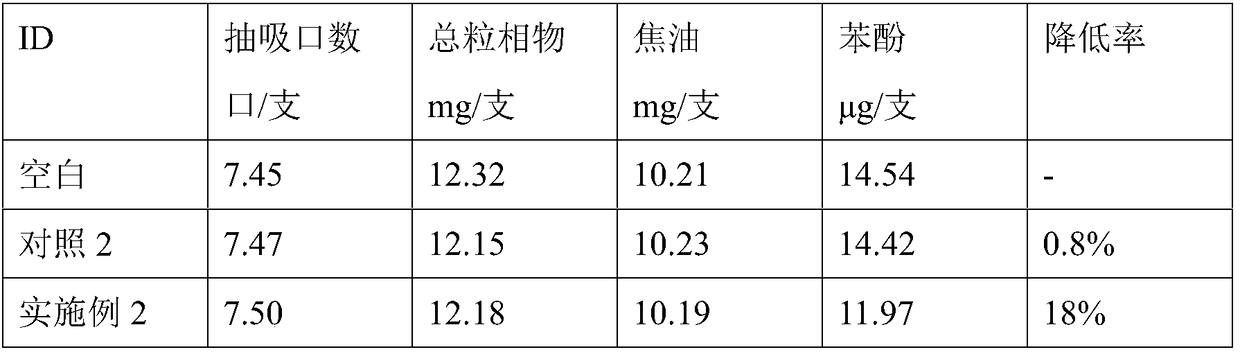

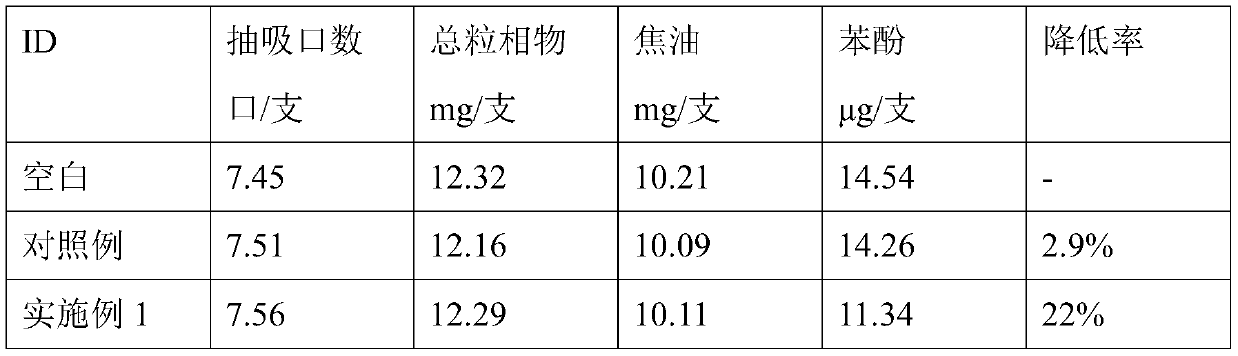

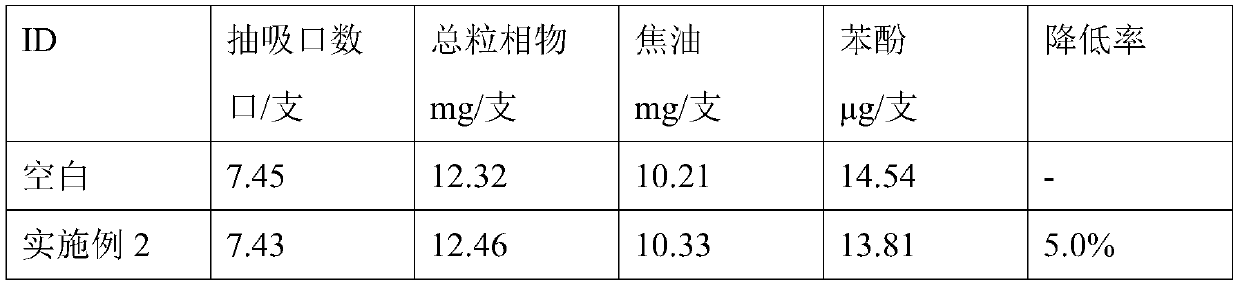

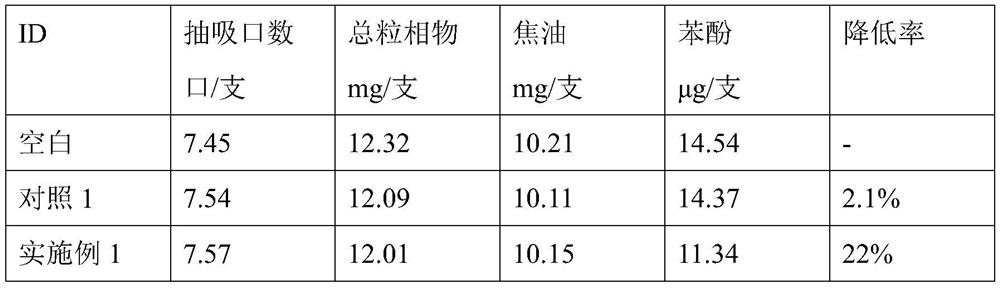

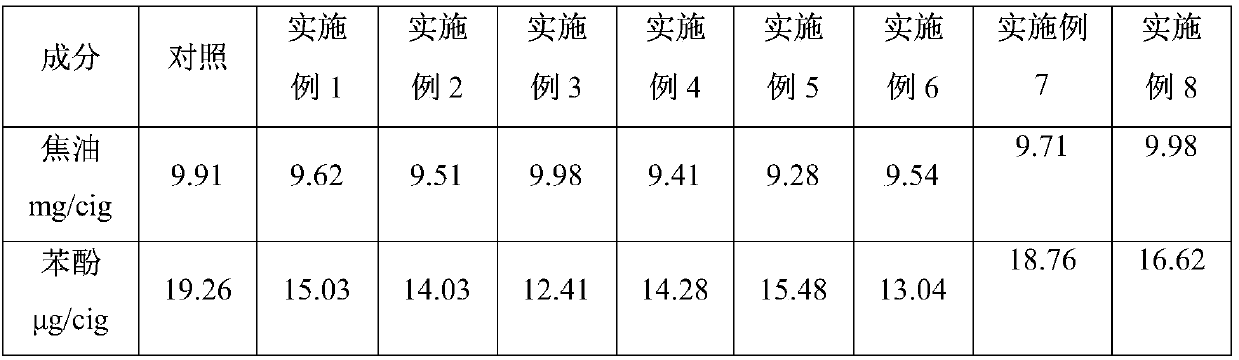

Compound additive for reducing release amount of phenol in flue gas and preparation method and application thereof

The invention relates to a compound additive for reducing the release amount of phenol in flue gas and a preparation method and application thereof. The compound additive comprises, by weight, 1-20 parts of polymers, 0.1-5 parts of acid compounds, 0.1-5 parts of polyol and 20-50 parts of solvents; and the polymers are one or more of polyvinyl pyrrolidone and vinyl pyrrolidone-maleic acid copolymers with the molecular weight of 1,000 to 1,000,000. Suitable ligands are selected to be mixed with PVP, the amount of phenol in the flue gas is quickly and selectively reduced, the effect is obvious, the smoke flavor of cigarettes is not obviously affected, and the irritation is relieved. The preparation method is simple, the cost is low, and the harm reduction effect is obvious.

Owner:CHINA TOBACCO YUNNAN IND

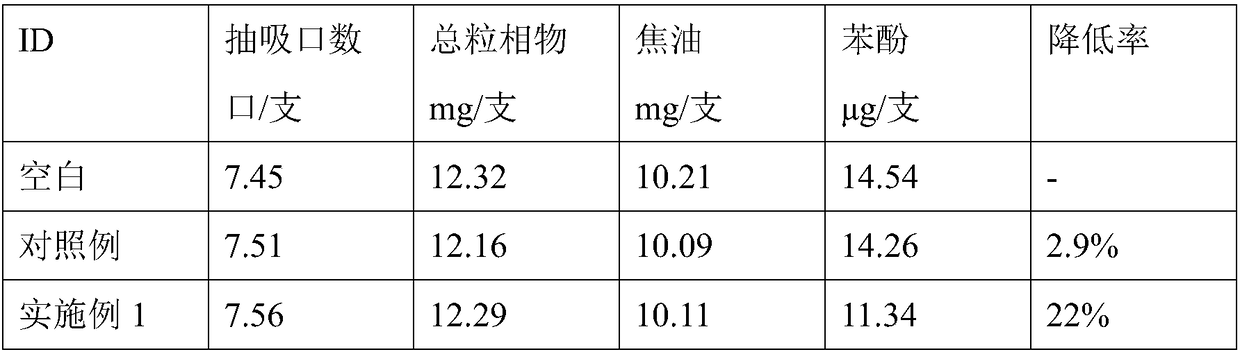

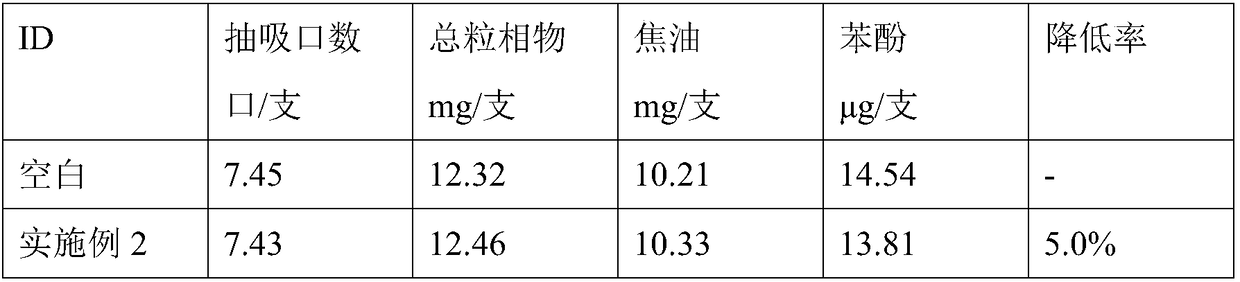

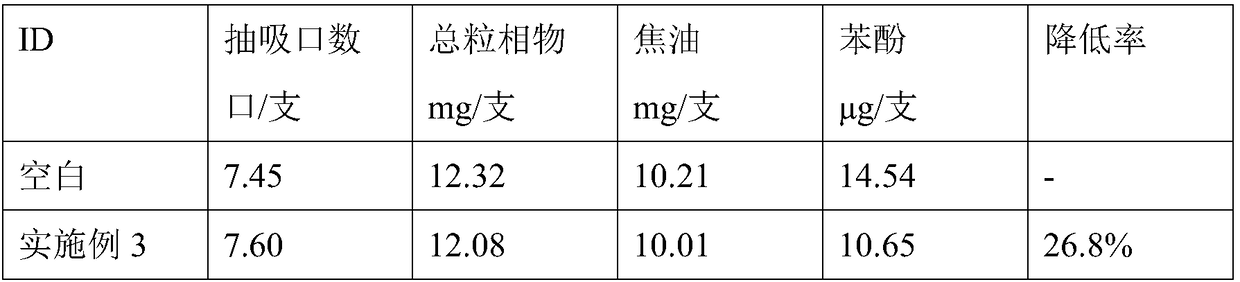

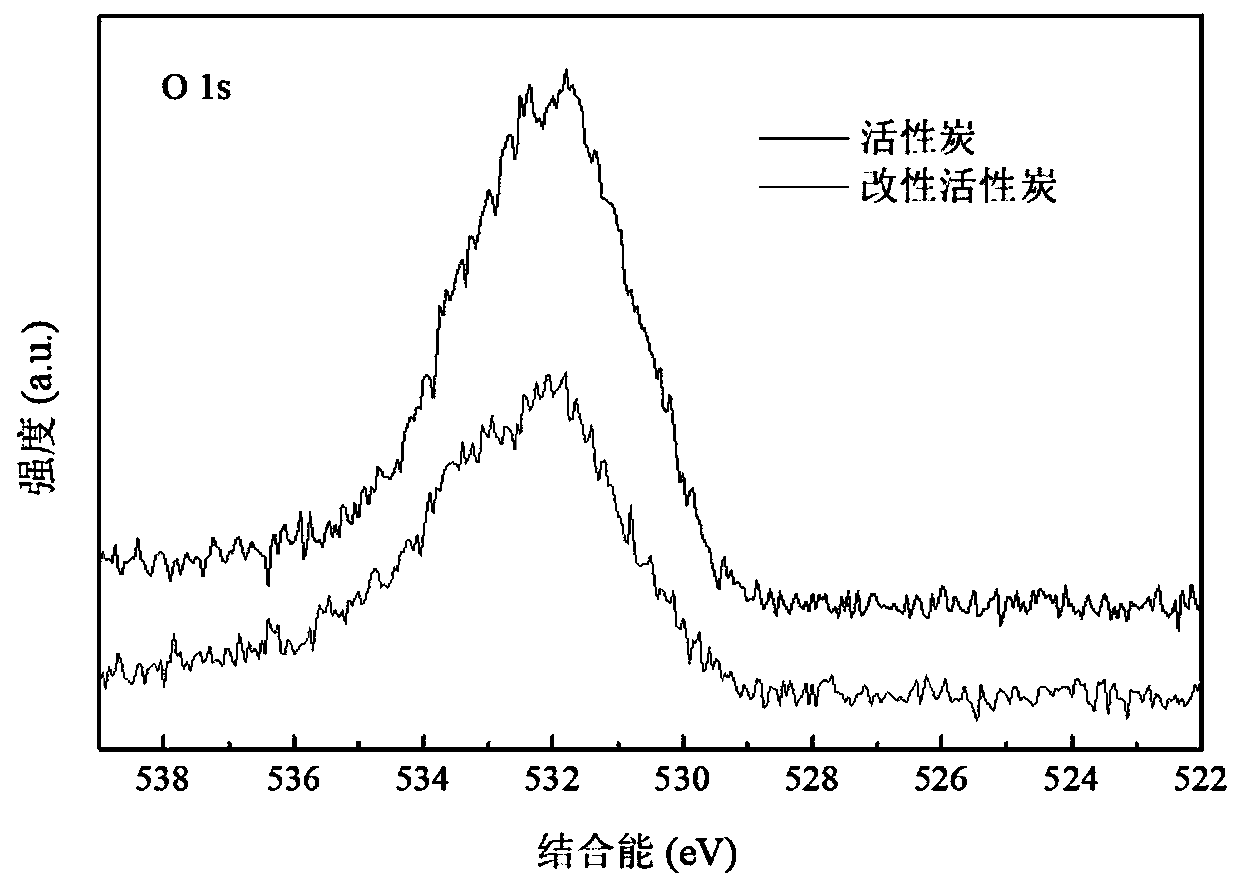

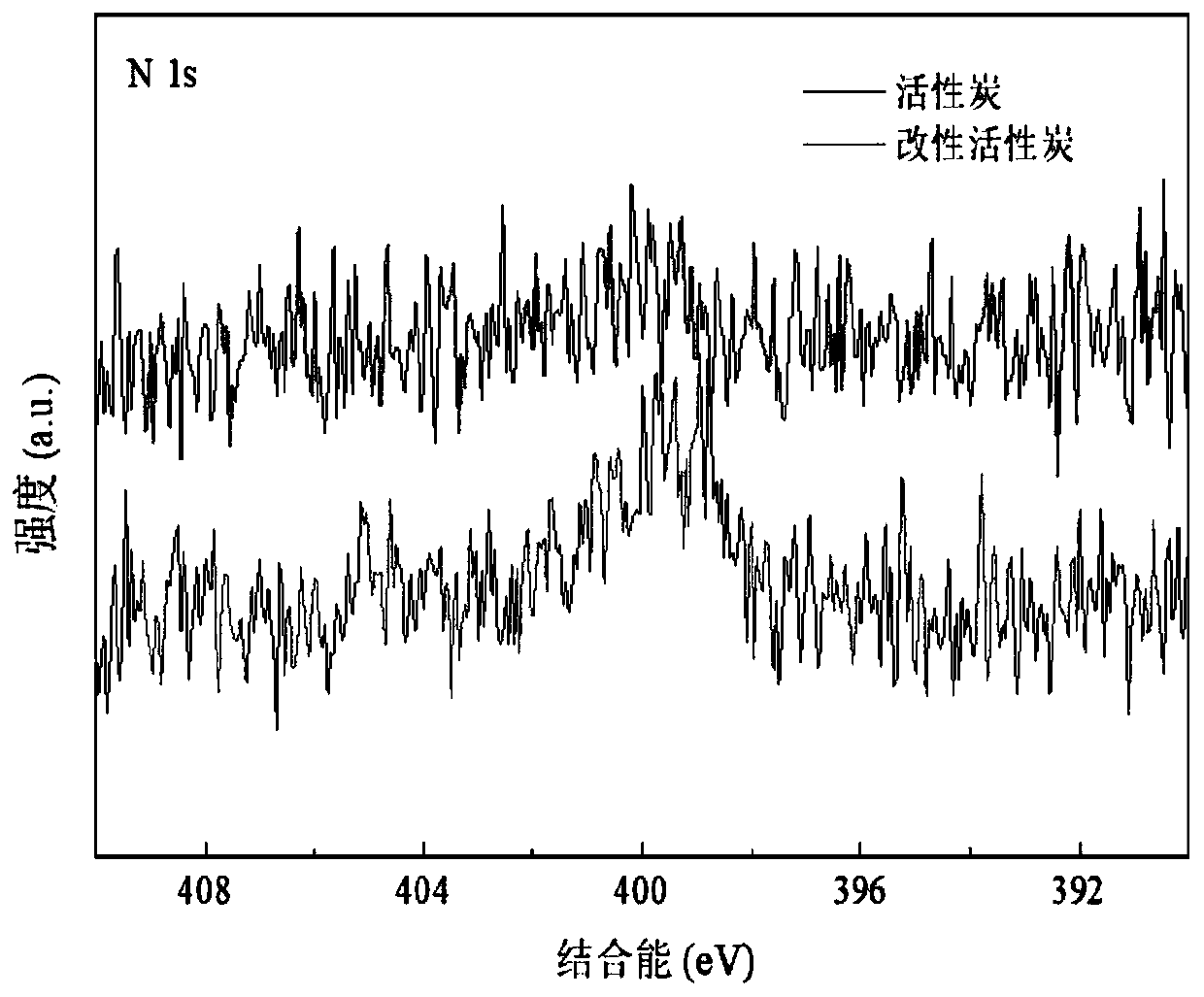

Modified activated carbon for adsorbing phenol as well as preparation method and application thereof

InactiveCN111203182ANot macroporous structureLittle specific surface changeGas treatmentOther chemical processesActivated carbonPyridine

The invention discloses modified activated carbon for adsorbing phenol as well as a preparation method and an application of the modified activated carbon. The preparation method of the modified activated carbon for adsorbing phenol comprises the following steps: firstly, oxidizing activated carbon by adopting an oxidizing agent to obtain oxidized activated carbon; secondly, dipping the obtained oxidized activated carbon into an aqueous solution containing nitrogen-containing small molecules to obtain activated carbon adsorbed with the nitrogen-containing small molecules; and thirdly, carryingout microwave irradiation treatment on the obtained activated carbon adsorbed with the nitrogen-containing small molecules to obtain the modified activated carbon for adsorbing phenol. The surface ofthe prepared activated carbon has stable nitrogen-containing functional groups such as pyridine, pyrrole and amino, the pore structure and the specific surface area of the activated carbon are not greatly changed, the mass transfer process of phenol in the activated carbon particles is not influenced, and the adsorption capacity of the activated carbon to phenol can be effectively improved. Meanwhile, when the prepared modified activated carbon for adsorbing phenol is applied to a cigarette rate filter tip, the content of phenol in cigarette smoke is remarkably reduced, and no adverse effectis caused to cigarette aroma and smoking taste.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Modified phenol-formaldehyde resin adhesive for wood and preparation method thereof

InactiveCN107177335AImprove mechanical propertiesReduce phenol contentNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesHeat resistanceMontmorillonite

The invention provides a modified phenol-formaldehyde resin adhesive for wood and a preparation method thereof. The modified phenol-formaldehyde resin adhesive is prepared from the following components in parts by weight: 100 parts of phenol, 41 to 55 parts of formaldehyde, 5 to 25 parts of anacardol, 3 to 10 parts of sodium hydroxide and 1 to 5 parts of modified montmorillonoid. The preparation method of the modified phenol-formaldehyde resin adhesive, provided by the invention, comprises the following steps: adding the fused phenol, formaldehyde, anacardol, sodium hydroxide and modified montmorillonoid into a three-mouth flask at certain temperature; heating, keeping the heat and refluxing at high temperature; rapidly cooling and discharging, wherein the formaldehyde and the sodium hydroxide are added by two times. The anacardol is a phenol-like substance with long-chain hydrocarbonyl at a meta-position; the modified montmorillonoid is Na-montmorillonite which is organically modified by cetyltrimethylammonium bromide. The modified phenol-formaldehyde resin adhesive provided by the invention has lower free phenol content, higher adhesion strength and better heat resistance.

Owner:成都博美实润科技有限公司

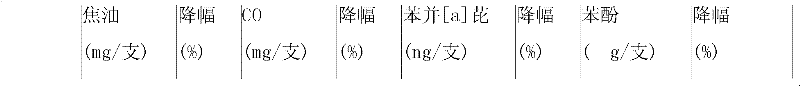

Calixarene additive capable of simultaneously and optionally reducing benzo (alpha) pyrene and phenol contents in cigarette smoke and application method thereof

ActiveCN101664228BReduce phenol contentSubstance addition is lessOrganic chemistryBenzeneChemical composition

Owner:CHINA TOBACCO HUNAN INDAL CORP

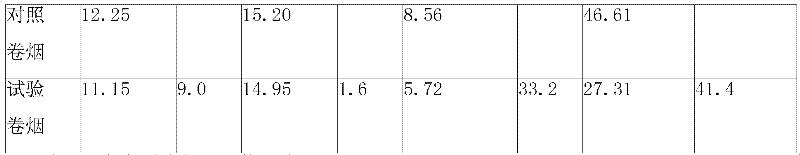

High-phenol content wastewater treatment technology

InactiveCN102964001AReduce phenol contentReduce formaldehyde contentWater contaminantsWater/sewage treatment by ion-exchangeLiquid wasteChemical oxygen demand

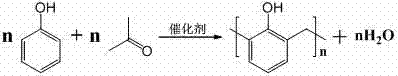

The invention relates to a dephenolization treatment technology of high-phenol content wastewater produced in the production of phenolic resin, which comprises the following steps: membrane separation: after a dephenolization and dealdehyding technology, the phenol-containing waste liquid is fed into a cross-flow flat membrane device for nanofiltration, and the concentrate obtained by the nanofiltration returns to the system and enters a secondary dephenolization treatment technology; and ion exchange: the filtrate obtained by the membrane separation enters a secondary series resin exchange column which performs dephenolization and dealdehyding and elution respectively for use, wherein the phenol content is controlled at a standard of 0.5ppm, 0.4ppm or 0.2ppm, and the formaldehyde content and CODcr (Chemical Oxygen Demand) are reduced to reach the requirements of the emission standard. According to the invention, phenolic resin is generated by the reaction between phenol and formaldehyde, and a large amount of aldehyde in the system is recycled; urea-formaldehyde resin is generated through the reaction between formaldehyde and urea; and moreover, by mixing urea, formaldehyde and water-soluble phenolic resin, the content of water-soluble resin and phenol in the solution is further reduced.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

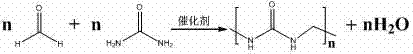

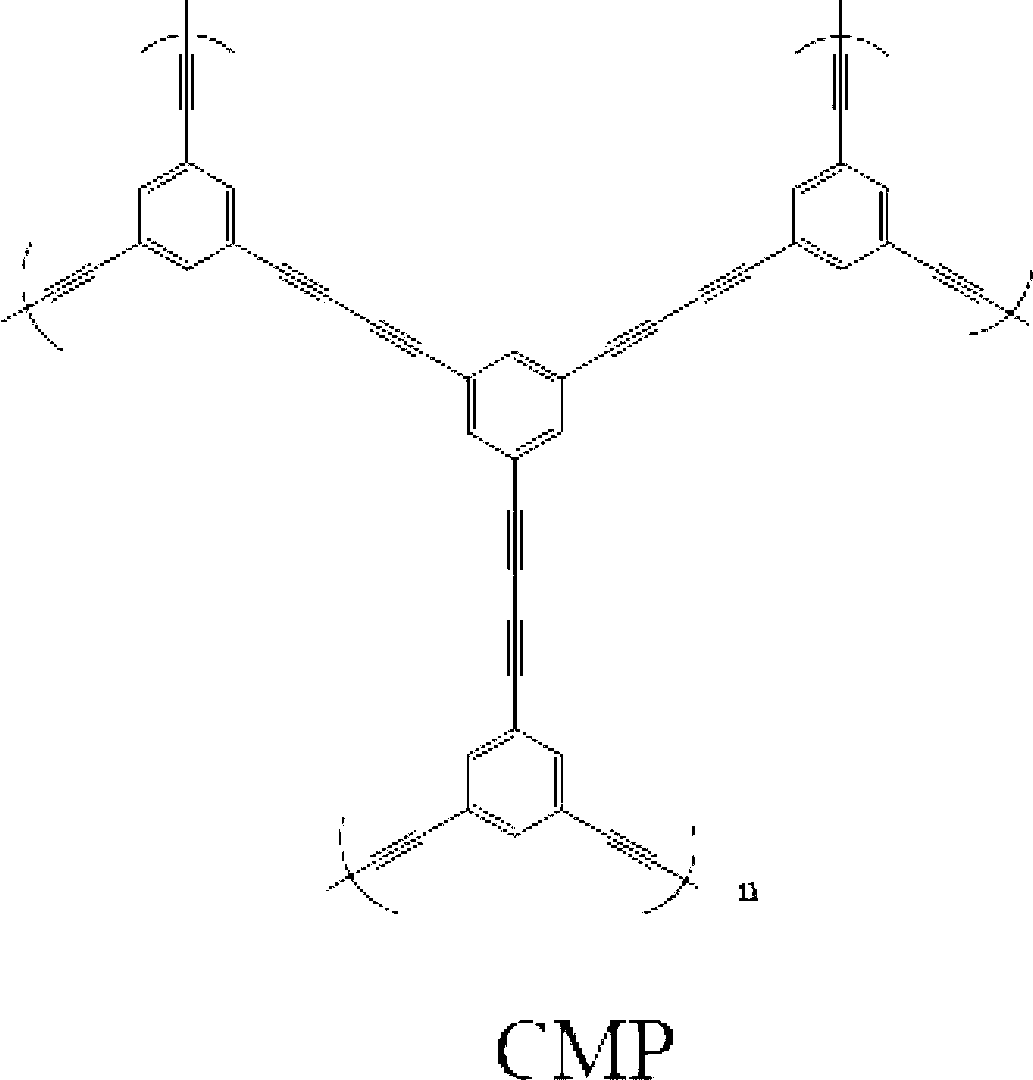

Additive capable of reducing phenol content in main stream smoke, as well as preparation and application methods of additive

ActiveCN102920021AReduce phenol contentSimple preparation processTobacco smoke filtersActivated carbonComposite filter

The invention discloses an additive capable of reducing phenol content in main stream smoke, as well as a preparation method and an application method of the additive. The preparation method comprises the following steps: taking CMP (conjugated microporous polymer) as an active ingredient; taking activated carbon, chitosan and sodium alginate as carriers; obtaining loaded type materials; adding the prepared loaded type materials into a cigarette filter stick to prepare a composite filter stick; and rolling up the cigarette. The analysis shows that the cigarette with the loaded type materials can effectively reduce content of phenol in the smoke by 10-35%. The cigarette filter stick additive capable of reducing harm is simple in preparation method and convenient to industrially produce at large scale.

Owner:CHINA TOBACCO HUNAN INDAL CORP

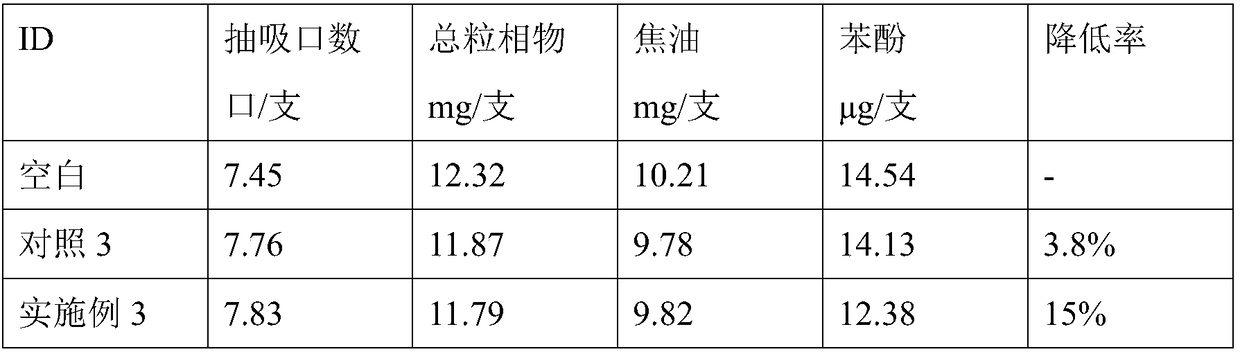

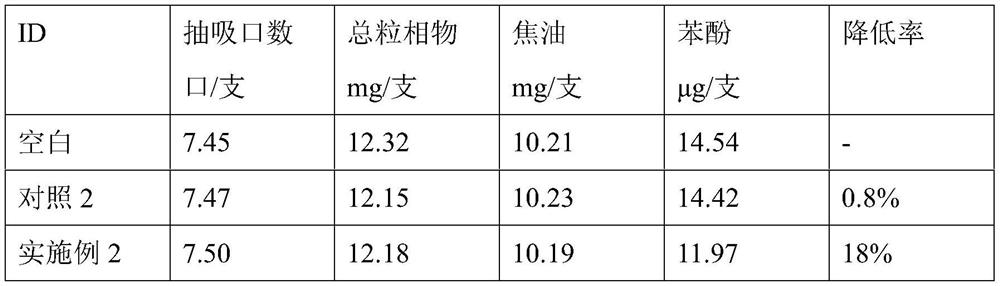

Composite material for reducing phenol emission from flue gas and preparation method and application thereof

ActiveCN108576921AIncrease contact areaImprove adsorption efficiencyTobacco smoke filtersActivated carbonFlue gas

The present invention relates to a composite material for reducing phenol emission from flue gas and a preparation method and application thereof. The preparation method comprises the following stepsof (1), preparation of polymer solution, (2), preparation of surfactant solution and (3), preparation of composite materials. The composite material for reducing phenol emission from flue gas is combined with PVP and activated carbon, the contact area between the PVP and the flue gas is effectively improved, the adsorption efficiency and capacity of phenol in the flue gas by the composite materialfor reducing phenol emission from flue gas are improved. The phenol content in the flue gas is quickly and selectively reduced, and the phenol content in the flue gas can be obviously reduced, and obvious influence on the smoking of cigarettes is not produced, and at the same time the irritation is improved. Besides, the composite material for reducing phenol emission from flue gas is simple in preparation and low in cost.

Owner:CHINA TOBACCO YUNNAN IND

Alkali lignin modified sulfamate high-effective water reducer and preparation method thereof

The invention discloses a preparation method of alkali lignin modified sulfamate highly effective water reducing agent, which includes the steps that: firstly, alkali lignin, phenol and water are evenly mixed, and an alkaline regulator is used to adjust the pH value of a reaction system to 8.0-10.0 and heat the temperature to 80-100 DEG C for half an hour to two hours; secondly, the pH value is adjusted to 9.0-11.0, and aminobenzene sulfonic acid sodium is added to react under the temperature of 60 to 80 degrees for half an hour to one hour; thirdly, the temperature is heated to 75-95 DEG C, and condensing agent is dropped. After that, the reaction continues for three to six hours and then the temperature is lowered. The obtained water reducing preparation, having low cost and small content of free formaldehyde and phenol, can improve the fluidity of concrete and compressive strength significantly. The preparation method is a simple technique without the discharge of three wastes in production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation process of phenoxyethanol serving as raw material for cosmetics

ActiveCN111718244AReduce phenol contentLow costEther separation/purificationEther preparation from oxiranesAlkaline waterPtru catalyst

The invention discloses a preparation process of phenoxyethanol serving as a raw material for cosmetics, which comprises the following steps: reacting phenol serving as an initiator with ethylene oxide in the presence of a base catalyst to obtain a phenoxyethanol crude product; rectifying the phenoxyethanol crude product under reduced pressure to obtain high-purity phenoxyethanol; adsorbing phenolin high-purity phenoxyethanol by adopting the activated macroporous adsorbent to obtain a saturated macroporous adsorbent and a cosmetic raw material phenoxyethanol; using the saturated macroporous adsorbent for adsorbing phenol in high-purity phenoxyethanol again after being activated and dried by alkaline water. The phenoxyethanol obtained in the invention has high purity (> = 99.9%, GC) and low phenol content (< = 10ppm, LC). The process is simple, the macroporous adsorbent can be recycled after being activated by alkali liquor, the production cost is low, and industrial production is easy.

Owner:ZHEJIANG HUANGMA TECH +3

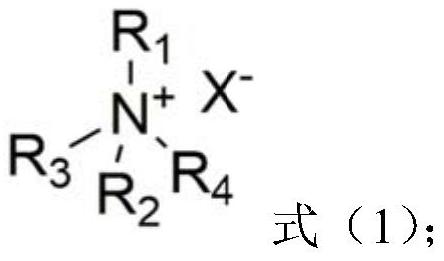

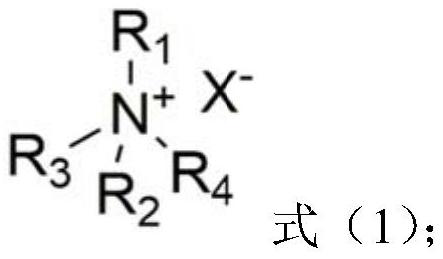

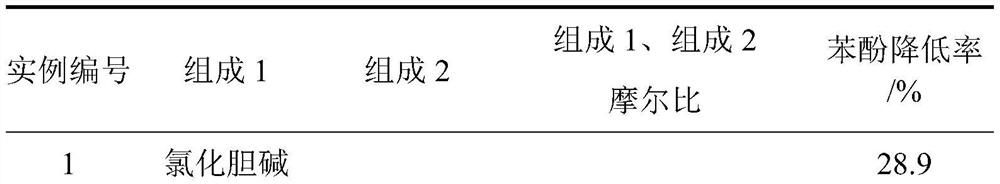

Method for reducing content of phenol in waste gas

PendingCN113115980AReduce phenol contentTobacco smoke filtersDispersed particle separationEnvironmental chemistryGlycerol

The invention belongs to the field of waste gas treatment and particularly relates to a method for reducing the content of phenol in waste gas. The method for reducing the content of phenol in the waste gas comprises a step of treating the waste gas by using an absorbent, and the absorbent is quaternary ammonium salt or a eutecticevaporate solvent containing the quaternary ammonium salt; the quaternary ammonium salt is selected from choline chloride and has a structure shown as a formula (1); in the formula (1), R1, R2, R3 and R4 are independently selected from C1-4 alkyl groups; and the eutecticevaporate solvent containing the quaternary ammonium salt is composed of a hydrogen bond acceptor and a hydrogen bond donor, the hydrogen bond acceptor is the quaternary ammonium salt, and the hydrogen bond donor is selected from one of glycerin, 1, 2-propylene glycol, citric acid, malic acid and levulinic acid. According to the method for reducing the phenol content in the waste gas, the quaternary ammonium salt or the eutecticevaporate solvent containing the quaternary ammonium salt is used as the adsorbent for treating the waste gas, the content of phenol in the waste gas can be effectively reduced, and emission poison of the phenol-containing waste gas is reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

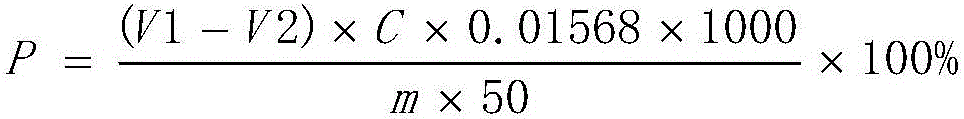

Method for reducing content of phenol in water through unburnt carbon in solid waste fly ash

InactiveCN106241934ALow volatile contentLoose structureWater contaminantsWater/sewage treatment by sorptionAfter treatmentGranularity

The invention provides a method for reducing the content of phenol in water through unburnt carbon in solid waste fly ash. The method includes the steps of fly ash flotation, unburnt carbon stirring and adsorption, centrifugal solid and liquid separation, detection and the like. Industrial solid waste fly ash is subjected to flotation to obtain the foam product, namely unburnt carbon; the unburnt carbon is added into sewage containing phenol to be adsorbed, solid and liquid separation is conducted by means of a centrifugal machine after adsorption is finished, and supernate is purified water obtained after treatment; the unburnt carbon removal rate of unburnt carbon in water is calculated. Fine granularity, large specific surface area and a rich porous structure of unburnt carbon are used for adsorbing and removing phenol in water, accordingly the content of phenol in water is reduced, and the effect of reducing waste by means of waste is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

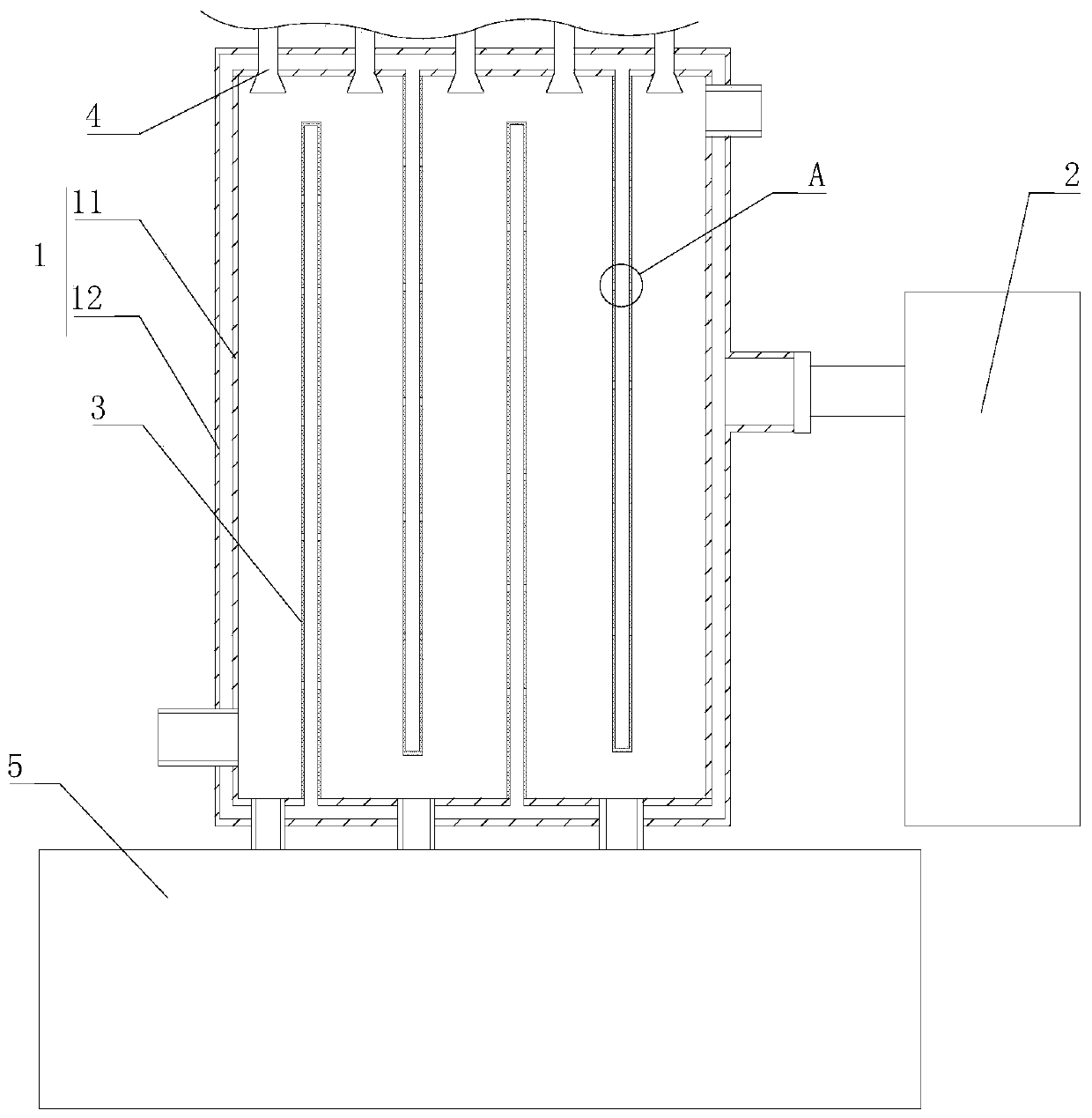

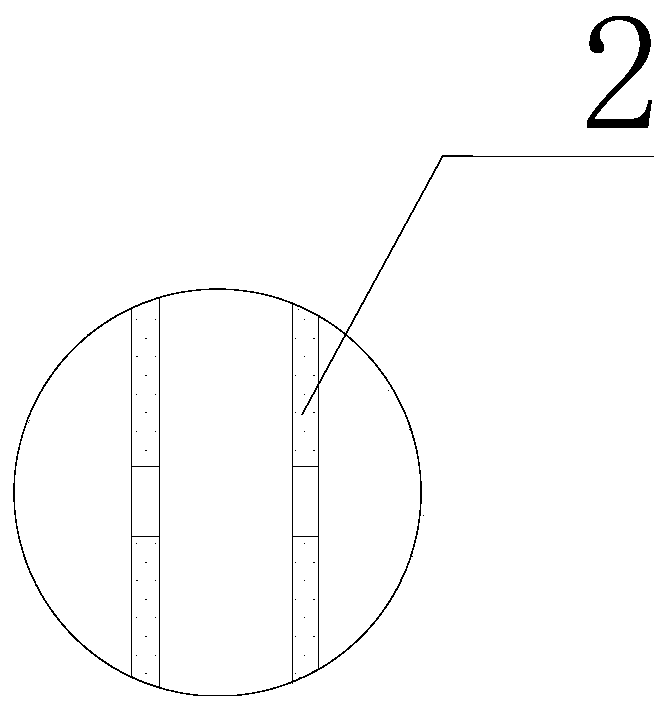

High-temperature flue gas treatment device

InactiveCN111036053APromotes rapid oxidationReduce contentGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention provides a high-temperature flue gas treatment device, which comprises a mixer and an ozone generator, wherein the mixer has a shell, a gas inlet connected with high-temperature flue gasis formed in the bottom of the shell, a gas outlet is formed in the top of the shell, a plurality of partition plates are arranged in the shell and divide the interior of the shell to form a gas flowchannel, one end of the gas flow channel communicates with the gas inlet, the other end of the gas flow channel communicates with the gas outlet, the partition plates are of hollow structures, the hollow structures of the partition plates communicate with the ozone generator, and through holes are formed in the partition plates. According to the invention, the contact time of high-temperature flue gas and ozone is effectively prolonged, and ozone is supplemented in time, so that the ozone in the gas flow channel is always in a high-concentration state so as to rapidly oxidize formaldehyde andphenol in the high-temperature flue gas, and the content of formaldehyde and phenol in the high-temperature flue gas is effectively reduced.

Owner:安徽微宇仪器科技有限公司

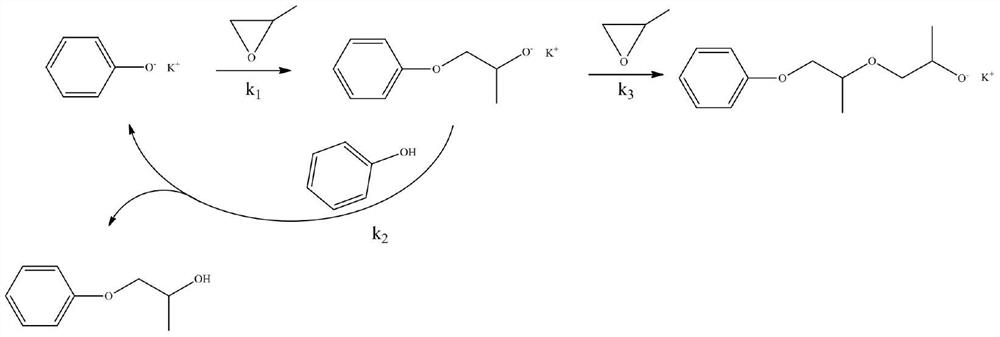

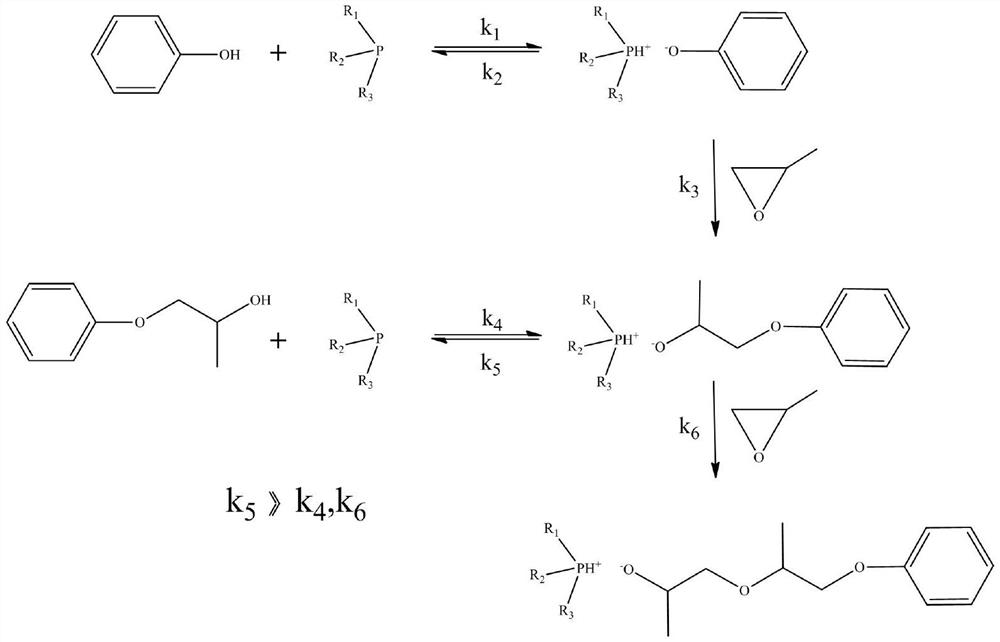

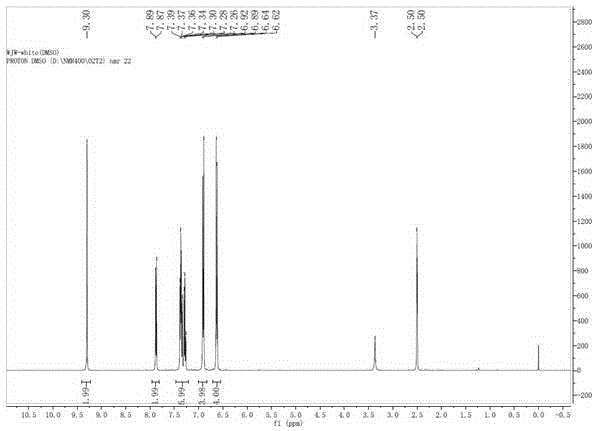

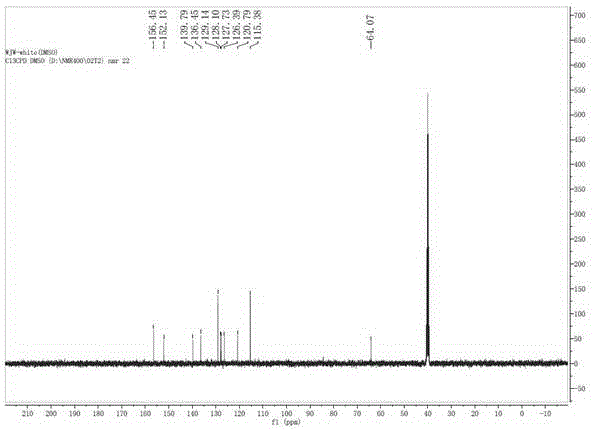

High-selectivity synthesis method of 3-phenoxy-1-propanol

InactiveCN113072431APromote conversionReduce generationEther preparation from oxiranesPtru catalystEngineering

The invention provides a high-selectivity synthesis method of 3-phenoxy-1-propanol, which comprises the following step that phenol and epoxypropane are catalyzed by organic phosphorus to obtain 3-phenoxy-1-propanol through a one-step method. The chemical structure of the organic phosphorus is as shown in (I) (See the specification), wherein R1, R2 and R3 are electron-rich substituents including alkyl, phenyl or alkoxy, and the number of C in the alkyl and the alkoxy is 2-6. The selected catalyst is high in selectivity, the content of phenol in the synthesized product is low (smaller than or equal to 100 ppm, GC), the purity of 3-phenoxy-1-propanol is high (larger than or equal to 98.0%, GC), and the 3-phenoxy-1-propanol can be directly applied to industries closely related to coatings and life. In addition, no post-treatment process is needed, neither waste liquid not waste residue is generated, so that the method is an economic and environment-friendly process.

Owner:ZHEJIANG HUANGMA TECH +3

Green synthesis method of 9, 9-bis (4-hydroxy) fluorene

ActiveCN104693012AEmission reductionThe reaction process is green and environmentally friendlyOrganic chemistryOrganic compound preparationSynthesis methodsReaction temperature

The invention discloses a synthesis method of fluorene-9-bisphenol, in particular to a green synthesis method of 9, 9-bis (4-hydroxy) fluorine. The method comprises the steps of enabling phenol and 9-fluorenone to react in an organic solvent in a concentrated sulfuric acid acidic medium condition under the catalysis of 3-thiohydracrylic acid, wherein the mole ratio of the phenol to the concentrated sulfuric acid to the 3-thiohydracrylic acid to the 9-fluorenone is (2-8): (0.1-0.6): (0.01-0.1): 1, the reaction temperature is -5 to 80 DEG C, and the reaction time is 2-8h; after the completion of the reaction, cooling to room temperature, filtrating, and washing a filter cake with the organic solvent; combining filtrate, and then adding the 9-fluorenone, the phenol, the concentrated sulfuric acid and the 3-thiohydracrylic acid into the filtrate sequentially to carry out circular reaction. In the synthesis process, since the organic solvent is used, the dosage of the phenol can be greatly reduced, the excessive phenol can be directly recycled through the filtrate, the efficiency of the system can be improved, and the discharge of acidic wastewater and the phenol can be reduced; meanwhile, the fluorene-9-bisphenol can be synthesized with high yield and high selectivity.

Owner:DALIAN TRICO CHEM

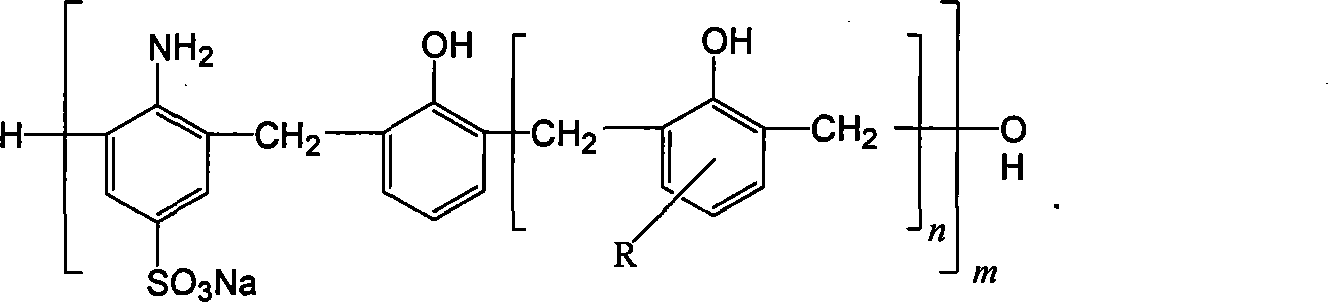

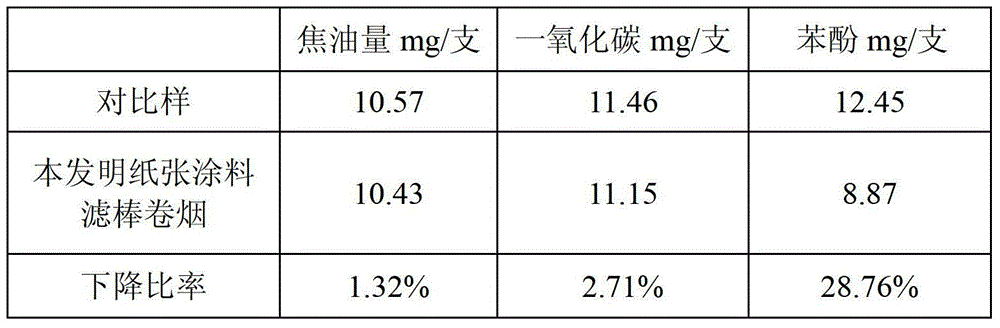

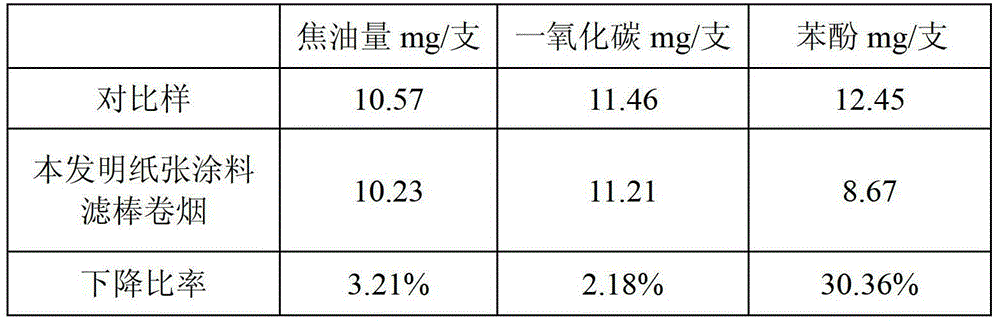

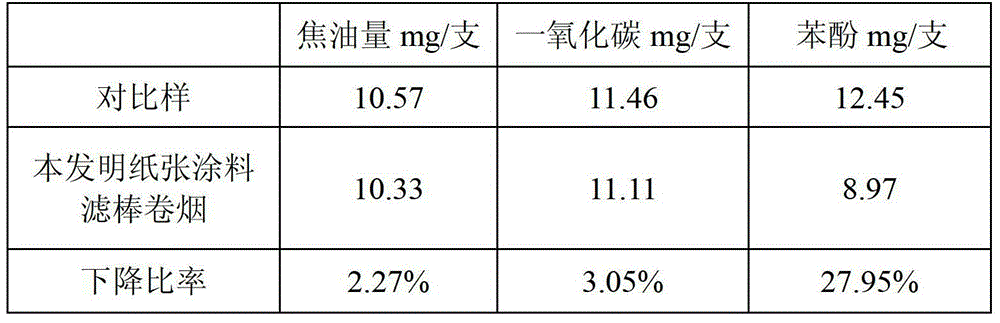

A kind of selective phenol reduction paper coating and its preparation method and application

Owner:CHINA TOBACCO HUNAN INDAL CORP

A filter stick additive capable of reducing phenol content in cigarette mainstream smoke, its preparation method and application

The invention discloses a filter stick additive with the function of reducing the content of phenol in the cigarette mainstream smoke and a preparation method and application thereof. The additive is a composite material prepared by loading Mn-Ce oxide with potassium ions on carriers. The method includes dissolving soluble manganese salts and cerium salt in water, adding alkali solution in a dripped manner to obtain precipitation through reaction, filtering, and obtaining Mn-Ce oxide by drying and calcining the precipitate; after mixing the Mn-Ce oxide with the carriers evenly, adding potassium chloride solution, mixing evenly, drying, and obtaining the filter stick additive. The filter stick additive has high chemical stability, and the content of phenol in the cigarette smoke can be reduced; in addition, the the preparation process and operation of the filter stick additive are simple, cost is low, and the industrial production requirements can be met.

Owner:CHINA TOBACCO HUNAN INDAL CORP

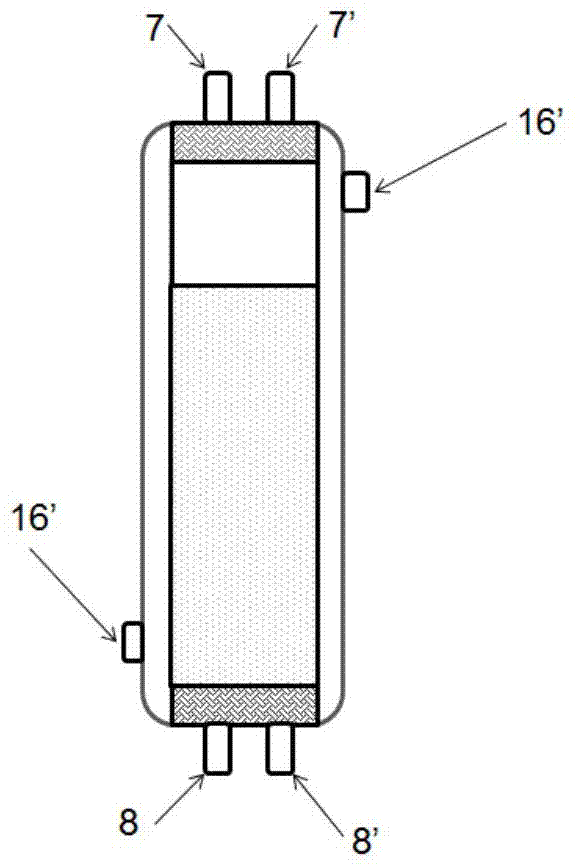

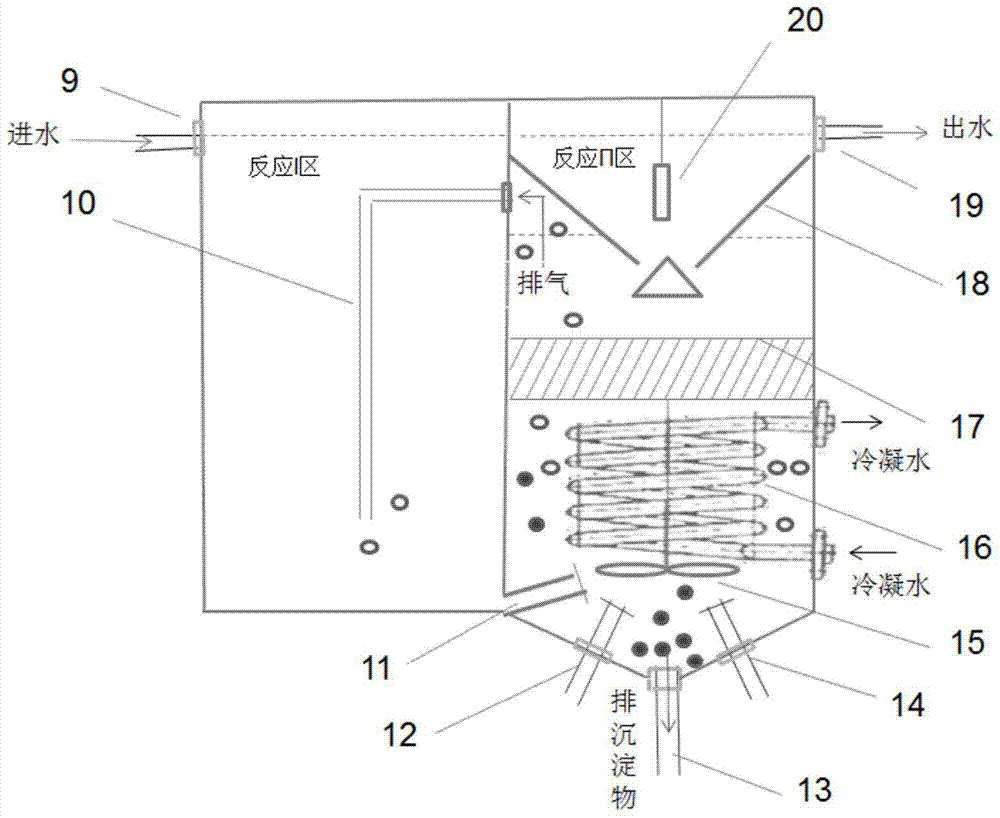

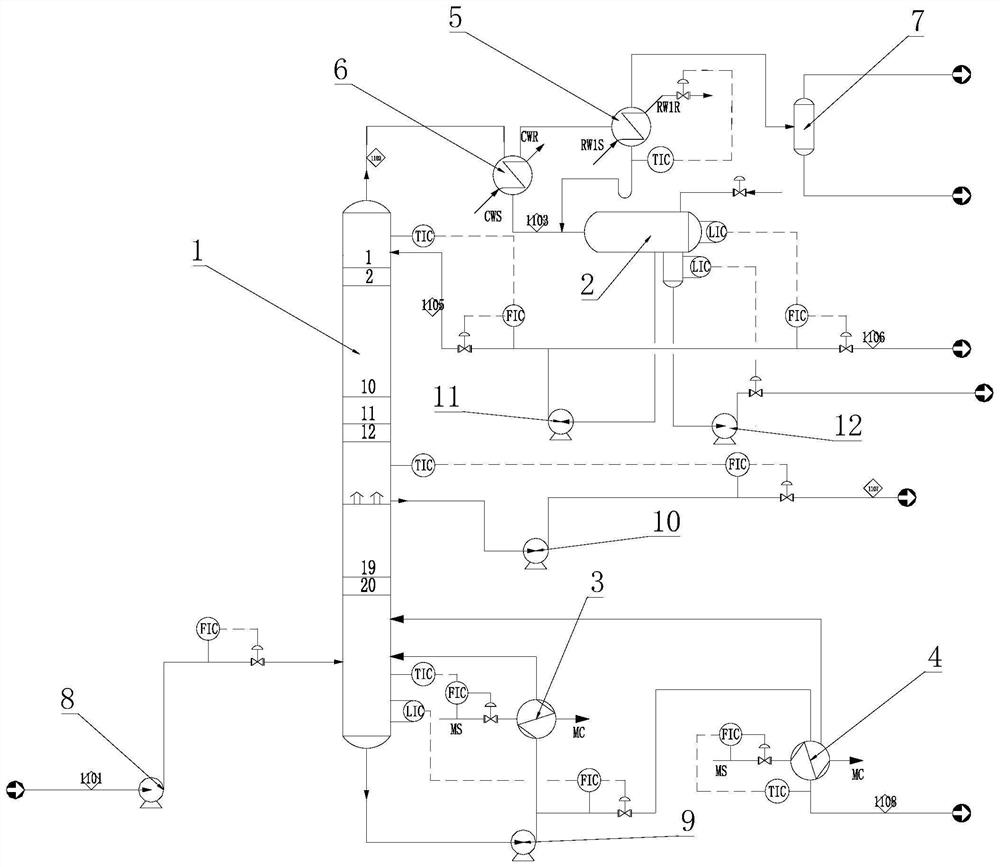

Condensation mother liquid waste water pretreatment and resource system and method in compound neutralization reactor in disperse blue 56 production process

ActiveCN103588329BReduce dosageAvoid harmOrganic chemistryOrganic compound preparationLiquid wasteNitrite ion

The invention discloses a compound neutralization reactor and a condensation mother liquor wastewater pretreatment and resource utilization system and method in the production process of dispersed blue 56, and belongs to the field of wastewater treatment. It neutralizes the condensation mother liquor wastewater and mixed acid solution (sulfuric acid, sulfamic acid) in the production process of highly alkaline Dispersed Blue 56 in a compound neutralization reactor, thereby reducing the pH value of the wastewater, precipitating phenol, and removing nitrous acid Three purposes are achieved at the same time; the neutralized wastewater passes through a fixed-bed adsorption column equipped with adsorption resin, so that the residual phenol in the wastewater is adsorbed on the resin column. The adsorbed saturated resin can be reused after desorption and regeneration with NaOH solution. The desorption solution undergoes acid adjustment and vacuum distillation of phenol to realize the resource utilization of phenol. The present invention pretreats the condensation mother liquor wastewater in the production process of Dispersed Blue 56. The CODCr value is reduced from about 55000mg / L to less than 500mg / L, the phenolic substance concentration is reduced from about 19000mg / L to less than 20mg / L, and the nitrite ion is reduced from about 19000mg / L to less than 20mg / L. 87000mg / L reduced to less than 20mg / L; effectively realizing wastewater treatment and resource utilization.

Owner:江苏吉易达环保科技有限公司

A compound additive for reducing phenol release in flue gas and its application

ActiveCN108576922BReduce phenol contentSmell has no obvious effectTobacco smoke filtersPolyolFlue gas

The invention relates to a compound additive for reducing the release amount of phenol in flue gas and a preparation method and application thereof. The compound additive comprises, by weight, 1-20 parts of polymers, 0.1-5 parts of acid compounds, 0.1-5 parts of polyol and 20-50 parts of solvents; and the polymers are one or more of polyvinyl pyrrolidone and vinyl pyrrolidone-maleic acid copolymers with the molecular weight of 1,000 to 1,000,000. Suitable ligands are selected to be mixed with PVP, the amount of phenol in the flue gas is quickly and selectively reduced, the effect is obvious, the smoke flavor of cigarettes is not obviously affected, and the irritation is relieved. The preparation method is simple, the cost is low, and the harm reduction effect is obvious.

Owner:CHINA TOBACCO YUNNAN IND

Cigarette filter stick additive capable of reducing phenol content in main stream smoke and preparing method and application thereof

InactiveCN106509987AReduce phenol contentStable chemical structureTobacco smoke filtersPhenolChemical stability

The invention discloses a cigarette filter stick additive capable of reducing phenol content in main stream smoke, a preparing method and application thereof. The cigarette filter stick additive is a capsule formed by alginate encapsulating propylene glycol alginate. The preparing method comprises the steps of dropwise adding a solution containing propylene glycol alginate and sodium alga acid into a solution containing calcium ions, conducting static settlement and solid-liquid separation, and drying the materials to obtain the cigarette filter additive capable of reducing the phenol content in the main stream smoke. The cigarette filter stick additive is good in chemical stability and is safe for human body, and the addition of the additive in the cigarette filter stick can effectively reduce the phenol content in the main stream smoke; in addition, the preparing technological process and operation of the filter stick additive are simple, thus meeting industrialized production.

Owner:CHINA TOBACCO HUNAN INDAL CORP

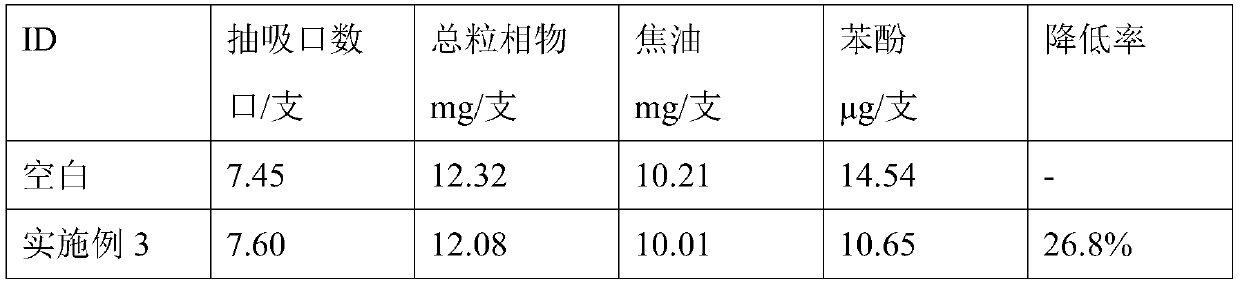

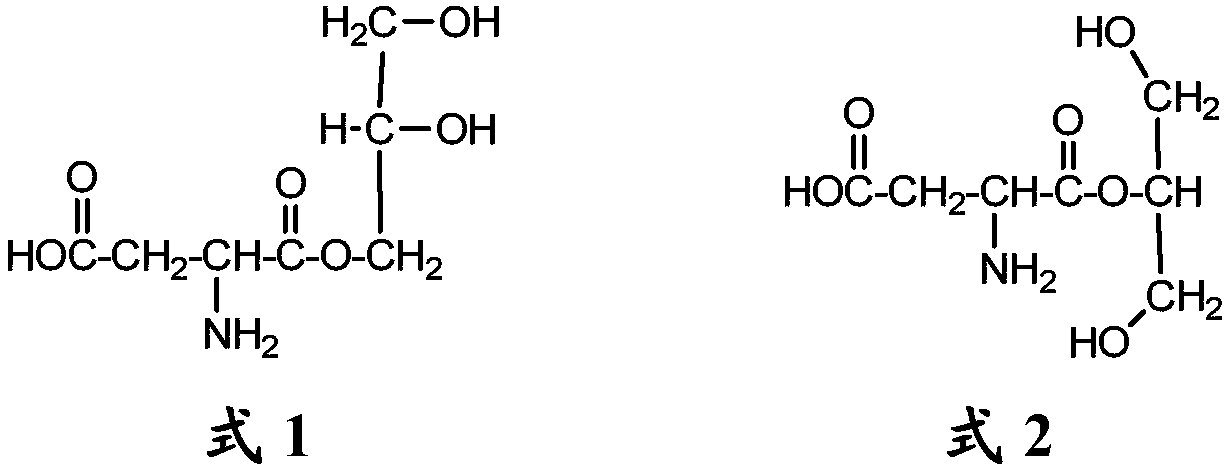

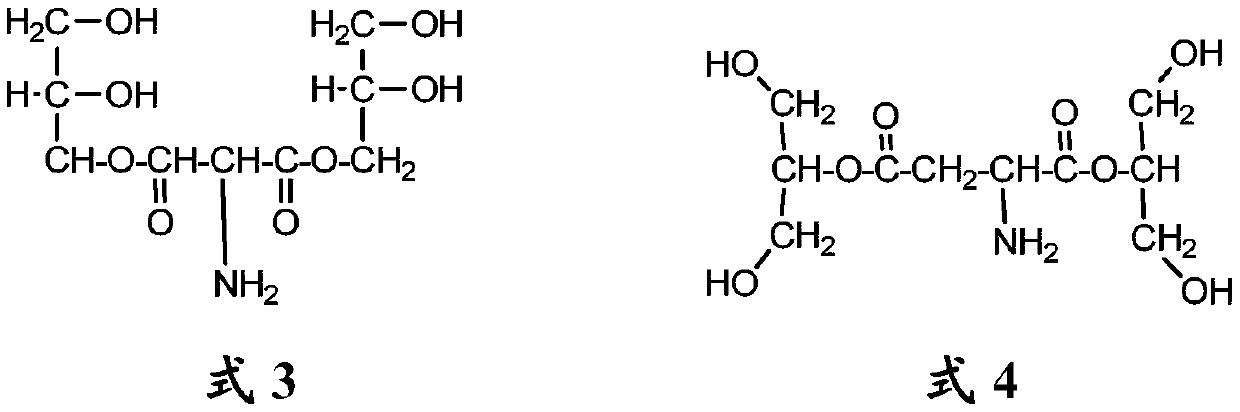

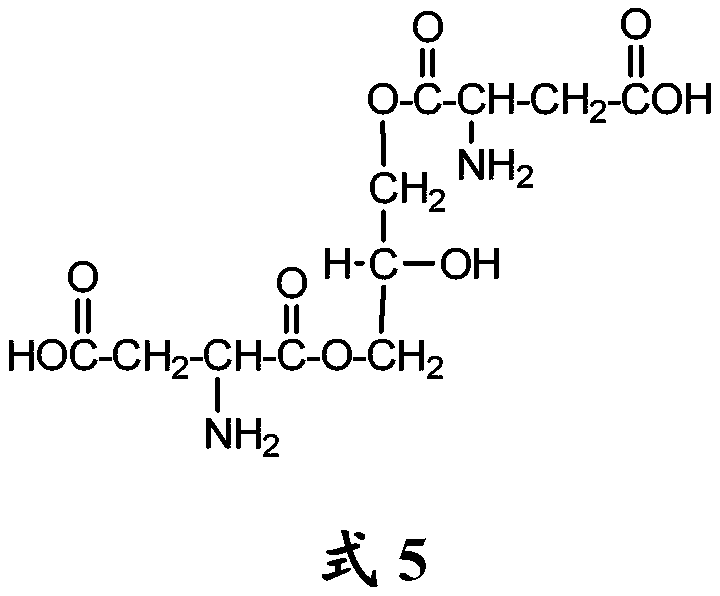

Use of glyceryl aspartate for reducing phenol release in cigarette smoke

ActiveCN105996126BReduce phenol contentDoes not affect the feeling of smokingTobacco smoke filtersGlycerolPhenol

Owner:CHINA TOBACCO FUJIAN IND

A composite material for reducing phenol release in smoke, its preparation method and application

ActiveCN108576921BIncrease contact areaImprove adsorption efficiencyTobacco smoke filtersActivated carbonFlue gas

The present invention relates to a composite material for reducing phenol emission from flue gas and a preparation method and application thereof. The preparation method comprises the following stepsof (1), preparation of polymer solution, (2), preparation of surfactant solution and (3), preparation of composite materials. The composite material for reducing phenol emission from flue gas is combined with PVP and activated carbon, the contact area between the PVP and the flue gas is effectively improved, the adsorption efficiency and capacity of phenol in the flue gas by the composite materialfor reducing phenol emission from flue gas are improved. The phenol content in the flue gas is quickly and selectively reduced, and the phenol content in the flue gas can be obviously reduced, and obvious influence on the smoking of cigarettes is not produced, and at the same time the irritation is improved. Besides, the composite material for reducing phenol emission from flue gas is simple in preparation and low in cost.

Owner:CHINA TOBACCO YUNNAN IND

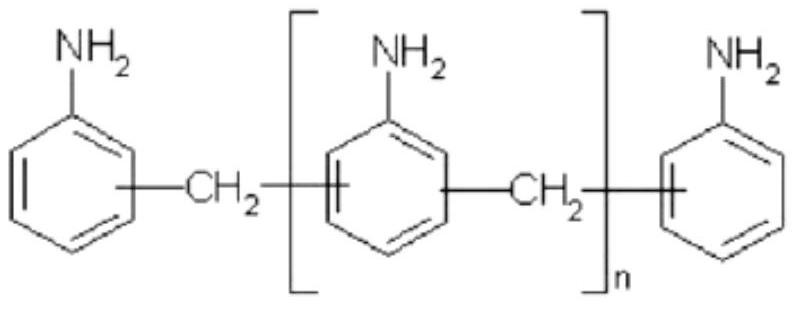

Treatment method of desalted water generated in MDA preparation process

ActiveCN112279441AReduce environmental stressTargetedMultistage water/sewage treatmentNature of treatment waterEnvironmental chemistrySodium bromide

The invention provides a method for treating desalted water generated in a MDA preparation process. According to the method, before catalytic oxidation treatment, a phenol content is controlled not toexceed 0.8 mg / L and / or a sodium bromide content is controlled not to exceed 0.2 mg / L. According to the treatment method provided by the invention, the impurity components of the desalted water are deeply analyzed, the phenol content and the sodium bromide content in the desalted water are effectively controlled, deep purification effect can be achieved, the TOC content and the bromophenol contentin the treated desalted water are relatively low, organic matters are thoroughly removed, and environmental pressure is reduced; and the treatment method provided by the invention is strong in pertinence, simple and convenient in process, convenient for industrial implementation and stable in operation, does not need a large amount of manpower and equipment investment, and has a very good application prospect.

Owner:WANHUA CHEM GRP +1

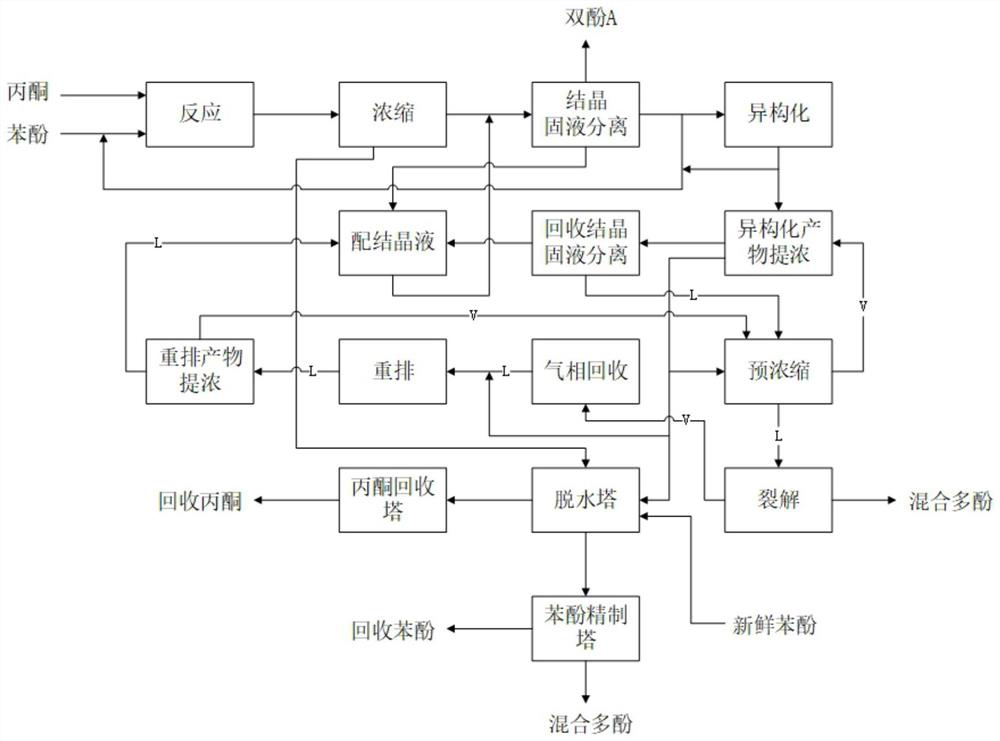

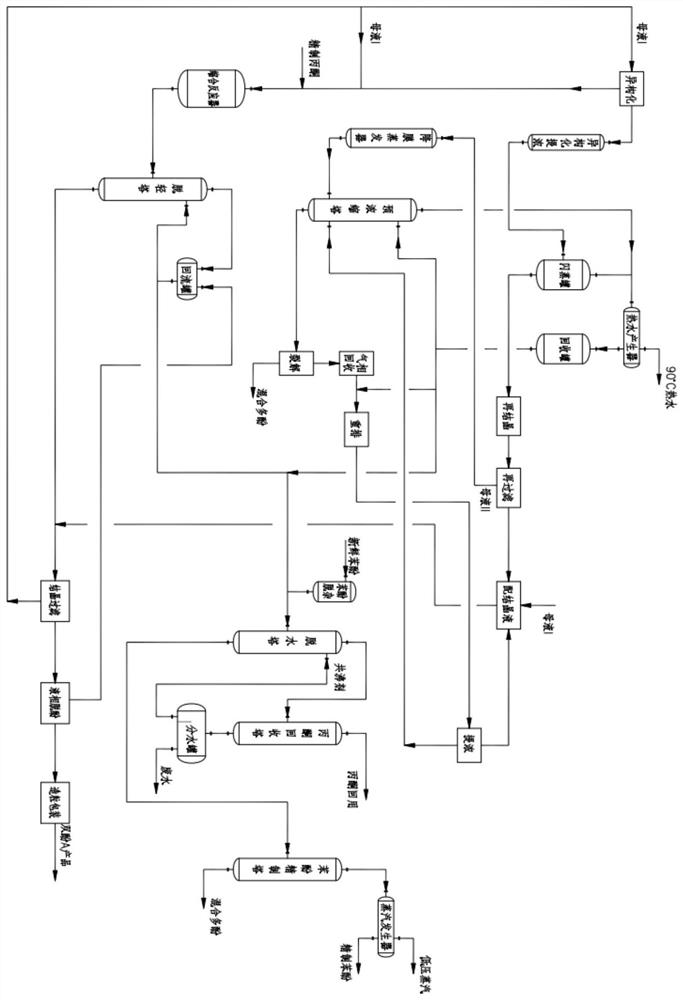

Method for reducing isopropyl phenol in bisphenol A preparation reaction system

PendingCN114230442ASolve problems that reduce catalyst lifeReduce phenol contentOrganic chemistryOrganic compound preparationPtru catalystIsomerization

The invention discloses a method for reducing isopropyl phenol in a bisphenol A preparation reaction system, which comprises the following steps of: performing condensation reaction on excessive phenol and acetone in a condensation reactor through a catalyst, performing isomerization-cracking-rearrangement on at least one part of post-reaction liquid to obtain rearrangement liquid, and performing concentration process treatment on the rearrangement liquid containing isopropyl phenol, the isopropyl phenol enters a phenol recovery system and is separated from the phenol along with the mixed polyphenol; the mass percent content of isopropyl phenol in the condensation reactor is less than or equal to 0.25%. According to the present invention, the isopropyl phenol-containing cracking rearrangement product is subjected to the concentration process, such that the isopropyl phenol enters the light component and is discharged along with the mixed polyphenol, and the isopropyl phenol content in the phenol extracted from the tower top can be adjusted by adjusting the tower kettle extraction amount and other means; the problem that the service life of a catalyst is shortened due to the fact that lysate or redrainage liquid for generating isopropyl phenol directly enters a reaction system in the prior art is solved.

Owner:凯美科(无锡)技术有限公司

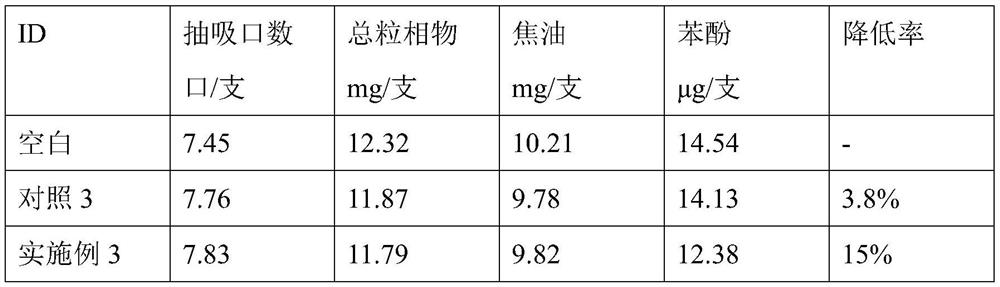

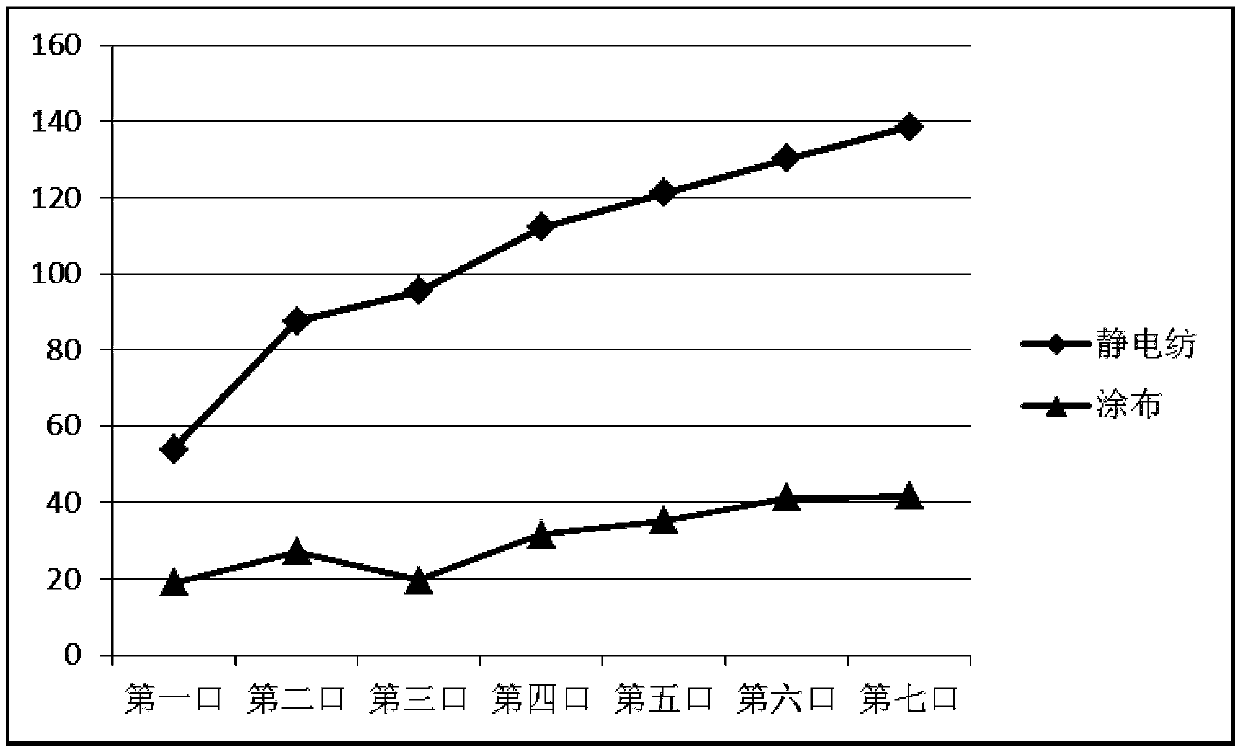

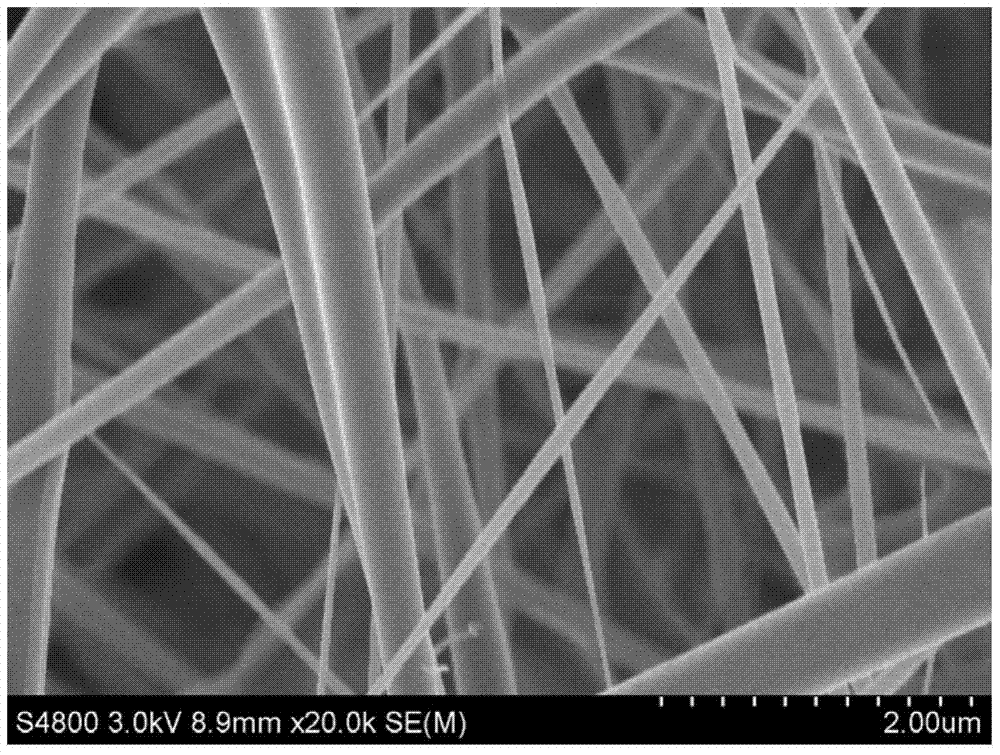

Ultrafine fiber functionalized cellulose formed paper with functions of carrying aroma and selectively reducing phenol content in smoke, and preparation method and application thereof

ActiveCN111155357AReduce releaseDoes not reduce tar contentSurface covering paperNon-fibrous pulp additionCellulosePolymer science

The invention discloses an ultrafine fiber functionalized cellulose formed paper with functions of carrying aroma and selectively reducing the phenol content in smoke, and a preparation method and anapplication thereof. The ultrafine fiber functionalized cellulose formed paper is composed of a cellulose formed paper and an aroma-carrying substance doped polyvinylpyrrolidone micro-nano ultrafine fiber film layer on the surface of the cellulose formed paper, and the ultrafine fiber functionalized cellulose formed paper is processed into a groove filter stick. The phenol in smoke is remarkably selectively reduced, the harmful component phenol in the smoke can be reduced by 15-40%, smoke tar basically has no obvious change, the selective reduction effect on the phenol in the smoke is highlighted, and the smoke is endowed with unique aroma.

Owner:CHINA TOBACCO HUNAN INDAL CORP

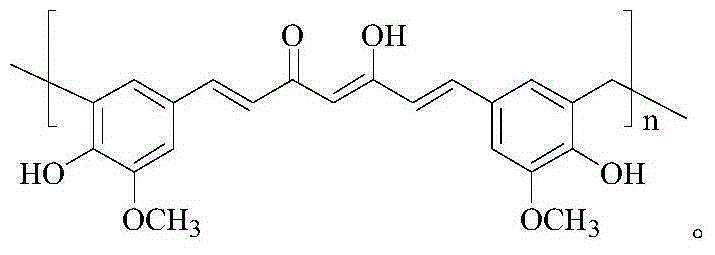

Cigarette filter additive capable of lowering phenol content in mainstream smoke and preparation method and application of cigarette filter additive

The invention discloses a cigarette filter additive capable of lowering phenol content in mainstream smoke and a preparation method and application of the cigarette filter additive. The cigarette filter additive is a composite formed by loading curcumin formaldehyde resin on a solid carrier. The preparation method includes dispersing the curcumin formaldehyde resin in water and adding in the carrier for soaking prior to filtering and drying to obtain the cigarette filter additive. The cigarette filter additive is good in chemical stability and safe to human bodies, the phenol content in the mainstream smoke can be lowered effectively by adding the cigarette filter additive to a cigarette filter; in addition, the preparation process and operation of the cigarette filter additive are simplified, and industrial production is satisfied.

Owner:CHINA TOBACCO HUNAN INDAL CORP

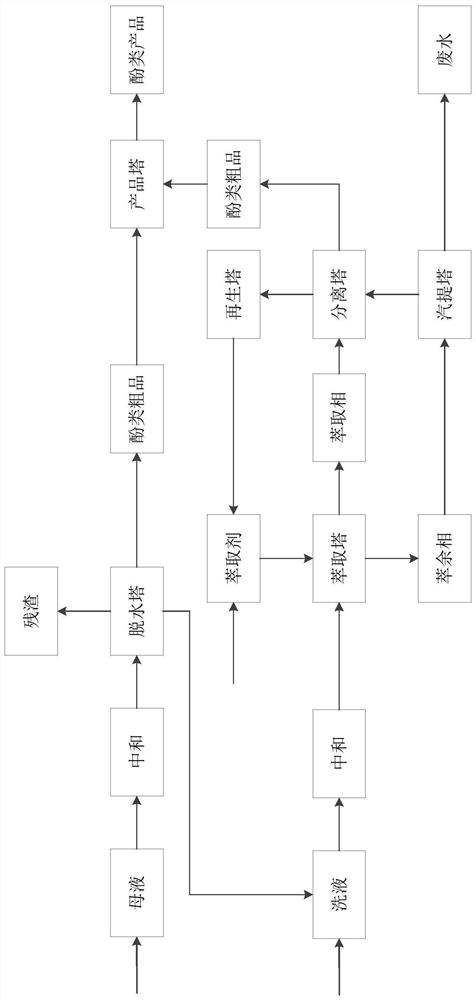

Phenolic wastewater treatment method and device thereof

ActiveCN113121052ANo need to think about sales outletsReduce phenol contentWater contaminantsMultistage water/sewage treatmentProcess engineeringPhenol product

The invention discloses a phenol-containing wastewater treatment method and a device thereof, and the method comprises the following steps: separating phenol-containing wastewater into a high-concentration mother solution and a low-concentration washing solution, respectively treating the mother solution and the washing solution, extracting the washing solution by adopting an extraction agent, carrying out heavy component removal treatment on the mother solution, and then extracting the mother solution by adopting the extraction agent; performing heavy component removal treatment on the mother liquor through a dehydrating tower, extracting the light components at the top of the dehydrating tower by adopting an extracting agent, and arranging an evaporator at the bottom of the dehydrating tower and used for evaporating materials at the bottom of the dehydrating tower; combining light components at the top of the dehydrating tower with the washing liquor, and extracting by adopting an extracting agent; wherein the evaporator is a scraper type evaporator. The device comprises a dehydrating tower, an extracting tower, a stripping tower, a separating tower, a product tower and a regenerating tower. According to the method, the raw material sodium chloride does not need to be purchased additionally, phenol sodium salt is not generated additionally, the sales way of the phenol sodium salt does not need to be considered, and waste residues are directly incinerated; and the recovery purity of phenol products is high.

Owner:QINGDAO DOUBLE PEACH SPECIALTY CHEM GRP

Paper filter material capable of effectively reducing phenol content in cigarette smoke and processing method thereof

ActiveCN102720001BReduce tarReduce phenolicsFiltration separationNon-woven fabricsFibre treatmentPaper filter

The invention discloses a paper filter material capable of effectively reducing phenol content in cigarette smoke and a processing method thereof. The paper filter material is formed by processing 40%-80% of base fiber, 5%-30% of acetified pulp, 0.5%-10% of carrier and 5%-15% of adhesive in a dry process. The method comprises the steps of fiber processing, single fibrillation, screening, air laying, adhesive material application, roll-in molding, drying and the like. The paper filter material obtained by adding the powdery acetified pulp can effectively reduce tar and phenols substance in the cigarette smoke, and particularly reduce the content of phenol which is one of seven harmful constituents, and the harms on smokers are reduced. The hardness of a molded filter stick can be enhanced by the acetified pulp and the carrier thereof, the problem of collapse existing in the prior art is reduced, and particle matter, the phenols substance and the tar in the cigarette smoke can be effectively reduced. The preparation process of the processing method is simple, acetate fiber is replaced by the acetified pulp, the production cost is effectively reduced, and the economic benefits are improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

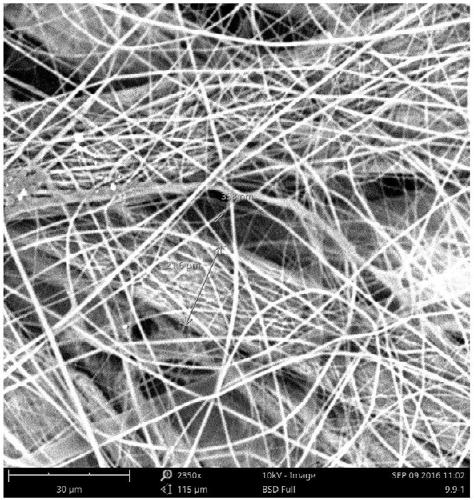

A nanofiber composite tow for reducing phenol content in flue gas and its preparation method and application

ActiveCN105155027BReduce releaseEfficient removalTobacco smoke filtersConjugated cellulose/protein artificial filamentsFiberCellulose acetate

The invention discloses a nanofiber composite tow for reducing phenol content in smoke and its preparation method and application, wherein the nanofiber composite tow includes tobacco tow and nanofibers deposited on the surface of the tobacco tow. The diameter of the nanofiber is 20-500nm, and the nanofiber is formed by electrospinning cellulose acetate modified by cyclodextrin. The preparation method of nanofiber composite tow comprises the following steps: (1) using isocyanate to activate cellulose acetate, and the activated cellulose acetate is graft-copolymerized with cyclodextrin to obtain cyclodextrin-modified cellulose acetate; (2) Electrospinning the spinning solution containing cyclodextrin-modified cellulose acetate with tobacco tow as the base material to obtain the nanofiber composite tow. The raw materials used in the invention are cheap and easy to obtain, the preparation method is green, environmentally friendly, safe and controllable, and the obtained nanofiber composite tow has good adsorption effect on phenol.

Owner:CHINA TOBACCO ZHEJIANG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com