High-phenol content wastewater treatment technology

A treatment process and technology for phenolic wastewater, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc. Hardening replacement and other issues to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings, but this description will not constitute a limitation to the present invention.

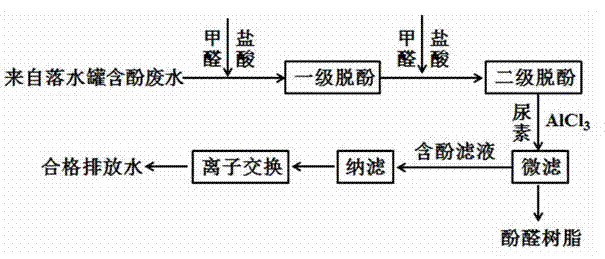

[0025] Primary dephenolization: add formaldehyde and hydrochloric acid to the raw wastewater from the drop tank (generally containing 6-8% phenol), and control the pH to 1.0 at the same time. After dephenolization, the obtained wastewater contains 0.9% phenol and 0.9% formaldehyde;

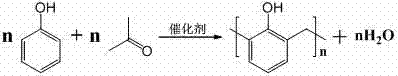

[0026] Secondary dephenolization: Add hydrochloric acid and formaldehyde to the waste water containing 0.9% phenol obtained after the first dephenolization, control the pH to 0.8, separate layers after full reaction, reuse the phenolic resin, and obtain The phenol content in the wastewater is controlled at ≤300-500ppm, and the formaldehyde content is ≤3000ppm;

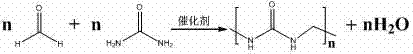

[0027] Aldehyde removal: add urea to the wastewater obtained after secondary dephenolization, and then add flocculant AlCl 3 , after precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com