Green synthesis method of 9, 9-bis (4-hydroxy) fluorene

A synthesis method and phenol technology, which is applied in the field of synthesis of bisphenol fluorene, can solve the problems of difficult industrialization, non-environmental protection, and high phenol content, and achieve the effects of reducing phenol content, reducing environmental pressure, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

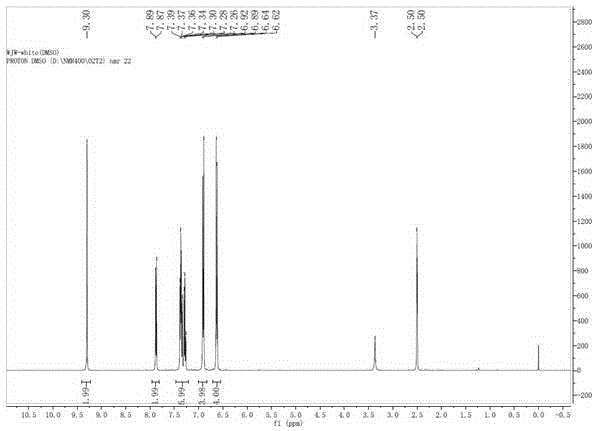

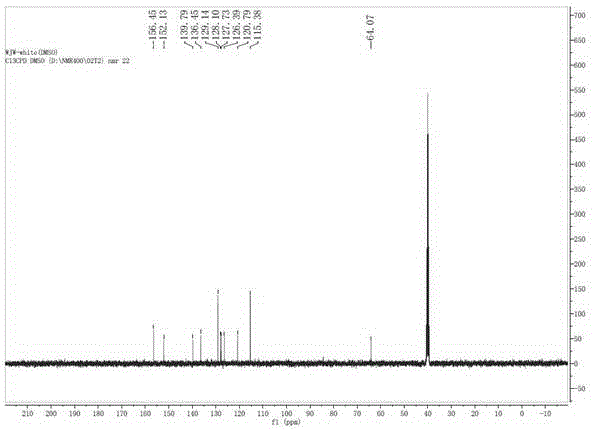

[0030] Add 10 grams of 9-fluorenone (0.055mol), 21 grams of phenol (0.22mol), and 16 grams of toluene to a 100ml flask equipped with a mechanical stirrer, a thermometer, and a condenser. Stir and place it in a water bath, then add 1.5 grams of Concentrated sulfuric acid, control the temperature at about 20 degrees, slowly add 0.37 g of 3-mercaptopropionic acid (0.0035 mol), after the addition, react at 20 ° C for 2 hours, slowly raise the temperature to 30 ° C and continue the reaction for 1 hour. After the system completely turned into a pure white slurry, liquid phase analysis was carried out, and the reaction of 9-fluorenone was complete, with a liquid phase content of 95% (excluding phenol). After adding 30 grams of toluene, cool down to room temperature and filter, and the filter cake is washed with a small amount of toluene. The filter cake was beaten in 5% sodium hydroxide solution with a mass ratio of 1:1, filtered, and dried to obtain 18.1 grams of pure white solid wi...

Embodiment 2

[0033] To a 100ml flask equipped with a mechanical stirrer, a thermometer, and a condenser, add 10 grams of 9-fluorenone (0.055mol), 31.5 grams of phenol (0.33mol), and 16 grams of dichloroethane in sequence, place them in a water bath with stirring, and add 2.5 grams of concentrated sulfuric acid, control the temperature at about 20°C, slowly add 0.37 grams of 3-mercaptopropionic acid (0.0035mol), after the addition, react at 20°C for 2 hours, slowly raise the temperature to 30°C and continue the reaction for 1 hour. After the system completely turned into a pure white slurry, liquid phase analysis was carried out, and the reaction of 9-fluorenone was complete, with a liquid phase content of 95% (excluding phenol). After adding 30 grams of dichloroethane, cool down to room temperature and filter, and the filter cake is washed with a small amount of dichloroethane. The filter cake was beaten in a 5% sodium hydroxide solution with a mass ratio of 1:1, filtered, and dried to obt...

example 3

[0036] Add 10 grams of 9-fluorenone (0.055mol), 21 grams of phenol (0.22mol), and 16 grams of toluene to a 100ml flask equipped with a mechanical stirrer, a thermometer, and a condenser. Stir and place it in a water bath, then add 2.5 grams of Concentrated sulfuric acid, control the temperature at about 20°C, slowly add 0.185 g of 3-mercaptopropionic acid (0.0018mol), after the addition, react at 20°C for 2 hours, slowly raise the temperature to 60°C and continue the reaction for 2 hours. After the system completely turned into a pure white slurry, liquid phase analysis was carried out, and the reaction of 9-fluorenone was complete, with a liquid phase content of 95% (excluding phenol). After adding 30 grams of toluene, cool down to room temperature and filter, and the filter cake is washed with a small amount of toluene. The filter cake was beaten in 5% sodium hydroxide solution with a mass ratio of 1:1, filtered, and dried to obtain 18.1 grams of pure white solid with a yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com