Condensation mother liquid waste water pretreatment and resource system and method in compound neutralization reactor in disperse blue 56 production process

A reactor and duplex technology, applied in the field of condensation mother liquor wastewater pretreatment and resource utilization system, can solve the problems of polluted air, high biological toxicity, difficult adsorption and removal of sodium phenolate, etc., so as to save the amount of acid and reduce the content of COD and phenol. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Strong Alkaline Condensation Mother Liquor Wastewater COD in the Production Process of Disperse Blue 56 Cr It is 54400mg / L, the pH is greater than 14, and the concentration of phenolic substances is 18900mg / L.

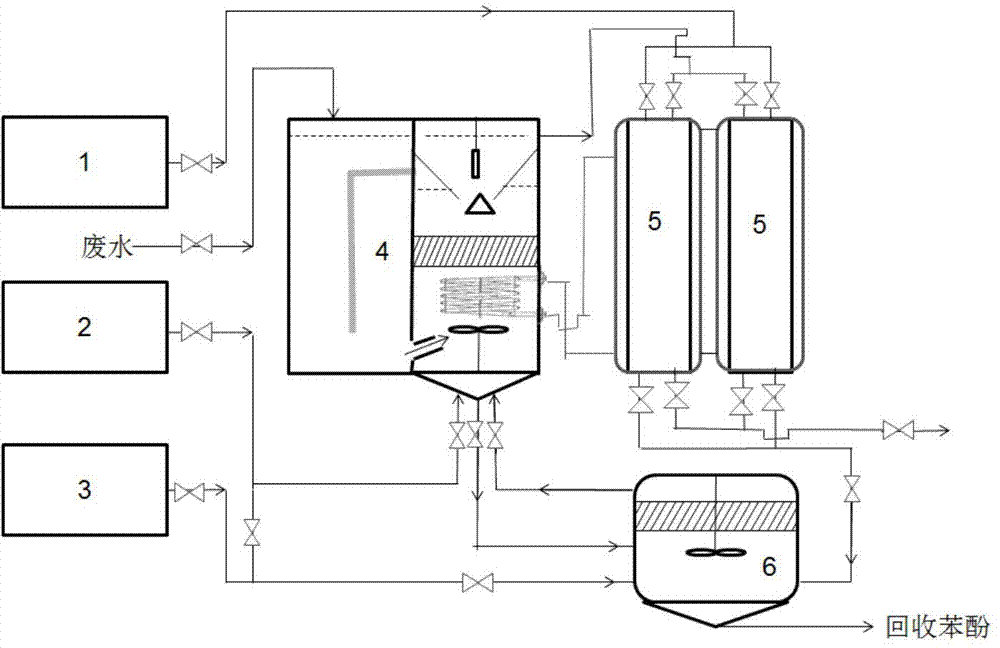

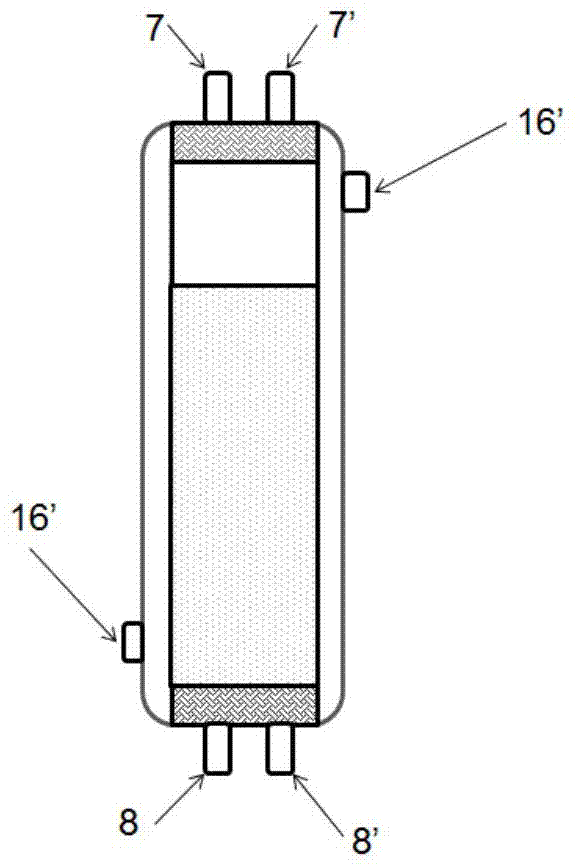

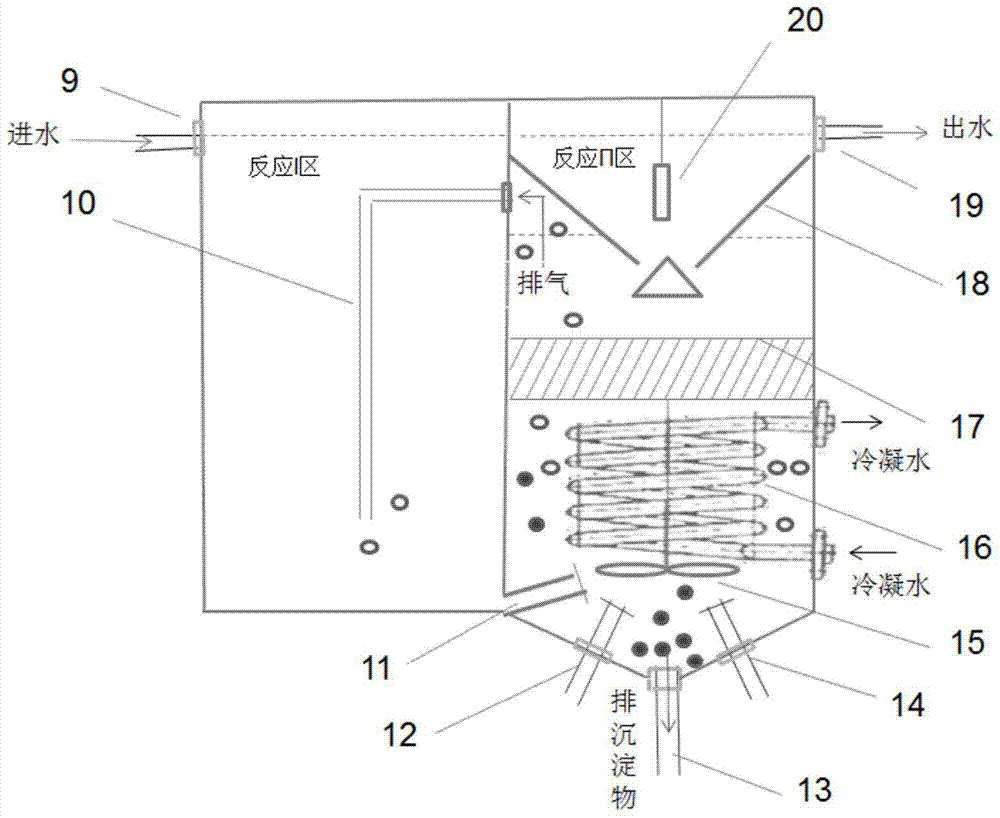

[0043] The wastewater treatment pilot system is attached figure 1 As shown, it includes: sodium hydroxide solution storage tank 1, sulfamic acid storage tank 2, concentrated sulfuric acid storage tank 3, multiple neutralization reactor 4, resin adsorption column 5, acid-base neutralization solid-liquid separator 6, multiple neutralization reactor The water outlet of the reactor is connected with a water inlet of the resin adsorption column, the mixed acid solution inlet is connected with the concentrated sulfuric acid storage tank and the sulfamic acid storage tank respectively, and the sediment discharge port and the acid liquid return port are respectively connected with the acid-base The neutralization solid-liquid separator is connected; the two water inlet...

Embodiment 2

[0053] Waste water quality is with embodiment 1, and waste water treatment system is similar with embodiment 1, and operation steps are as follows:

[0054] 2.1 The strong alkaline condensation mother liquor wastewater in the production process of Disperse Blue 56 is used at a flow rate of v 1 =20L / min is passed into zone I of the compound neutralization reactor, and the mixed acid solution of sulfuric acid (mass concentration 95%, flow rate 0.4L / min) and sulfamic acid solution (mass concentration 14.5%, flow rate 14L / min) passes through the acid inlet pipe Enter the compound neutralization reactor, the stirring rate of the mechanical stirrer (120r / min), the reaction is adjusted to effluent (pH=5);

[0055] 2.2 The water output is v 2 The flow rate of =20L / min enters the adsorption column filled with 220L polystyrene-divinylbenzene ultra-high cross-linked resin, the COD of the first 1800L of adsorbed water drops to 476mg / L, and the concentration of phenolic substances drops t...

Embodiment 3

[0062] The wastewater quality is the same as in Example 1, and the treatment system and operation steps are similar to Example 1, but the resin filled in the processing resin column is changed to macroporous polystyrene-divinylbenzene resin.

[0063] 3.1 The strong alkaline condensation mother liquor wastewater in the production process of Disperse Blue 56 is used at a flow rate of v 1 =20L / min is passed into zone I of the compound neutralization reactor, and the mixed acid solution of sulfuric acid (mass concentration 95%, flow rate 0.4L / min) and sulfamic acid solution (mass concentration 14.5%, flow rate 14L / min) passes through the acid inlet pipe Enter the compound neutralization reactor, the stirring rate of the mechanical stirrer (120r / min), the reaction is adjusted to effluent (pH=6);

[0064] 3.2 The water outlet is v 2 The flow rate of =20L / min enters the adsorption column filled with 220L polystyrene-divinylbenzene ultra-high cross-linked resin, the COD of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com